P70626014V

lnstallation

WIREINSTALLATION

FROMTHESWITCH

TO

THE

CONTHOL

UNIT

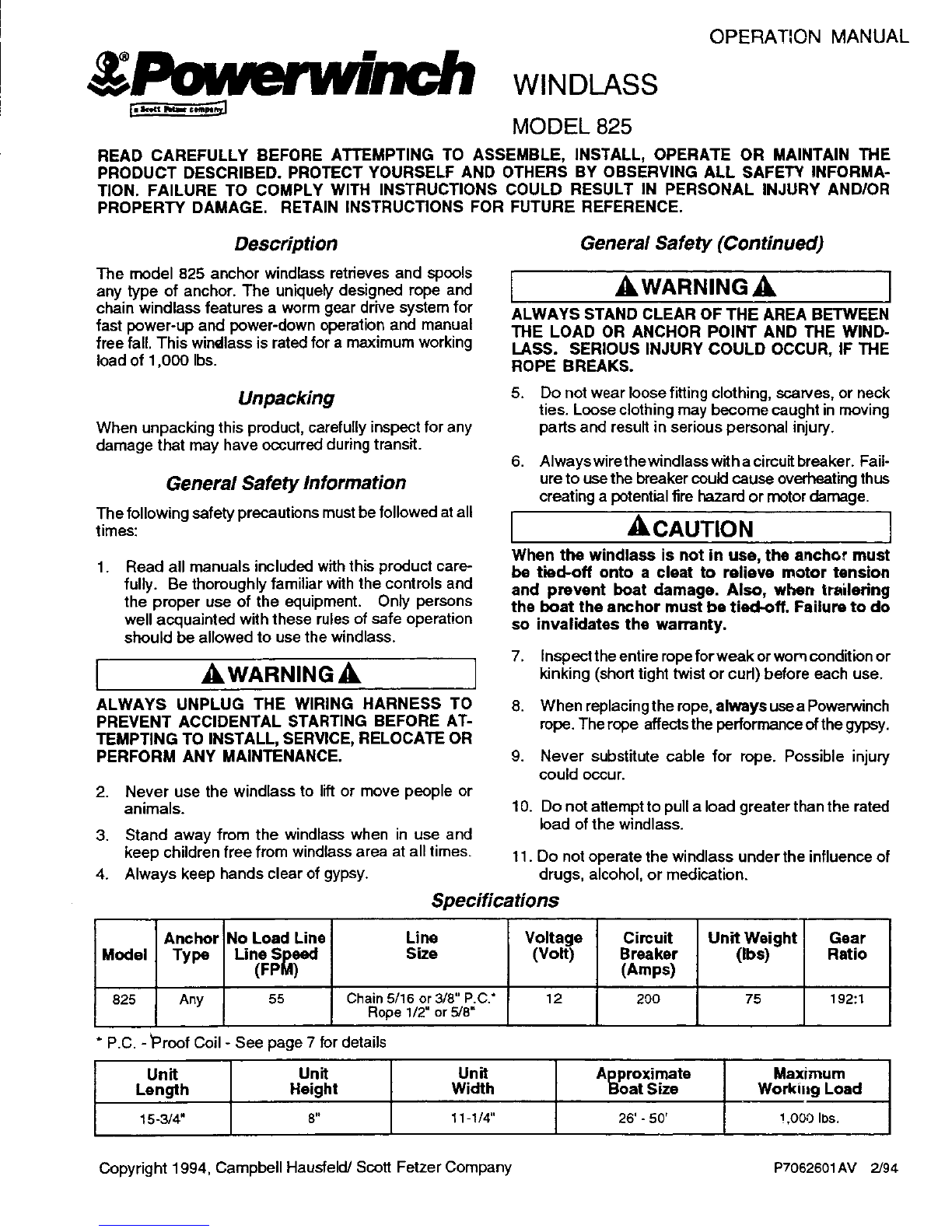

Towiretheswitchlothecontrolunil.refertoFioure3and

followtheoutlined

procedures.

