PRINTED IN USA PAGE 1 OF 4

VSR

VANE TYPE WATERFLOW

ALARM SWITCH WITH RETARD

MFG. #5401146 - REV M

11/15

UL, CUL and CSFM Listed, FM Approved,LPCBApproved,For

CE Marked (EN12259-5) / VdSApproved model use VSR-EU

Service Pressure: 450 PSI (31 BAR) - UL

Flow Sensitivity Range for Signal:

4-10 GPM (15-38 LPM) - UL

Maximum Surge: 18 FPS (5.5 m/s)

Contact Ratings: Two sets of SPDT (Form C)

10.0 Amps at 125/250VAC

2.0 Amps at 30VDC Resistive

10 mAmps min. at 24VDC

Conduit Entrances: Two knockouts provided for 1/2" conduit.

Individual switch compartments suitable

for dissimilar voltages.

Environmental Specications:

• NEMA4/IP54RatedEnclosuresuitableforindooror

outdoor use with factory installed gasket and die-cast housing

whenusedwithappropriateconduittting.

• TemperatureRange:40°F-120°F,(4.5°C-49°C)-UL

• Non-corrosivesleevefactoryinstalledinsaddle.

Service Use:

AutomaticSprinkler NFPA-13

Oneortwofamilydwelling NFPA-13D

Residentialoccupancyuptofourstories NFPA-13R

NationalFireAlarmCode NFPA-72

•Installationmustbeperformedbyqualiedpersonnelandin

accordance with all national and local codes and ordinances.

•Shockhazard.Disconnectpowersourcebeforeservicing.Serious

injury or death could result.

•Riskofexplosion.Notforuseinhazardouslocations.Serious

injury or death could result.

Ordering Information

NominalPipeSize Model PartNumber

2" DN50 VSR-2 1144402

2 1/2" DN65 VSR-2 1/2 1144425

3" DN80 VSR-3 1144403

3 1/2" - VSR-3 1/2 1144435

4" DN100 VSR-4 1144404

5" - VSR-5 1144405

6" DN150 VSR-6 1144406

8" DN200 VSR-8 1144408

Specicationssubjecttochangewithoutnotice.

Optional:CoverTamperSwitchKit,stockno.0090148

Replaceable Components:Retard/SwitchAssembly,stockno.1029030 Waterowswitchesthataremonitoringwetpipesprinklersystemsshall

notbeusedasthesoleinitiatingdevicetodischargeAFFF,deluge,

orchemicalsuppressionsystems.Waterowswitchesusedforthis

application may result in unintended discharges caused by surges,

trappedair,orshortretardtimes.

Potter Electric Signal Company, LLC• St. Louis, MO • Phone: 866-956-1211/Canada 888-882-1833 •www.pottersignal.com

