P a g e | 4 P o o l C o p M a n u a l : V 4 2 EN

www.poolcop.com PCFR

Figures

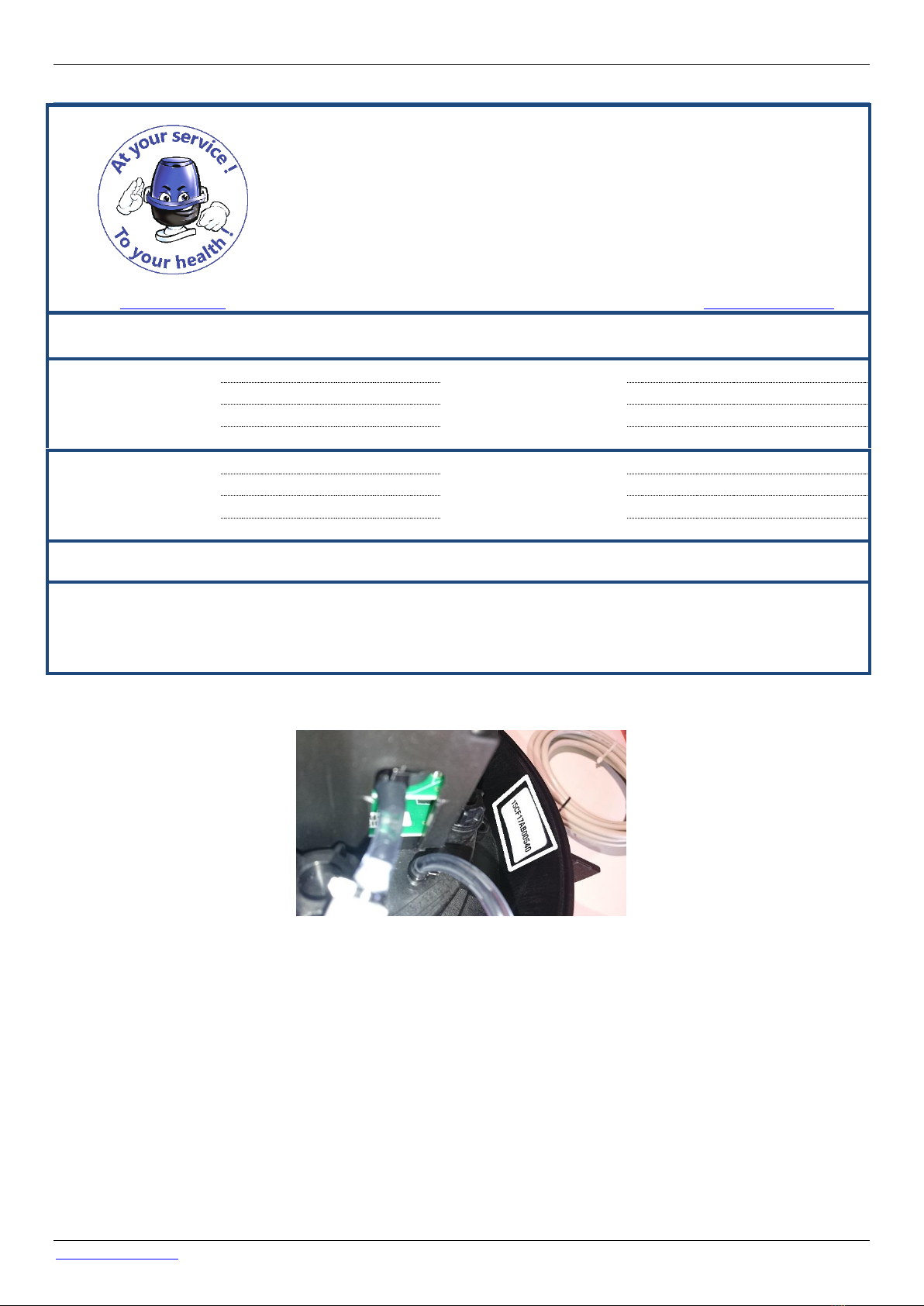

Figure 1 - Serial Number Location in VDU............................................................................................................................................................................................................ 10

Figure 2 - VDU on Filter .............................................................................................................................................................................................................................................. 18

Figure 3 - Control Connection Unit......................................................................................................................................................................................................................... 18

Figure 4- Valve Data Unit ........................................................................................................................................................................................................................................... 20

Figure 5 - Filter connection Kit sample.................................................................................................................................................................................................................. 20

Figure 6 - 1.5" valve O-ring........................................................................................................................................................................................................................................ 20

