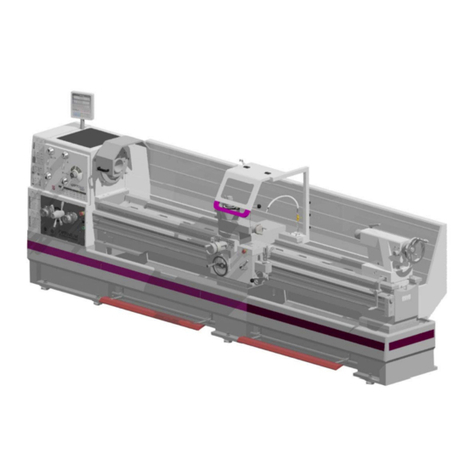

Pragati BTP-63 User manual

BI-DIRECTIONAL

TOOL TURRETSTOOL TURRETS

TOOL TURRETSTOOL TURRETS

TOOL TURRETS

INSTRUCTION MANUAL

JUNE 2003

BTP-63 BTP-80 BTP-100 BTP-125

vv

vv

vvv

vv

vvv

vv

vvv

vv

v

INDEX

Page

1. Principle of working. 4

2. Instructions for fitment on the machine. 6

3. Fitment of tool disc on the turret. 6

4. Operation of coolant system. 7

5. Details of electrical connections. 8

6. Electrical motor wiring diagram. 9

7. Electricalsignals. 10

8. Handcranking. 11

9. Lubrication. 11

10. Turret control flow chart. 12

11. Requirements of turret control. 13

12. Adjustment of rotary encoder. 14

13. Adjustment of proximity switch. 15

14. Replacement of the proximity switch 15

15. Assemblydrawings. 16

16. Instructions for opening of gearbox. 21

17. Instructions for assembly. 22

18. Adjustment of Ringfeder Clamps 26

19. List of spare parts. 28

20. Faults and corrective actions. 31

BI-DIRECTIONAL TOOL TURRETS

3

1. Principle of Working :

Threepieceface gearcouplingis thebasicelement usedforindexing. Couplingdesignallows thetooldisc to

be indexed without lifting. It also ensures high repeat positioning accuracy as well as rigidity.

3phase electrictorque motordrives the camshaft througha systemof gears.‘Cam shaft’drives the‘follower

shaft’in a non-uniform manner, similarto that of ‘Geneva’ mechanism. Cam shaft is alsogeared to the ‘drum

cam’ which controls clamping and release of the coupling.

Initial 90° (approximate) movement of cam shaft does not transfer any rotary movement to follower shaft.

However,thedrumcamrotatesthrough30°,whichmovementreleasestheclampingforceandpullsthesliding

couplingoutofengagement.Further180°(approx.)movementofcamshaftindexesthefollowershaftthrough

90°,which inturn, indexesthe turretby 30° or45° dependingon gearratio. Duringthis movement,drum cam

profilekeepstheslidingcouplingindis-engagedposition.Inthefinal90°movementofthecamshaft,thefollower

shaftremainsstationary.Thedrumcampullstheslidingcouplingintoengagementandappliesclampingforce

through disc spring. One revolution of cam shaft completes one indexing cycle of declamp-index-clamp.

Absolutepositionencodergivesfeed-backoftheturretposition.Proximityswitchinspectstheclampedposition

of the turret.

