IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, basic safety precautions should

always befollowed to reducethe risk offire,electric shock and personalinjury,

including the following:

READ AND FOLLOW ALL INSTRUCTIONS.

There are certain applications for which this tool was designed. Porter-Cable

strongly recommends that this tool NOT be modified and/or used for any

application other than for which it was designed. If you have any questions

relative to its application DO NOT use the tool until you have written Porter‑

Cable and we have advised you.

Product Manager

Porter-Cable Corporation

4825 Highway 45 North

P. O . Box 2468

Jackson, TN 38302-2468

POLARIZED PLUGS:To reducethe risk of electric shock,this equipment has

apolarized plug (one blade is wider than the other). This plug will fit in a

polarized outlet only one way. Ifthe plug does not fit fully in the outlet, reverse

the plug. If it still does notfit, contact aqualified electrician to installthe proper

_Outlet. Do not change the plug in any way.

1. KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

2. AVOID DANGEROUS ENVIRONMENT. Don’t expose power tools to

rain. Don’t use power toolsin damp or wet locations. Keep area well lit.Avoid

chemical or corrosive environment. Do not use toolin presence of flammable

liquids or gases.

3. GUARD AGAINST ELECTRIC SHOCK. Prevent bodycontact with

grounded surfaces. For example: pipes, radiators, ranges, refrigerator

enclosures.

4. KEEP CHILDREN AWAY. Do not let visitors contact tool or extension

cord. All visitors should be kept away from work area.

5. STOREIDLETOOLS. When notinuse,tools should bestoredindry, and

high or locked-up place‐out of reach of children.

6. DON’T FORCE TOOL. It will do the job better and safer at the rate for

which it was intended.

7. USE RIGHT TOOL. Don't force small tool or attachment to do the job of

aheavy duty tool. Don’t use tool for purpose not intended‐for example‐do

not useacircular saw for cutting tree limbs or logs.

8. DRESS PROPERLY. Do not wear loose clothing or jewelry. Loose

clothing, draw strings and jewelry can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

9. USE SAFETY GLASSES. Wear safety glasses or goggles while operat‑

»ing power tools. Also face or dust mask if operation creates dust. All persons

in the area where power tools are being operated should also wear safety

glasses and face or dust mask.

“a

eA)

10. DON’TABUSE CORD. Never carry tool by cord or yank it to disconnect

from receptacle. Keep cord from heat, oil, and sharp edges. Have damaged

or worm power cord and strain reliever replaced immediately. DO NOT

ATTEMPT TO REPAIR POWERCORD.

11. SECUREWORK. Useclamps ora vise to holdwork. It’ssafer than using

your hand and it frees both hands to operate tool. ]

12. DON’T OVERREACH. Keep proper footing and balance at all times.

13. MAINTAINTOOLS WITH CARE. Keep tools sharp and clean for better

and safer performance. Follow instructions for lubricating and changing

accessories. Inspecttool cords periodically and if damaged, have repaired by

authorized servicefacility. Inspect extension cords periodically and replace if

damaged. Have all worn, broken or lost parts replaced immediately. Keep

handles dry, clean and free from oil and grease.

14. DISCONNECT TOOLS when not in use, before servicing, and when

changing accessories such as blades, bits, cutters, etc. ‑

15. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed from the tool

before turning it on.

16. AVOID UNINTENTIONAL STARTING. Do not carry aplugged-in tool

withfingeron switch. Besure switch is offwhen pluggingin.Keep hands,body

and clothing clear of blades, bits, cutters, etc., when plugging in the tool.

17. OUTDOOR USE EXTENSION CORDS. When tool is used outdoors,

use only extension cords marked “Suitable for use with outdoor appliances ‑

store indoors when not in use.”

18. STAY ALERT. Watch what you are doing. Use common sense. Donot

operate tool when you are tired or while under theinfluence of medication,

alcohol or drugs.

19. CHECK DAMAGED PARTS. Before further use of the tool, aguard or

other partthat is damaged should be carefully checkedto determine that itwill

operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting,and any

other conditions that may affect its operation. Aguard or other part that Is

damaged should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere inthis instruction manual. Have

defective switches replaced by authorized service center. Do not use tool if

switch does not turn it on and off.

