Industrial Damper

Installation, Operation, and Maintenance Manual

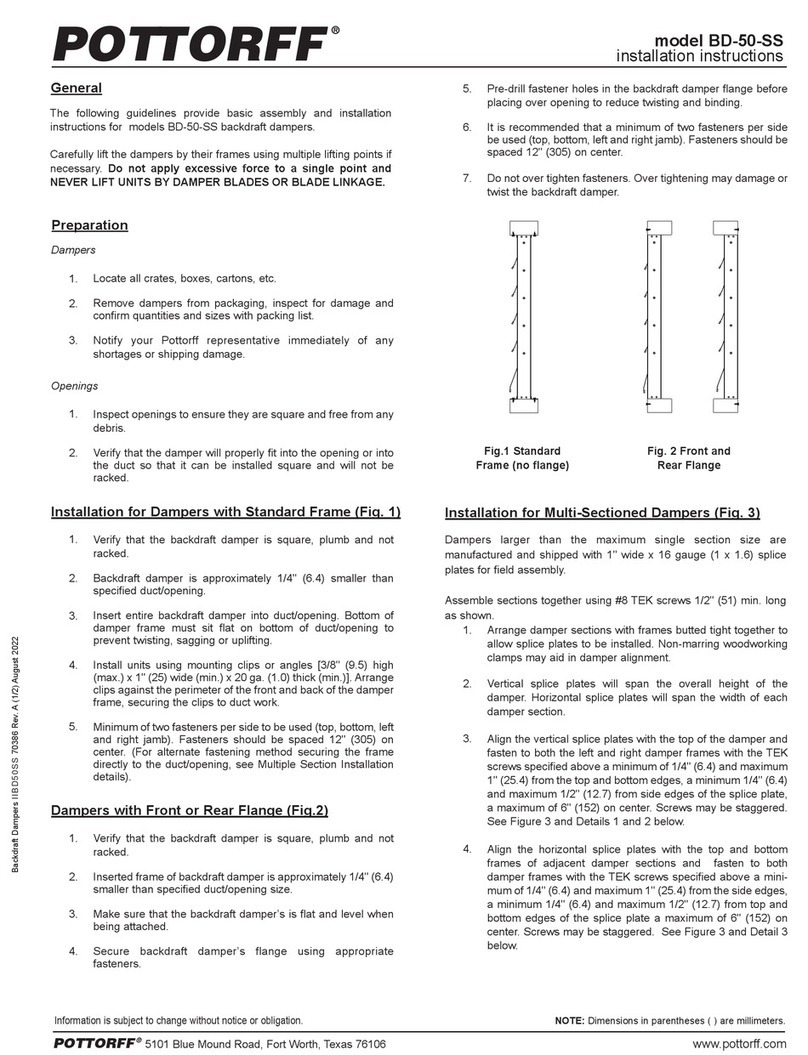

Bearings

Jamb Seal

Stop Seal

Blade Seal

1. Clean the dampers. Over time, dirt and

grime may collect on damper surfaces.

This can be a hindrance to airflow as

well as reduce the sealing efficiency of

the damper when closed. Be especially

careful in cleaning non-metallic blade

seals as they can be torn if abused. Mild

soap and water is the recommended

cleaning agent. Avoid abrasives and

solvents as these could degrade seals,

adhesives, oil on bearings, etc.

2. Check moving parts such as crank arms,

linkages, pins, blades, etc., to make sure

they move freely. While not required,

lubricating these components can prevent

possible rusting and unnecessary friction

increase. Use only a molybdenum spray

oil or similar graphite-based oil as regular

lubricating oil will attract dirt.

3. The bearings located on the blade axles

do not require lubrication.

4. If installed, inspect the blade seals and

stop seals for damage such as tears and

nicks. If damaged, replace as needed.

5. Check for worn shaft seals if applicable

and repair or replace as necessary.

6. Look for debris that may be interfering

with blade closure or effective sealing of

the blades and remove.

7. Check for loose hardware.

Refer to the actuator installation manual

for details on the actuator maintenance

requirements as well.

Industrial Damper IOM 2 of 3, January, 2023 pottorff.com

If any NEMA electrical enclosure is supplied, use appropriate electrical

connections to maintain the NEMA rating. All wiring and fusing must

be in accordance with national electric code, local code, and project

specification requirements. If the unit is supplied with an actuator, refer to

the actuator installation manual for details on the actuator before startup

as well.

If pneumatic power is required, check all pneumatic connections. The

supplied pressures must match the pressures required. A qualified

technician must be used. Improper connections are hazardous and can

cause permanent damage to the pneumatic equipment. All plumbing

must be in accordance with national code, local code, and project

specification requirements. If the unit is supplied with an actuator, refer to

the actuator installation manual for details on the actuator before startup

as well.

Maintenance

Pottorff dampers are designed to be maintenance free under normal

operation. Dampers are to be installed square, level, and straight to

prevent binding during operation. The following damper maintenance is

suggested to help ensure proper operation and increase life expectancy

of the damper. The frequency of maintenance should be determined by

the severity of the application. Before performing maintenance ensure

that the damper has been locked out. The blades should also be securely

blocked to eliminate the potential for movement while maintaining.

Single Section Dampers

If damper is supplied without mounting holes, drill or punch as required.

Pottorff is not responsible for corrosion around field punched or drilled

holes on painted dampers. Unless specifically designed for vertical

blades, damper must be mounted with blade axis horizontal. Connect the

damper to the mounting location using the proper hardware. Attach the

damper to all connection points before tightening bolts. Confirm that the

damper is square, straight, and level, and free from bending, twisting, or

racking. Manually operate the damper to ensure that it operates freely.

Multi-Section Dampers

Follow instructions for single section dampers. Additionally, position

damper sections together in opening or duct. Align and match frame

markings or labels on adjacent sections. Fasten adjacent sections

together on front and back sides with screws or nuts and bolts. Shim

damper frame and opening or duct as required to prevent distortion of

frame. Multi-section dampers require bracing to support the weight of

the assembly and to hold against system pressure. Bracing should

support the damper horizontally, minimum 8 feet center-to-center. Large

vertical assemblies and high system pressure may require additional

bracing. All additional bracing and supports designed, supplied, and

installed by others.

Do's

1. DO use provided lifting lugs.

2. DO install bolts into all supplied mounting holes, then tighten in an

even and staggered pattern to evenly compress the flange gasket (if

using).

3. DO check that the mating flange is flat, square, and parallel to the

damper flange.

4. DO check that damper blade(s) and linkages do not interfere with the

mating opening or duct when the damper is cycled between open

and closed positions.

Don'ts

1. DO NOT lift damper by blade(s).

2. DO NOT use actuator, linkage, or axles as lifting point.

3. DO NOT pry flanges to mate flange holes with opening or duct

flange as the frame could become warped, twisted, bent, or pulled

out-of-round causing binding.

4. DO NOT tighten mounting bolts by working around damper.

Please follow these instructions carefully. Failure to do so may void the

warranty. If the unit is supplied with an actuator, refer to the actuator

installation manual for details on the actuator before installation as well.

If the actuators were factory installed some adjustment may be required

after installation.

Start Up

Precautions should be taken before startup of the damper. All additional

safety accessories should be installed before starting the damper to

ensure the safety of everyone around. Rotate the blade(s) by hand to

ensure free movement of all components. Remove any construction

debris, loose hardware, tools, etc., from inside the damper and opening

or duct.

If electrical power is required, check all electrical connections before

turning on power. The supplied voltage must match the voltage required.

A qualified electrician must be used. Improper connections are hazardous

and can cause permanent damage to the electrical equipment.