ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

TURCK Inc. 3000 Campus Drive Minneapolis, MN 55441 Application Support: 1-800-544-7769 Fax: (763) 553-0708 www.turck.com

PK01VR…P vacuum

PK010R…P pressure

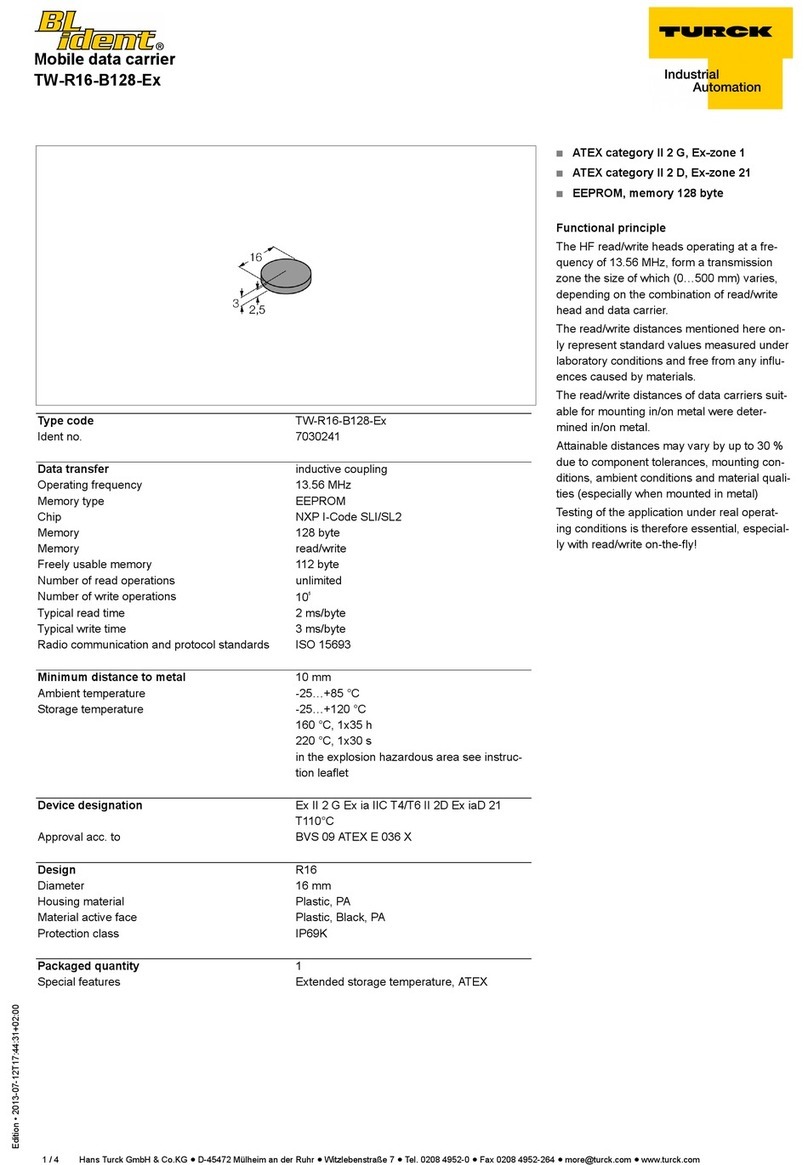

Technical Data

Dimensions

Electrical Data

Response time <2.5 ms

Operating frequency 400 Hz

Supply voltage 10.8-30 V, keyed residual ripple 10%

Input current during programming <55 mA

Input current in normal operation <35 mA

Switchable outputs 2x PNP 250 mA

short-circuit protected

Display 3 digit 7 segment display

Ambient temperature effect: 3% of measured

value of 0 to 50°C

Repeat accuracy: 0.2% of measured value

Hysteresis adjustable: 0 to 100%

Measuring range: 0 to -1 bar/0 to 10 bar

Max. over pressure: 5 bar/16 bar

•

•

•

•

•

•

•

•

•

•

•

•

Environmental Conditions

Protection: IP 65

Measuring medium: filtered compressed air,

lubricated or unlubricated, inert gases

Emitted interference adheres to DIN EN 50081-1

Interference immunity adheres to DIN EN 50082-2

High voltage test 1000 VDC 1 min

Insulation resistance >100 MΩat 500 VDC

Operating temperature: -10 to +50°C

Storage temperature: -20 to +85°C

Permissible humidity: 10 to 90% RH

Shock resistance: 10G XYZ

Vibration resistance: 10 to 55 Hz, 1.5 mm,

XYZ 2 hours

Mechanical Data

Electrical connector: M8 4-pin

Process connector: male 1/8” NPT

Weight: approx. 25 g

Wetted parts: nickel plated brass

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Circuits

Programming

Start-Up

Apply Voltage

Display Segment

Check

Type Pressure

Unit

Measure

Mode

Display

Output 1 Output 2 Special

Functions

Hysteresis

Mode

Hysteresis

Mode

Pressure

Unit Bar

Unlock

4.6 bar /

-0.46 bar

NC Mode NC Mode

0 sec. 0 sec.

0 sec. 0 sec.