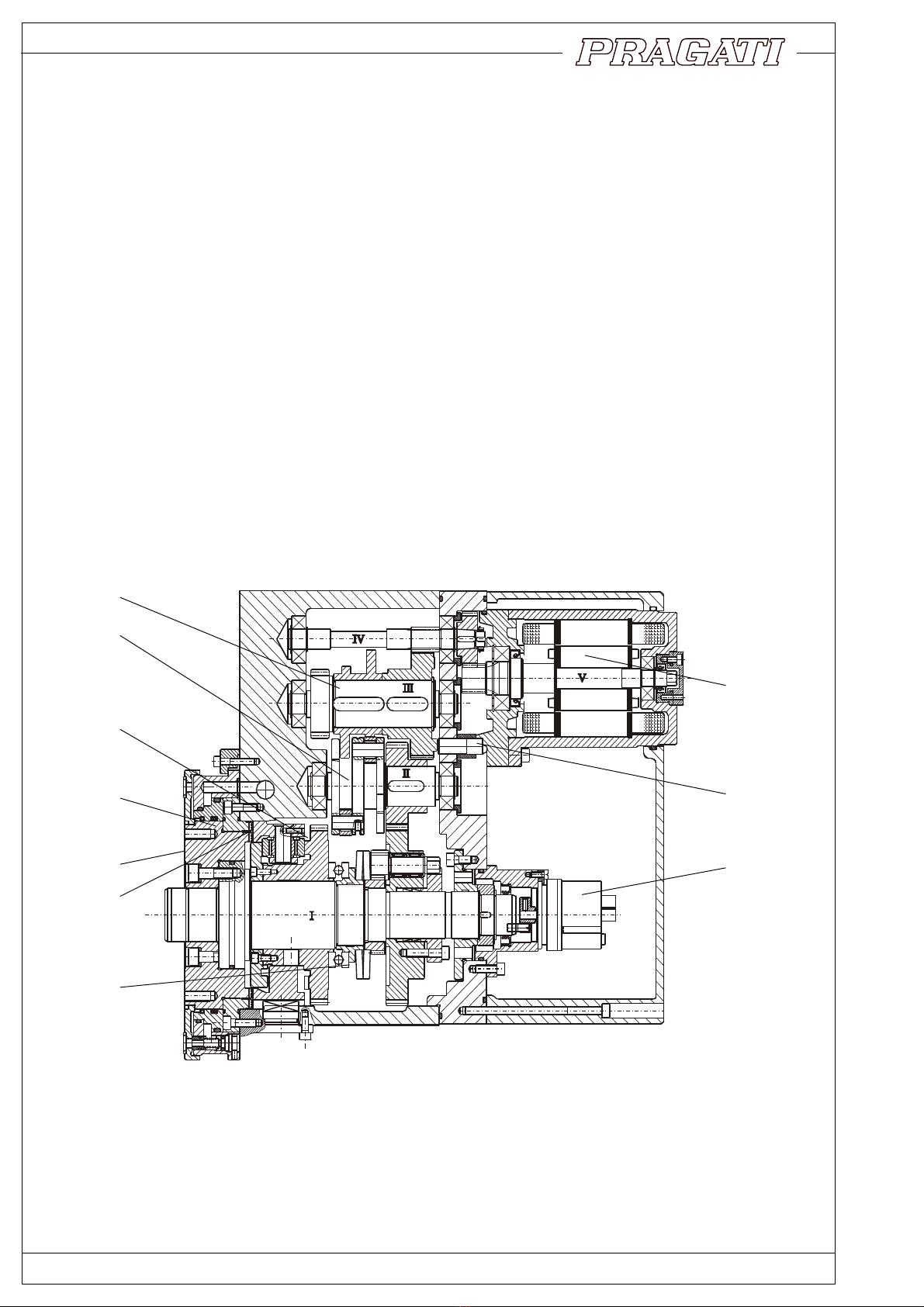

FIG 1.1

4

BI-DIRECTIONAL TOOL TURRET

1. Cam Shaft 2. Follower Shaft 3. Drum Cam 4. Fixed Coupling

5. Indexing Coupling 6. Sliding Coupling 7. Disc Spring 8. Torque Motor

9. Proximity Switch 10. Encoder

8

9

10

1

2

3

4

5

6

7

Diagrambelowgives relativepositionsof mechanicalelementsand electricalsignalsduring onerevolution

of the cam shaft.

