6

Pololu

Connecting the Motor Controller

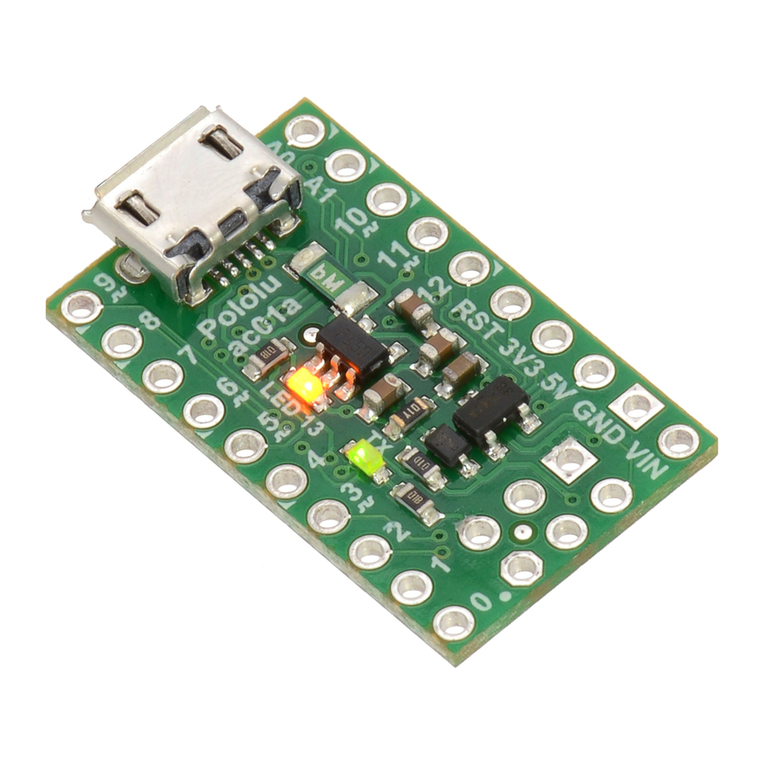

There are eight pins on the bottom of the motor

controller for connecting it to the rest of your system.

A closeup of the bottom of the PCB is shown to the

right, in case you have a hard time reading the

silkscreen on your board. The eight pin

labels and the corresponding functions are

shown in the table.

Connecting Power. Warning:

connecting power incorrectly can cause

some components to explode. Connect

the ground pin to a ground terminal on

your robot controller. If you have a

separate power supply for just the motors,

make sure that you connect the negative

terminal of that supply to the same ground.

(This situation may arise if, for example, you want to run your robot controller off of a

9-volt battery and you want to run your motors off of a 12-volt battery. You will also

need an independent power supply for the motors if you want to use a personal

computer as the robot controller. In that case, you might use a battery for the motor

supply and use a wall outlet for the PC supply.) Connect the ‘+’ pin to the positive

terminal of the motor supply; this terminal may connect only to the motor controller, or

it may connect to any other device powered by that supply. Warning: the supply

voltage may not exceed 16 volts or 25 volts, depending on which capacitor you chose

for C1 in step 5 of assembly.

Reset Input. The reset input is optional, but you

C

may need to use it to ensure that

spurious signals sent when your robot controller turns on do not cause the motor

controller to detect the baud rate incorrectly. onnect this pin to a 0-5V digital output

on your robot controller. The line should normally be kept high (+5V), but bringing it

low (to 0V) for at least 2 microseconds resets the motor controller to its initial state (all

motors off, waiting for its first serial command).

Serial Input. Use a pin on your robot controller that can be used as a TTL-level,

asynchronous serial output. Serial data can be sent down this line 8 bits at a time, with

no parity bit, at any rate between 1200 and 19200 baud. Once you choose a baud rate,

you cannot change it until the motor controller is reset. Important note: unlike

RS-232 serial lines (the standard for serial ports used to connect devices to personal

computers), this line uses TTL voltages (between 0 and 5 volts). The higher voltages

used on RS-232 lines will damage the motor controller. If you need to convert RS-232

levels to TTL levels, you will need to use a level converter such as the MAX220 (made

by Maxim). You could also use the simple circuit shown at the top of the next page.

When building circuits that connect to a PC, be especially careful because you

could potentially destroy the PC’s serial port. Before attempting to connect your

own electronics to a computer, make sure you know what you are doing!

LABEL FUNCTION

-

+

1

2

M1+

M2-

M2-

M1-

ground (0V)

positive supply (5.6-25V)

reset

serial control input

motor 1, negative output

motor 2, positive output

motor 1, positive output

motor 2, negative output

© 2001

http://www.pololu.com/