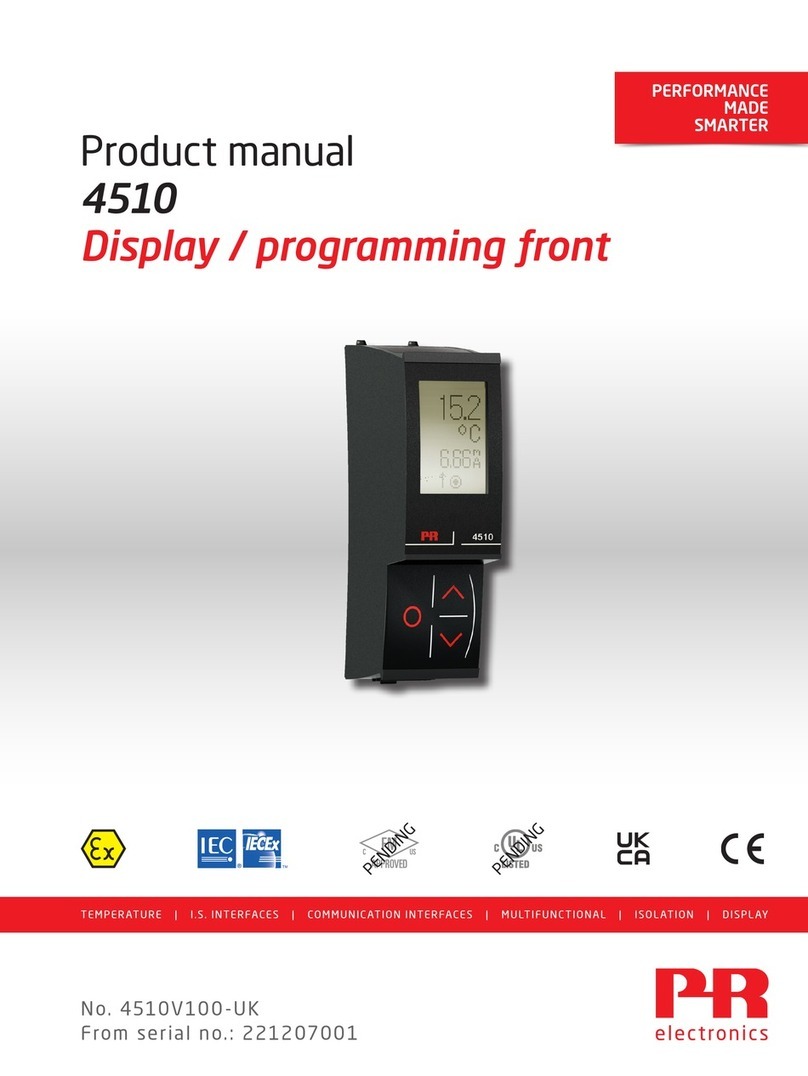

PR electronics 5714 User manual

Programmable displays with a wide se-

lection of inputs and outputs for display of temperature,

volume and weight, etc. Feature linearisation, scaling,

and difference measurement functions for programming

via PReset software.

Interfaces for analogue and digital

signals as well as HART®signals between sensors / I/P

converters / frequency signals and control systems in Ex

zone 0, 1 & 2 and for some modules in zone 20, 21 & 22.

Galvanic isolators for analogue and digital

signals as well as HART®signals. A wide product range

with both loop-powered and universal isolators featuring

linearisation, inversion, and scaling of output signals.

PC or front programmable modules with

universal options for input, output and supply. This range

offers a number of advanced features such as process

calibration, linearisation and auto-diagnosis.

A wide selection of transmitters for DIN

form B mounting and DIN rail modules with analogue

and digital bus communication ranging from application-

specific to universal transmitters.

Displays

Temperature

Isolation

Ex interfaces

Universal

DK

UK

FR

DE

Side 1

Page 23

Page 45

Seite 67

SIGNALS THE BEST

5714

Programmable

LED Indicator

No. 5714V101-IN (0951)

From ser. no. 060137001

22 23

PROGRAMMABLE LED INDICATOR

PREVIEW 5714

TABLE OF CONTENTS

Warnings ............................................................................ 24

Safety instructions.............................................................. 25

Declaration of Conformity .................................................. 27

Front and back layout ........................................................ 28

Applications........................................................................ 29

Technical characteristics.................................................... 29

Mounting ............................................................................ 29

Applications........................................................................ 30

Order .................................................................................. 31

Electrical specifications...................................................... 29

Sensor error detection ....................................................... 35

Connections ....................................................................... 36

Block diagram .................................................................... 37

Routing diagram................................................................. 38

Scrolling help text .............................................................. 40

Configuration / operating the function keys ...................... 42

Graphic depiction of the relay function setpoint .............. 43

24 25

SYMBOL IDENTIFICATION

Triangle with an exclamation mark: Warning / demand. Potentially

lethal situations.