CAM ANGLE

MOTOR

TURRET

CLAMP

SWITCH

BIT 1

BIT 2

BIT 4

BIT 8

STROBE

PARITY

ENCODER

POSITION

OF

COUPLING

TEETH

DRUM CAM

PROFILE

PARRALLEL

INDEX

DRIVE

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

O˚ 35˚ 9O˚ 18O˚ 27O˚ 325˚ 36O˚

FIG 1.2

BI-DIRECTIONAL TOOL TURRETS

5

6

BI-DIRECTIONAL TOOL TURRETS

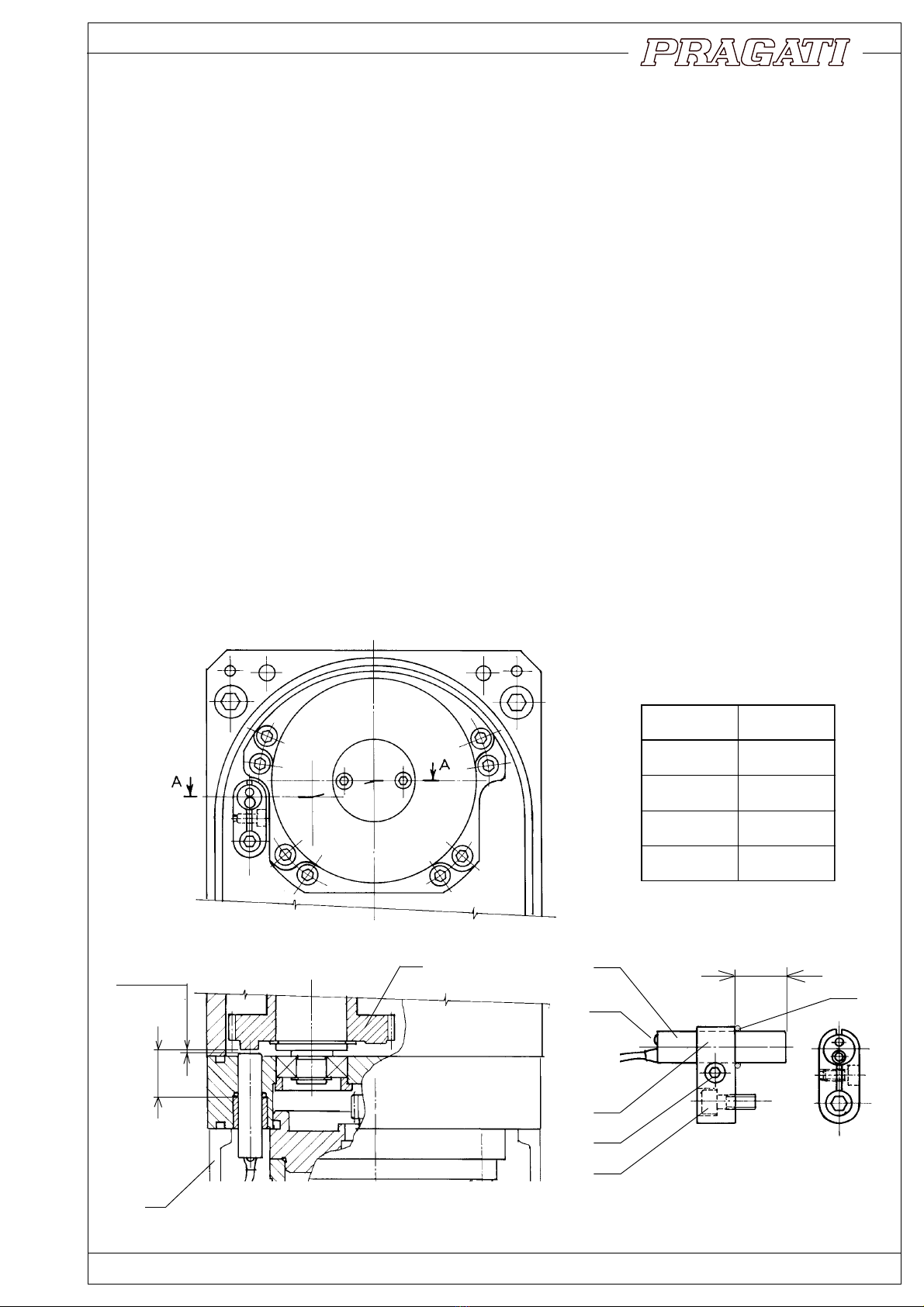

2. Fitment on the machine :

Seatingsurfaceofthemachineshouldbeflattoensureproper

contactwiththeturretbase.Machinesurfaceshouldbeeither

scraped or surface-ground.

Turret should be aligned by dialing surface of the indexing

flange.Clampingboltsshouldbetightenedafteraligningthe

seating surface, square to the lathe axis.

Clampingboltsshouldusemachinewashersofextrathickness

(min.5 mm) to ensure proper clamping.

DowelPinsarenotrecommendedforensuringthealignment

of turret. It is preferable to allow the turret to slip in the event

of an accidental shock or overload. This slipping absorbs

some of the energy of the shock and reduces the possible

damage. Turret can again be brought back to alignment by

dialing a reference surface on the tool disc.