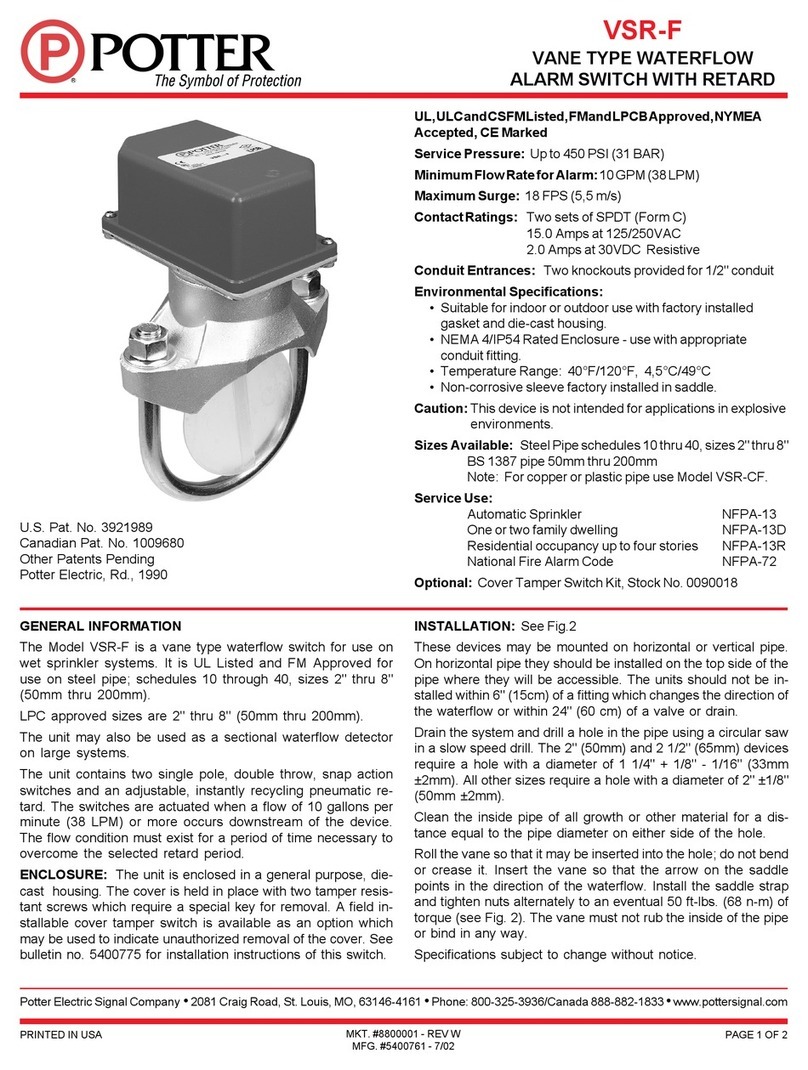

General Information

TheModelVSRisavanetypewaterowswitchforuseonwetsprinkler

systems.ItisULListedforuseonasteelpipe;schedules5through40,

sizes2"-6"andisULListedandFMApprovedforuseonsteelpipe;

schedules10through40,sizes2"thru8"(50mmthru200mm).LPC

approvedsizes are 2" thru8"(50 mm thru 200mm). See Ordering

Information chart.

TheVSRmayalsobeusedasasectionalwaterowdetectoronlarge

systems.TheVSRcontainstwosinglepole,doublethrow,snapaction

switchesandanadjustable,instantlyrecyclingpneumaticretard.The

switchesareactuatedwhenaowof10GPM(38LPM)ormoreoccurs

downstreamofthedevice.Theowconditionmustexistforaperiod

of time necessary to overcome the selected retard period.

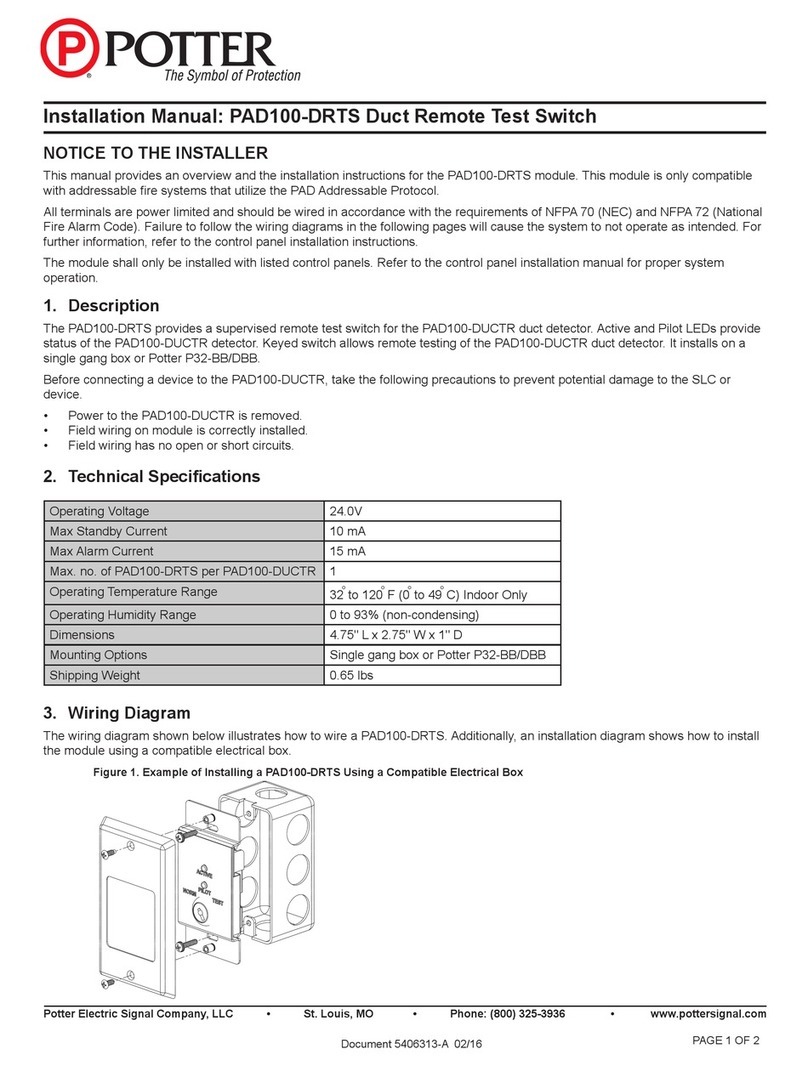

Enclosure

TheVSRswitchesandretarddeviceareenclosedinageneralpurpose,

die-cast housing. The cover is held in place with two tamper resistant

screws which require a special key for removal. A eld installable

cover tamper switch is available as an option which may be used

to indicate unauthorized removal of the cover. See bulletin number

5401103 for installation instructions of this switch.

Important: This document contains important information on the installation and operation of the VSR waterow switches. Please read all

instructionscarefullybeforebeginninginstallation.AcopyofthisdocumentisrequiredbyNFPA72tobemaintainedonsite.