Trox EK-JZ User manual

Smoke control damper

Type EK-JZ

Installation and operating manual

Read the instructions prior to performing any task!

according to EN12101-8

Declaration of performance DoP / EK-JZ / 003

GB/en

A00000062392, 5, GB/en

Translation of the original

© 2017

TROX GmbH

Heinrich-Trox-Platz

47504 Neukirchen-Vluyn, Germany

Germany

Phone: +49 (0) 2845 2020

Fax: +49 (0) 2845 202-265

E-mail: [email protected]

Internet: http://www.troxtechnik.com

07/2020

Smoke control damper Type EK-JZ

2

General information

About this manual

This operating and installation manual enables oper-

ating or service personnel to correctly install the TROX

product described below and to use it safely and effi-

ciently.

This operating and installation manual is intended for

use by fitting and installation companies, in-house tech-

nicians, technical staff, instructed persons, and qualified

electricians or air conditioning technicians.

It is essential that these individuals read and fully under-

stand this manual before starting any work. The basic

prerequisite for safe working is to comply with the safety

notes and all instructions in this manual.

The local regulations for health and safety at work and

general safety regulations also apply.

This manual must be given to the system owner when

handing over the system. The system owner must

include the manual with the system documentation. The

manual must be kept in a place that is accessible at all

times.

Illustrations in this manual are mainly for information

and may differ from the actual design.

Copyright

This document, including all illustrations, is protected by

copyright and pertains only to the corresponding

product.

Any use without our consent may be an infringement of

copyright, and the violator will be held liable for any

damage.

This applies in particular to:

Publishing content

Copying content

Translating content

Microcopying content

Saving content to electronic systems and editing it

TROX Technical Service

To ensure that your request is processed as quickly as

possible, please keep the following information ready:

Product name

TROX order number

Delivery date

Brief description of the fault

Online www.troxtechnik.com

Phone +49 2845 202-400

Limitation of liability

The information in this manual has been compiled with

reference to the applicable standards and guidelines,

the state of the art, and our expertise and experience of

many years.

The manufacturer does not accept any liability for dam-

ages resulting from:

Non-compliance with this manual

Incorrect use

Operation or handling by untrained individuals

Unauthorised modifications

Technical changes

Use of non-approved replacement parts

The actual scope of delivery may differ from the infor-

mation in this manual for bespoke constructions, addi-

tional order options or as a result of recent technical

changes.

The obligations agreed in the order, the general terms

and conditions, the manufacturer's terms of delivery,

and the legal regulations in effect at the time the con-

tract is signed shall apply.

We reserve the right to make technical changes.

Defects liability

For details regarding defects liability please refer to sec-

tion "VI. Warranty Claims" of the Delivery Terms of

TROX GmbH.

The General Delivery Terms of TROX GmbH can be

found on the Internet at www.trox.de.

General information

Smoke control damper Type EK-JZ 3

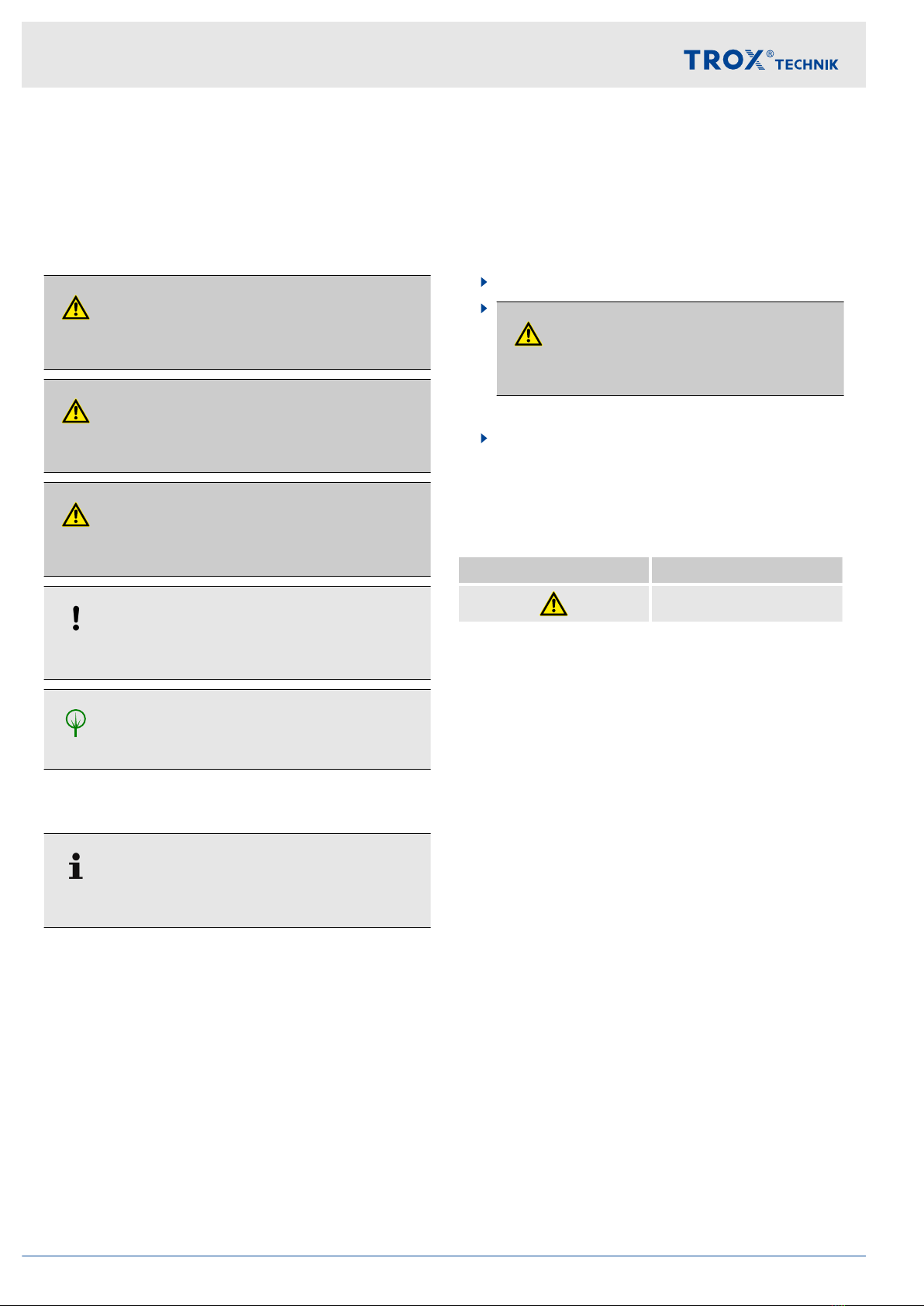

Safety notes

Symbols are used in this manual to alert readers to

areas of potential hazard. Signal words express the

degree of the hazard.

Comply with all safety instructions and proceed carefully

to avoid accidents, injuries and damage to property.

DANGER!

Imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING!

Potentially hazardous situation which, if not avoided,

may result in death or serious injury.

CAUTION!

Potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE!

Potentially hazardous situation which, if not avoided,

may result in property damage.

ENVIRONMENT!

Environmental pollution hazard.

Tips and recommendations

Useful tips and recommendations as well as informa-

tion for efficient and fault-free operation.

Safety notes as part of instructions

Safety notes may refer to individual instructions. In this

case, safety notes will be included in the instructions

and hence facilitate following the instructions. The

above listed signal words will be used.

Example:

1. Loosen the screw.

2.

CAUTION!

Danger of finger entrapment when closing

the lid.

Be careful when closing the lid.

3. Tighten the screw.

Specific safety notes

The following symbols are used in safety notes to alert

you to specific hazards:

Warning signs Type of danger

Warning – danger zone.