The CE markprovesthecomplianceofthemodulewiththeessential

requirements of the directives.

WARNING!

This module is designed for connection to hazardous electric

voltages.Ignoringthiswarningcanresultinseverepersonal

injury or mechanical damage. To avoid the risk of electric shock

and fire, the safety instructions of this manual must be observed

andtheguidelinesfollowed.Thespecificationsmustnotbe

exceeded, and the module must only be applied as described

inthefollowing.Priortothecommissioningofthemodule,this

manual must be examined carefully. Only qualified personnel

(technicians) should install this module.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

WARNING!

Until the module is fixed, do not connect hazardous voltages to

the module.

Thefollowingoperationsshouldonlybecarriedoutona

disconnected module and under ESD safe conditions:

Troubleshooting the module.

Repair of the module must be done by PR electronics A/S

only.

GENERAL

HAZARD-

OUS

VOLTAGE

SAFETY INSTRUCTIONS

DEFINITIONS:

Hazardous voltages have been defined as the ranges: 75 to 1500 Volt DC, and

50 to 1000 Volt AC.

Technicians are qualified persons educated or trained to mount, operate, and

alsotroubleshoottechnicallycorrectandinaccordancewithsafetyregulations.

Operators,beingfamiliarwiththecontentsofthismanual,adjustandoperate

the knobs or potentiometers during normal operation.

RECEIPT AND UNPACKING:

Unpackthedevicewithoutdamagingit.Thepackingshouldalwaysfollowthe

device until this has been permanently mounted. Check at the receipt of the

devicewhetherthetypecorrespondstotheoneordered.

ENVIRONMENT:

Avoid direct sunlight, dust, high temperatures, mechanical vibrations and shock,

aswellasrainandheavymoisture.Ifnecessary,heatinginexcessofthestated

limitsforambienttemperaturesshouldbeavoidedbywayofventilation.

All modules fall under Installation Category II, Pollution Degree 1, and Insulation

Class II.

MOUNTING:

Onlytechnicianswhoarefamiliarwiththetechnicalterms,warnings,and

instructionsinthemanualandwhoareabletofollowtheseshouldconnectthe

module.

Should there be any doubt as to the correct handling of the module, please

contact your local distributor or, alternatively,

PR electronics A/S, Lerbakken 10, DK-8410 Rønde, Denmark,

tel: +45 86 37 26 77.

Mountingandconnectionofthemoduleshouldcomplywithnationallegislation

formountingofelectricmaterials,i.a.wirecrosssection,protectivefuse,and

location.DescriptionsofInput/Outputandsupplyconnectionsareshownin

the block diagram and side label.

26 27

Thefollowingapplytofixedhazardousvoltages-connectedmodules:

Themax.sizeoftheprotectivefuseis10Aand,togetherwithapower

switch,itshouldbeeasilyaccessibleandclosetothemodule.The

powerswitchshouldbemarkedwithalabeltellingitwillswitchoffthe

voltage to the module.

UL INSTALLATION REQUIREMENTS:

For use on a flat surface of a type 1 enclosure

Use 60/75°C copper conducters only

Max. ambient temperature..................... 60°C

Max.wiresize,pins41...46.................... AWG 30-16

Max.wiresize,others ............................ AWG 30-12

UL file number........................................ E248256

CALIBRATION AND ADJUSTMENT:

During calibration and adjustment, the measuring and connection of external

voltages must be carried out according to the specifications of this manual. The

technician must use tools and instruments that are safe to use.

NORMAL OPERATION:

Operatorsareonlyallowedtoadjustandoperatemodulesthataresafelyfixed

in panels, etc., thus avoiding the danger of personal injury and damage. This

means there is no electrical shock hazard, and the module is easily accessible.

CLEANING:

Whendisconnected,themodulemaybecleanedwithaclothmoistenedwith

distilledwater.

LIABILITY:

To the extent the instructions in this manual are not strictly observed, the

customercannotadvanceademandagainstPRelectronicsA/Sthatwould

otherwiseexistaccordingtotheconcludedsalesagreement.

