Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 9

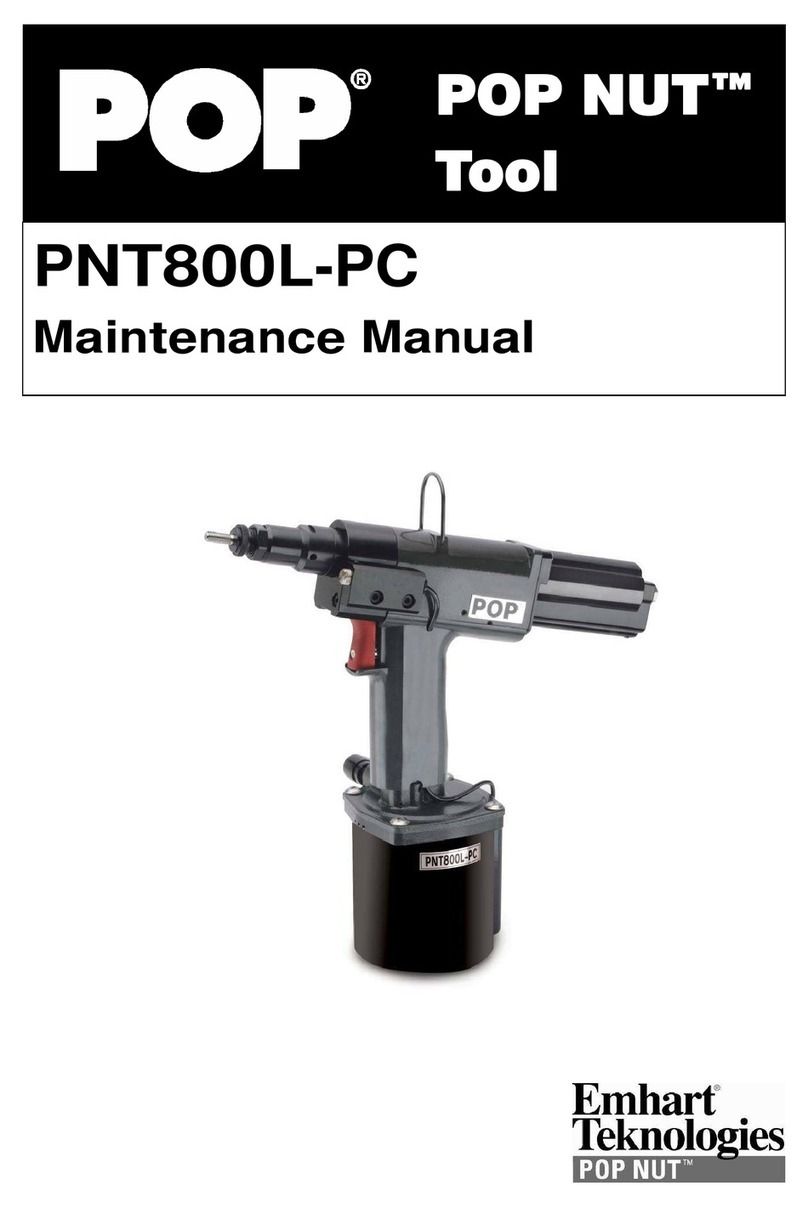

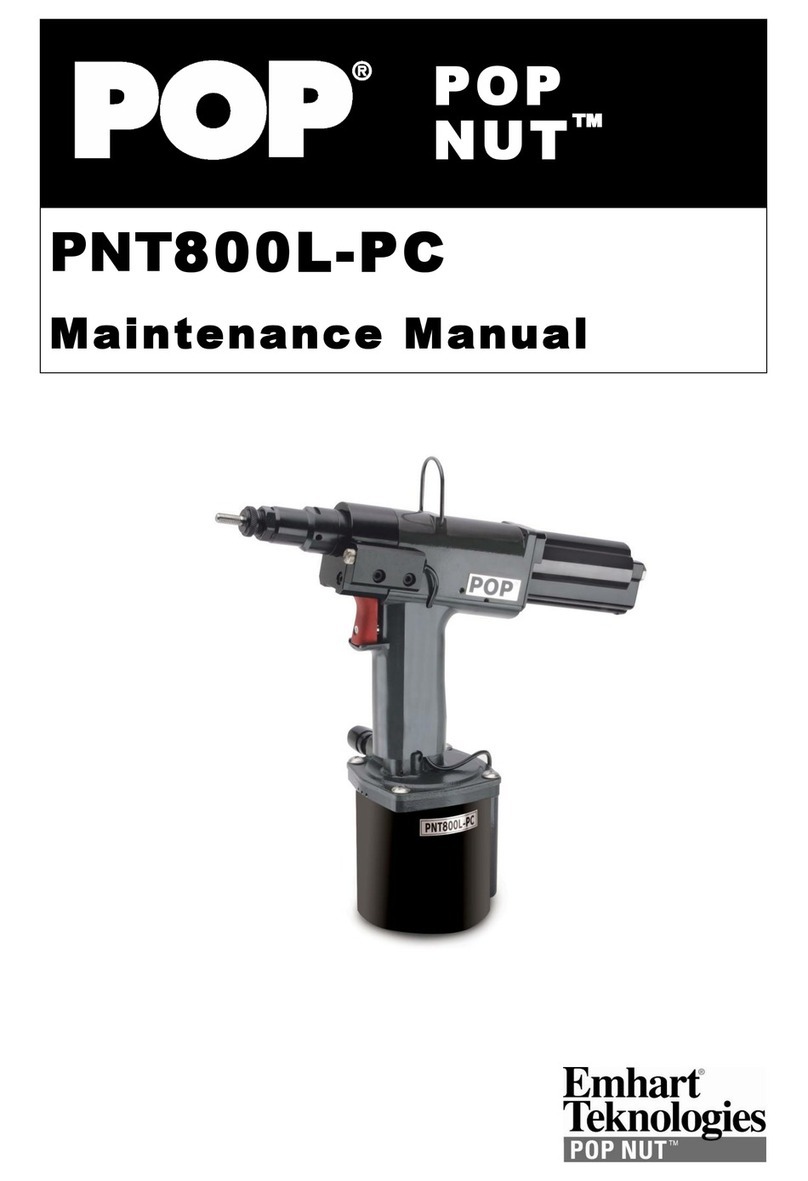

Figure 4-3

Figure 5-1

Work piece thickness

Maximum stroke (SMax )

Lock screw

(Never Loosen)

Lock screw

(Use 1.5mm hex)

Edge of control nut

Scale Control knob

Control nut

Figure 5-2

Stroke Adjustment

•Adjust the stroke length according to POP Nut size and the thickness of work piece.

•Make sure the tool has a consistent and adequate air supply.

•Note: The stoke may increase or decrease due to changes in air pressure [~0.1 mm (0.004

in) per 0.1 MPa (15 psi)]

PROCEDURE

1. Determine required stroke

Find Maximum Stroke (S max), Minimum Stroke (S min)

and Stroke (E), based on the POP Nut and work piece

thickness from Table 5-5 "POP Nut Stroke Formulas”

and Table 5-6 “S max vs. t Graph.”

Example:

POP Nut: SPH625

Work piece thickness: 1.5mm

S max = 3.4 from formula or graph

S min = 3.0 (S max −0.4.) from formula

E = 3.6 (S max + 0.2) from formula

Proper stroke: 3.0 ~ 3.4 (S min ~ S max)

2. Stroke Adjustment

a) Loosen the M3 lock screw on the control

nut using a 1.5mm hexagonal wrench. Adjust

stroke by turning control knob clockwise to

decrease and anti-clockwise to increase stroke.

Stroke, E is indicated by the right edge of

control nut. Tighten the lock screw (Figure 5-2).

Note: Never loosen the lock screw on the

control knob, as this will disturb the stroke.

b) Set a POP Nut and measure the stroke

with calipers etc. to check the stroke setting

‘E’.

Re-adjust the stroke according to (a) so that

the stroke is E ± 0.1mm. (Figure 5-3).

Note: Using the control knob, adjustments equal to

0.2mm per quarter turn can be made.

c) Set a POP Nut using work piece or the test piece,

and check that the stroke is between S min and S max.

Re-adjust the stroke as necessary. (Figure 5-4)

Stroke S min ~ S max.

Stroke ‘E’

Figure 5-4

Figure 5-3