General information

Smoke control damper Type EK-JZ4

1 Safety.................................................................. 6

1.1 General safety notes................................... 6

1.2 Correct use.................................................. 6

1.3 Qualified staff............................................... 6

2 Technical data.................................................... 7

2.1 General data................................................ 7

2.2 Dimensions and weight............................... 8

3 Transport and storage..................................... 10

4Parts and function........................................... 12

5 Installation........................................................ 13

5.1 Installation situations................................. 13

5.2 Safety notes regarding installation............ 14

5.3 General installation information................. 14

5.3.1 Installation materials .............................. 15

5.3.2 Fixing points........................................... 18

5.3.3 Adjoined damper installation.................. 19

5.4 Solid walls or solid shaft walls................... 20

5.4.1 Installation opening................................ 20

5.4.2 Installation type dry, mortarless / dry,

mortarless - mortar-based...................... 23

5.4.3 Installation type mortar-based / dry, mor-

tarless - mortar-based............................ 26

5.4.4 On solid external wall or solid shaft

wall......................................................... 32

5.4.5 Lift for fire and rescue service................ 34

5.5 Lightweight shaft wall................................ 36

5.6 Lightweight partition wall........................... 38

5.7 Solid ceiling slabs...................................... 40

5.7.1 Installation type, mortar-based............... 40

5.8 Fire-resistant smoke extract ducts............ 42

5.8.1 Installation on vertical smoke extract

ducts....................................................... 42

5.8.2 On a horizontal smoke extract duct........ 44

5.8.3 In a horizontal smoke extract duct.......... 46

5.8.4 At the end of a horizontal smoke extract

duct......................................................... 48

5.9 Suspending the smoke control damper..... 50

5.9.1 General................................................... 50

5.9.2 Fixing the unit to the ceiling slab............ 50

5.9.3 Suspended installation........................... 50

5.10 After installation....................................... 50

6 Smoke extract duct and cover grille.............. 51

6.1 Smoke extract ducts for multi compart-

ments......................................................... 51

6.2 Smoke extract duct for a single compart-

ment........................................................... 52

6.3 Inspection access...................................... 52

6.4 Cover grilles............................................... 53

6.4.1 Crimped wire mesh (A) and perforated

plate (B).................................................. 54

6.4.2 Aluminium grille with slanted blades (C,

D, E)....................................................... 55

7 Electrical connection...................................... 56

7.1 General safety notes................................. 56

7.2 Wiring and connection to the central

BMS........................................................... 56

7.3 Actuators B24 and B230........................... 57

7.4 Actuator with control module..................... 57

7.4.1 TROXNETCOM B24A, B24AM,

B24AS ................................................... 58

7.4.2 B24BKNE............................................... 59

7.4.3 SLC technology - B24C.......................... 60

7.4.4 B24D and B230D................................... 61

8 Commissioning/functional test...................... 63

8.1 Commissioning.......................................... 63

8.2 Functional test........................................... 63

9 Maintenance..................................................... 64

10 Decommissioning, removal and disposal..... 66

11 Index................................................................. 67

Table of contents

Smoke control damper Type EK-JZ 5

1 Safety

1.1 General safety notes

Sharp edges, sharp corners and thin sheet metal

parts

CAUTION!

Danger of injury from sharp edges, sharp cor-

ners and thin sheet metal parts!

Sharp edges, sharp corners and thin sheet metal

parts may cause cuts or grazes.

– Be careful when carrying out any work.

–Wear protective gloves, safety shoes and a hard

hat.

Electrical voltage

DANGER!

Danger of electric shock! Do not touch any live com-

ponents! Electrical equipment carries a dangerous

electrical voltage.

– Only skilled qualified electricians are allowed to

work on the electrical system.

–Switch off the power supply before working on

any electrical equipment.

1.2 Correct use

Type EK-JZ smoke control dampers are used in

smoke and heat exhaust systems to remove smoke

and heat. They may be used with the following sys-

tems:

– in pressurisation systems

– mechanical (i.e. powered) smoke exhaust sys-

tems

– natural smoke and heat exhaust systems

– heat exhaust systems

Operation of smoke control dampers is allowed only

in compliance with installation regulations and the

technical data in this installation and operating

manual.

Modifying the smoke control damper or using

replacement parts that have not been approved by

TROX is not permitted.

Incorrect use

WARNING!

Danger due to incorrect use!

Incorrect use of the smoke control damper can lead

to dangerous situations.

Never use the smoke control damper:

–in areas with potentially explosive atmospheres

– outdoors without sufficient protection against the

effects of weather

– in atmospheres where chemical reactions,

whether planned or unplanned, may cause

damage to the smoke control damper or lead to

corrosion

1.3 Qualified staff

WARNING!

Danger of injury due to insufficiently qualified

individuals!

Incorrect use may cause considerable injury or

damage to property.

– Only specialist personnel must carry out work.

Personnel:

Skilled qualified electrician

Specialist personnel

Skilled qualified electrician

Skilled qualified electricians are individuals who have

sufficient professional or technical training, knowledge

and actual experience to enable them to work on elec-

trical systems, understand any potential hazards related

to the work under consideration, and recognise and

avoid any risks involved.

Specialist personnel

Specialist personnel are individuals who have sufficient

professional or technical training, knowledge and actual

experience to enable them to carry out their assigned

duties, understand any potential hazards related to the

work under consideration, and recognise and avoid any

risks involved.

Safety

General safety notes

Smoke control damper Type EK-JZ6

2 Technical data

2.1 General data

Nominal sizes B x H 200 × 430 – 1200 × 2030 mm

Casing length 250 mm

Volume flow rate range up to 24361 l/s

up to 87700 m³/h

Differential pressure range Pressure level 2, -1000...500 Pa

Operating temperature -30 °C...50 °C the temperature should not fall below the dew

