8 GB/IE/NI

J On no account use the lashing strap if:

- there are broken threads or cuts in the thread, especially if the edges have been

nicked or there are other alarming cases of damage

- the labelling is missing or is no longer legible

- there is damage to the connections, or deformation due to exposure to heat (friction,

radiation)

- there is damage due to the effect of corrosive substances.

J On no account use the ratchets if:

- there are incipient tears, breakages or considerable cases of or damage from corrosion

- there is widening > 5% (5% in the hook mouth or general deformation)

- there is visibly permanent deformation of load-bearing parts

J Repairs to the lashing straps may only be carried out if the information regarding the

manufacturer, material and maximum permissible tensile load is clearly designated on

the label. They may only be carried out by the manufacturer or a person specified by

him. Following repair, the manufacturer or the person designated by the manufacturer

must ensure that the maximum permissible tensile load of the lashing straps as originally

specified on the label is maintained.

J Never exceed the permissible tensile load of the lashing strap as stated on the label.

(see also “Technical data”).

J Choose the most suitable lashing strap in accordance with the intended load that needs

to be lashed down, the tensile load and loading surface (see label).

CAUTION! DANGER OF ACCIDENT! When lashing using additional fittings and

lashing devices, make sure that they are suitable for the lashing strap.

J Check that the vehicle parts you wish to strap the load to are sturdy enough.

CAUTION! In addition to the accelerating forces, wind may cause lateral forces to arise

during the journey.

J Never pull the lashing strap over rough surfaces or sharp edges if they are not furnished

with suitable protection.

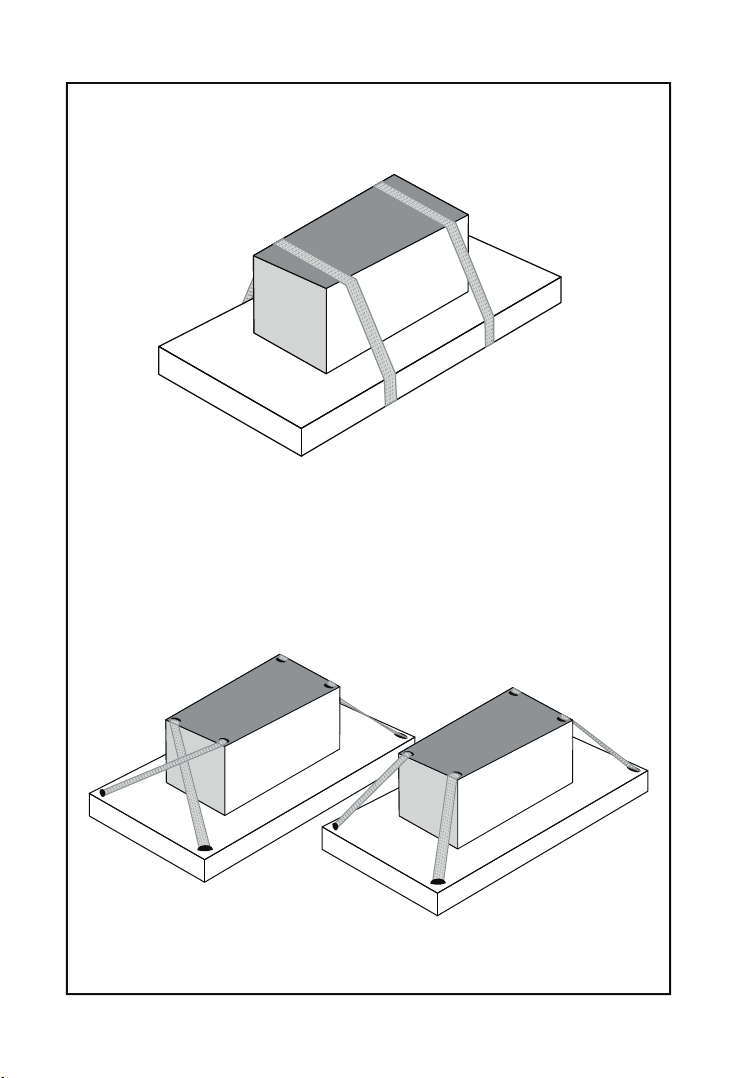

J Make sure that the lashing straps are not twisted and that the load is distributed across

their entire width.

J Do not place any objects onto the lashing strap if this may damage it.

J Keep lashing strap away from hot surfaces.

J Evenly distribute the lashing straps on the load to be secured.

J Never use the lashing straps to lift loads.

J Make sure you do not put any load on the tip of the S hook unless it is a hook that is

designed for such a purpose. To avoid detachment of a lashing hook without a lock in

a lashing point on the loading surface, suspend from the inside outwards.

J Never attach S hooks and ratchets to edges.

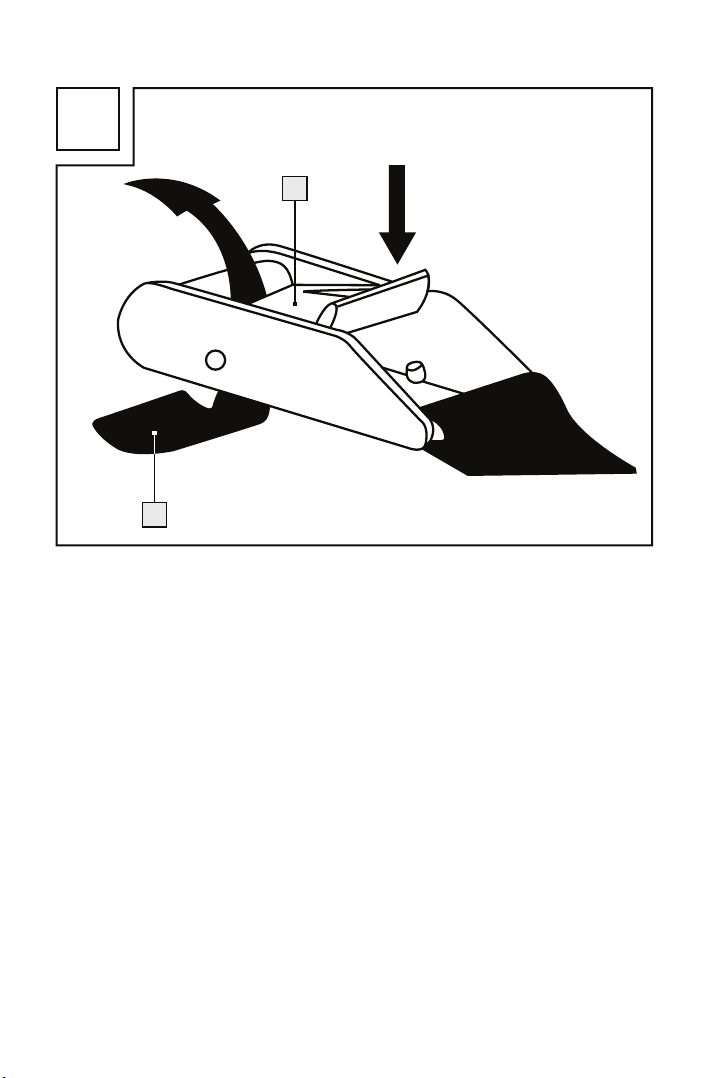

J Never extend the ratchet handle to achieve greater tensioning forces if this is not

expressly allowed by an instruction.