DECLARATION OF CONFORMITY

As manufacturer

PR electronics A/S

Lerbakken 10

DK-8410 Rønde

herebydeclaresthatthefollowingproduct:

Type: 5714

Name: Programmable LED indicator

isinconformitywiththefollowingdirectivesandstandards:

The EMC Directive 2004/108/EC and later amendments

EN 61326-1

For specification of the acceptable EMC performance level, refer to the

electrical specifications for the module.

TheLowVoltageDirective2006/95/ECandlateramendments

EN 61010-1

Rønde, 22 December 2009 Kim Rasmussen

Manufacturer’s signature

28 29

FRONT AND BACK LAYOUT

Picture 1:FrontofPReview5714.

Picture 2: BackofPReview5714.

PROGRAMMABLE LED INDICATOR

PREVIEW 5714

• 4-digit 14-segment LED indicator

• Input for mA, V, potentiometer, RTD and TC

• 2 relays and analogue output

• Universal voltage supply

• Front key programmable

Application:

• Displayfordigitalreadoutofcurrent,voltage,temperatureorpotentiometer

signals.

• Processcontrolwith2pairsofpotential-freerelaysand/oranalogueoutput.

• Forlocalreadoutinextremelywetatmosphereswithaspeciallydesigned

splash-proof cover.

Technical characteristics:

• 4-digitLEDindicatorwith13.8mm14-segmentcharacters.Max.display

readout-1999...9999withprogrammabledecimalpoint,relayON/OFFindi-

cation.

• Alloperationalparameterscanbeadjustedtoanyapplicationbyuseofthe

front keys.

• PReview5714isavailablefully-configuredacc.tospecificationsreadyfor

process control and visualisation.

• Helptextsineightlanguagescanbeselectedviaamenuitem.

• Inversionswithrelayoutputstheusercanminimisetheinstallationtesttime

by activating / deactivating each relay independently of the input signal.

Mounting:

• Tobemountedinfrontpanel.Theincludedrubberpackingmustbemounted

betweenthepanelcutoutholeandthedisplayfronttoobtainIP65(NEMA4)

tightness.Forextraprotectioninextremeenvironments,PReview5714can

bedeliveredwithaspeiallydesignedsplash-proofcoverasaccessory.

+

-

12

11

26

25

24

23

22

21

32

31

1 2

1 2

+

-+

-

46

45

44

43

42

41

4 3 2

TC

1 2

+

-

30 31

Applications

Input signals:

Current

Potentio-

meter

Output signals:

2 changeover relays

Analogue, 0/4...20 mA

Supply:

21.6...253 VAC

or

19.2...300 VDC

Voltage

RTD -

Connection,wires

2-wiretransmitter

NB! Please order the splash-proof cover seperately. Order No. 8335.

Electrical specifications:

Specifications range:

-20°C to +60°C

Common specifications:

Supply voltage, universal ............................ 21.6...253 VAC, 50...60 Hz or

19.2...300 VDC

Consumption

Isolation voltage, test / operation .............. 2.3 kVAC / 250 VAC

Signal- / noise ratio.................................... Min. 60 dB (0...100 kHz)

Response time (0...90 %, 100...10 %), programmable:

Temperature input................................. 1...60 s

Current / voltage input.......................... 0.4...60 s

Calibration temperature.............................. 20...28°C

Accuracy, the greater of general and basic values:

General values

Input type Absolute

accuracy Temperature

coefficient

All ≤±0.1% of reading ≤±0.01% of reading / °C

Type Internal consumption Max. consumption

5714A 2.2 W 2.5 W

5714B 2.7 W 3.0 W

5714C 2.7 W 3.0 W

5714D 3.2 W 3.5W

Type Version

5714 Standard...................:A

2relays....................:B

Analogue output. . . . . . . . . . . . .: C

Analogue output and 2 relys . . .: D

Order: 5714

32 33

Auxiliary supplies:

2wiresupply(pin46...45) ........................... 25...15 VDC / 0...20 mA

Wire size, pin 41...46 (max.)........................ 1 x 1.5 mm2strandedwire

Wire size, others (max.)............................... 1 x 2.5 mm2strandedwire

Relative humidity......................................... < 95% RH (non cond.)