point

Upstream velocity ≤ 10 m/s with the maximum size

>10...15 m/s with smaller sizes, up to 87700 m³/h

Closed blade air leakage EN 1751, Class 3

Casing air leakage EN 1751, Class C

EC conformity EU Construction Products Regulation no. 305/2011

EN 12101-8 – Smoke and heat control systems –

Smoke control dampers

EN 1366-10 – Fire resistance tests for service installa-

tions – Smoke control dampers

EN 1366-2 – Fire resistance tests for service installa-

tions – Part 2: Fire dampers

EN 13501-4 – Fire classification of construction products

and building elements – Fire resistance tests on compo-

nents of smoke control

EN 1751 – Ventilation for buildings – Air terminal

devices

Declaration of performance DoP / EK-JZ / 003

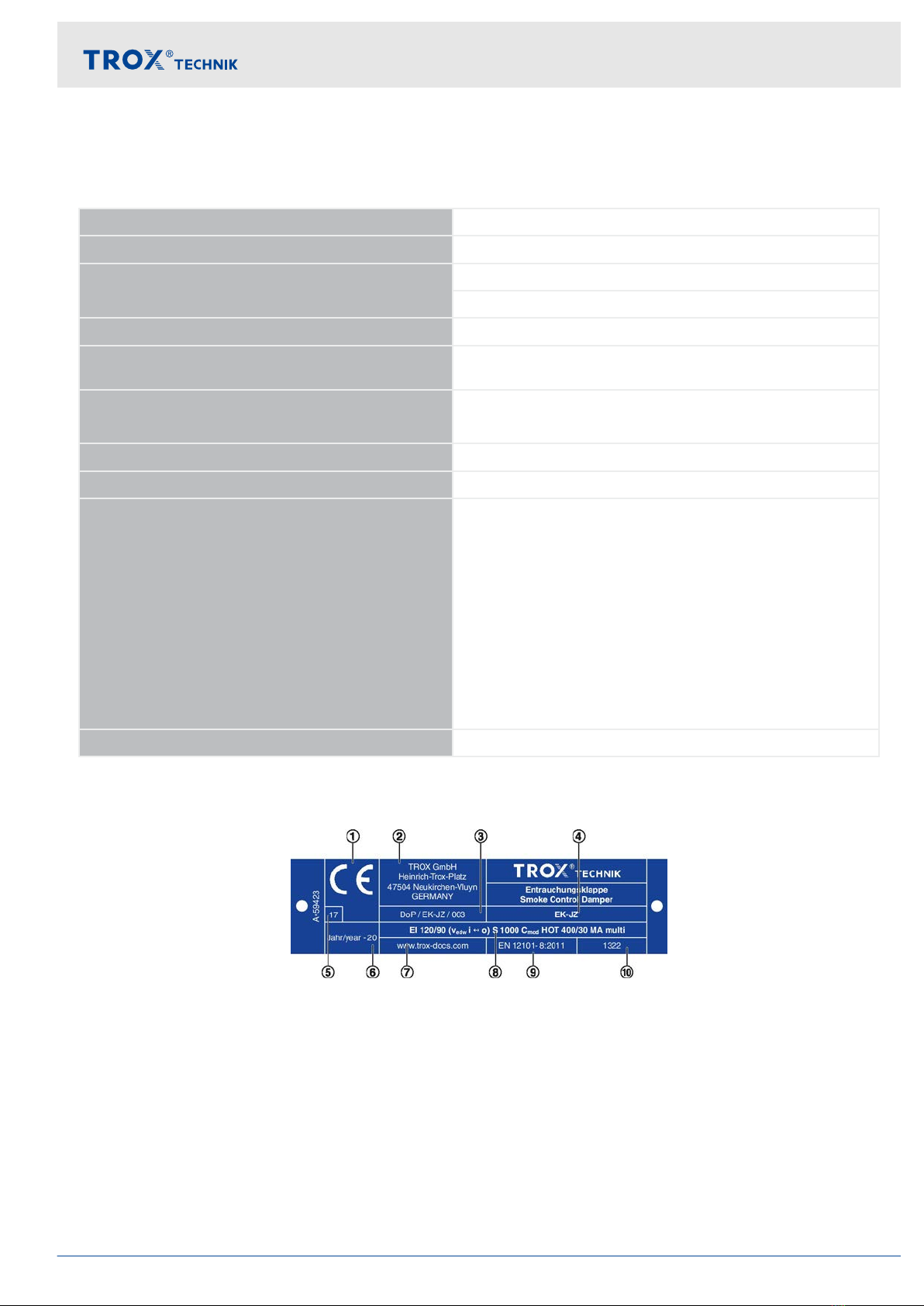

Rating plate

Fig. 1: Smoke control damper rating plate (example)

①CE mark

②Manufacturer's address

③No. of the declaration of performance

④Type

⑤The last two digits of the year in which the CE

marking was affixed

⑥Year of manufacture

⑦Website from which the DoP can be downloaded

⑧Regulated characteristics; the fire resistance class

depends on the application and may vary

⑨Number of the European standard and year of its

publication

⑩Notified body

Technical data

General data

Smoke control damper Type EK-JZ 7

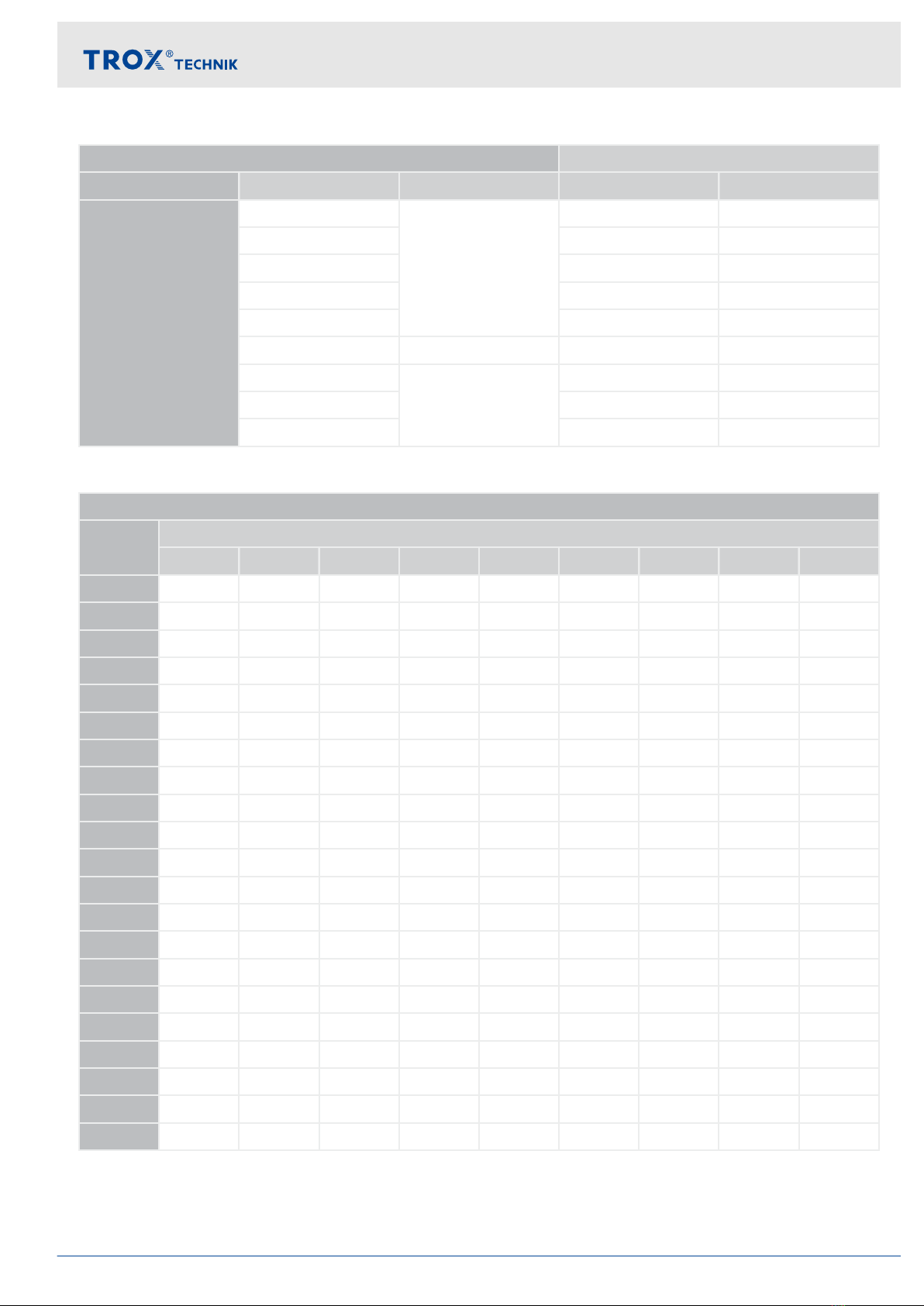

2.2 Dimensions and weight

Fig. 2: EK-JZ

B x H = nominal size = area exposed to the airflow

①Connecting subframe for smoke extract duct

(steel, optional)

②Keep clear to provide access to the actuator

encasing

ⒶInstallation side

ⒷOperating side

Technical data

Dimensions and weight

Smoke control damper Type EK-JZ8

Dimensions [mm] Number

B H C Blades Handles

200..1200

(50 mm)

430 – 2 1

630 3 1

830 4 1

1030 5 1

1230 6 1

1430 550 7 2

1630 650 8 2

1830 9 2

2030 10 2

Weight [kg]

B

[mm]

H [mm]

430 630 830 1030 1230 1430 1630 1830 2030

200 29 37 46 54 62 71 79 87 95

250 31 39 48 56 65 73 82 91 99

300 32 41 50 59 67 76 85 94 103

350 33 43 53 61 70 79 88 98 107

400 35 44 54 63 73 82 92 101 111

450 36 46 56 66 75 85 95 105 114

500 38 48 58 68 78 88 98 108 118

550 39 50 61 70 81 91 101 112 122

600 41 51 62 73 83 94 105 115 126

650 42 53 64 75 86 97 108 119 130

700 44 55 66 77 89 100 111 122 134

750 45 57 69 80 91 103 114 126 137

800 47 58 70 82 94 106 118 129 141

850 48 60 72 84 97 109 121 133 145

900 49 62 75 87 99 112 124 136 149

950 51 64 77 89 102 115 127 140 153

1000 52 65 78 91 104 117 130 143 156

1050 54 67 80 94 107 120 134 147 160

1100 55 69 83 96 110 123 137 150 164

1150 57 71 85 98 112 126 140 154 168

1200 58 72 87 101 115 129 143 158 172

Technical data

Dimensions and weight

Smoke control damper Type EK-JZ 9

3 Transport and storage

Delivery check

Check delivered items immediately after arrival for

transport damage and completeness. In case of any

damage or an incomplete shipment, contact the ship-

ping company and your supplier immediately.