There is one more reason for avoiding the dowel pin. Acci-

dentalcollisionsarenotun-commoninthefieldofCNClathes.

In the event of a collision, dowel pins can get sheared or

damaged.Itisadifficulttasktoremovesuchdowelpins,and

to fit new ones. New dowels may involve enlarging the

damagedholebydrillingandreaming.Thisisdifficulttodoat

the customer's place. This is a difficult operation to be done on site, and is most likely to be less than perfect.

Onthe otherhand, it isperfectly possibleto usethe turret andtool discwithout theuse of dowels.The friction

joint can easily take up normal cutting loads, including occasional over loads.

Pragati turrets, therefore, do not have a provision of dowelling the body to the base.

TOOL

DISK

3. Fitment of Tool Disc on Turret Flange :

Tool disc is to be fitted on the indexing flange with the help of

clampingbolts,andmachinewashers.Discshouldbeangularly

adjustedwithintheclearanceoftheboltholes,togetthecorrect

centre height of the tool. It should then be firmly clamped by

tighteningthebolts.Dowelpinsforensuringthepositionarenot

recommendedfor the reasons explained earlier.

However,dowelpincanbeusedforthepurposeofalignment,but

itisrecommendedtoremovethepinafterclampingthetooldisc

inposition.Thereisaprovisionofsoftareasontheindexingflange

to facilitate drilling and reaming for dowel pins.

Boltholesinthetooldiscshouldbeofextralargesizetoallowfor

angularadjustment.Extrathickmachinewashersshouldbeused

to ensure proper clamping.

TURRET

BODY

FLAT

SEATING

SURFACE

(SCRAPEDOR

GROUND)

EXTRATHICK

WASHERS

OVERSIZE

BOLTHOLE

EXTRA

THICK

WASHERS

FIG 3.1

FIG 2.1

BI-DIRECTIONAL TOOL TURRETS

7

Turrethastwoalternativepositionsfortheconnectionofcoolantpipe.Coolantpassesthroughthedrilledhole

inthebodyandentersthepassageinthecoolantring(01&24).Thisringhasspringloadedcoolantvalve.Valve

button(130)continuouslypressesagainstcoolantflange(26)fittedonindexingflange.Coolantringaswellas

coolantflange haveprovision forangular adjustment.Coolant flange shouldbe adjustedto alignthe ‘O’rings

(37)withcoolantpassagesontooldisc.Coolantringshouldthenbeadjustedtoalignthecoolantvalvewiththe

proper hole on the coolant flange (ref. 4.1). There are 2 valve positions on the coolant ring. Only one of the

positionsistobechosenasfunctional,andshouldbefittedwiththespringloadedvalvebutton(130).Theother

valve positions should be blocked by plug (136).

Thisdesignensuresthatthecoolantisconnectedonlytotheworkingtoolposition.Coolantflowautomatically

stopsduringthe indexingmovement, as thecoolant flangeclosesthe openingofthe valvebutton.

Coolant passage through the turret body, coolant ring and the valve has been designed to provide as little

resistancetocoolantflowaspossible.However,thepathislongandnarrow,withanumberofbendsintheflow

passage.Furthermore, coolant hasto pass throughdrilled passagesin the tooldisc, before reachingthe tool

point. It might therefore be necessary to employ high pressure coolant pump, to ensure sufficient flow at tool

point. Coolant passages in tool turret can withstand a maximum pressure of 6 bar.

4.1 Procedure for adjustment of coolant ring :

Coolantringholdsontotheindexingflange(27),becauseofthefrictionofwiperseals.Itistherefore,notpossible

toadjusttheangularpositionofcoolantringbyhand.Followingprocedureistobefollowedforthisadjustment.

*Loosenclamps(140).Movethecoolantringalongwithindexingflangebyhandcranking(Ref.section8,page

11) to required position. Tighten clamps (140).

INDEXING

FLANGE(27)

CLAMPSFOR

COOLANTFLANGE

(137)

COOLANTFLANGECLAMPED

TOINDEXING FLANGE (26)

CLAMPFOR

COOLANTRING

(140)

COOLANTVALVE

ADJUSTMENTRANGE COOLANTVALVE ALTERNATE

POSITION AVAILABLE ON

OPPOSITE SIDE.

COOLANTENTRYPOSITION

AVAILABLE ON OPPOSITE SIDE.

