6. If you do not use the printer a long time, please disconnect the printer

power adapter power.

7. Users can not make bold to take down printer repair or remake.

8. The power adapter to use only the power adapter with random special

configuration.

9.In order to ensure print quality and product life, it is suggested to use

the recommended or equivalent quality thermal printing paper.

10. When plugged into the power connect cable or the data cable, please

make sure the printer power is turned off.

11.Please properly keep this manual,in order to use of reference

Application Area

Electronic Cash Register POS System Bill Print

Electronic Funds Transfer (EFT) POS Systems Bill Print

Sports, postal services, civil aviation ticket printing

Inquiries and service system for ticket printing

Measuring instrument information on printing

Tax, single-bill printing

Main Feature

Print high-quality, low cost

Low-noise, high-speed printing

Support cash drawer driving

Small and lightweight, beautiful shape

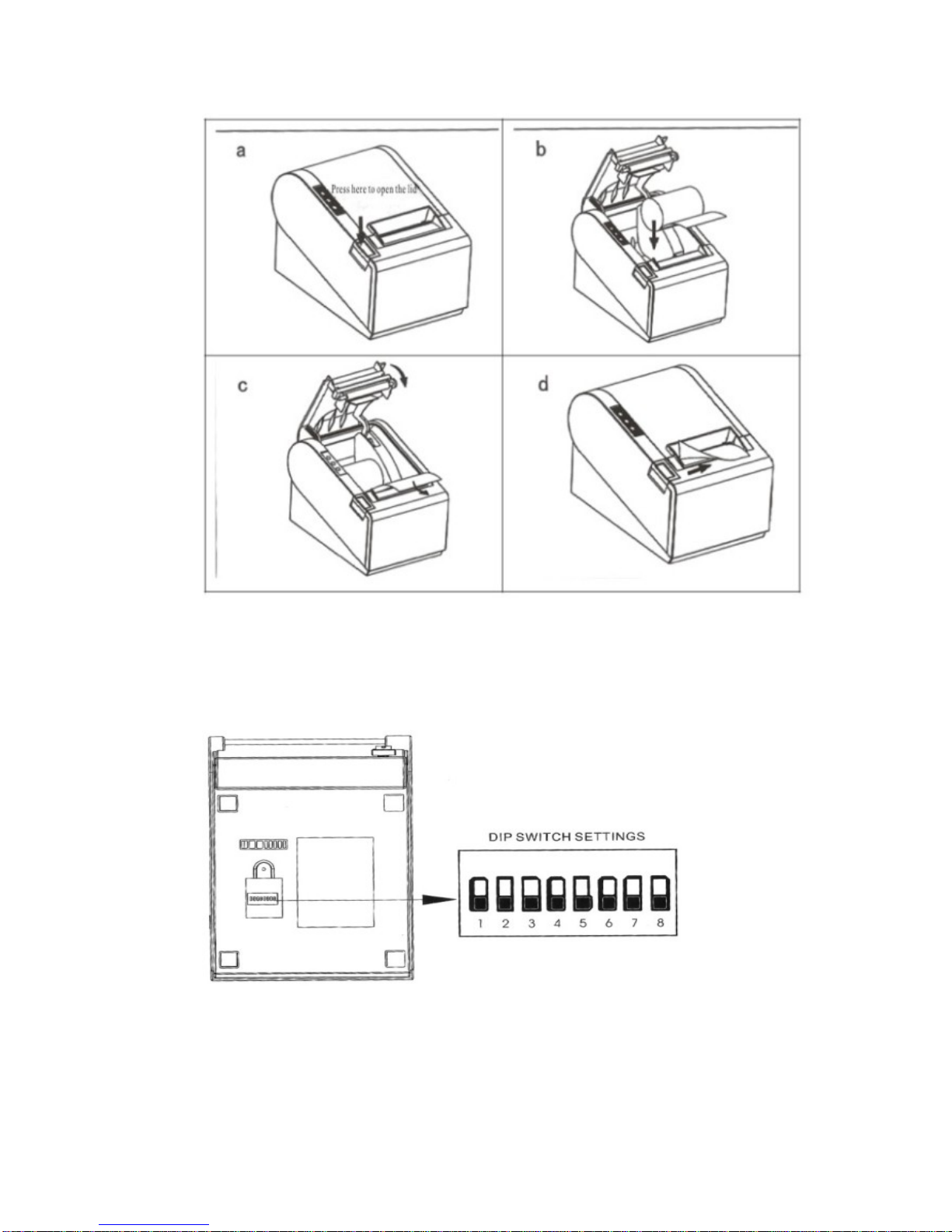

Easy paper loading structure, reasonable structure, easy to use

maintenance

Built-in data buffer (when printing can receive print data)

Character can enlarge print, Bold print, adjust character the line

spacing printed