A complete shipment includes:

Smoke control damper(s)

– Attachments/accessories, if any

Installation and operating manual (one per ship-

ment)

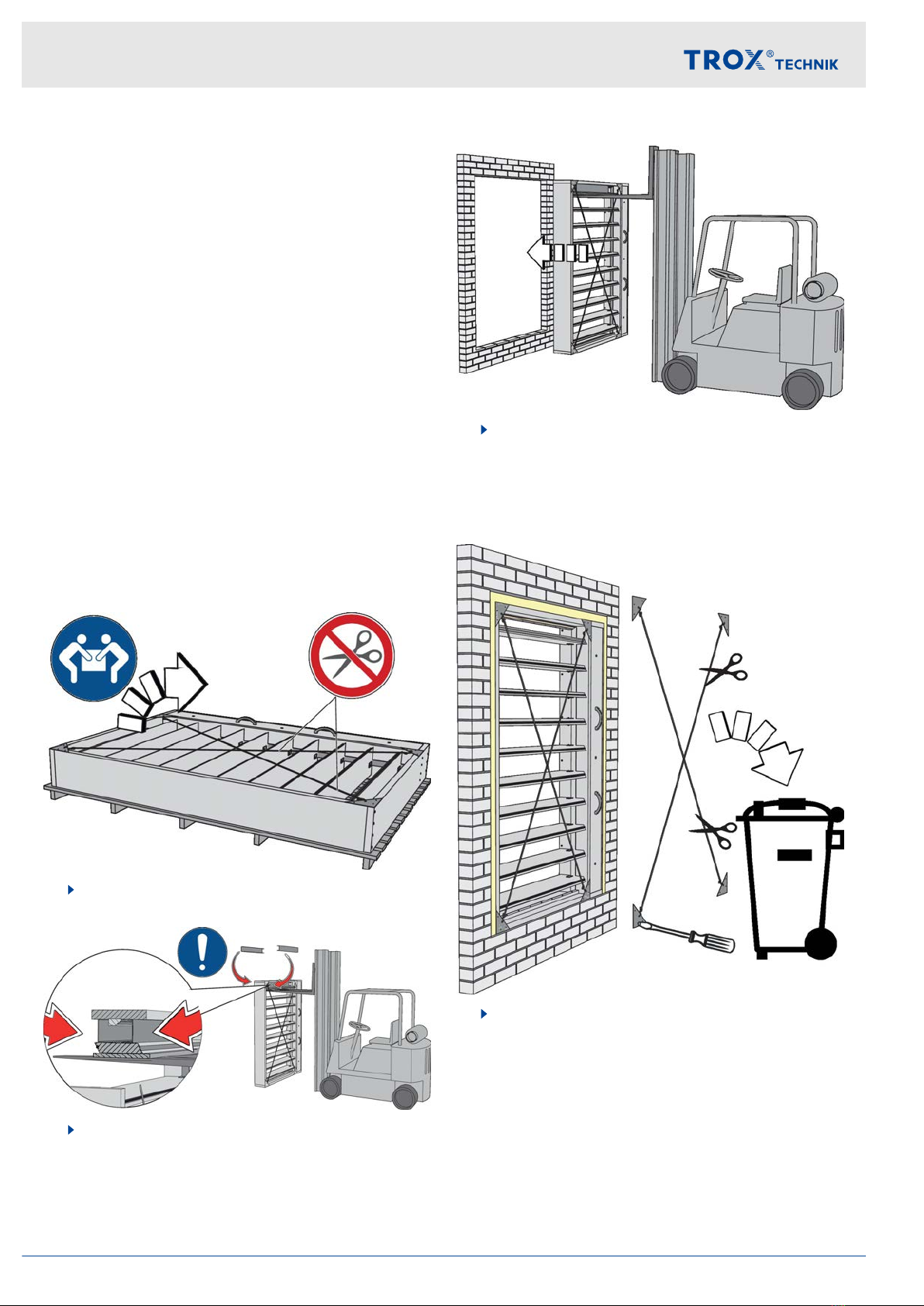

Transport on site

If possible, take the product in its transport packaging

up to the installation location.

Smaller dampers can be lifted and placed in the installa-

tion opening by two people. Ask someone to give you a

hand.

Dampers which are supplied with U channel sections as

a transport aid have to be moved with suitable lifting

equipment, e.g. a forklift truck.

1. Unpack the damper and place it upright on the

floor. Do not remove the straps yet.

2. Place the U channel sections between the upper-

most blade and the frame.

3. Move the fork carefully underneath the uppermost

blade, then lift it. Put a piece of wood or anything

similar between the blade and the fork so as not to

damage the blade.

Carefully lift the smoke control damper with the

forklift truck and place it in the installation opening.

4. Once you have installed the smoke control

damper, remove the straps; in case of mortar-

based installation, remove the straps only after the

mortar has cured. Remove the corner protectors.

Dispose of the straps and corner protectors.

Storage

For temporary storage please note:

Remove any plastic wrapping.

Protect the product from dust and contamination.

Transport and storage

Smoke control damper Type EK-JZ10

Store the product in a dry place and away from

direct sunlight.

Do not expose the unit to the effects of weather (not

even in its packaging).

Do not store the product below -30 °C or above 50

°C.

Packaging

Properly dispose of packaging material.

Transport and storage

Smoke control damper Type EK-JZ 11

4 Parts and function

Smoke control dampers are used in mechanical smoke

extract systems. They are used for extracting smoke

gases and for providing additional supply air to one or

more fire compartments.

Smoke control dampers are made from calcium silicate

boards, and the electric actuator and the optional con-

trol module are encased so that the functional reliability

is ensured even in the event of a fire.

Regular maintenance of the smoke control damper is

required to ensure its functional reliability

Ä

9 ‘Mainte-

nance’ on page 64.

Fig. 3: EK-JZ smoke control damper

①Casing

②Blades

③Blade tip seal (special profile seal)

④Side seal

⑤Travel stop, bottom

⑥Rating plate

⑦Actuator

⑧Cover fixing

⑨Linkage

⑩Actuator encasing

⑪Cover of the actuator encasing (sectional view)

⑫Handle (to remove the cover)

⑬Travel stop, top

Smoke extract

Fig. 4: Smoke extract system

①EK-JZ in a solid shaft wall

②EK-JZ in a solid wall and a duct

③EK-JZ on a solid shaft wall

④On a vertical smoke extract duct (shaft)

⑤On a horizontal smoke extract duct

⑥In a horizontal smoke extract duct

⑦At the end of a horizontal smoke extract duct

⑧EK-JZ as additional supply air inlet

⑨Cover grilles

During normal operation Type EK-JZ smoke control

dampers remain closed. For smoke extract, the smoke

control dampers in the affected fire compartment fully

open so that smoke can be extracted. All other smoke

control dampers remain closed.

In the event of a fire, smoke control dampers that are

used as additional supply air inlets in the affected fire

compartment also open so that smoke can be extracted.

To ensure the creation of a layer that is nearly free from

smoke, smoke control dampers used as additional

supply air inlets should be installed near the ground.

The control input signal for the actuator may come from

a duct smoke detector or from the central fire alarm

system. Using cables with specific circuit integrity for the

supply voltage ensures that the actuator is supplied with

voltage even in the event of a fire and hence that its

function and the communication are maintained.

Supply air and smoke extraction in ventilation sys-

tems

When authorised by building authorities or authorised

bodies, smoke extract and supply air applications as

well as ventilation can be enabled in combined systems

with smoke control dampers. Depending on the system

layout, the damper blade can be fully opened, fully

closed or in the intermediate position. Depending on

where the dampers are installed, country-specific regu-

lations may apply to ventilation applications.

