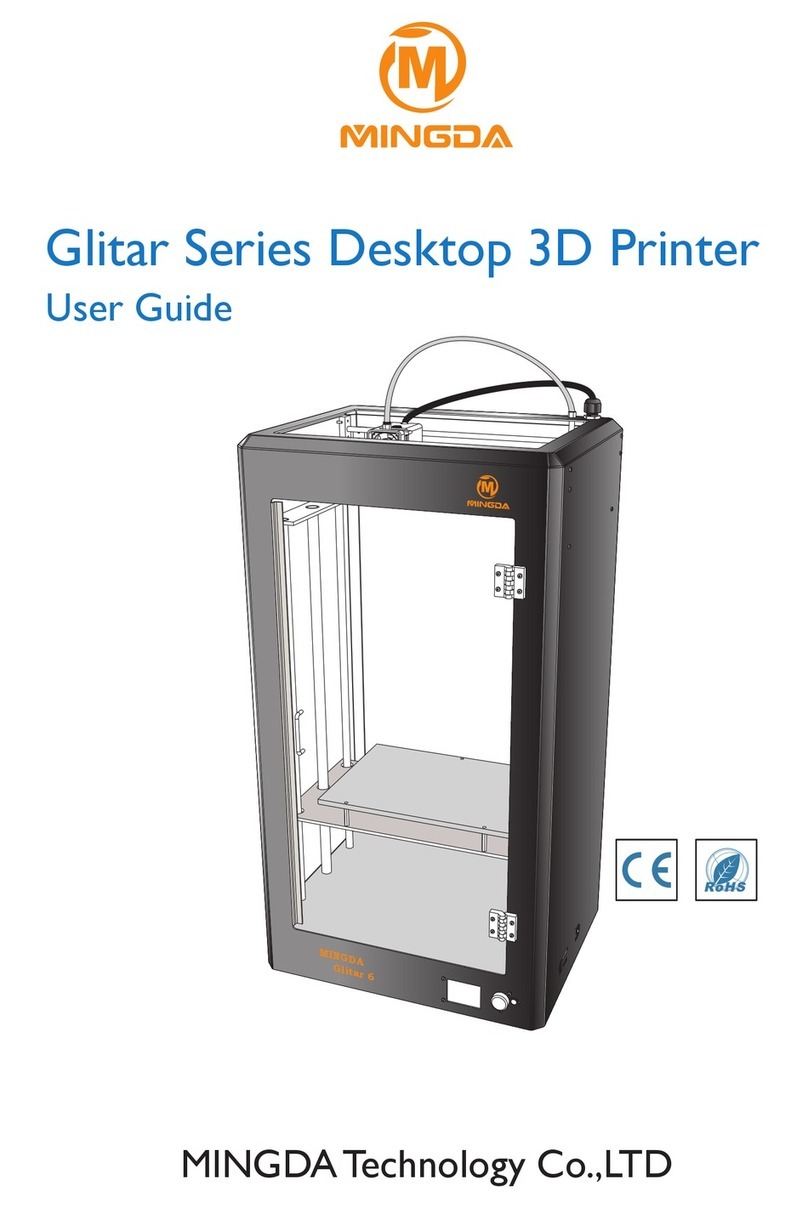

MINGDA TECHNOLOGY CO.,LTD

Chapter 1 The Debugging of the machine

We will do our best to provide our customers more perfect 3D products. Our

principle is that make the user less trouble, and more easily. Before delivery,

we will debug the 3D printer precision from inside to outside. Ensure the

printing quality of the 3D printer

1. Open the packing box

Please when users receive the printer, make sure the integrity of the product

packaging, and check whether there is damage of printer.

Confirmed the packaging is completely, open box, now bring up 3Dprinter from

the box, carefully grasp the top of the frame, from both sides to lift the machine

(Caution: do not touch the internal drive belt and guide rail, have a chance to

cause a deformation of the guide rail, affect the performance of the machine.)

Gently bring up 3D printer from the box, put in your workstation.

Please open bag, you will find that all the parts have been out, Please don't

have to worry about the box there is missing any parts, because packagers

already in delivery sheet, inspection, inventory, to ensure that each delivery

integrity.

2、Install

After take out the machine you will find that most of the parts we have installed

for you, if not installed, then the machine we sent to you without adjustment

and test (note: this is not possible). So, you only need to install two parts: (1)

extruder. (2) The feeding. To the correct location, (extruder is fixed in inside

offrame and the feeding in accessories box.)

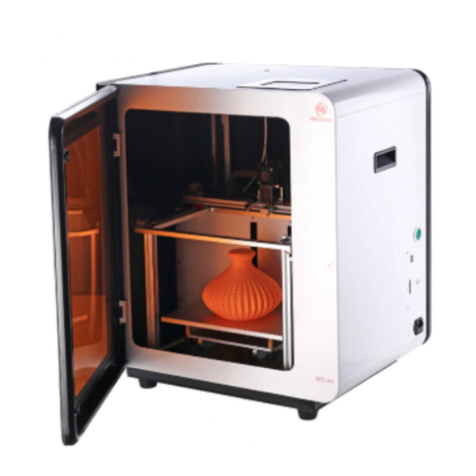

Left image feeding frame (Has been properly installed )

Middle image extruder (Has been properly installed)

2