4 DESIGN

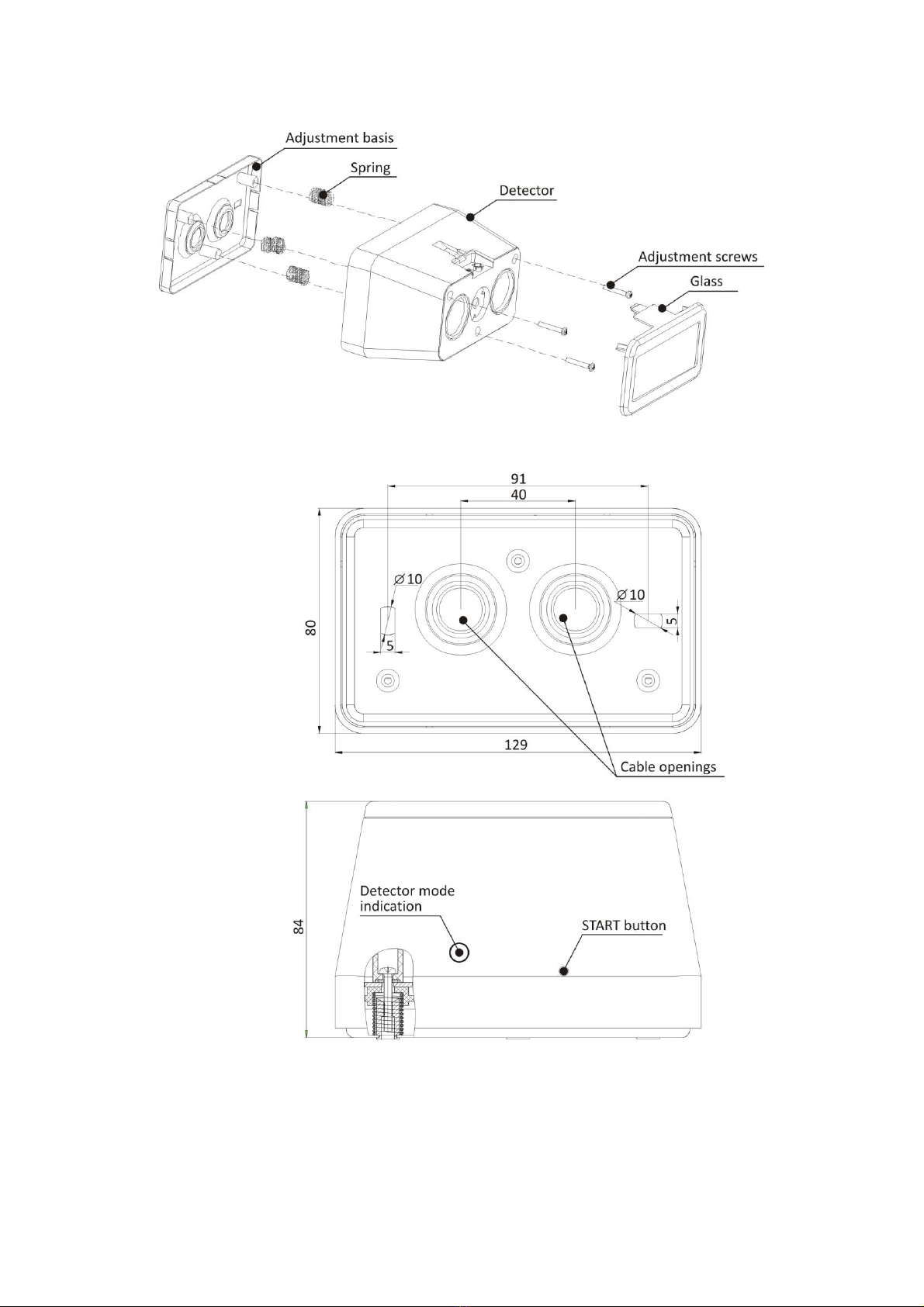

The DOP-6001R detector design is shown in Fig. 1 and Fig. 3. The detector casing, made of plastic, embraces

electronic circuits and optical elements of the transmitter and receiver as well as a laser diode that

facilitates the detector easy optical alignment. The lenses for infrared beam focusing are covered with a

detachable filter. On the detector back side a connecting block is mounted, to connect power supply wires

and four terminal blocks of the PU and PA relay contacts. The detector is fastened to the wall with a metal

adjustment basis. On the detector front part an optical fibre for illuminating diodes is placed as well as the

START push button that initiates the detector adjustment process.

The illuminating diode colour signals accordingly:

- green one –a state of the detector self-adjustment to the detector-reflector/reflector panel

distance, when the signal level is too high;

- yellow one –a state of the detector self-adjustment to the detector-reflector/reflector panel

distance, when signal level is too low;

The self-adjustment process takes approximately 30 seconds. When the detector is correctly adjusted, it

switches to the supervision mode and in case of any error, including wrong self-adjustment, the yellow LED

flashes every 2 sec.

- red one –an alarm mode;

- green diode flashing (every 10 seconds) –a supervision mode

The START push button enables initiation of the detector adjustment process (self-adjustment) and the

detector parameters renewed set-up after optical parts cleaning works.

5 INSTALLATION

The DOP-6001R detector interoperates with a reflector panel and then its operating distance ranges from

50 m to 100 m, or with the E39-R8 prism reflector at the operating distance between 5 m and 50 m. The

reflector or the reflector panel as well as the M42-00 00 00 service kit, containing test foils and an

adjustment mirror, are not included in the detector standard pack and should be ordered separately.

In case the detector is seen with difficulty or is installed in a hardly accessible place, it is possible to connect

the WZ-31 additional operation indicator to be placed in a convenient and visible place.

Before installation, it is necessary to declare an alarm mode and a sensitivity threshold. The operations are

executed using appropriate jumpers placed on the back side of the detector casing, pursuant to Fig. 6. One

of the criteria taken into consideration when choosing sensitivity may be the distance between the

detector and the reflector/reflector panel, and so:

-for a distance from 5 m to 20 m –18 % sensitivity is recommended;

-for a distance from 20 m to 50 m –30 % sensitivity is recommended;

-for a distance from 50 m to 100 m –50 % sensitivity is recommended.

It is possible to set sensitivity level experimentally: adopting it to a certain environment in the case of the

detector difficult operating conditions. The DOP-6001R detector and the reflector/reflector panel are

mounted on opposite walls, pillars or other construction elements of the premises. The walls or pillars must

be stable and vibration-free. The detector adjustment base should be mounted on a wall and the

reflector/reflector panel - on the opposite wall. The detector should be placed on the adjustment base (Fig.

3) after preliminary connection of the wires to the connecting blocks in accordance with Fig. 4. The

detector should be fixed to the basis with three screws that are accessible from the front side (after

removing the cover). Then a 6F22 battery should be connected to the laser viewfinder contacts.