Parts and function

Smoke control damper Type EK-JZ12

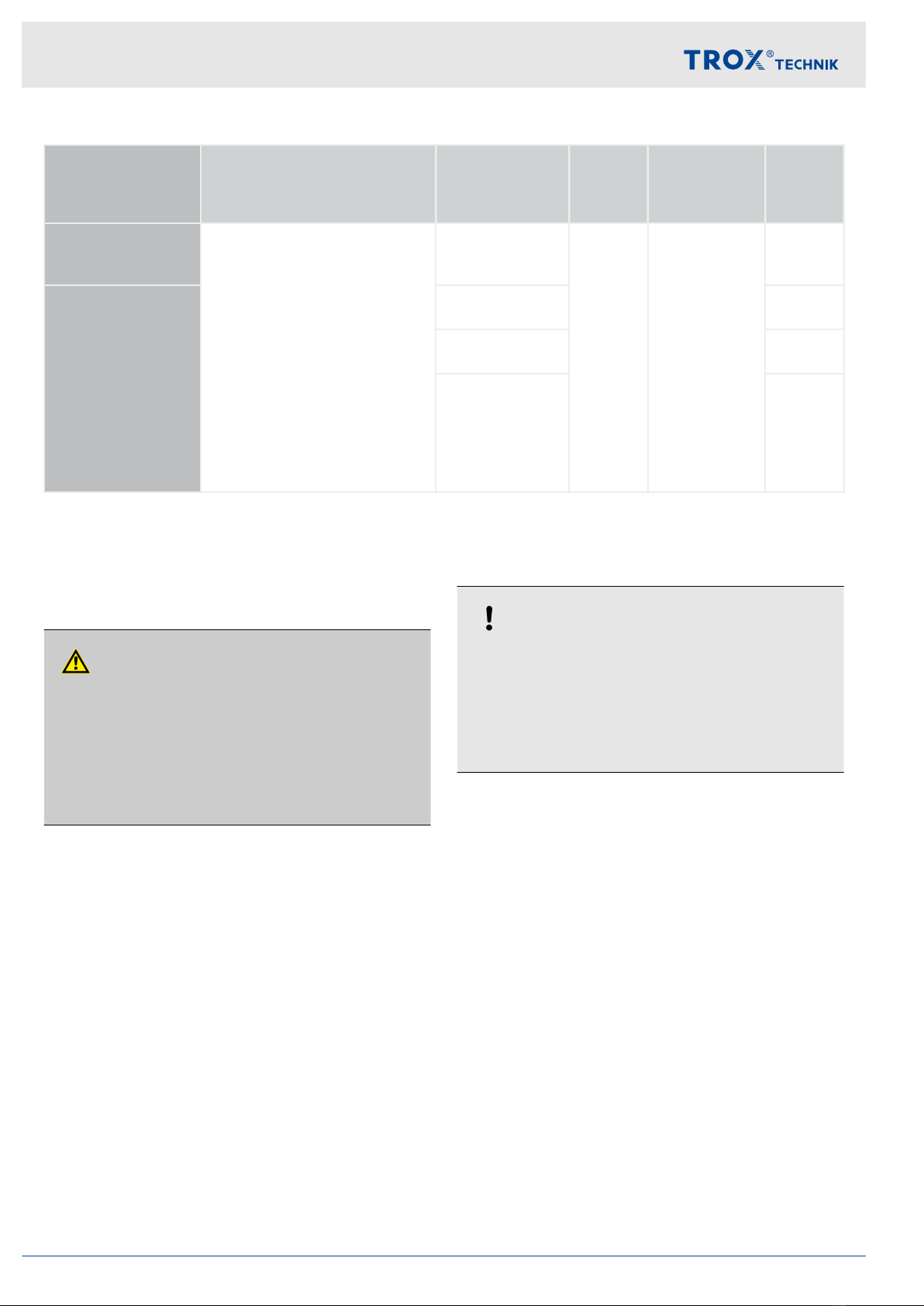

5 Installation

5.1 Installation situations

The table lists the various EK-JZ installation types; for details on the performance level see the declaration of per-

formance.

Installation locations described here may be combined with other installation location characteristics. For example, a

smoke control damper may be installed on a vertical smoke extract duct where a horizontal smoke extract duct

branches off.

Supporting con-

struction

Construction Installation loca-

tion

Installa-

tion type

Performance

level

Installa-

tion

informa-

tion

Solid wall

Concrete, aerated concrete,

bricks

d ≥ 100 mm

ρ ≥ 500 kg/m3

Adjoined installation of two

dampers is possible

EN 1366-8 (smoke extract

ducts for multi compart-

ments can be used)

EN 1366-9 (smoke extract

ducts for single compart-

ments can be used)

In a solid wall

(wall is not part of

the smoke extract

duct)

NEI 120

(Vew, i↔o)

Ä

26

T / N EI 120

(Vew, i↔o)

Ä

23

TEI 90

(Vew, i↔o)

Solid shaft wall as

part of a smoke

extract duct

In a shaft wall

(the shaft is part

of a smoke

extract duct)

N

T;

N is pos-

sible on

one side EI 120

(Ved, i↔o)

Ä

23

On a shaft wall

(the shaft is part

of a smoke

extract duct)

T

Ä

32

Lightweight shaft

wall

Plasterboard fire barrier 2 x

20 mm

d ≥ 90 mm

In a shaft wall

(the shaft is part

of a smoke

extract duct)

T/N EI 90

(Vedw, i↔o)

Ä

36

Lightweight parti-

tion wall

Plasterboard fire barrier 2 x

12.5 mm

d ≥ 100 mm

In a lightweight

partition wall, the

wall is not part of

the smoke extract

duct

T/N EI 90

(Vew, i↔o)

Ä

38

Solid ceiling slabs

Concrete, aerated concrete

d ≥ 150 mm

ρ ≥ 550 kg/m3

EN 1366-8 (smoke extract

ducts for multi compart-

ments can be used)

EN 1366-9 (smoke extract

ducts for single compart-

ments can be used)

in solid ceiling

slab NEI 120

(how, i↔o)

T = dry mortarless installation, N = mortar-based installation, LE = as specified for the duct

Installation

Installation situations

Smoke control damper Type EK-JZ 13

Supporting con-

struction

Construction Installation loca-

tion

Installa-

tion type

Performance

level

Installa-

tion

informa-

tion

Fire-resistant ver-

tical smoke extract

duct

Firestop board (calcium sili-

cate)

d ≥ 35 mm

ρ ≥ 500 kg/m3

Perimeter strips (i.e. on four

sides)

Adjoined installation of two

dampers is possible

EN 1366-8 (smoke extract

ducts for multi compart-

ments can be used)

EN 1366-9 (smoke extract

ducts for single compart-

ments can be used)

on a vertical duct

LE EI 120

(Ved, i↔o)

Ä

42

Fire-resistant hori-

zontal smoke

extract duct

on a horizontal

duct

Ä

44

in a horizontal

duct

Ä

46

at the end of a

horizontal duct

Ä

48

T = dry mortarless installation, N = mortar-based installation, LE = as specified for the duct

5.2 Safety notes regarding installation

Sharp edges, sharp corners and thin sheet metal

parts

CAUTION!

Danger of injury from sharp edges, sharp cor-

ners and thin sheet metal parts!

Sharp edges, sharp corners and thin sheet metal

parts may cause cuts or grazes.

– Be careful when carrying out any work.

–Wear protective gloves, safety shoes and a hard

hat.

5.3 General installation information

NOTICE!

Be careful to not damage the smoke control

damper

– Protect the smoke control damper from contami-

nation and damage.

–Cover the flange openings and the actuator (e.g.

with plastic) to protect them from mortar and

dripping water.

Please note:

The smoke control damper has to be installed so

that the damper blade shaft is horizontal.

Smoke control damper and electric actuator

(encasing) must remain accessible for maintenance.

Make sure that no loads are imposed on the casing

as this may impair the function of the smoke control

damper.

Install the smoke control damper without torsion

(horizontal/vertical).