Figure 7 - 2.0" valve O-ring........................................................................................................................................................................................................................................ 21

Figure 8 –Wagon wheel gasket ............................................................................................................................................................................................................................... 21

Figure 9 - Orientation viewed from the top of.................................................................................................................................................................................................... 21

Figure 10 - Cables entries........................................................................................................................................................................................................................................... 22

Figure 11 –Terminals................................................................................................................................................................................................................................................... 23

Figure 12 - Single Phase Pump Connection......................................................................................................................................................................................................... 24

Figure 13 - Three-Phase Pump Connection ......................................................................................................................................................................................................... 24

Figure 14 - Pentair IntelliFlo VSD with IntelliComm........................................................................................................................................................................................... 25

Figure 15 - Pentair SuperFlo VS/VS2 ...................................................................................................................................................................................................................... 25

Figure 16 - Hayward EcoStar..................................................................................................................................................................................................................................... 26

Figure 17 - Hayward VSTD Series ............................................................................................................................................................................................................................ 26

Figure 18 - Speck Badu Eco-Touch ......................................................................................................................................................................................................................... 27

Figure 19 - Speck Badu Eco Motion........................................................................................................................................................................................................................ 27

Figure 20 - Zodiac FloPro VS..................................................................................................................................................................................................................................... 28

Figure 21 - Invertek Optidrive e2 inverter............................................................................................................................................................................................................. 28

Figure 22 –Binary combination................................................................................................................................................................................................................................ 29

Figure 23 –Davey ProMaster VSD400.................................................................................................................................................................................................................... 29

Figure 24 –PoolCop water analysis sensor .......................................................................................................................................................................................................... 30

Figure 25 - Sensor and Housing............................................................................................................................................................................................................................... 30

Figure 26 - Sensor Housing plug ............................................................................................................................................................................................................................. 30

Figure 27 –Sensor connection ................................................................................................................................................................................................................................. 30

Figure 28 –pH Dosing pump connexion............................................................................................................................................................................................................... 33

Figure 29 –example of connecting dosing pump to Aux6 ............................................................................................................................................................................. 34

Figure 30 –Example of solenoid valve connection for flow control via Aux3........................................................................................................................................... 35

Figure 31 - Salt sytem connection........................................................................................................................................................................................................................... 36

Figure 32 - Air temperature sensor J27 ................................................................................................................................................................................................................. 38

Figure 33 –Water line level sensor........................................................................................................................................................................................................................... 39

Figure 34 - Buffer tank water level sensors........................................................................................................................................................................................................... 39

Figure 35 - Connecting Water level ........................................................................................................................................................................................................................ 40

Figure 36 - Cables entries........................................................................................................................................................................................................................................... 41

Figure 37 –Terminals................................................................................................................................................................................................................................................... 41

Figure 38 - Auxiliaries connection terminal in CCU (left) and in XM8 Extension Module (right)........................................................................................................ 43

Figure 39 - Single Phase 230VAC Auxiliary........................................................................................................................................................................................................... 44

Figure 40 - Three-Phase 380VAC Auxiliary Connection.................................................................................................................................................................................... 44

Figure 41 - Connection 24VAC Auxiliary ............................................................................................................................................................................................................... 44

Figure 42 - Additonal Relays ..................................................................................................................................................................................................................................... 45

Figure 43 - Waste valve connexion ......................................................................................................................................................................................................................... 45

Figure 44 –Connecting Inputs in CCU................................................................................................................................................................................................................... 46

Figure 45 - Connecting Inputs in XM8................................................................................................................................................................................................................... 46

Figure 46 –External thermostat ............................................................................................................................................................................................................................... 47

Figure 47 –Example of external Thermostat Connection................................................................................................................................................................................ 47

Figure 48 –Suction Wand with Low Level Detection........................................................................................................................................................................................ 47

Figure 49 –Example of consumables Low Level Detection............................................................................................................................................................................. 47

Figure 50 - Pool Cover connexion (control and position)................................................................................................................................................................................ 48

Figure 51 - Connection example with MecaTecCenter cover......................................................................................................................................................................... 48

Figure 52 –Connection example with Astral Roussillon cover....................................................................................................................................................................... 49

Figure 53 –Connection example with SWIMSAFE cover.................................................................................................................................................................................. 49

Figure 54 - Jetstream connection ............................................................................................................................................................................................................................ 50

Figure 56 - Valve Data Unit display and keyboard............................................................................................................................................................................................. 54

Figure 57 –Power Line Adaptors...........................................................................................................................................................................................................................104

Figure 58 - RJ45 Connector for Ethernet.............................................................................................................................................................................................................104