Dimensions (HxWxD)................................... 48 x 96 x 120 mm

Cutout dimensions ...................................... 44.5 x 91.5 mm

Protection degree (mounted in panel)......... IP65

Weight ......................................................... 230 g

RTD and potentiometer input:

Input for RTD types:

Pt10, Pt20, Pt50, Pt100, Pt200, Pt250, Pt300, Pt400, Pt500, Pt1000

Ni50, Ni100, Ni120, Ni1000

Cableresistancepr.wire,RTD(max.)......... 50 Ω

Input

type Min.

value Max.

value

Standard

Pt100

Ni100

Potentiometer

-200°C

-60°C

10 Ω

+850°C

+250°C

100 kΩ

IEC60751

DIN 43760

-

Sensor current, RTD.................................... Nom. 0.2 mA

Effect of sensor cable resistance

(3-/4-wire),RTD......................................... < 0.002 Ω/ Ω

Sensor error detection, RTD ....................... Yes

Short curcuit detection, RTD....................... < 15 Ω

TC input:

NB.:TCinputtypeBcanbemeasuredandconfigureddownto0°C,but

the basic accuracy is only valid in the range 85...1820°C

Cold junction compensation (CJC)

via internally mounted sensor ............... < ±2.0°C ±0.2°C/°C

Sensor error detection, all TC types ........... Yes

Sensor error detection ................................ Yes

Sensor error current:

whendetecting ...................................... Nom. 2 μA

else ........................................................ 0 μA

Current input:

Measurement range .................................... 0...20 mA

Programmable measurement ranges.......... 0...20 and 4...20 mA

Input resistance........................................... Nom. 20 Ω+ PTC 25 Ω

Sensor error detection:

loop break 4...20 mA............................. Yes

Voltage input:

Measurement range .................................... 0...12 VDC

Programmable measurement ranges.......... 0...1 / 0,2...1 /

0...10 / 2...10 VDC

Input resistance........................................... Nom. 10 MΩ

Type Min.

value Max.

value

Standard

B

E

J

K

L

N

R

S

T

U

W3

W5

LR

0°C

-100°C

-100°C

-180°C

-200°C

-180°C

-50°C

-50°C

-200°C

-200°C

0°C

0°C

-200°C

+1820°C

+1000°C

+1200°C

+1372°C

+900°C

+1300°C

+1760°C

+1760°C

+400°C

+600°C

+2300°C

+2300°C

+800°C

IEC 60584-1

IEC 60584-1

IEC 60584-1

IEC 60584-1

DIN 43710

IEC 60584-1

IEC 60584-1

IEC 60584-1

IEC 60584-1

DIN 43710

ASTM E988-90

ASTM E988-90

GOST 3044-84

Basic values

Input type Basic

accuracy Temperature

coefficient

mA ≤±4 μA ≤±0.4 μA / °C

Volt ≤±20 μV ≤±2 μV / °C

Potentiometer ≤±0.1 Ω ≤ ±0.01 Ω/ °C

Pt100 ≤±0.2°C ≤±0.02°C / °C

Ni100 ≤±0.3°C ≤±0.03°C / °C

TC type:

E, J, K, L, N, T, U

≤±1°C

≤±0.05°C / °C

TC type: R, S,

W3, W5, LR

≤±2°C

≤±0.2°C / °C

TC type: B

85...400°C

≤±4.5°C

≤±0.45°C / °C

TC type: B

400...1820°C

≤±2°C

≤±0.2°C / °C

EMC immunity influence ..................................... < ±0,5% of reading

34 35

Outputs:

Display:

Display readout ........................................... -1999...9999 (4 digits)

Decimal point .............................................. Programmable

Digit height .................................................. 13.8 mm

Display updating ......................................... 2.2 times / s

Input outside input range is

indicated by................................................. Explanatory text

Current outout:

Signal range (span)...................................... 0...20 mA

Programmable signal ranges ...................... 0...20 / 4...20 /

20...0 / 20...4 mA

Load (max.).................................................. 20 mA / 800 Ω/ 16 VDC

Load stability............................................... ≤0.01% of span / 100 Ω

Sensor error detection ................................ 0 / 3.5 / 23 mA / none

NAMURNE43up/downscale .................. 23 mA / 3.5 mA

Output limitation:

on 4...20 and 20...4 mA signals............. 3,8...20.5 mA

on 0...20 and 20...0 mA signals............. 0...20.5 mA

Current limit................................................. ≤28 mA

Relay outputs:

Relay function.............................................. Setpoint

Hysteresis, in % / display counts ............... 0.1...25% / 1...2999

On and Off delay......................................... 0...3600 s

Sensor error detection ................................ Make / Break / Hold

Max. voltage................................................ 250 VRMS

Max. current ................................................ 2 A / AC

Max.ACpower ........................................... 500 VA

Max. current at 24 VDC............................... 1 A

Marine approval:

Det Norske Veritas, Ships & Offshore ......... Standard for Certification No. 2.4

GOST R approval:

VNIIM, Cert. no............................................ Seewww.prelectronics.com

Observed authority requirements: Standard:

