TX Series User’s Manual

iii

Table of Contents

Preface .......................................................................................................................................................................................1

Important Notice, Read Me First............................................................................................................................................1

Chapter 1: Introduction...........................................................................................................................................................2

Printer Specifications..........................................................................................................................................................2

Contents of Box..................................................................................................................................................................3

Packing List ................................................................................................................................................................3

Chapter 2: Setup and Use ........................................................................................................................................................4

Setting up the Printer..........................................................................................................................................................4

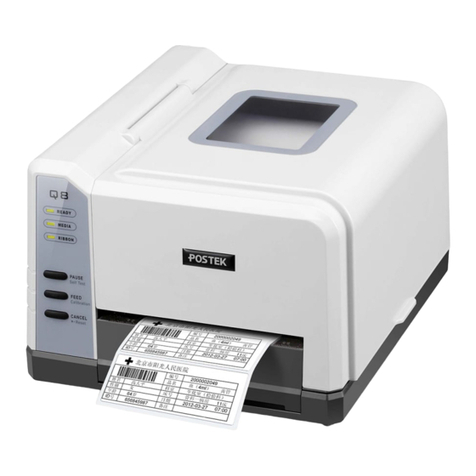

Main Parts and Structures...........................................................................................................................................4

Loading Path...............................................................................................................................................................8

Connecting the Printer................................................................................................................................................9

Interface Connection...................................................................................................................................................9

Loading the Ribbon ..........................................................................................................................................................10

Loading the Media............................................................................................................................................................13

Standard Mode..........................................................................................................................................................13

Peel-off and Tear-off Mode:......................................................................................................................................17

Cutting Mode:...........................................................................................................................................................17

Chapter 3: Operations and Settings......................................................................................................................................18

Basic Operations...............................................................................................................................................................18

Power Switch............................................................................................................................................................18

The Front Panel.........................................................................................................................................................18

LCD Display.............................................................................................................................................................19

Tear-off .....................................................................................................................................................................23

Manual Peel-off ........................................................................................................................................................23

Cutting Mode............................................................................................................................................................24

Adjusting the Pressure of the Printhead............................................................................................................................26

Windows Driver and Label Software................................................................................................................................27

Chapter 4: Maintenance.........................................................................................................................................................28

Cleaning the Printhead......................................................................................................................................................28

Cleaning the Platen Roller................................................................................................................................................29

Cleaning the Printer Interior .............................................................................................................................................29

Chapter 5: Troubleshooting...................................................................................................................................................30

Error Indications...............................................................................................................................................................30

Miscellaneous...................................................................................................................................................................31

Vertical Blank Lines Appear.....................................................................................................................................31

Printer Timeout Error Message.................................................................................................................................31

Data Sent but Not Printing........................................................................................................................................31

Poor Printing Quality................................................................................................................................................31

Recovery...................................................................................................................................................................31

Appendix

A: Interface Specifications....................................................................................................................................32

Appendix B:ASCII Table ......................................................................................................................................................27