PAGE 1 OF 2PRINTED IN USA MKT. #8800001 - REV W

MFG. #5400761 - 7/02

VSR-F

VANE TYPE WATERFLOW

ALARM SWITCH WITH RETARD

UL,ULCandCSFMListed,FMandLPCBApproved,NYMEA

Accepted, CE Marked

Service Pressure: Up to 450 PSI (31 BAR)

Minimum Flow Rate for Alarm: 10 GPM (38 LPM)

Maximum Surge: 18 FPS (5,5 m/s)

ContactRatings: Two sets of SPDT (Form C)

15.0 Amps at 125/250VAC

2.0 Amps at 30VDC Resistive

Conduit Entrances: Two knockouts provided for 1/2" conduit

Environmental Specifications:

• Suitable for indoor or outdoor use with factory installed

gasket and die-cast housing.

• NEMA 4/IP54 Rated Enclosure - use with appropriate

conduit fitting.

• Temperature Range: 40°F/120°F, 4,5°C/49°C

• Non-corrosive sleeve factory installed in saddle.

Caution: This device is not intended for applications in explosive

environments.

Sizes Available: Steel Pipe schedules 10 thru 40, sizes 2" thru 8"

BS 1387 pipe 50mm thru 200mm

Note: For copper or plastic pipe use Model VSR-CF.

Service Use:

Automatic Sprinkler NFPA-13

One or two family dwelling NFPA-13D

Residential occupancy up to four stories NFPA-13R

National Fire Alarm Code NFPA-72

Optional: Cover Tamper Switch Kit, Stock No. 0090018

U.S. Pat. No. 3921989

Canadian Pat. No. 1009680

Other Patents Pending

Potter Electric, Rd., 1990

GENERAL INFORMATION

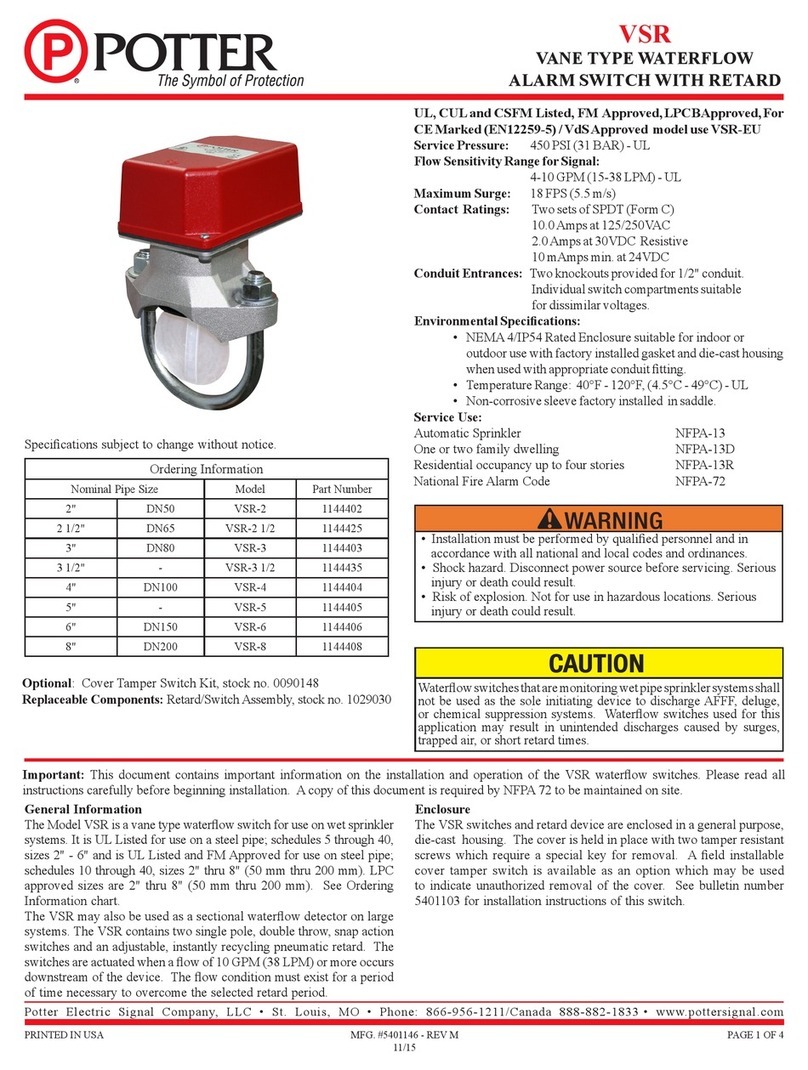

The Model VSR-F is a vane type waterflow switch for use on

wet sprinkler systems. It is UL Listed and FM Approved for

use on steel pipe; schedules 10 through 40, sizes 2" thru 8"

(50mm thru 200mm).

LPC approved sizes are 2" thru 8" (50mm thru 200mm).

The unit may also be used as a sectional waterflow detector

on large systems.

The unit contains two single pole, double throw, snap action

switches and an adjustable, instantly recycling pneumatic re-

tard. The switches are actuated when a flow of 10 gallons per

minute (38 LPM) or more occurs downstream of the device.

The flow condition must exist for a period of time necessary to

overcome the selected retard period.

ENCLOSURE: The unit is enclosed in a general purpose, die-

cast housing. The cover is held in place with two tamper resis-

tant screws which require a special key for removal. A field in-

stallable cover tamper switch is available as an option which

may be used to indicate unauthorized removal of the cover. See

bulletin no. 5400775 for installation instructions of this switch.

INSTALLATION: See Fig.2

These devices may be mounted on horizontal or vertical pipe.

On horizontal pipe they should be installed on the top side of the

pipe where they will be accessible. The units should not be in-

stalled within 6" (15cm) of a fitting which changes the direction of

the waterflow or within 24" (60 cm) of a valve or drain.

Drain the system and drill a hole in the pipe using a circular saw

in a slow speed drill. The 2" (50mm) and 2 1/2" (65mm) devices

require a hole with a diameter of 1 1/4" + 1/8" - 1/16" (33mm

±2mm). All other sizes require a hole with a diameter of 2" ±1/8"

(50mm ±2mm).

Clean the inside pipe of all growth or other material for a dis-

tance equal to the pipe diameter on either side of the hole.

Roll the vane so that it may be inserted into the hole; do not bend

or crease it. Insert the vane so that the arrow on the saddle

points in the direction of the waterflow. Install the saddle strap

and tighten nuts alternately to an eventual 50 ft-lbs. (68 n-m) of

torque (see Fig. 2). The vane must not rub the inside of the pipe

or bind in any way.

Specifications subject to change without notice.

Potter Electric Signal Company • 2081 Craig Road, St. Louis, MO, 63146-4161 •Phone: 800-325-3936/Canada 888-882-1833 •www.pottersignal.com