Mortar-based installation: The installation gap must

be large enough so that mortar can be filled in even

in case of thicker walls/ceilings.

Requirements for wall systems

EK-JZ smoke control dampers may be installed in wall

systems if these walls have been erected in compliance

with regulations and the manufacturers' instructions,

and if the information on the respective installation sit-

uation applies and the following requirements are met.

Provide any installation openings according to the

installation details in this manual.

Installation

Safety notes regarding installation

Smoke control damper Type EK-JZ14

Solid walls or solid shaft walls

Solid walls or solid shaft walls made of, for example,

concrete, aerated concrete or bricks, gross density

≥ 500 kg/m³.

Wall thickness W ≥ 100 mm.

Provide each installation opening according to the

local and structural conditions and with regard to the

dimensions of the smoke control damper.

Lightweight partition walls with metal support struc-

ture

Lightweight partition wall with metal support or steel

support structure, with European classification to

EN 13501-2 or equivalent national classification.

Cladding on both sides made from plasterboard fire

barriers.

Wall thickness W ≥ 100 mm.

≤ 625 mm distance between metal studs.

Create an installation opening with trimmers (studs

and noggings).

Trim panels and a support extension must be pro-

vided and screw-fixed to the support structure.

Additional layers of cladding (if stated in the usability

certificate for the wall) and double stud construc-

tions are approved.

Connect the metal sections near the installation

opening according to the installation details in this

manual.

Shaft walls with metal support structure

Shaft walls or additional leaves with metal support

structure or steel support structure, with European

classification to EN 13501-2 or equivalent national

classification.

Cladding on one side made from plasterboard fire

barriers.

Wall thickness W ≥ 90 mm (cladding according to

installation details).

≤ 625 mm distance between metal studs.

Be sure to follow the manufacturers' instructions for

the height, width and thickness of walls.

Create an installation opening with trimmers (studs

and noggings).

Trim panels and a support extension must be pro-

vided and screw-fixed to the support structure.

Ensure accessibility to the shaft from the rear.

5.3.1 Installation materials

Mineral wool infill

Unless stated otherwise in the installation details, use

mineral wool with a gross density or compact density of

≥ 80 kg/m³ and a melting point of ≥ 1000 °C.

Fig. 5: Installation gap

①Wall

②Mineral wool

③Ablative coating (if required)

④EK-JZ

For a smooth look you can apply ablative coating of one

of the following types to the mineral wool in the installa-

tion gap:

Hilti:

–Ablative coating CFS-CT

Hensel:

– Ablative coating HENSOMASTIK 5 KS Farbe

Promat:

– Ablative coating Promastopp-CC

Acceptable mortars for mortar-based installation

In case of mortar-based installation, the open spaces

between the fire damper casing and the wall or ceiling

slab must be closed off with mortar. Entrapped air is to

be avoided. The mortar bed depth should be equal to

the thickness of the wall but must be at least 100 mm.

The following mortars are acceptable:

DIN 1053: Groups II, IIa, III, IIIa; fire protection

mortar of groups II, III

EN 998-2: Classes M 2.5 to M 10 or fire protection

mortar of classes M 2.5 to M 10

Equivalent mortars that meet the requirements of

the above standards, gypsum mortar or concrete

Installation

General installation information > Installation materials

Smoke control damper Type EK-JZ 15

Fixing tab for wall installation

With mortar bed widths of s ³40 mm, attach a fixing tab

to the damper frame and spread open prior to mortar-

fixing.

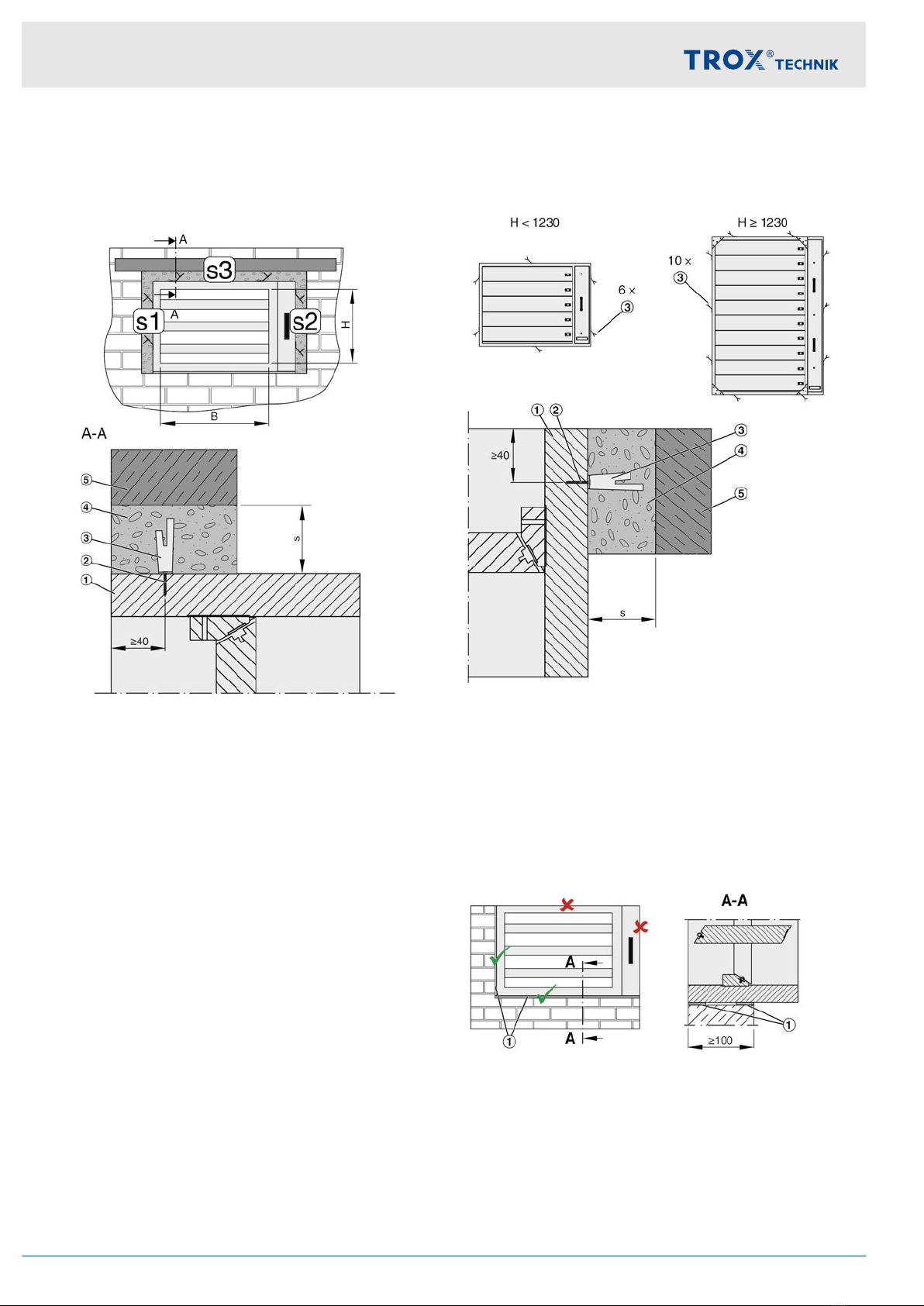

Fig. 6: EK-EU mortar-based installation with fixing tab

1 EK-JZ

2 Chipboard screw Æ3x25 mm (accessories)

3 Fixing tab (accessories)

4 Mortar bed

5 Solid shaft wall or solid wall

s Mortar bed width (installation gap)

The fixing tab is not needed if the installation of the

damper is partly dry and mortarless and there is a screw

connection in the installation gap S1 and S3.

