Page 2 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Contents

Introduction ............................................................................................................................................... 3

Safety Instructions .................................................................................................................................... 4

Specifications............................................................................................................................................ 5

Tool Parts .............................................................................................................................................. 6

Packaged Accessories .......................................................................................................................... 6

PNT800L-PC Diagram.............................................................................................................................. 8

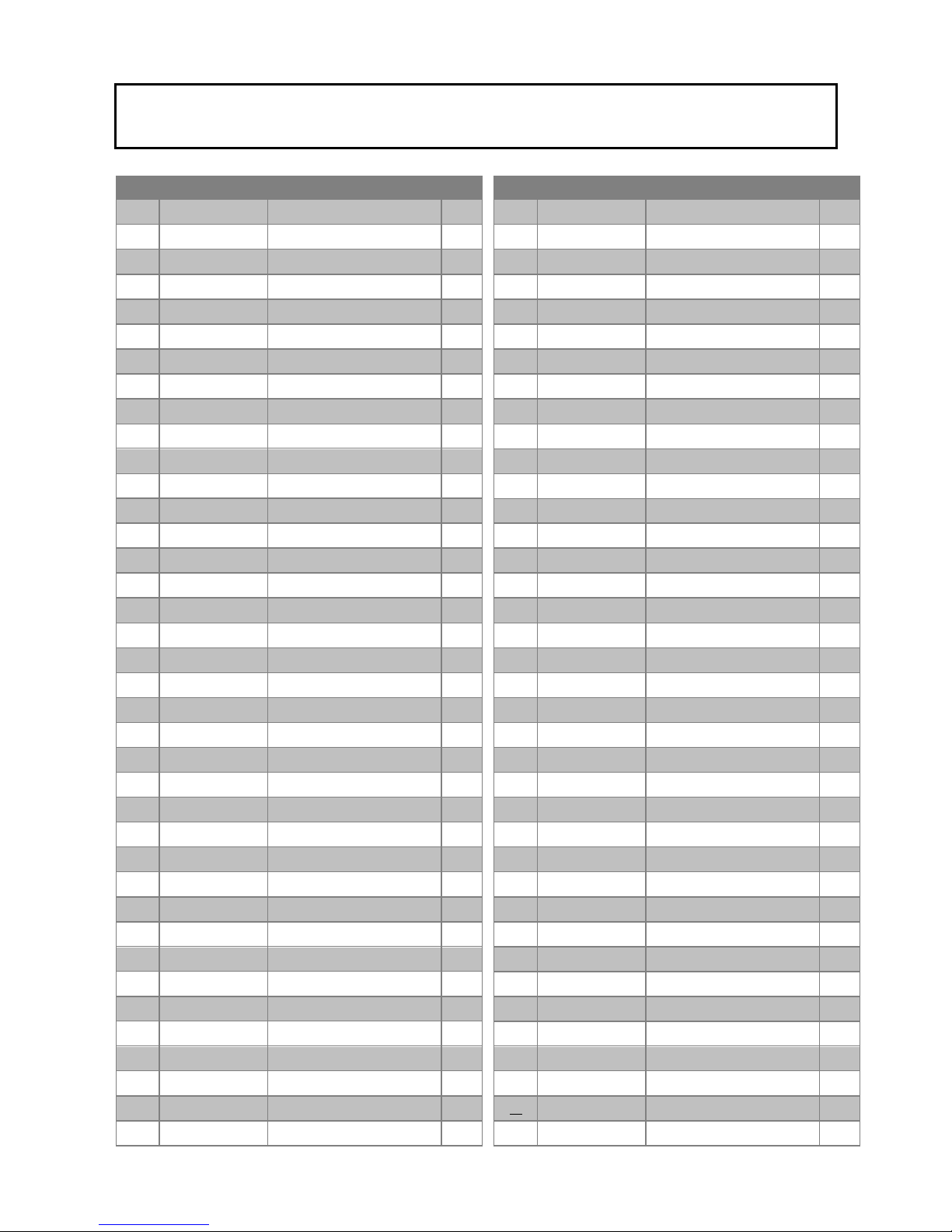

Parts List................................................................................................................................................. 10

Tool Setup............................................................................................................................................... 12

Mandrel and Nosepiece installation .................................................................................................... 13

Basic Tool Operation............................................................................................................................... 14

Mandrel & Nosepiece Adjustment ....................................................................................................... 14

Setting Force Valve Spring Selection.................................................................................................. 15

Tool Operation..................................................................................................................................... 16

Setting Force Adjustment........................................................................................................................ 18

Adjustment for Standard POP NUTs™ ............................................................................................... 18

Adjustment for ST & Thin Wall POP NUTs™ ...................................................................................... 18

Adjustment of Setting Force................................................................................................................ 18

Maintenance ........................................................................................................................................... 19

Clean & Lube Mandrel ........................................................................................................................ 19

Lubricate Rotating Parts...................................................................................................................... 19

Recharging Hydraulics ........................................................................................................................ 20

Troubleshooting ...................................................................................................................................... 22

Safety Data ............................................................................................................................................. 24

EC Declaration of Conformity ................................................................................................................. 26