Table of Contents

1Safety precautions ................................................................................................................ 4

1.1 Warning symbols ..................................................................................................................... 4

1.2 General safety.......................................................................................................................... 4

1.3 Stopping the PS-5..................................................................................................................... 6

1.4 Hydrogen gas safety................................................................................................................. 8

1.5 Electrical safety........................................................................................................................ 9

1.6 Disposal.................................................................................................................................... 9

1.7 Field Support............................................................................................................................ 9

2Introduction.........................................................................................................................10

2.1 Type selection guide .............................................................................................................. 10

2.2 Disclaimer............................................................................................................................... 10

2.3 About this manual.................................................................................................................. 10

2.4 Definitions and abbreviations................................................................................................ 11

3System description...............................................................................................................12

3.1 Overview................................................................................................................................ 12

3.2 Fuel cell module..................................................................................................................... 12

3.3 Cooling module...................................................................................................................... 14

3.4 Power and electronics module (PE)....................................................................................... 15

4Installation ..........................................................................................................................16

4.1 Tools and Materials................................................................................................................ 16

4.2 Pre-installation requirements................................................................................................ 16

4.3 Electrical connections ............................................................................................................ 21

4.4 Lifting instruction................................................................................................................... 21

4.5 Internal system connections.................................................................................................. 23

4.6 External system connections ................................................................................................. 24

4.7 Pre-Start Testing .................................................................................................................... 26

4.8 First Start................................................................................................................................ 26

4.9 Optional External Component ............................................................................................... 26

5Operation ............................................................................................................................27

5.1 Quick Guide............................................................................................................................ 27

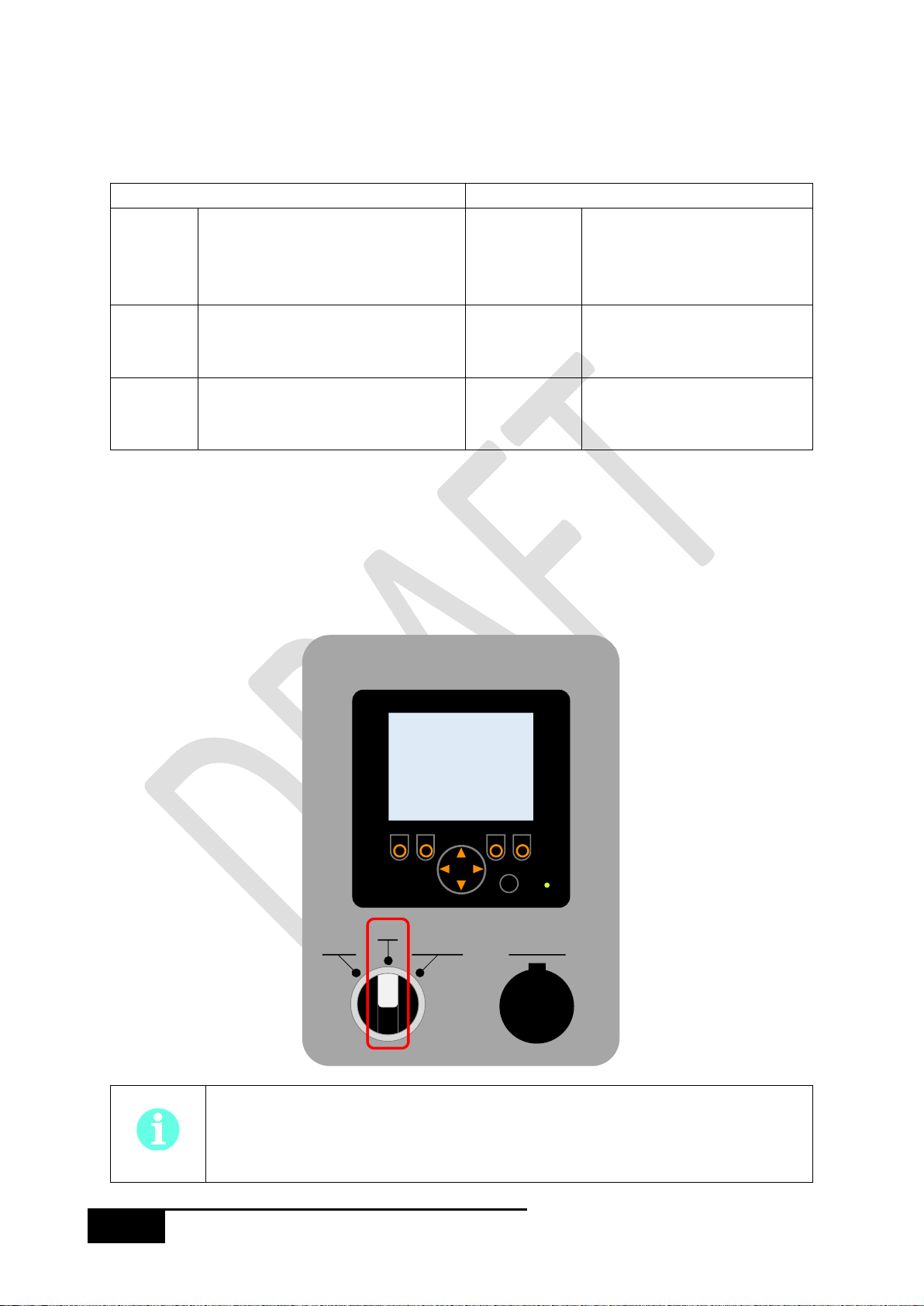

5.2 User interface......................................................................................................................... 29

5.3 Remote Control Mode ........................................................................................................... 33

6Troubleshooting...................................................................................................................34

6.1 Alarm Stop........................................................................................................................... 34

6.2 Alarm Shutdown ................................................................................................................. 36

6.3 Warnings................................................................................................................................ 38

7Service and Maintenance .....................................................................................................39

7.1 Service intervals..................................................................................................................... 39

7.2 Cleaning.................................................................................................................................. 39

7.3 Changing coolant ................................................................................................................... 40

7.4 Replacing the air filter............................................................................................................ 40

7.5 Replacing fuses ...................................................................................................................... 41

7.6 Hydrogen sensor replacement............................................................................................... 41

8Replacement and additional parts ........................................................................................42

8.1 Coolant................................................................................................................................... 42

8.2 Filter....................................................................................................................................... 42

8.3 Fuses ...................................................................................................................................... 42