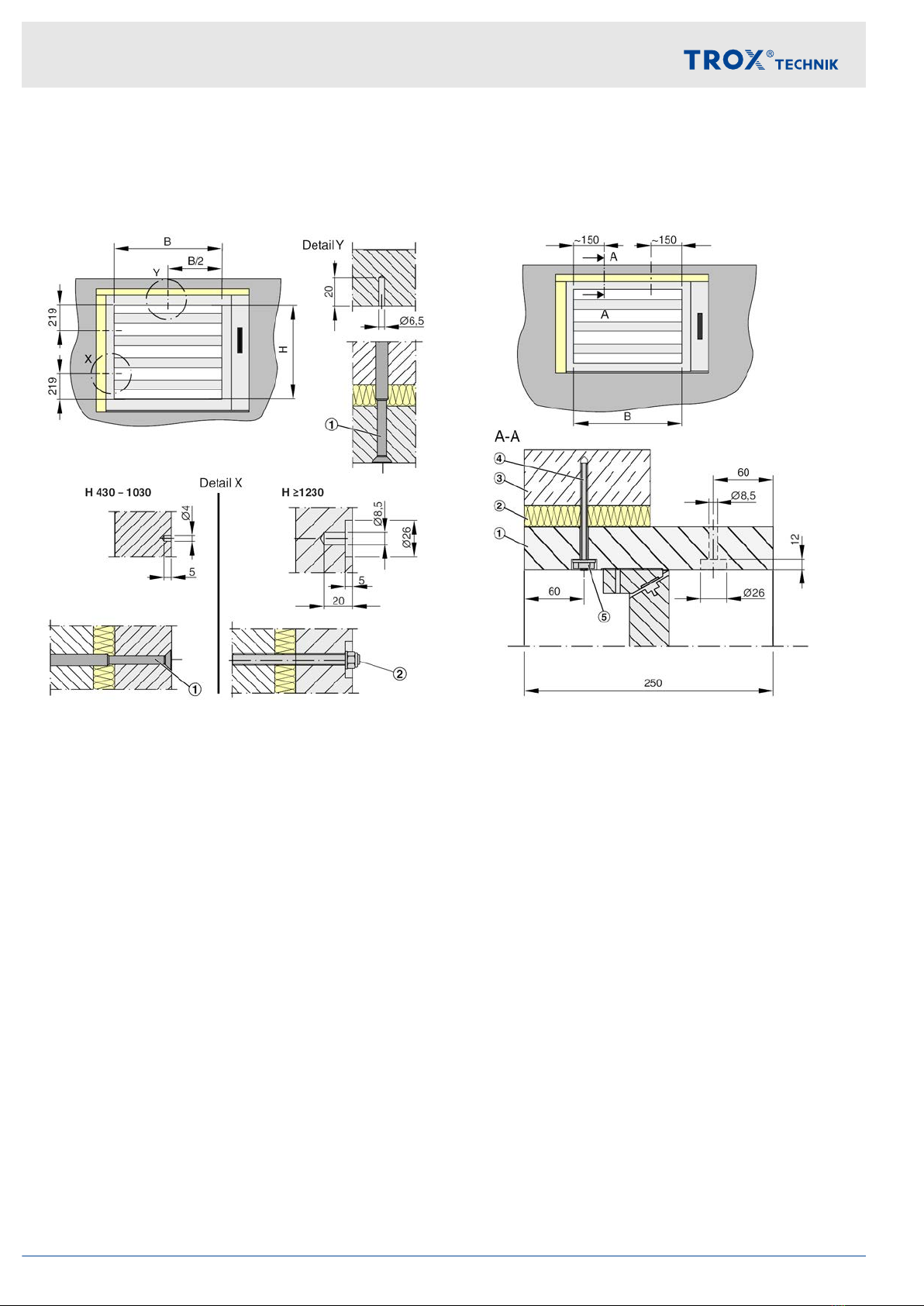

Fixing tab for ceiling slab installation

Before the subframe is mortared in, the fixing tabs on

the damper frame must be bent and spread.

Fig. 7: EK-EU mortar-based installation with fixing tab

1 EK-JZ

2 Chipboard screw Æ3x25 mm (accessories)

3 Fixing tab (accessories)

4 Mortar bed

5 Solid ceiling slab

s Mortar bed width (installation gap)

High-temperature sealing tape

Fig. 8: Affix the sealing tape

Affix the high-temperature sealing tape (Fig. 8/1) with

trim panel thickness (flush at front and rear) to the

damper frame (if necessary, mark the trim panel thick-

ness beforehand). Do not glue the ceramic fibre

paper onto the wall or trim.

Installation

General installation information > Installation materials

Smoke control damper Type EK-JZ16

Permitted use (depending on installation situation)

Lower damper frame

Damper frame on non-drive side

The high-temperature sealing tape (melting point

1200 °C) is – unless otherwise agreed – included in the

supply package.

Impregnation and coating

Impregnation (included in the supply package unless

otherwise agreed) or coating of the smoke control

damper for colour adjustment is acceptable if:

Mass per unit area ≤ 1.0 kg/m²

or thickness ≤ 0.5 mm

Apply only to calcium silicate surfaces, never to a

seal

Impregnation

–Promat GmbH - Impregnation 2000

– Promat GmbH - SR Impregnation

– Promat GmbH - Tunnel Impregnation

Coating

– Commercially available emulsion paint

Installation

General installation information > Installation materials

Smoke control damper Type EK-JZ 17

5.3.2 Fixing points

The frame of the smoke control damper has pre-drilled

connection points that are used to screw-fix the damper

to the wall.

Fig. 9: EK-EU pre-drilled attachment options

1 e.g. concrete screw with countersunk head

2 Threaded bolts with nut and washer M8

Note: The fixing elements must not protrude on the

inside of the damper frame. Contact with the damper

blade will damage the damper blade and the entire

damper will need to be replaced.

Additional fixing points

If the pre-drilled fixing points cannot be used or addi-

tional drilled holes are needed, these must be provided

as follows in the damper frame.

Fig. 10: Create additional fixing options

1 EK-JZ

2 Mineral wool or high-temperature sealing tape

3 Solid shaft wall or solid wall

4 Wallplug with fire safety engineering certification

and threaded bolts M8

5 Washer, nut M8

Number of fixing points

B < 800 mm - 1 fixing point

B ³ 800 mm - 2 fixing points

Note: The fixing elements must not protrude on the

inside of the damper frame. Contact with the damper

blade will damage the damper blade and the entire

damper will need to be replaced.

Installation

General installation information > Fixing points

Smoke control damper Type EK-JZ18

5.3.3 Adjoined damper installation

Side by side

The vertical frame section opposite the actuator

encasing has markings that indicate where the screw

holes to join dampers have to be drilled. If additional or

alternative fixing points are required, these must be pro-

vided as described under

Ä

5.3.2 ‘Fixing points’

on page 18.

Fig. 11: EK-JZ dampers side by side (left side construc-

tion and right side construction)

1 Dry wall screw 4.5 x 70 mm or 5.0 x 70 mm

2 Hexagon head screw M8 x 90 mm or threaded rod

M8 with washers and nuts

On top of each other

Screws can be set anywhere on the horizontal frame

sections; leave approx. 200 mm between screws,

approx. 40 mm between screws and edges; predrill

holes if necessary. Insert screws both from the top

damper and from the bottom damper; do not insert all

screws in one line, but in an offset pattern.

Fig. 12: EK-JZ dampers on top of each other (right side

construction)

1 Dry wall screw 4.5 x 70 mm or 5.0 x 70 mm

If you need more than two dampers sidy by side or on

top of each other, consult with TROX to determine if this

is technically feasible.

