IK-E325-001GB 3

1 PURPOSE

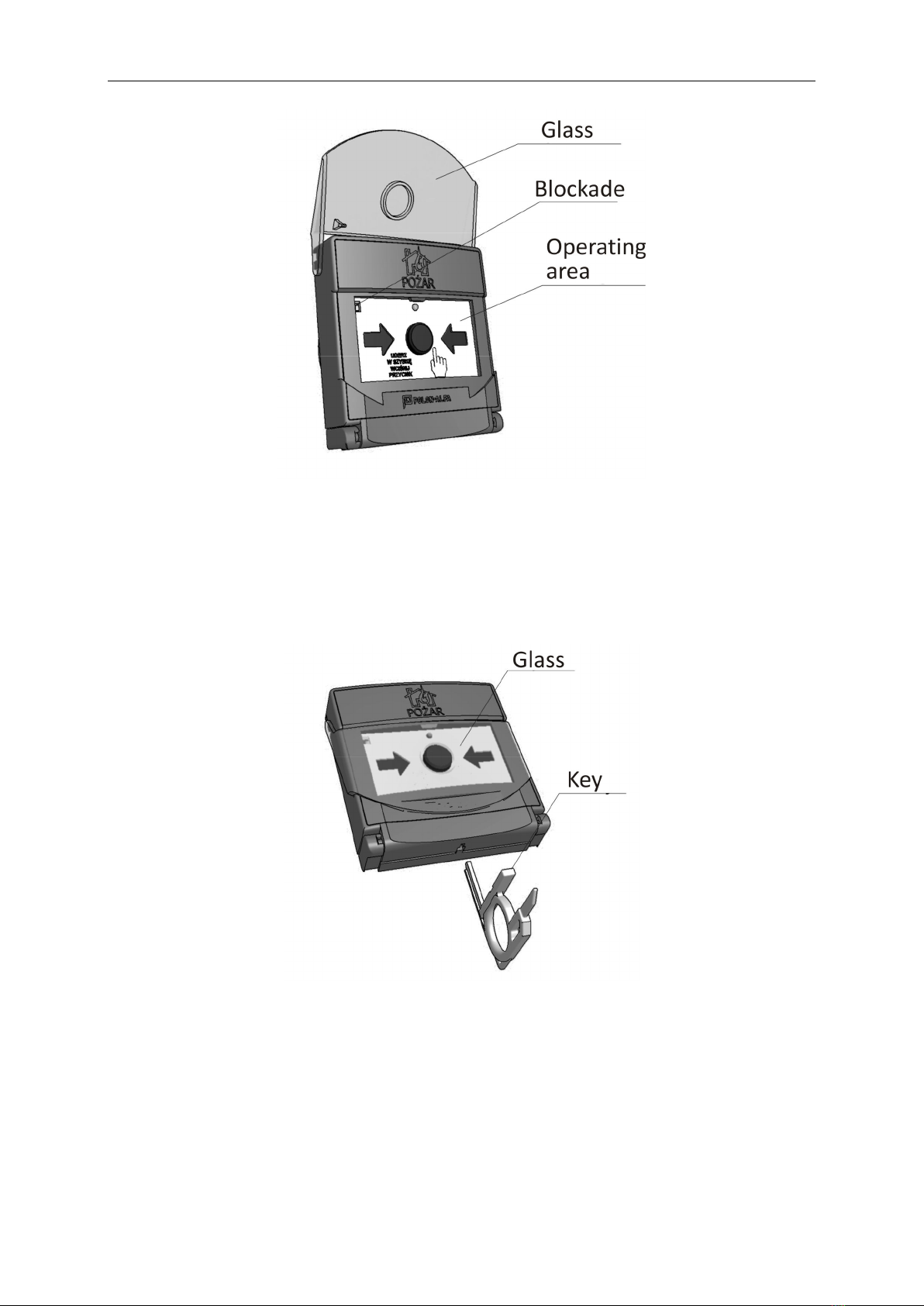

The ROP-4001M and ROP-4001M manual call points are designated for operation in addressable

loops of the POLON 4000 system detecting lines. They are addressable devices installed in order to

transfer information about a noticed fire by their manual actuation.

The ROP-4001M manual call point in the standard execution is intended for indoor installation.

The ROP-4001M manual call point (with a higher ingress protection level) is intended for outdoor

installation.

