KNOW YOURCOMPONENTS

Page 4

DELTADECK

®

GATE CATCH

The gate catch is a steel spring clip that can be released by pushing on the tab

indicated by the arrow. To close the gate simply pull the gate and ensure the

catch springs over the side guardrail vertical tube gripping it fully.

SIDE GUARDRAIL LOCKING DEVICE

The side guardrail locking device is a gravity operated locking collar used to lock

the side guardrail folding hinge in the upright position. Simply allow the collar

to drop over the hinge when assembling the unit and slide the collar up to

release the hinge when disassembling the unit.

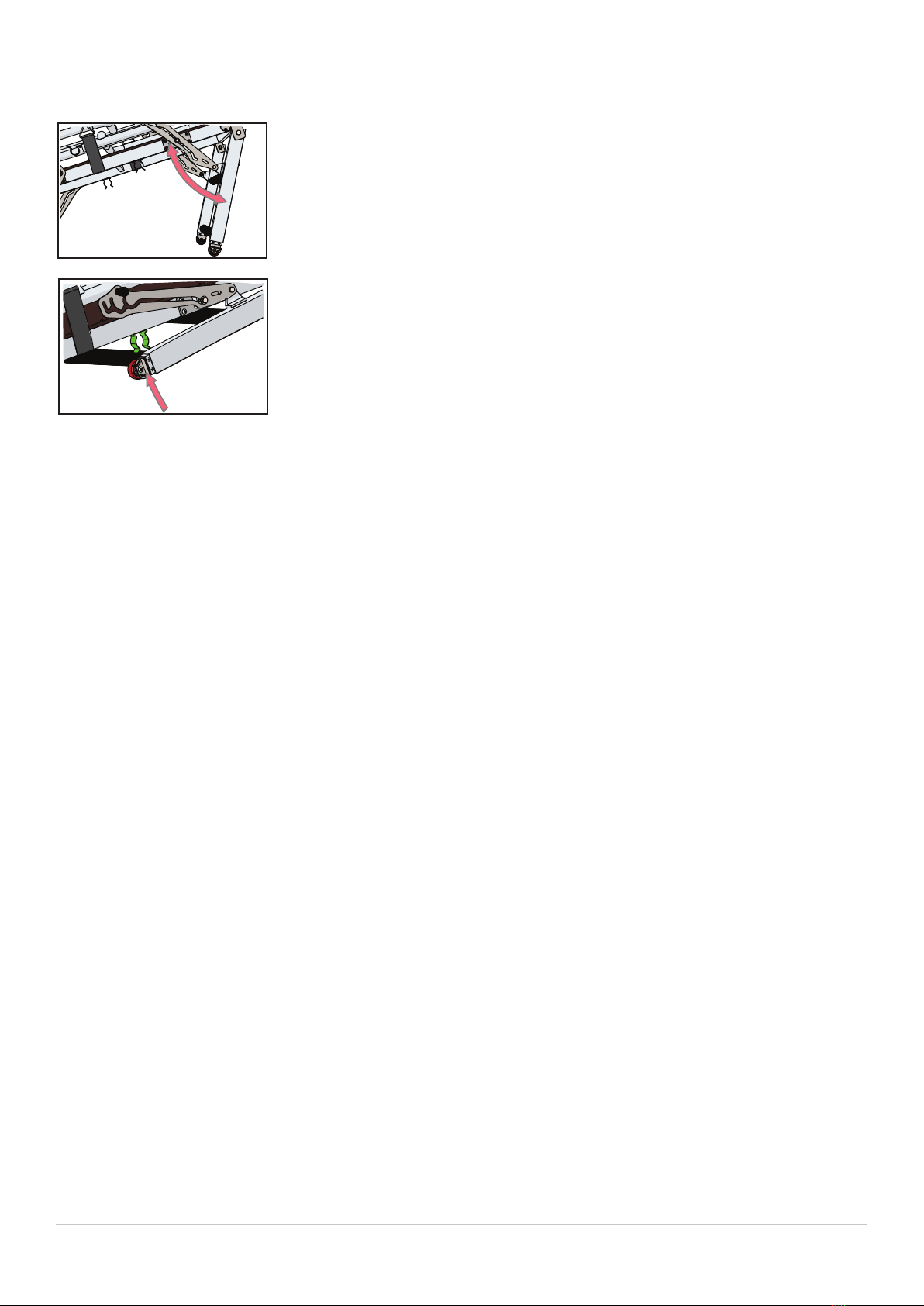

SIDE GUARDRAIL BRACKETS

The side guardrail brackets allow the side guardrails to fold and serve as a locking

device for the lower portion of the side guardrail. The wide slotted bracket is the

side highlighted in green and the narrow slotted bracket highlighted in red. On

assembly the green bracket is opened last and on disassembly closed rst. The

side guardrail must be lifted and rotated simultaneously as shown, during both

assembly and disassembly.

LOCKING CASTOR

The castors allow the unit to be moved smoothly between

workplaces. They must be locked o when the unit is in use and unlocked to

allow the unit to be moved. The foot pedal (Highlighted in yellow) can be rotat-

ed using your foot,to lock or release the brake.

OFF

ON

ADJUSTABLE LEG

The adjustable leg allows further height changes to be made and can be extend-

ed or retracted by simply pushing in the spring locating pin (A) and either

extending or retracting the adjustable leg (B) until the spring pin locates into

one of the three locating holes in the outer leg assembly (C).

A

B

C

The lever (Highlighted in green) allows rotation of the leg assembly (A) and once

locked o in either of the positions (1,2 or 3), it provides height changes to the

unit. Release the leg adjustment lever using the handle (B) and rotate the leg

assembly (A) either way until the lever engages in either position 1,2 or 3.

LEG ADJUSTMENT LEVER

123 A

B

TRANSPORT STRAP

The transport strap holds the folded side guardrail assemblies in place for when

the unit is being transported or stored. Pull the elasticated

transport strap until the metal hook is clear of the guardrail and then either let it

drop over the guardrail for transportation or remove the hook from the guardrail

and release the tension if assembling the unit.