20. WEAR EAR PROTECTIONto safeguard against possible hearing loss.

SAVE THESE INSTRUCTIONS

ADDITIONAL SAFETY RULES FOR POCKET CUTTER®

1. KEEPGUARDIN PLACEAND IN WORKING ORDER.Check operation

before each use. Do not use if guard does not close briskly over cutter bit.

2. ALWAYS DISCONNECT MACHINE from power source before making

adjustments or changing bits.

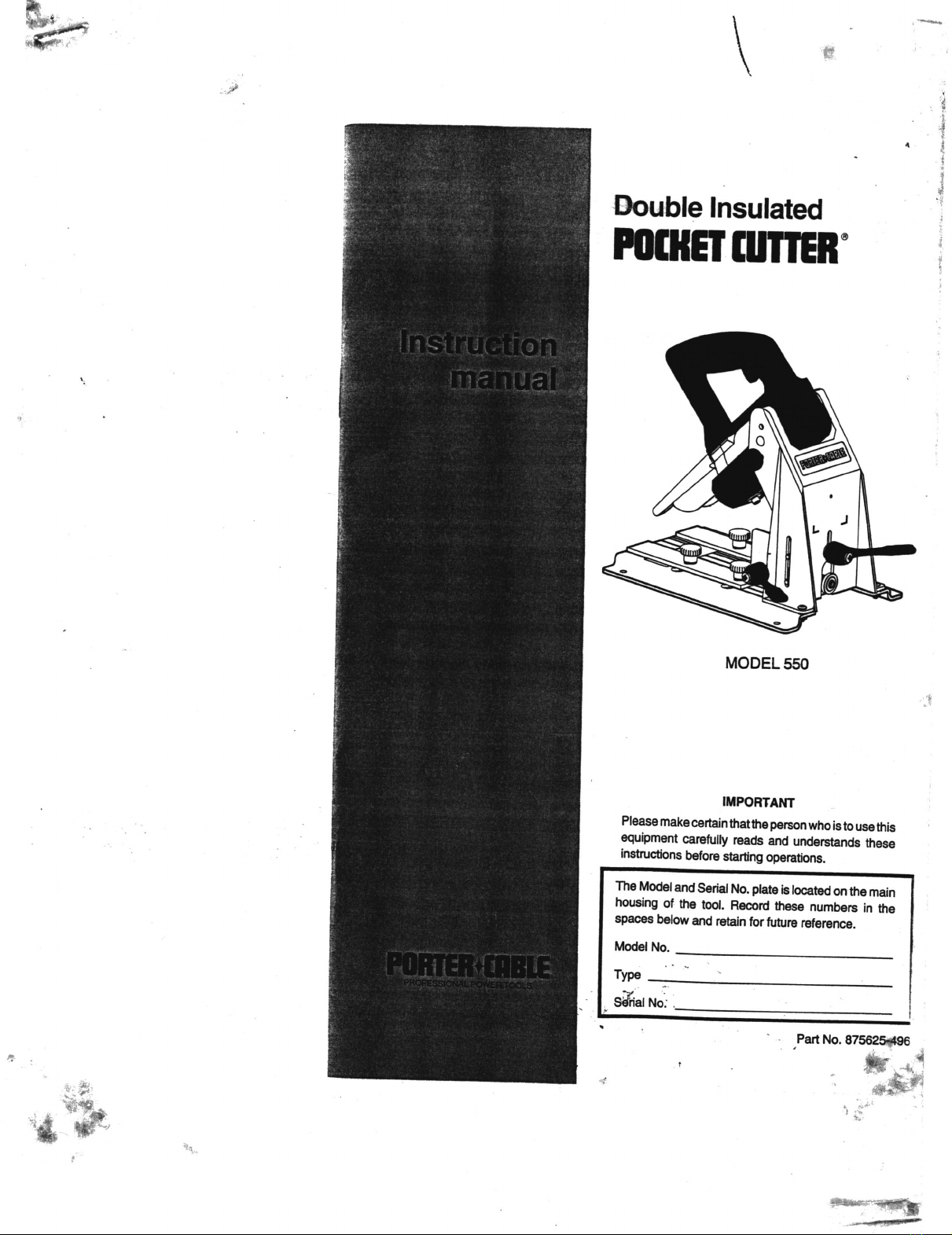

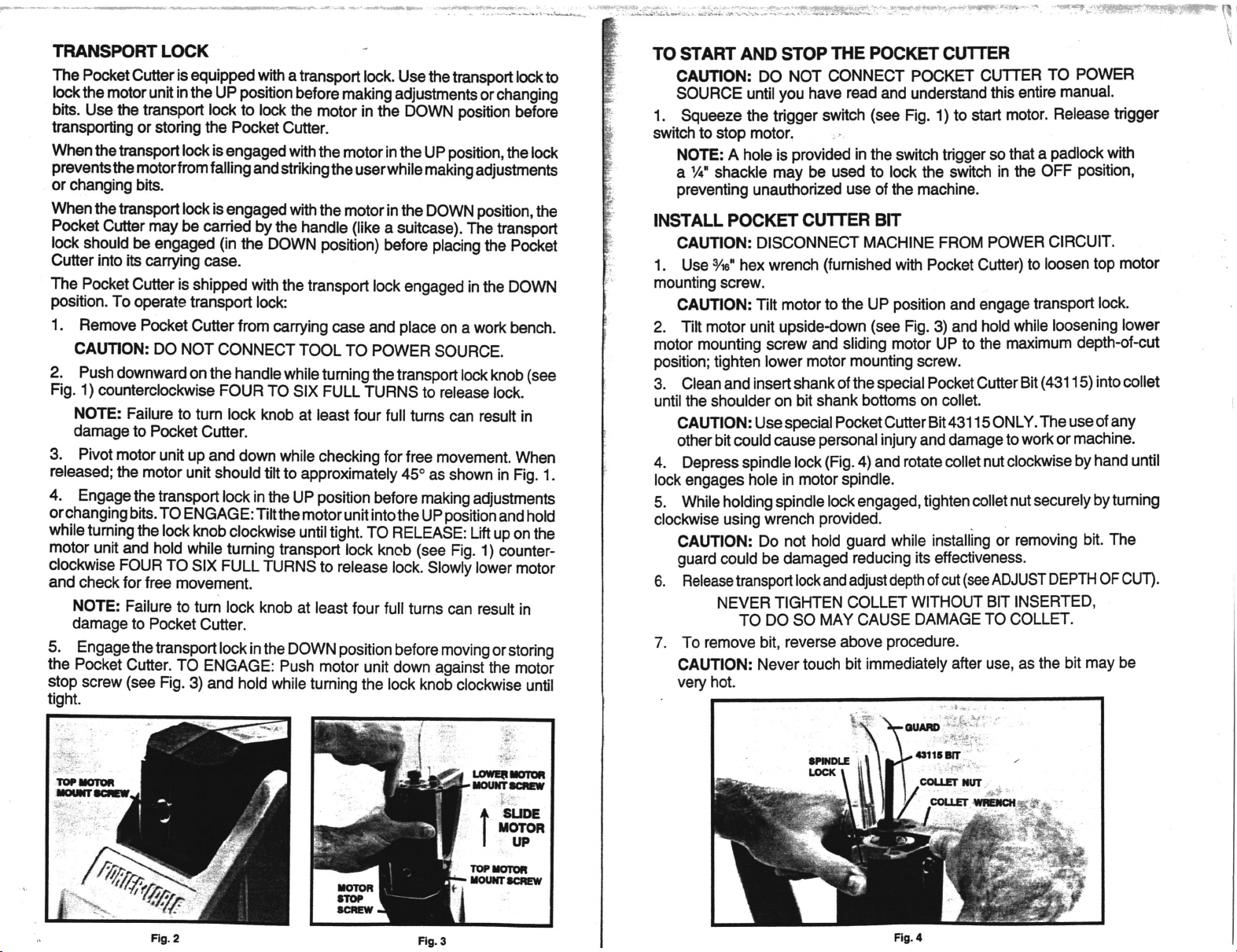

3. ENGAGE TRANSPORT LOCK in UP position before making adjust‑

ments or changing bits (See page 6).

4. ALWAYS BE SURE collet nutissecurelytightened to preventthe bitfrom

slipping during use.

Q