PostProcess Technologies, Inc. • www.postprocess.com • REV B | page 8

1. OPERATION

1.3 Maintenance Operations

1.3.1 Media Maintenance

1.3.2 Liquids Maintenance

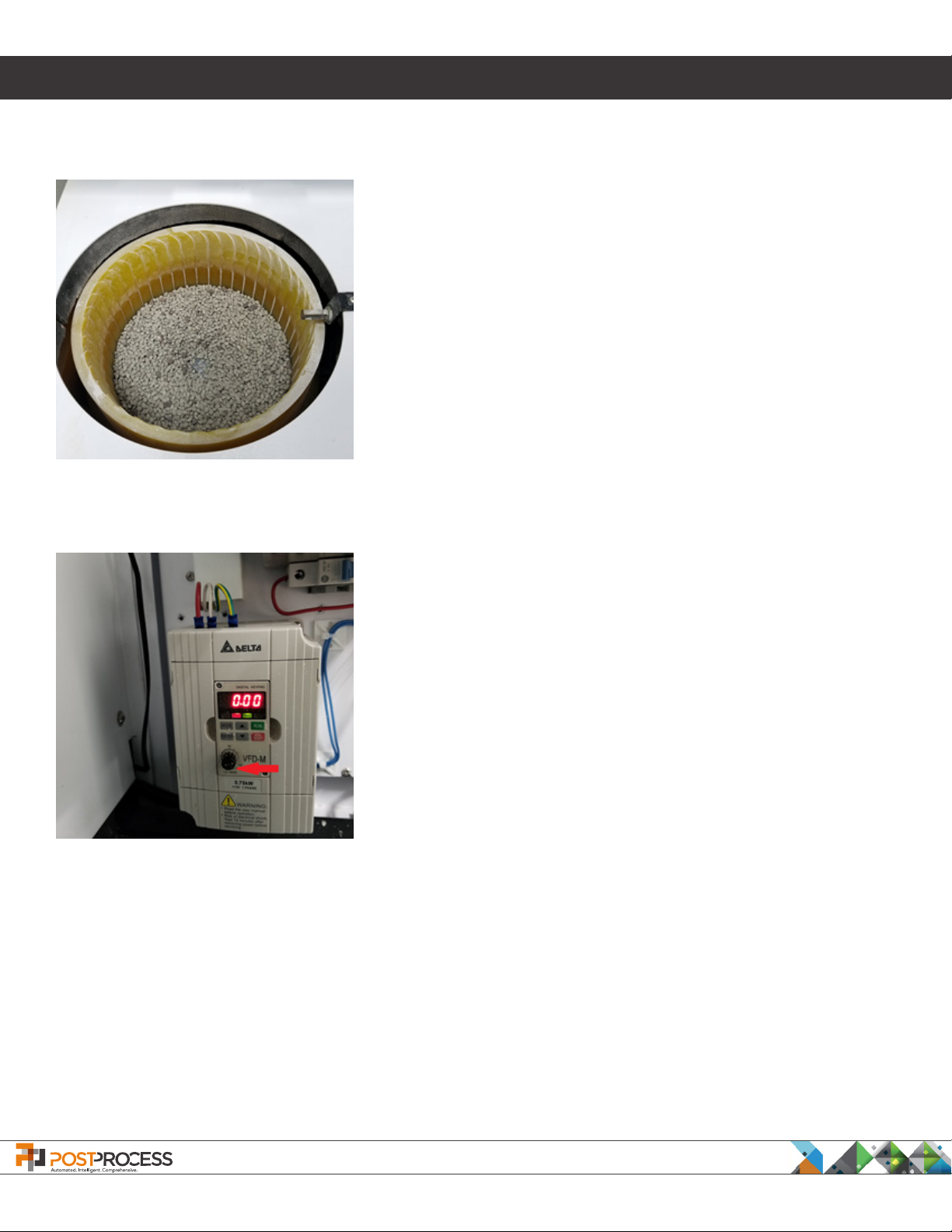

As shown in Figure 6. Abrasive / Finishing Media, the LEVO has a

chamberthatislledwithspeciallyformulatedabrasiveorpolishing

media.Duringthesurfacenishingoperation,theprintedpartis

immersed in this media and the combination of rotational energy,

the abrasive qualities of the media, and the patented PG3 liquids

allactonthepartuntilthedesirednishinglevelisachieved.The

media has a useful life based on the application it is being used in

and the amount of processing that is occurring.

Once the media has degraded to one-third of its original size, it is

time to change out the media.

To change the media, carefully scoop out all of the media particles, and dispose of them according to local

regulations. Next, with a damp cloth and mild cleaning solution, clean out the envelope and wipe down the spray

nozzle to remove any sediment build-up. Also, wipe down the grate that covers the drain inside the chamber

withaplasticbristlebrush.Finally,rellthechamberwithfreshmediasuppliedbyPOSTPROCESS. NEVER use

media other than POSTPROCESS supplied abrasive and polishing media or risk damaging the machine.

The appropriate ratio of PG3 to water is designated for each

customer application but most typically the ratio is 99 parts of

water to 1 part of PG3. The LEVO has a 1.5-gallon tank, so the

correctformulawouldbe2oz.ofPG3andlltheremainderofthe

tank with fresh water. The operator using the SF MICRO C should

always ensure that the correct levels of liquid are being utilized

duringthenishingprocess.Behindtheright-sidepanel(belowthe

PG3 access opening) is the liquids tank and the LEVO drain bucket,

as shown in Figure 7. Reservoir and Drain Bucket.

The Liquids Reservoir is translucent allowing the operator to see

how

much liquid remains in the tank. It is important to note that

whenever

the tank is empty, the correct recipe of PG3 and water

should

be added to the reservoir before operation. Never run the

LEVO

without liquids.

Figure 6. Abrasive / Finishing

Media

Figure 7. Reservoir and

Drain Bucket

NOTE

WhenthereservoirisrelledwithPG3andwater,thedrainbucketshouldbeemptied.Ifitisnotemptiedevery

timeliquidisaddedtotheLEVO,theDrainBucketcanoverow.