1. Measureandcultherequired

lengths

of#16

gauge

green,

whileandbluewirestoconnecttheswitch

tothecontrcl unit.

2. Connectlhe #16gaugegreenwireto the grcen

wireonlheco?trol

unitand

thegreen

wireonthe

swilchusingbuttconneclors.

3. Connectthe#16

gauge

whitewiretothewhitewire

on

lhecontrolunitandthewhite

wireon

lheswitch

usingbuttconnectors.

3. Connecl

the#16

gauge

blue

wiretothebluewire

onthecontrolunilandthebluewire

onthe

switch

usingbunconneclors.

WIBEINSTALLATIONFROMTHECONTFOL

UNIT

TO THE BATTERY

Towirethecontfolunittothebattery,reierto Figure3

and

followthe

outlined

procedures.

1. Measureandcuttherequired

lengths

ol#2gauge

redandblackwirestoconneclthecontrol unitto

thebanory.

2. Crimpalf2gauge

lugtoallfourendsofthewires.

CAUTION

Never attach tho circuit breaker to the battery

ground terminal(negative

G)post).

3. Attachthecircuitbreakertothe

positive

(+)

sideof

thebattery.

4. Attachoneendoftheredwirelotheotherendofthe

circuitbreaker

byusinga 5/16'-18x 1' hexhead

screwwitha5/16'lockwasherandnut.

5. Removethetopnutfromthe

post

locatedtotheleft

ofthegreen,

whiteandbluewiresusedtoconnecl

theswilchtothecontrolunit

(Post

#3). Attachthe

redwireonthepost

and

tighten

thenut

securely.

Neverattachthe black wire to the batteryhot ter-

minal(positive(+) post).

6. Attachtheblackwirelothenegative

O sideofthe

batterv.

CAUTION Awnnxrue

MODEL

825

(Continued)

7. Rernovethetopnut

lrom

the

postlocatedtotheright

ofthe

green,

whiteardbluewiresused

loconnecllhe

switchtothe

controlunit

(Pos{

tt2).

Attachlheblack

wireonthe

post

and

tighlenthenutsecurely.

RODEINSTALLATION

Thewirdlassis

designedtoacceplanchorline,

chainor

acombinationolthetwo.Howaner.

itisimoortanlthatthe

rope-to-chain

splicebedoneconea!. Ashaclde

will not

fitthrough

thechain

gypsy.

Thewarranty

isinvalilatedif

ashaclde

isused.Useaneyesplbe

toatlachtheanchor

chainlotherope.This

prrcedure

shouldbedone

by

a

prolessional

atarnarina.However,complete

ropesplic-

ing

instnrclion

areavailableinChapnan

PibtingS@rnan-

shipand Snma

B@tHandling,Chales E.Clraprnan.

