HPS126-HPS67 Horizontal Panel Scoring Saw

The Gold Standard Since 1921.

Whether you need a full 10.5' cut on

long panels, or you have space constraints

yet still need the features of a big saw,

Powermatic has the right saw for you.

■

Both of these machines feature a generous

size sliding carriage assembly that travels

effortlessly on precision ball bearings

guided by hardened and ground support

rods. Heavy walled extrusions on both

the slider and support beam eliminate

distortion and twist found on some

machines. All carriage parts are hard

anodized to prevent marring of the

workpiece and insuring the life of the

parts.

■

Saw bodies of heavy steel plate

are full seam welded to provide a strong

platform and base leveling screws assure

an accurate installation. Crosscut tables

are box-welded components and cross

braces that are full seam welded to

prevent distortion, even with the heaviest

loads. A two position cross cut fence with

extension and dual flip stops make short

work of big jobs quickly and accurately.

■

The main table of cast iron supports the

rugged rip fence, which locks on a solid

steel guide bar. The rip fence features a

dual position fence body and has a micro-

adjust for precise cuts.

■

The main saw

unit consists of massive steel plate that

carries the main and scoring motors.

All rise/fall and tilting controls are fully

enclosed to prevent dust contamination.

Blades and riving knives are shrouded

under the table and have dust collection

and blade brushes to minimize nuisance

dust.

■

Other features include: Dual dust

collection ports, Overarm blade guards

with dust collection, Full size miter gage

with fence, extension, stock clamp and

flip stop. Auxiliary panel supports, Rear

out-feed extension table, Right side

extension table. Self-braking motors,

Independent external scoring adjustment

with separate switch. All this and a host

of other features are included.

■

The long

and short of it is: if you are working sheet

goods, Powermatic has the saw for you.

FEATURE

Saw body constructed of heavy

steel plate and full seam welded

Heavy walled extra-wide carriage

assembly travels on ball bearings

and hardened steel ways

71/2HP main and 3/4HP scoring

motors mounted on massive

steel plate

Auxiliary stock rollers on crosscut

carriage and ripping position

Extra long dual position crosscut

Auxiliary long stock squaring

attachment travels on rail

Swing away guard with 4-inch

dust port

Both blades shrouded and

Includes blade brushes

Easy access controls

BENEFIT

Basis for a rock solid platform and

insures accuracy of machine

Eliminates distortion of carriage under

load and glides effortlessly through

the cut

Assures constant alignment with no

deflection for excellent cutting results

Ease of handling large workpieces

Accurate crosscuts in any position

and ease of handling

Allows user to square long work while

using carriage

Fast tooling changes and a clean

work environment

Exceptional dust collection with

minimized noise

Fast set-ups for blade adjustments

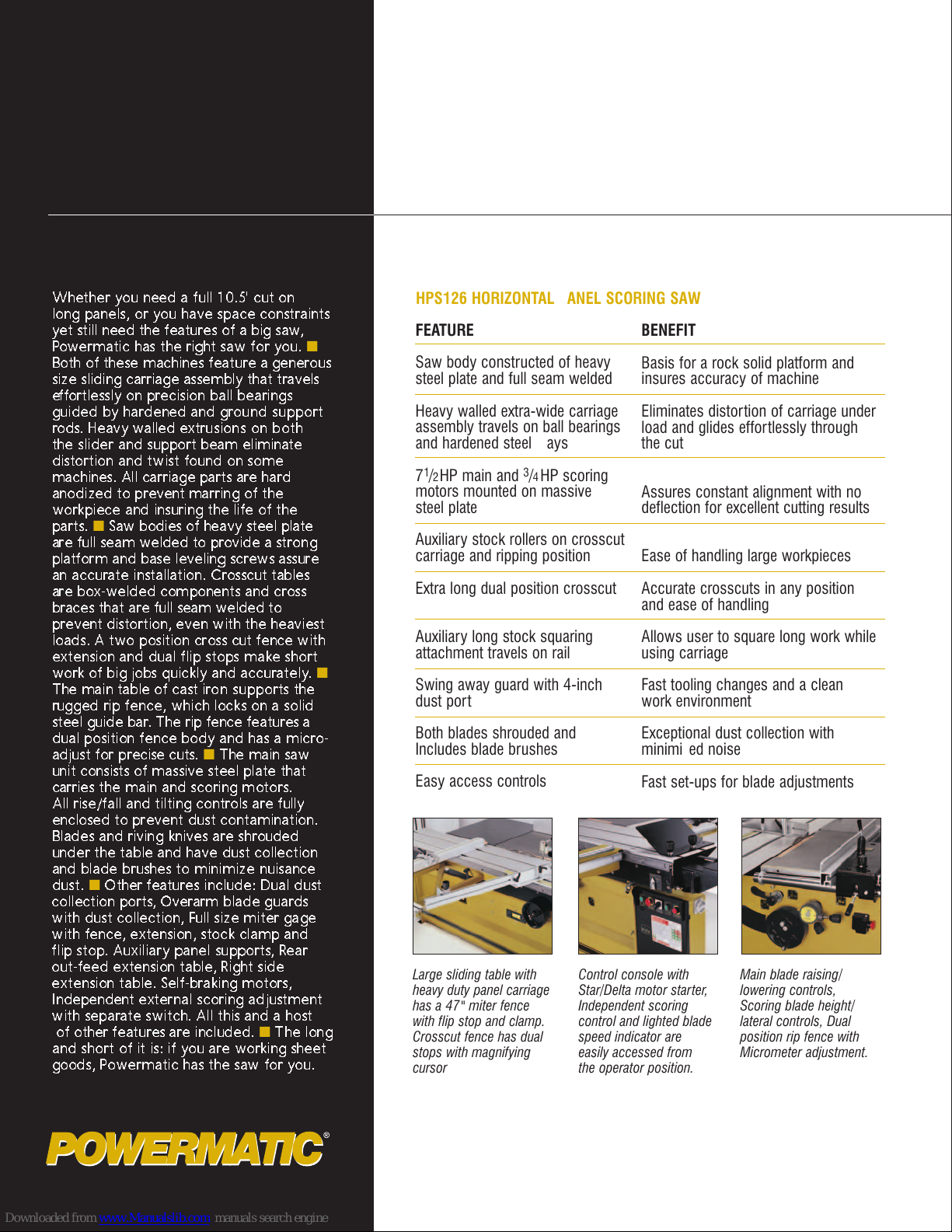

Large sliding table with

heavy duty panel carriage

has a 47" miter fence

with flip stop and clamp.

Crosscut fence has dual

stops with magnifying

cursor.

Control console with

Star/Delta motor starter,

Independent scoring

control and lighted blade

speed indicator are

easily accessed from

the operator position.

Main blade raising/

lowering controls,

Scoring blade height/

lateral controls, Dual

position rip fence with

Micrometer adjustment.

HPS126 HORIZONTAL PANEL SCORING SAW