PRINTED IN USA PAGE 1 OF 6

AUTO TEST VSR (VSR-AT)

VANE TYPE WATERFLOW ALARM SWITCH WITH

ELECTRONIC RETARD AND AUTO TEST FEATURE

MFG. #5401239 - REV B

3/14

UL, CUL, FM Approved

Service Pressure: 450 PSI (31 BAR) - UL

Flow Sensitivity Range for Signal:

4-10 GPM (15-38 LPM) - UL

Maximum Surge: 18 FPS (5.5 m/s)

Contact Ratings: 2.5 AMP @ 125/250 VAC & 30 VDC

Power Requirements: 24 VDC From Listed or Approved Source

With Battery Backup

Typical Current Draw:

Standby 20 mA

Alarm 65 mA

Autotest 120 mA

Conduit Entrances: Two knockouts provided for 1/2" conduit.

Environmental Specications:

• NEMA 4/IP54 Rated Enclosure suitable for indoor or

outdoor use with factory installed gasket and die-cast housing

when used with appropriate conduit tting.

• Temperature Range: 40°F - 120°F, (4.5°C - 49°C) - UL

• Non-corrosive sleeve factory installed in saddle.

Service Use:

Automatic Sprinkler NFPA-13

One or two family dwelling NFPA-13D

Residential occupancy up to four stories NFPA-13R

National Fire Alarm Code NFPA-72

Ordering Information

Nominal Pipe Size Model Part # Replacement PCB #

2" DN50 VSR-AT-2 1116102 1029074

2 1/2" DN65 VSR-AT-2 1/2 1116125 1029075

3" DN80 VSR-AT-3 1116103 1029076

3 1/2" - VSR-AT-3 1/2 1116135 1029077

4" DN100 VSR-AT-4 1116104 1029078

5" - VSR-AT-5 1116105 1029079

6" DN150 VSR-AT-6 1116106 1029080

8" DN200 VSR-AT-8 1116108 1029081

Optional Power Supply: Ordering Information

Model Description Part Number

- Power Supply 3006479

BT-80 12V Battery-8AH (2 REQUIRED) 5130084

Optional Test Switch: Ordering Information

Model Description Part Number

ATC-1 Single Zone Test Control 1000221

ATC-4 Four Zone Test Control 1000224

SGB-R Single Gang Box-Red 1000483

DGB-R Double Gang Box-Red 1000484

General Information

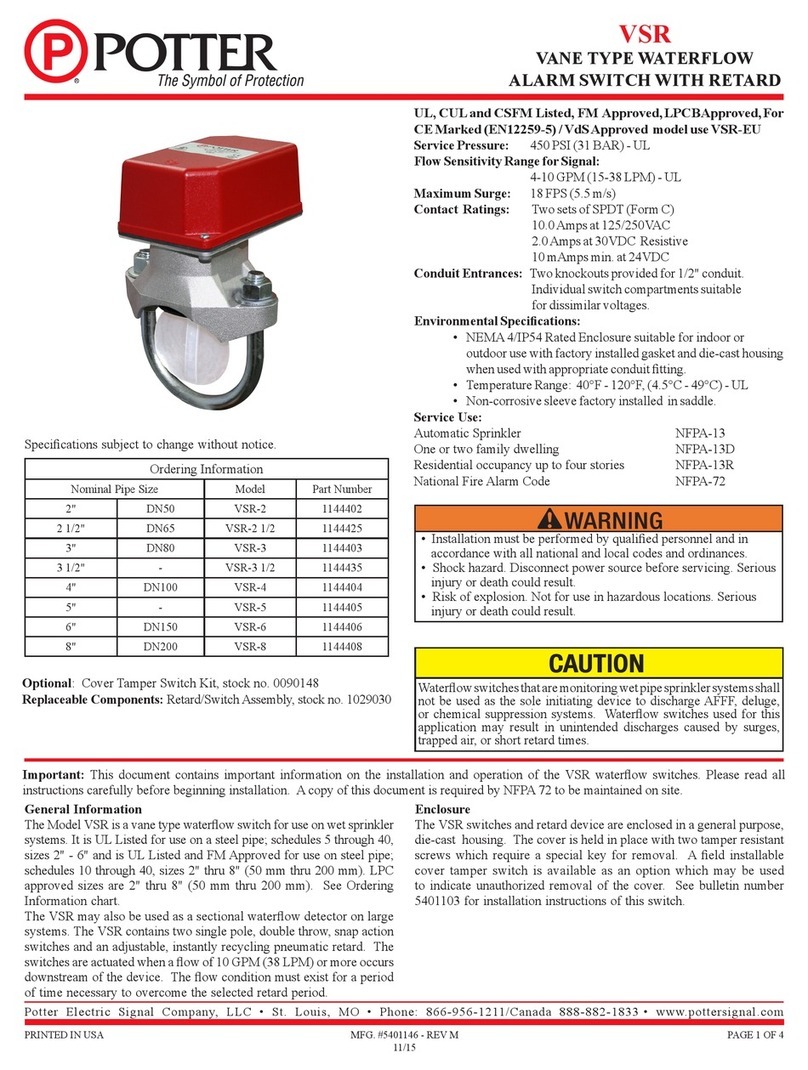

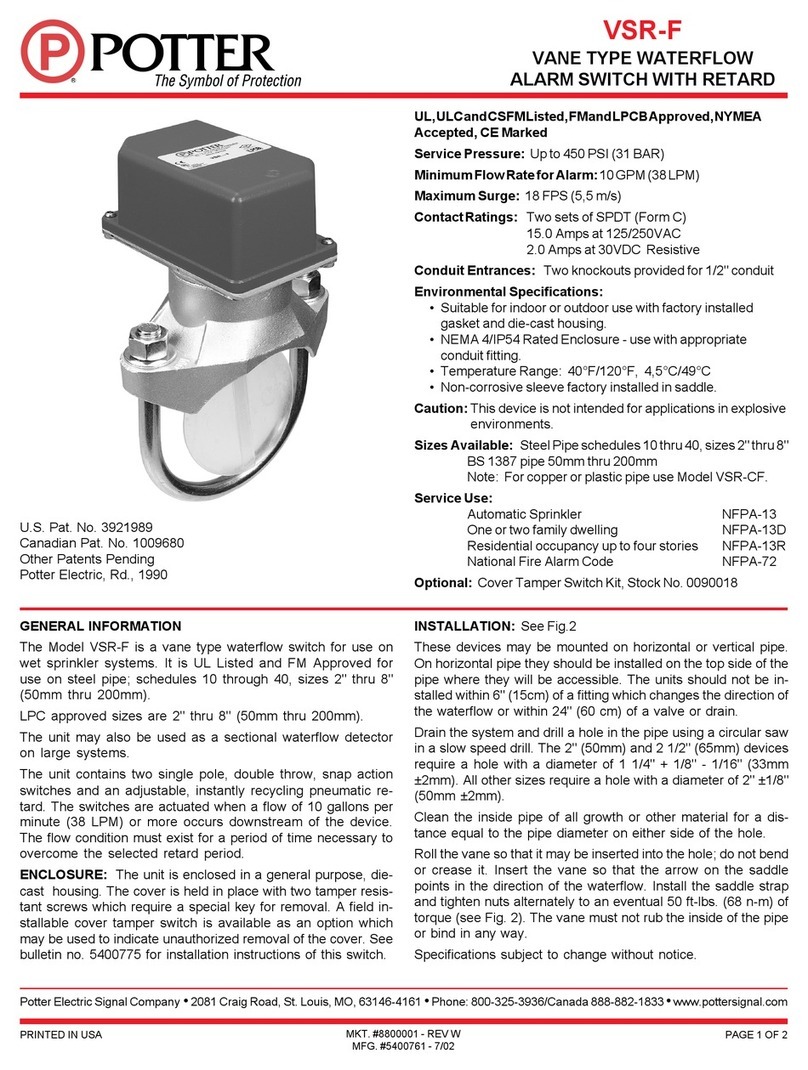

The model VSR-AT is an electronic vane type waterow switch for

use on wet sprinkler systems. It is UL Listed and FM Approved for

use on steel pipe schedules 10 thru 40 sizes 2” thru 8”. See ordering

Information chart.

The VSR-AT may also be used as a sectional waterow detector on large

systems. The VSR-AT has two sets of alarm contacts and an adjustable

instantly recycling electronic retard. The alarm contacts are actuated