EMC 2004/108/EC ...................................... EN 61326-1

LVD 2006/95/EC.......................................... EN 61010-1

UL, Standard for Safety .............................. UL 508

Sensor error check in 5714 variants

Variant: Configuration Sensor error detection:

5714A Always: ON

5714B ERR1=NONE, ERR2=NONE: OFF

else: ON

5714C O.ERR=NONE: OFF

else: ON

5714D ERR1=NONE, ERR2=NONE, O.ERR=NONE: OFF

else: ON

Sensor error detection / sensor error detection outside range:

Outside range readout (IN.LO, IN.HI):

If the valid range of the A/D converter or the polynomial is exceeded

Input Range Readout Limit

VOLT

0..1 V / 0.2..1 V IN.LO < -25 mV

IN.HI > 1.2 V

0..10 V / 2..10 V IN.LO < -25 mV

IN.HI > 12 V

CURR 0..20 mA / 4..20 mA IN.LO < -1.05 mA

IN.HI > 25.05 mA

POTM - IN.LO < -0.5%

IN.HI > 100.5%

TEMP TC / RTD IN.LO < temperature range

IN.HI > temperature range

Sensor error detection (SE.BR, SE.SH):

Input Range Readout Limit

CURR Loop break (4..20mA) SE.BR <= 3.6 mA; > = 21 mA

TEMP

TC SE.BR > ca. 750 kohm / (1,25V)

Pt1002-wire

No SE.SH for Pt10, Pt20 and Pt50

SE.BR > ca. 15 kohm

SE.SH < ca. 15 ohm

Pt1003-wire

No SE.SH for Pt10, Pt20 and Pt50

SE.BR > ca. 15 kohm

SE.SH < ca. 15 ohm

Pt1004-wire

No SE.SH for Pt10, Pt20 and Pt50

SE.BR > ca. 15 kohm

SE.SH < ca. 15 ohm

Displayreadoutbelowmin./abovemax.(-1.9.9.9,9.9.9.9):

Input Range Readout Limit

CURR All -1.9.9.9 Display readout <-1999

9.9.9.9 Display readout >9999

VOLT All -1.9.9.9 Display readout <-1999

9.9.9.9 Display readout >9999

POTM - -1.9.9.9 Display readout <-1999

9.9.9.9 Display readout >9999

+

-

+

-

+

-Tx +

-

31 32

41 42 43 44 45 4641 42 43 44 45 4641 42 43 44 45 46

41 42 43 44 45 46 41 42 43 44 45 46 41 42 43 44 45 46

41 42 43 44 45 46 41 42 43 44 45 46

+

-mA

11 12

R2

R1

21 22 23 24 25 26

I+

Gnd.

11

12

31

32

CPU

AD

EEPROM

0.2 mA

PTC

20 Ω

5714

1 2 3 4

46

45

44

43

42

41

TC+V

4 3 2

21

22

23

24

25

26

R1

R2

1

3

2

Tx

+

+

+

mA

36 37

CONNECTIONS

RTD,2-wire RTD,3-wire RTD,4-wire

PotentiometerVoltage

TC 2-wiretransmitter Current

Current Relays

Inputs:

Output:

Supply:

I

Output

Common

Relay 1 N.O.

Relay 1 N.C.

Common

Relay 2 N.O.

Relay 2 N.C.

Supply

Supply

21.6...253 VAC

or

19.2...300 VDC

Version D

Int.

CJC

2-wiresupply

> 15 VDC

Input +,

mA

Input gnd.

RTD,

wires

Potm.

BLOCK DIAGRAM

Readoutathardwareerror

Error search Readout Error cause

Test of internal communication uC / ADC HW.ER Permanent error in ADC

Test of internal CJC sensor CJ.ER CJC sensor defect

Check-sum test of the configuration in RAM RA.ER Error in RAM

Check-sum test of the configuration in EEPROM EE.ER Error in EEPROM

! Error indications in the display blink once a second. The help text explains the error.