7.9 bar /

-0.79 bar

0.7 bar /

-0.07 bar

0.7 bar /

-0.07 bar

Output 1 Output 2 Special

Functions

Pressure

Unit

Unlock

Hysteresis

Mode

Switching

Threshold

Closing

Delay

Release

Delay

Normally

Closed

Hysteresis

Comparator

Mode

Upper

Switching

Threshold

Closing

Delay

Release

Delay

Normally

Open

Lower

Switching

Threshold

Factory

Settings

Rotate

Display 180°

1. Factory Settings

The Clear All special

function loads the

factory settings, and

all previous settings

are cleared.

2. Setting Options

- Menu items listed under OU1 are settings specific to output 1

- Menu items listed under OU2 are settings specific to output 2

- Menu items listed under SF OU2 are general settings which influence both outputs.

Output setting options

Hysteresis mode

- Switching threshold

- Hysteresis

- Type of contact (normally open, normally closed)

- Closing delay

- Release delay

Comparator mode

- Upper switching threshold

- Lower switching threshold

- Type of contact (normally open, normally closed)

- Closing delay

- Release delay

Special functions settings options

Vacuum unit for PK01VR => bar, mmHg, inHg, KPa

Pressure unit for PK01VR => bar, psi, MPa

Clear All => factory setting loaded

Key lock activated = BLC, inactive = UnL

Rotate display 180°

3. General Procedure for Adjusting Settings

By following the flow diagram, you can move to any menu item you wish

using the three buttons (Up, Down and Mode).

For example: output 2

- Comparator mode

- Lower threshold: PK010R = 3.0 bar, PK01VR = -0.3 bar

- Upper threshold: PK010R = 5.0 bar, PK01VR = -0.5 bar

- Position of normally closed contact

- Closing delay 0 sec.

- Release delay 0 sec.

Procedure: Measure mode output

a) Briefly press Mode button => OU1 display

b) Briefly press Up button => OU2 display

c) Briefly press Mode button to enter Menu level => HY2 display

d) Proceed to desired menu item with Up or Down

button and confirm by pressing the Mode button.

e) In this case: confirm HY2 with Mode button. => HY2 display flashes

f ) Go to the desired setting with the Up or Down button.

In this case: CP2. Then confirm setting with Mode button.

g) To adjust further settings, follow the procedure in (d) above. In this case, set U-2

(lower threshold) and confirm with Mode button. => U-2 display flashes

h) Adjust the desired setting with the Up or Down button.

In this case: set U-2 to 0.50 and then confirm setting with Mode button.

i) Proceed in the same way for all other settings.

j) To enter another setting level, e.g. output 1 (OU1) or special functions (SF), you use

the Up or Down button to go to the menu item rEt (Return). If this is confirmed with

the Mode button, you arrive at the previous level. In this case you would arrive at

the menu item OU2 and now you can switch between the menu items Output 1 or

Special functions with the Up or Down button in order to adjust settings.

4. Activate Key Lock

The locking function ensures that the switch settings are safeguarded against

unintentional changes or manipulation. To activate the locking function, proceed

as follows:

Starting state is Measure => Display: Pressure activated

Briefly press Mode button (select level) => Display OU1

Press Up or Down button until SF reached => Display SF

Briefly press Mode button until menu entered => Display PU

Press Up or Down button until UnL reached => Display UnL

Briefly press Mode button until menu entered => Display UnL flashes

Set BLC with Up or Down button => Display BLC flashes

Confirm setting with Mode button => Display Measure

5. Deactivate Key Lock

Briefly press Up, Down and Mode buttons simultaneously => Display BLC

Briefly press Mode button once => Display BLC flashes

Set UnL with Up or Down button => Display UnL flashes

Confirm with Mode button => Display UnL static

Return to Measure state via rEt (Return) menu item

6. Selectable Display Units

The following units of measurement are available

7. Setting Display To Zero

Operate switch in Measure mode

Depress Mode button for 3 sec.

Display is set to zero

8. Peak Values

Briefly press Down button, the lowest measured value will be displayed for 3 sec.

Briefly press Up button, the highest measured value will be displayed for 3 sec.

9. Error Messages

PK01VR Display Procedure for adjusting settings

bar

KPa

mmHg

inHg

- Looking at the flow diagram, select the

menu item SF (special functions) and

briefly press Mode button.

- PU appears on the display (pressure unit).

- Select PU with Mode button. Now the

desired unit can be selected with the Up or

Down button.

- Confirm the selected unit with the Mode

button and exit the menu via the rEt

function (Return).

PK010R Display

bar

Psi

bar

MPA

Error Messages Cause

Overcurrent

Out1

Overcurrent

Out2

Applied vacuum

> range

EEPROM

defective

Distance to

zero point >3%

Output 1 overloaded

(current > 125 mA)

EEPROM defective, data

memory defective

Vaccuum or pressure was

higher than +/- 3% of the

measuring range

Pressure instead of vacuum

Remedy

Pressure instead

of vacuum

Output 2 overloaded

(current > 125 mA)

Applied vacuum >

measuring range

Increase load impedance

Increase load impedance

Apply vacuum

Switch defective, replace

Put the vacuum within the

measure range

Reset zero point to

ambient pressure

Red Status LED

Output 1

Up

Down

Mode

Green Status LED

Output 2