Installation

General installation information > Adjoined damper installation

Smoke control damper Type EK-JZ 19

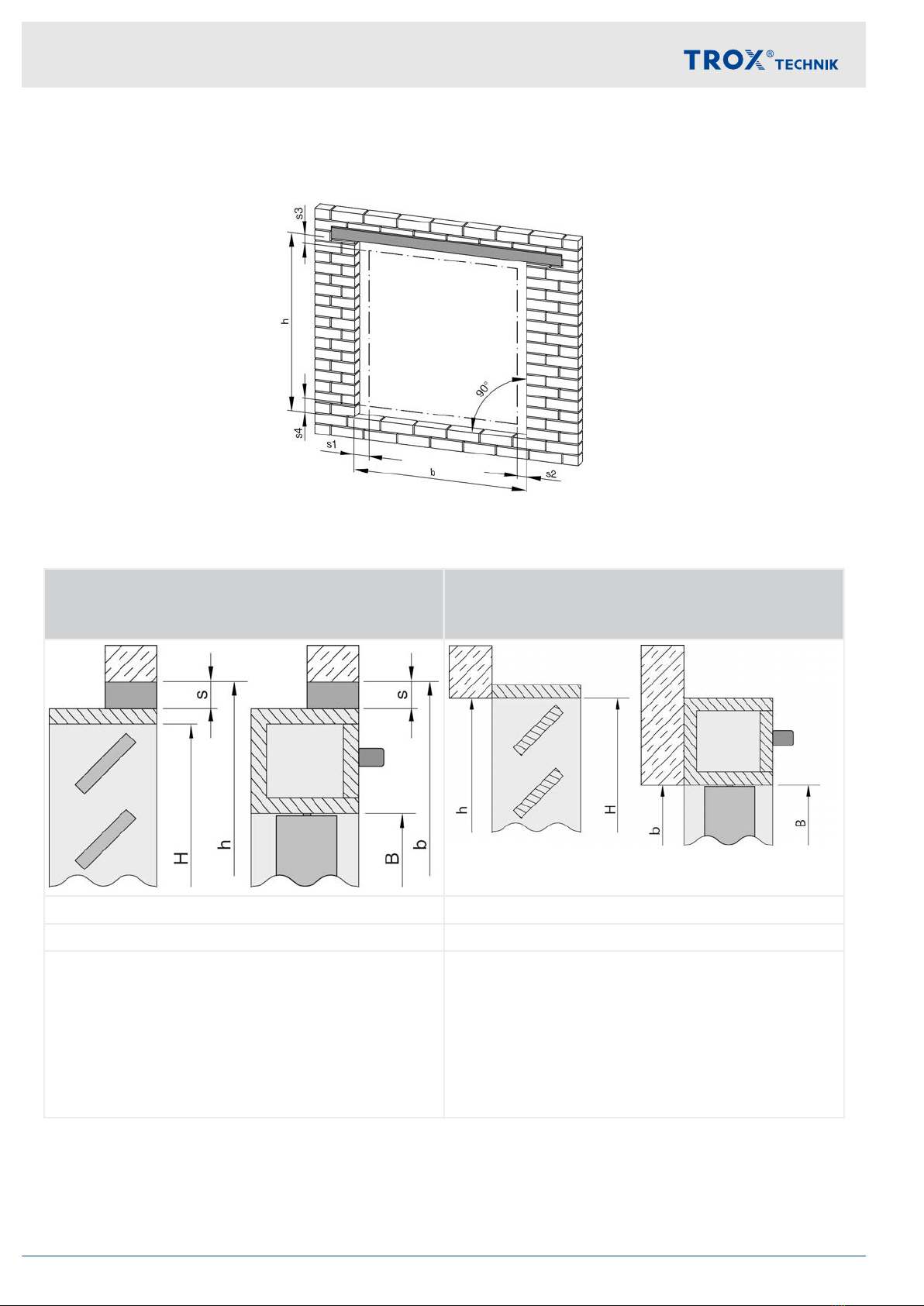

5.4 Solid walls or solid shaft walls

5.4.1 Installation opening

Fig. 13: Ideal installation opening

in

solid wall or shaft wall

on

solid wall, shaft wall or fire-resistant smoke extract

duct

b = [B + 280 mm] + s1 + s2 b = nominal width B

h = [H + 80 mm] + s3 + s4 h = nominal height H

b / h= [nominal size B / H + damper casing] + installation

gap

The installation gap (s) is dependent on the filling mate-

rial used:

Fibre paper: 3-5 mm

Mortar: up to 150 mm

Mineral wool: 10 to 40 mm

Ideally, the installation opening is equal to the nominal

size of the smoke control damper. For installation on a

wall, however, the installation opening may also be

smaller than the nominal size of the damper, for

example, when no damper standard height fits the instal-

lation opening exactly. In such a case you have to make

sure that there is enough clearance to install the

damper.

Installation

Solid walls or solid shaft walls > Installation opening

Smoke control damper Type EK-JZ20

Other manuals for EK-JZ

1

Table of contents

Other Trox Fire And Smoke Damper manuals

Popular Fire And Smoke Damper manuals by other brands

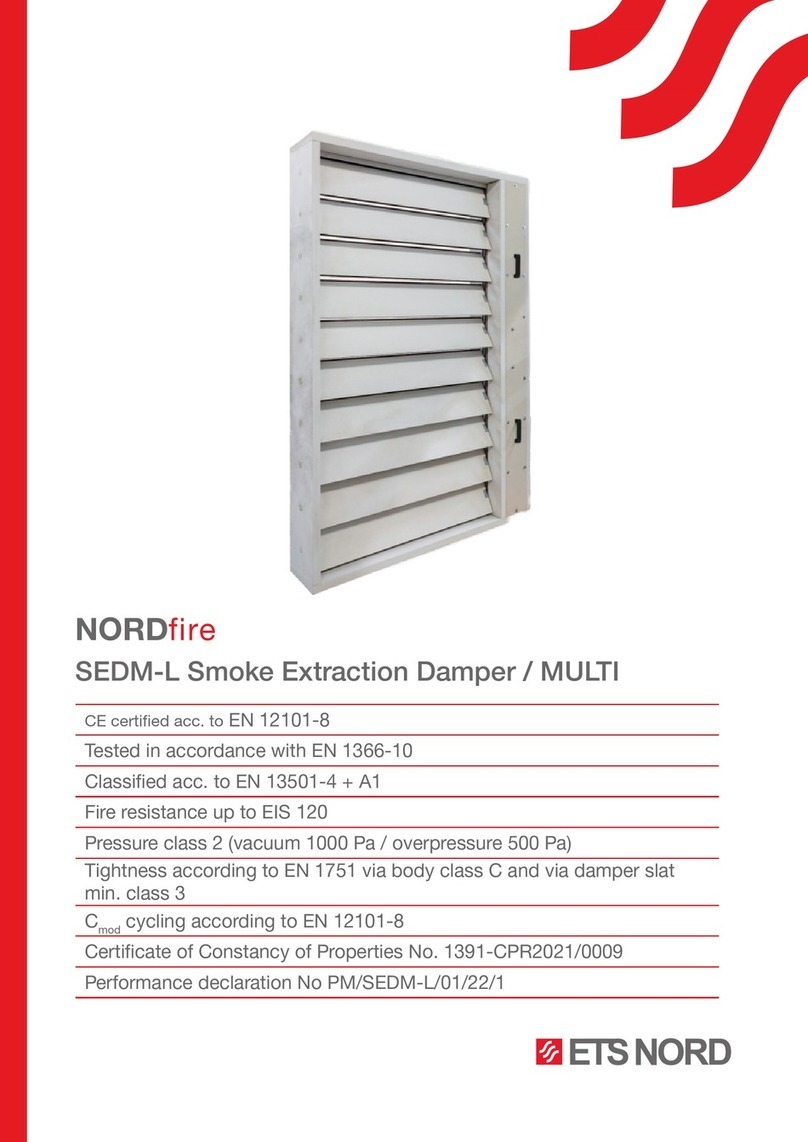

ETS NORD

ETS NORD NORDfire SEDM-L manual

Honeywell Home

Honeywell Home TrueZONE ARD Series installation instructions

Greenheck

Greenheck FD150X Installation, operation and maintenance instructions

Lindab

Lindab RECTANGULAR Series Installation booklet

System air

System air FDR-3G EX Series Handbook

Rf-t

Rf-t CR120 user manual

System air

System air PKIR-E60S Installation, operation and maintenance instructions

Greenheck

Greenheck FSD Series Installation instruction supplement

Mandik

Mandik SEDS-R manual

Swegon

Swegon actionair DWFX-F installation guide

klimaoprema

klimaoprema FDSD product manual

HVC

HVC NCA 700 Series Operation and maintenance manual