Powerup

50.0

3

F.SET

REL1

REL2 3

1.0

1.2

1 2 1 2

SETP

-1999

9999

/OFF 3

1 2

DI.LO REL.U

DI.HI

1.1

0000

9999

1 2

3

CURR 3RANG

4-20

0-20

1 2

VOLT 3RANG 3

1 2

0-10

2-10

0.2-1

0.0-1

IN

1 2

DEC.P

1111

1.1.1.1

1 2

POTM CA.LO CA.HI

YES

NO

1 2

YES

NO

1 2

3

TEMP TYPE

3

PT.TY

TC

CON.W

TC.TY

1 2

PT 3

10

-

1000

1 2

4W

3W

2W

1 2

NI NI.TY CON.W

50

-

1000

1 2

4W

3W

2W

1 2

1 2

3

3

3

3

3

PASS

LANG

3

1 2

3

3a999

9999

1 2

3a999

9999

1 2

3PERC

DISP

1 2

3

1.3

REL.1

SET

SKIP

OFF

1 2

3

SETP

a999

9999

1 2

3

ACT1

INCR

DECR

1 2

3

HYS1

1

2999

1 2

3

ERR1

HOLD

ACTI

DEAC

NONE

1 2

3

ON.DE

0000

3600

1 2

3

OF.DE

0000

3600

1 2

3

3

1.5

REL.2

SET

SKIP

OFF

1 2

3

SETP

a999

9999

1 2

3

ACT2

INCR

DECR

1 2

3

HYS2

1

2999

1 2

3

ERR2

HOLD

ACTI

DEAC

NONE

1 2

3

ON.DE

0000

3600

1 2

3

OF.DE

0000

3600

1 2

3

3

1.5

A.OUT

4-20

0-20

20-4

20-0

1 2

3

O.LO

a999

9999

1 2

3

O.HI

a999

9999

1 2

3

O.ERR

3.5mA

0mA

23mA

NONE

1 2

3

RESP

0.0

60.0

1 2

3

E.PAS

YES

NO

1 2

3

N.PAS

0000

9999

1 2

3

NO

----

1.51.7 1.7

1.6

1.4

DEC.P

TC.B TC.E TC.J TC.K TC.L

TC.N TC.R TC.S TC.T TC.U

TC.W3 TC.W5 TC.LR

1111

111.1

1 2

3

3

UNIT

3'C

'F

1 2

3

3

1.6 1.6

1.4

3

DE_DK

ES_FR

IT_SE

UK_CZ

3

38 39

38 39

1.0 = Default state

1.1=Onlyifpassword-

protected

1.2 = Only is FastSet is enabled

1.3 = FastSet and relay test

disabledatpassword

5000...9999.

1.4 = No relay outputs

1.5 = Not valid for these input

signals: Potentiometer,

0...20 mA and voltage

1.6 = No analogue output

1.7 = Only if input signal is

temperature

ROUTING DIAGRAM

If no keys are activated for 2 minutes the display returns to default state

1.0withoutsavingconfigurationchanges..

1Increase value / choose next parameter

2Decrease value / choose previous parameter

3Accept the chosen parameter and go to the next menu

Hold 3Backtopreviousmenu/returntomenu1.0withoutsaving

Hold

To 1.0

To default state 1.0

Fast setpoint adjustment

and relay test

1Increase setpoint

2Decrease setpoint

3Save and exit the menu

1and 2simultaneously = change relay state

40 41

SCROLLING HELP TEXT

Display in default state xxxx, hardware error:

SE.BR --> SENSOR WIRE BREAKAGE

SE.SH --> SENSOR SHORT CIRCUIT

IN.HI --> INPUT OVERRANGE

IN.LO --> INPUT UNDERRANGE

9.9.9.9 --> DISPLAY OVERRANGE

-1.9.9.9 --> DISPLAY UNDERRANGE

HW.ER --> HARDWARE ERROR

EE.ER --> EEPROM ERROR -

CHECK CONFIGURATION

RA.ER --> RAM MEMORY ERROR

CJ.ER --> CJC SENSOR ERROR

Fastset (Enabled):

F.SET

REL1 --> FAST SET MENU -

SELECT RELAY

REL2 -->

SETP

xxxx --> RELAY SETPOINT - PRESS OK TO SAVE

Fastset (Disabled):

SETP

xxxx --> RELAY SETPOINT - READ ONLY

Configuration menus:

LANG

DE --> DE - WAEHLE DEUTSCHEN HILFETEXT

DK --> DK - VAELG DANSK HJAELPETEKST

ES --> ES - SELECCIONAR TEXTO DE

AYUDA EN ESPANOL

FR --> FR - SELECTION TEXTE D’AIDE

EN FRANCAIS

IT --> IT - SELEZIONARE TESTI DI

AIUTO ITALIANI

SE --> SE - VALJ SVENSK HJALPTEXT

UK --> UK - SELECT ENGLISH HELPTEXT

CZ --> CZ - VYBER CESKOU NAPOVEDU

PASS

xxxx --> SET CORRECT PASSWORD

IN

C.LIN* --> TEXT ENTERED BY USER IN PRESET

CURR --> CURRENT INPUT

VOLT --> VOLTAGE INPUT

POTM --> POTENTIOMETER INPUT

TEMP --> TEMPERATURE SENSOR INPUT

RANG When current selected:

0-20 --> INPUT RANGE IN mA

4-20 --> INPUT RANGE IN mA

RANG When voltage selected:

0-10 --> INPUT RANGE IN VOLT

2-10 --> INPUT RANGE IN VOLT

0.0-1 --> INPUT RANGE IN VOLT

0.2-1 --> INPUT RANGE IN VOLT

CA.LO

YES --> CALIBRATE POTENTIOMETER LOW

NO --> CALIBRATE POTENTIOMETER LOW

CA.HI

YES --> CALIBRATE POTENTIOMETER HIGH

NO --> CALIBRATE POTENTIOMETER HIGH

DEC.P

1111 --> DECIMAL POINT POSITION

111.1 --> DECIMAL POINT POSITION

11.11 --> DECIMAL POINT POSITION

1.111 --> DECIMAL POINT POSITION

DI.LO

xxxx --> DISPLAY READOUT LOW

DI.HI -->

xxxx --> DISPLAY READOUT HIGH

REL.U

PERC --> SET RELAY IN PERCENTAGE

DISP --> SET RELAY IN DISPLAY UNITS

TYPE

PT --> SELECT PT SENSOR TYPE

NI --> SELECT NI SENSOR TYPE

TC --> SELECT TC SENSOR TYPE

PT.TY

10 --> SELECT PT SENSOR TYPE

20 --> SELECT PT SENSOR TYPE

50 --> SELECT PT SENSOR TYPE

100 --> SELECT PT SENSOR TYPE

200 --> SELECT PT SENSOR TYPE

250 --> SELECT PT SENSOR TYPE

300 --> SELECT PT SENSOR TYPE

400 --> SELECT PT SENSOR TYPE

500 --> SELECT PT SENSOR TYPE

1000 --> SELECT PT SENSOR TYPE

NI.TY

50 --> SELECT NI SENSOR TYPE

100 --> SELECT NI SENSOR TYPE

120 --> SELECT NI SENSOR TYPE

1000 --> SELECT NI SENSOR TYPE

CONN When Pt and Ni sensor selected

2W --> SELECT 2-WIRE SENSOR CONNECTION

3W --> SELECT 3-WIRE SENSOR CONNECTION

4W --> SELECT 4-WIRE SENSOR CONNECTION

TC.TY

TC. B --> SELECT TC SENSOR TYPE

TC. E --> SELECT TC SENSOR TYPE

TC. J --> SELECT TC SENSOR TYPE

TC. K --> SELECT TC SENSOR TYPE

TC. L --> SELECT TC SENSOR TYPE

TC. N --> SELECT TC SENSOR TYPE

TC. R --> SELECT TC SENSOR TYPE

TC. S --> SELECT TC SENSOR TYPE

TC. T --> SELECT TC SENSOR TYPE

TC. U --> SELECT TC SENSOR TYPE

TC.W3 --> SELECT TC SENSOR TYPE

TC.W5 --> SELECT TC SENSOR TYPE

TC.LR --> SELECT TC SENSOR TYPE

DEC.P When temperature selected

1111 --> DECIMAL POINT POSITION

111.1 --> DECIMAL POINT POSITION

UNIT

°C --> DISPLAY AND RELAY SETUP IN CELSIUS

°F --> DISPLAY AND RELAY SETUP IN

FAHRENHEIT

REL1

SET --> ENTER RELAY 1 SETUP

SKIP --> SKIP RELAY 1 SETUP

OFF --> RELAY 1 DISABLED

SETP

xxxx --> RELAY SETPOINT

ACT1

INCR --> ACTIVATE AT INCREASING SIGNAL

DECR --> ACTIVATE AT DECREASING SIGNALL

HYS1

xxxx --> RELAY HYSTERESIS

ERR1

HOLD --> HOLD RELAY AT ERROR

ACTI --> ACTIVATE RELAY AT ERROR

DEAC --> DEACTIVATE RELAY AT ERROR

NONE --> UNDEFINED STATUS AT ERROR

ON.DE

xxxx --> RELAY ON-DELAY IN SECONDS

OF.DE

xxxx --> RELAY OFF-DELAY IN SECONDS

REL2

SET --> ENTER RELAY 2 SETUP

SKIP --> SKIP RELAY 2 SETUP

OFF --> RELAY 2 DISABLED

SETP

xxxx --> RELAY SETPOINT

ACT2

INCR --> ACTIVATE AT INCREASING SIGNAL

DECR --> ACTIVATE AT DECREASING SIGNAL

HYS2

xxxx --> RELAY HYSTERESIS

ERR2

HOLD --> HOLD RELAY AT ERROR

ACTI --> ACTIVATE RELAY AT ERROR

DEAC --> DEACTIVATE RELAY AT ERROR

NONE --> UNDEFINED STATUS AT ERROR

ON.DE

xxxx --> RELAY ON-DELAY IN SECONDS

OF.DE

xxxx --> RELAY OFF-DELAY IN SECONDS

A.OUT

0-20 --> OUTPUT RANGE IN mA

4-20 --> OUTPUT RANGE IN mA

20-0 --> OUTPUT RANGE IN mA

20-4 --> OUTPUT RANGE IN mA

O.LO

xxxx --> DISPLAY VALUE FOR OUTPUT LOW

O.HI

xxxx --> DISPLAY VALUE FOR OUTPUT HIGH

O.ERR

23 mA --> NAMUR NE43 UPSCALE AT ERROR