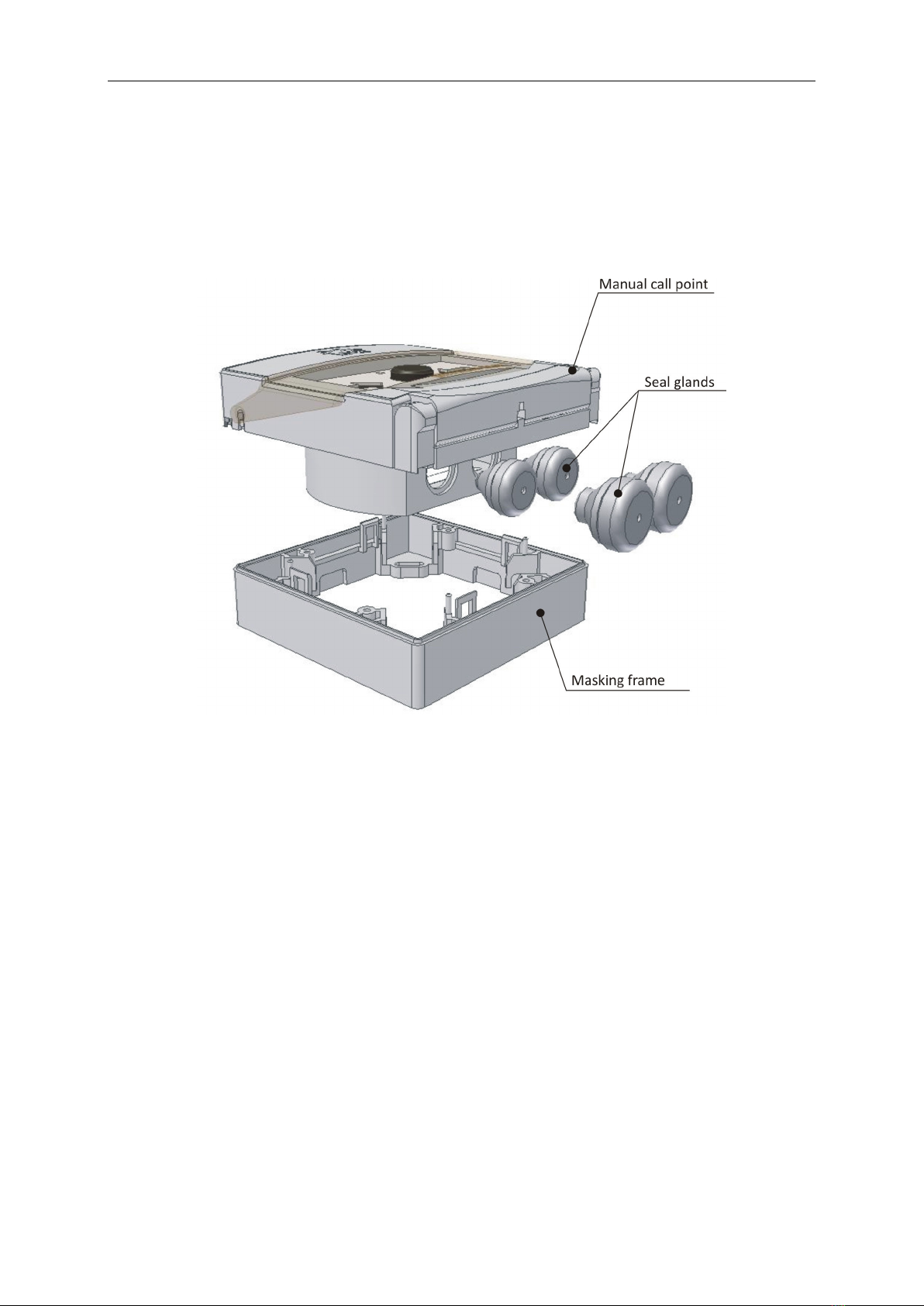

Both versions are suitable for semi-flush (in wall plaster) and surface (on wall plaster) mounting

installation – the basic version is the first one, the semi-flush type. A special auxiliary RM-60-R

masking frame is applied for surface mounting; it is not a part of the standard equipment and should

be ordered separately.