Use916" or U8"Acc@ proof

coil chainor 1/2"or

5/8"Powerwinchlineonly. Runthe chainthrough

thewindlassbeforesplicingto ensurethereis an

exactmatchbetweenthechain

andthe gypsy,

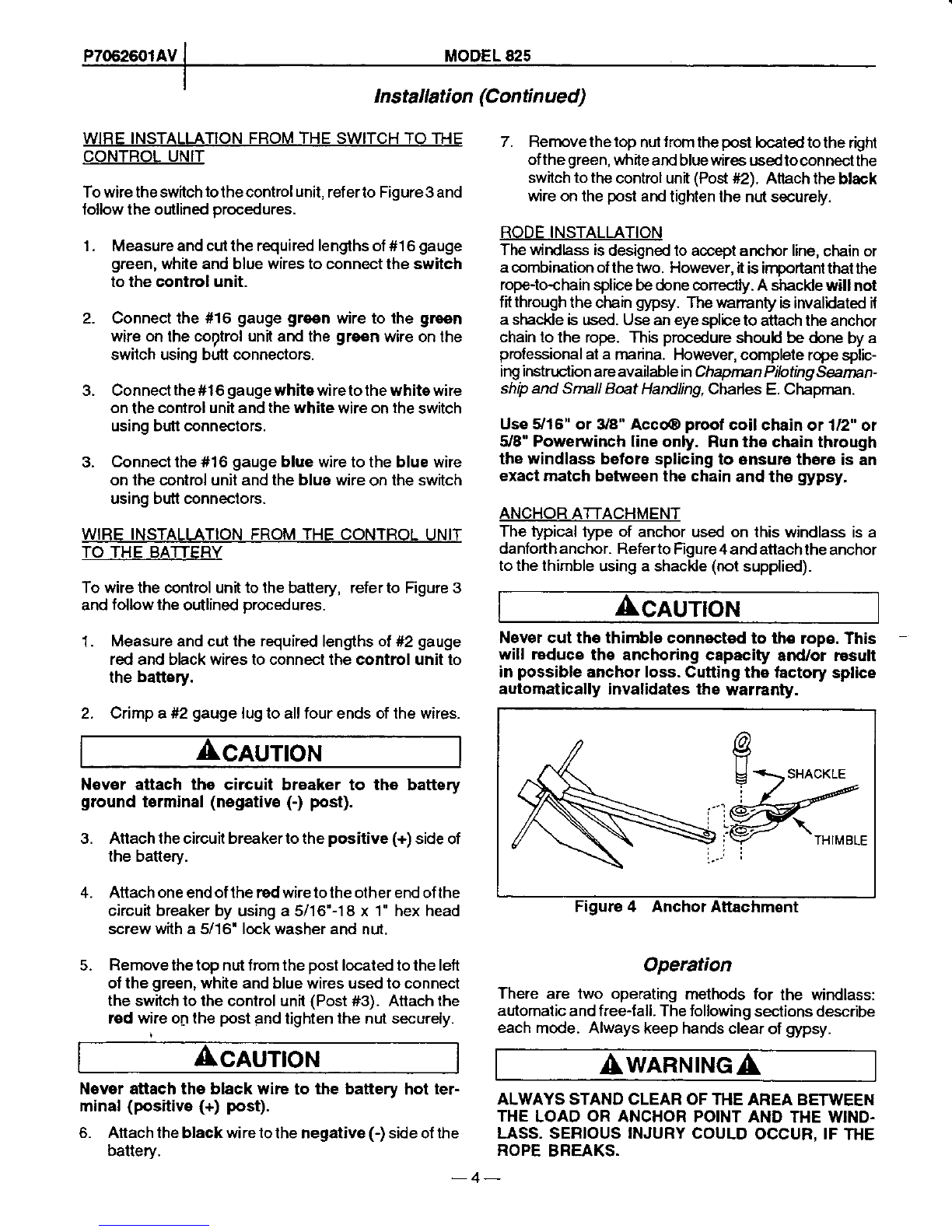

ANCHOR

ATTACHMENT

Thetypical

typeof anchorusedonlhiswindlassisa

danforthanchor.Referto

Figure4andattachthe

anchor

tothethimble

usingashackle

(not

supplied).

CAUTION

Nevercut the thimbleconnoctedto th€ rope.This

will r€dsce the anchoringcapacity and/or rosull

in possibl€

anchorloss.Cutting

the lactorysplice

automaticallyinvalidatesthe warranty.

tg

U

iSHACKLE

THIM8LE

Figure4 AnchorAttachment

Operation

There are two operating methods for the windlass:

automalic

andfree{all. Thefollowing

sectionsdescribe

eachmode. Alwayskeephandsclearof gypsy.

ALWAYSSTANDCLEAROFTHEAREABETWEEN

THE

LOAD

ORANCHORPOINTAND

THEWIND.

LASS,SERIOUSINJURYCOULD

OCCUR.IF

THE

ROPE

BREAKS.

-4-