3,5 mA --> NAMUR NE43 DOWNSCALE AT ERROR

0mA --> DOWNSCALE AT ERROR

NONE --> UNDEFINED OUTPUT AT ERROR

RESP

xxx,x --> ANALOGUE OUTPUT RESPONSE TIME

IN SECONDS

E.PAS

NO --> ENABLE PASSWORD PROTECTION

YES --> ENABLE PASSWORD PROTECTION

N.PAS

xxxx --> SELECT NEW PASSWORD

t

Off N.C.

On N.C. On N.C.

10

10

20

20

30

30

40

40

50

50

60

60

70

70

80

80

90

90

100

100

0

Off N.O. Off N.O.

On N.O.

t

10

10

20

20

30

30

40

40

50

50

60

60

70

70

80

80

90

90

100

100

0

Off N.O. Off N.O.On N.O.

Off N.C.On N.C. On N.C.

42 43

CONFIGURATION / OPERATING THE

FUNCTION KEYS

Documentation for routing diagram.

In general:

When configuring the display you are guided through all parameters, you can

choosethesettingswhichfittheapplication.Foreachmenuthereisascrol-

linghelptextwhichisautomaticallyshowninthedisplay,thisstartsafter5

seconds if no key has been activated.

Configuration is carried out by using the 3 function keys.

1 willincreasethenumericalvalueorchoosethenextparameter.

2 willdecreasethenumericalvalueorchoosethepreviousparameter.

3 willacceptthechosenvalueandendthemenu.

If a function does not exist in the display all parameters are skipped to make

the configuration as simple as possible.

Oncetheconfigurationhasbeenenteredthedisplaywillshow“----”.

Pressing and holding 3willreturntothepreviousmenuorreturntothedefault

state(1.0)withoutsavingthechangedvaluesorparameters.

Ifnokeyisactivatedfor2minutes,thedisplaywillreturntothedefaultstate

(1.0)withoutsavingthechangedvaluesorparameters.

Further explanations:

Fast setpoint adjustment and relay test:Thesemenusallowyoutochange

the set point quickly and to check the operation of the relays.

Pressing 1and 2atthesametimewillchangethestateoftherelay–thischange

is indicated by the diodes on the display. Pressing 3willsavethesetpoint

change.

Holdingdown3formorethan0.5secondswillreturntheunittothedefault

statewithoutchangingthesetpoint.

Password protection:

Usingapasswordwillstopaccesstothemenuandparameters.Therearetwo

levelsofpasswordprotection.Passwordsbetween0000…4999allowaccess

tothefastsetpointadjustmentandrelaytest.(Usingthispasswordstops

accesstoallotherpartsofthemenu).Passwordsbetween5000…9999stop

access to all parts of the menu, fast set point and relay test. (Current set

pointisstillshown).Byusingthemasterpassword2008,allconfiguration

menus are available.

Graphic depiction of the relay function setpoint:

Relay unitsRelay units

Setpoint = 50

Hysteresis = 10

Hysteresis = 10

Setpoint = 50

Relay action: Increasing Relay action: Decreasing

Other manuals for 5714

3

Table of contents

Other PR electronics Measuring Instrument manuals

PR electronics

PR electronics 4510 User manual

PR electronics

PR electronics 5714 User manual

PR electronics

PR electronics 4511 User manual

PR electronics

PR electronics PRetrans 5115 Series User manual

PR electronics

PR electronics 5511 User manual

PR electronics

PR electronics 5714 User manual

PR electronics

PR electronics 5714 User manual

PR electronics

PR electronics 5202 User manual

PR electronics

PR electronics 5514 User manual

PR electronics

PR electronics 5700 Series User manual