2 TECHNICAL SPECIFICATIONS

Call point type B, acc. to PN-EN 54-11:2004

Operation voltage (from detection line) 16.5 V … 24.6 V

Max. current draw in quiescent mode < 140 µA

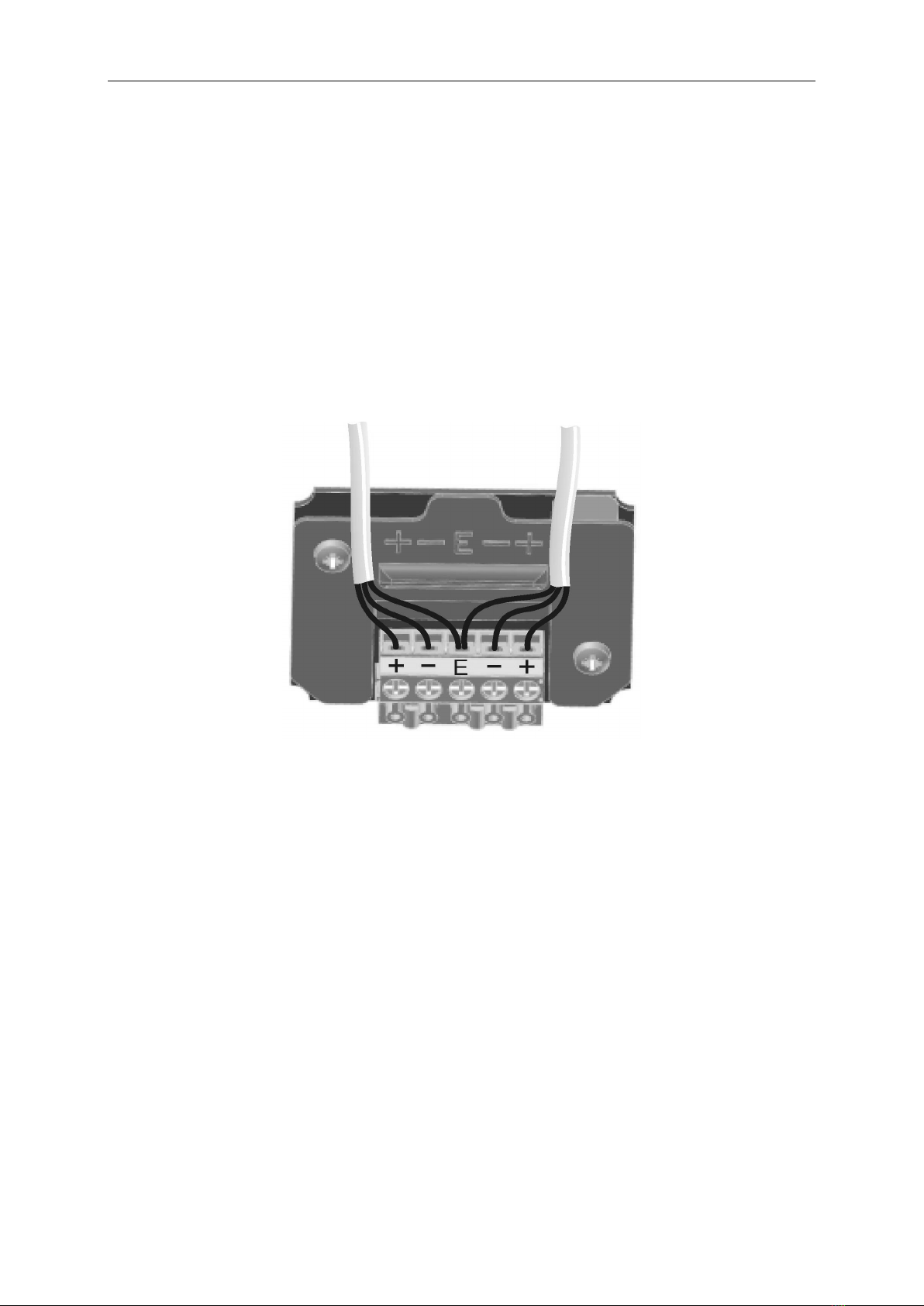

Allowable cable wire diameter 0.8…1.2 mm

Address coding range 1 ÷ 127

Ingress protection:

ROP-4001M IP 30

ROP-4001M IP 55

Operating temperature range:

ROP-4001M from -25 °C to +55 °C

ROP-4001M from -40 °C to +70 °C

Allowable relative humidity: up to 95 % at 40 °C

Dimensions 102.5 x 98 x 45.5 mm

Mass:

ROP-4001 < 220 g

ROP-4001 < 260 g

Case colour red

3 SAFETY CONDITIONS

3.1 Repairs and maintenan e

Any maintenance works or periodic inspections shall be executed by a skilled personnel employed by

companies authorised and trained by POLON-ALFA.

Any repairs must be carried out by the manufacturer. POLON-ALFA bears no responsibility for the

operation of any apparatus being serviced and repaired by an unauthorised personnel.

3.2 Anti-dusting eye prote tion

It is obligatory to use protective anti-dusting glasses and masks during installation works that

produce high amount of dust, such as hole drilling in walls.

Any electric tools shall be used strictly obeying the safety rules stated in the manufacturer instruction

manuals.