i

Contents

Preface ..........................................................................................................................1

Important Notes...........................................................................................................2

Chapter 1: Introduction..............................................................................................4

1.1 Specifications.........................................................................................................................4

1.2 Contents in the Box................................................................................................................5

Chapter 2: Setup and Use...........................................................................................6

2.1 Main Parts and Structures......................................................................................................6

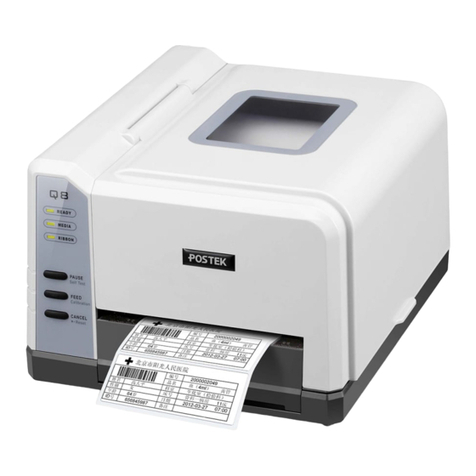

2.1.1 Front View.....................................................................................................................6

2.1.2 Internal View.................................................................................................................7

2.1.3 Rear View......................................................................................................................8

2.2 Setting up the Printer..............................................................................................................9

2.2.1 Interface Connection.....................................................................................................9

2.2.2 Power Connection.........................................................................................................9

2.2.3 Loading the Ribbon.....................................................................................................10

2.2.4 Loading the Media......................................................................................................14

2.2.5 Adjusting the Position of Media Sensor......................................................................16

Chapter 3: Operations and Settings........................................................................20

3.1 Basic Operations..................................................................................................................20

3.1.1 Power Switch ..............................................................................................................20

3.1.2 The Front Panel...........................................................................................................20

3.1.3 Advanced Functions....................................................................................................22

3.1.4 Setting Menu...............................................................................................................23

3.1.5 Setting Operation Mode..............................................................................................29

3.2 Adjusting the Printhead Pressure .........................................................................................32

3.3 RFID Operations..................................................................................................................33

3.3.1 RFID Calibration.........................................................................................................33

3.3.2 Reading RFID Data.....................................................................................................33

3.3.3 Setting RFID Power....................................................................................................34

3.3.4 Setting RFID Offset ....................................................................................................34

3.4 Installing Windows Driver and Label Editing Software......................................................35

Chapter 4: Maintenance...........................................................................................36

4.1 Cleaning the Printhead.........................................................................................................36

4.2 Cleaning the Platen Roller ...................................................................................................36

4.3 Cleaning the Printer Interior ................................................................................................37

4.4 Cleaning the Sensors............................................................................................................37

Chapter 5: Troubleshooting......................................................................................38

5.1 LCD Error Messages............................................................................................................38

5.2 LED Error Indications..........................................................................................................39

5.3 RFID Errors..........................................................................................................................41

5.4 Miscellaneous Issues............................................................................................................42