when a ow of 10 GPM (38 LPM) or more occurs downstream of the

device. The ow condition must exist for a period of time necessary to

overcome the selected retard time.

The VSR-AT may be remotely tested without owing water by using

the optional auto test Control model ATC-1or ATC-4 or the use of

addressable relays and monitor modules as part of a listed addressable

•Installation must be performed by qualied personnel and in

accordance with all national and local codes and ordinances.

• Shock hazard. Disconnect power source before servicing. Serious

injury or death could result.

• Risk of explosion. Not for use in hazardous locations. Serious

injury or death could result.

Specications subject to change without notice.

re alarm panel.

When the auto test feature is initiated, the VSR-AT performs a self test to

ensure compliance with UL requirements regarding waterow detection

and retard time. In addition, the auto test feature ensures the integrity of

the paddle/trip stem assembly. A successful completion of the auto test

will activate both sets of normally open contacts on the ow switch. If

the auto test detects a problem with the trip stem/paddle assembly or if

there is no water in the pipe, neither normally open contact will operate

and the ow switch will indicate a trouble condition at the test switch

and transmit a trouble signal to the re alarm panel.

Enclosure

The VSR-AT switches and retard device are enclosed in a general

purpose, die-cast housing. The cover is held in place with two tamper

resistant screws which require a special key for removal.

Waterow switches that are monitoring wet pipe sprinkler systems shall

not be used as the sole initiating device to discharge AFFF, deluge,

or chemical suppression systems. Waterow switches used for this

application may result in unintended discharges caused by surges,

trapped air, or short retard times.

Potter Electric Signal Company, LLC • St. Louis, MO •Phone: 866-956-1211/Canada 888-882-1833 •www.pottersignal.com

Important: is document contains important information on the

installation and operation of VSR-AT waterow switches. Please read

all instructions carefully before beginning installation. A copy of this

document is required by NFPA 72 to be maintained on site.