20°

20°

4. Operation of Coolant system :

FIG 4.1

COOLANT

RING(24)

4.2 Replacement of Valve Button ( fig. 4.2 ) :

Valvebutton(130)rubsagainstthecoolantflangeduring

indexing,andisliabletowear.Provisionhasbeenmade

toreplacethebutton,withoutremovingthetooldiscfrom

theturret.

Forreplacement,loosen theclamp (140)and move the

coolantringtobringthevalveinasuitablepositiontoget

access to the plug (134).

Removetheplug,thespringandthevalvebutton.Replace

withanewbutton,andplacebackthespringandtheplug.

Coolantringshouldthenbeshiftedbackandclampedin

originalposition.

01

26

24

134

37

136

FIG 4.2

27

130

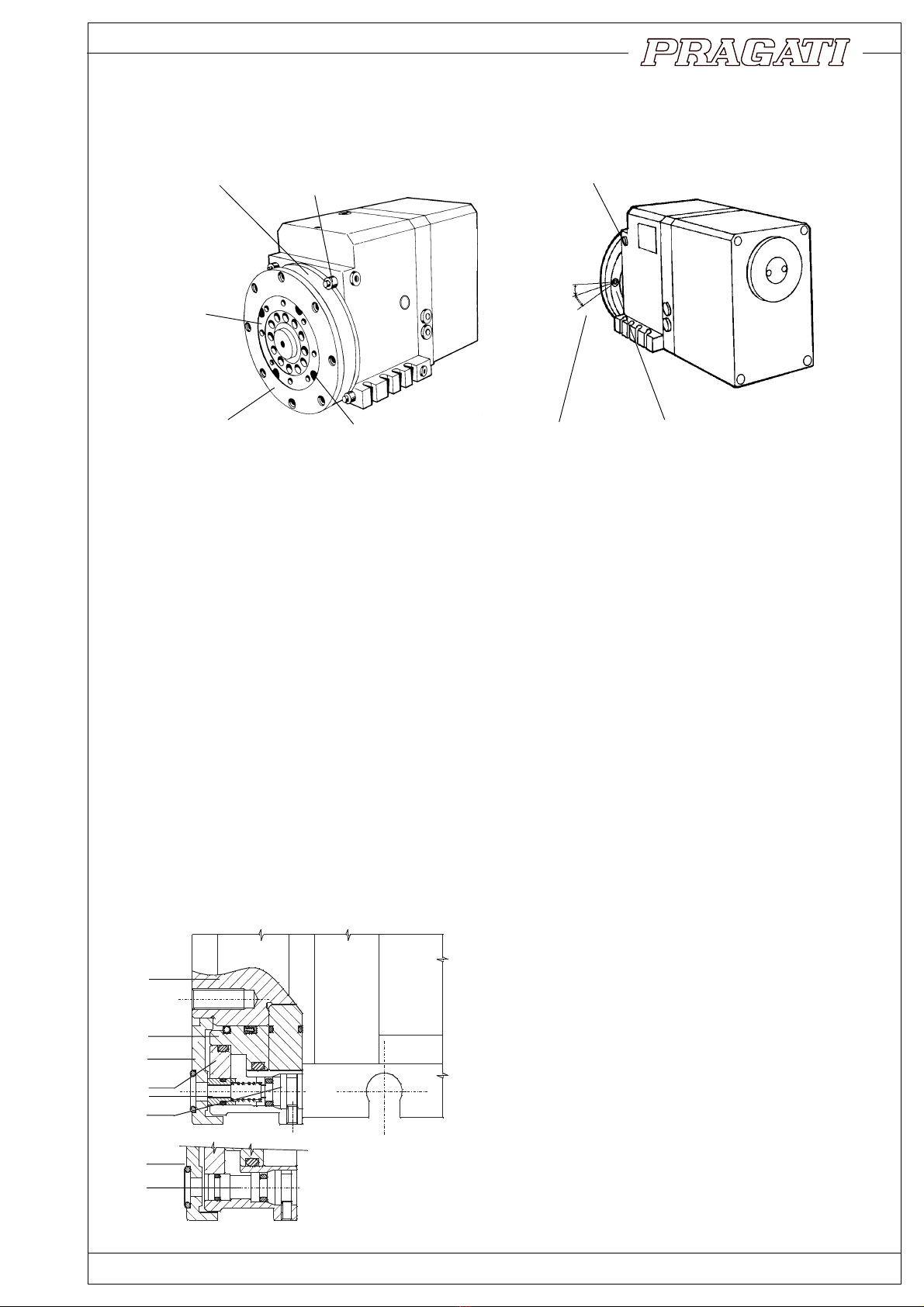

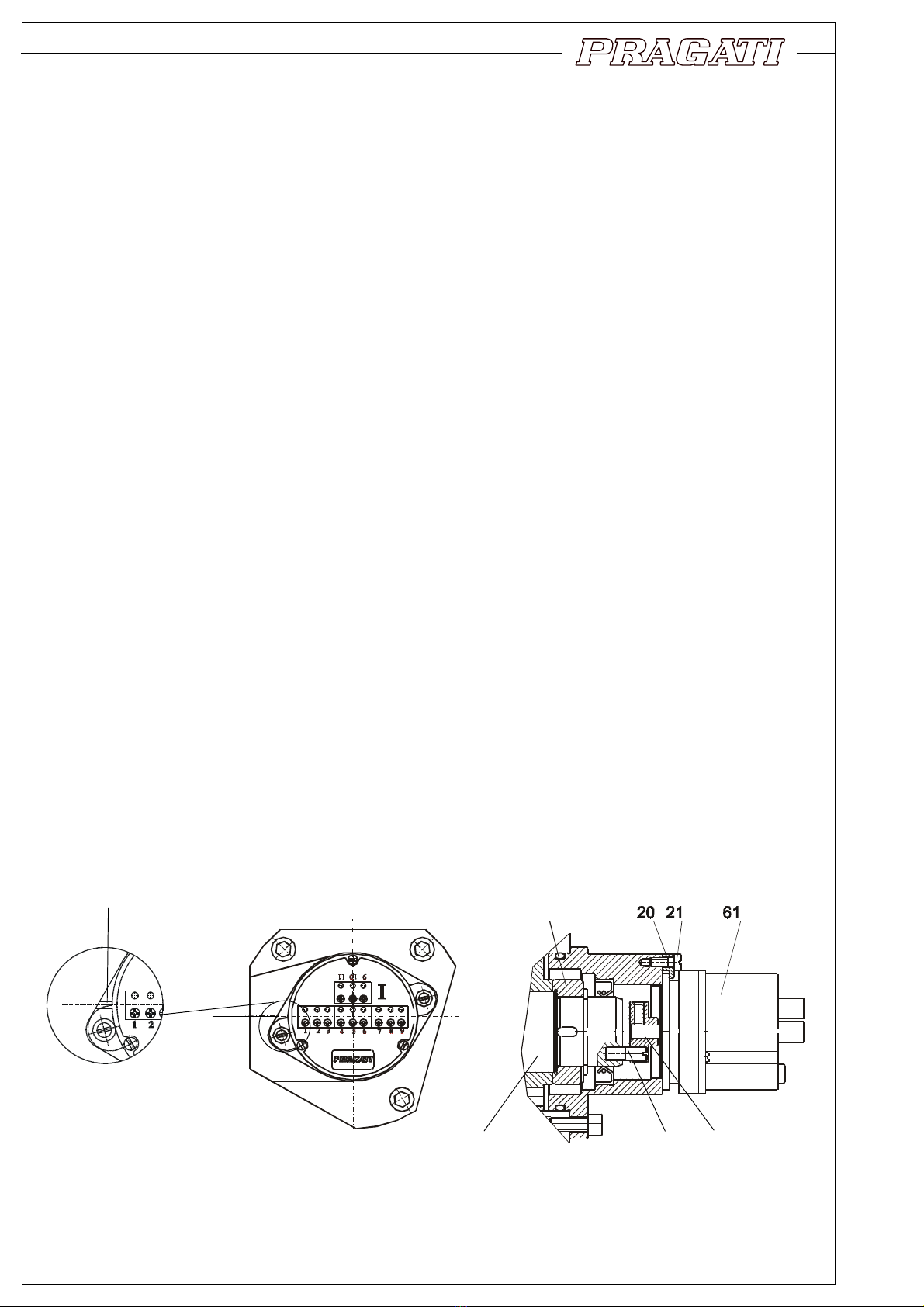

5. Details of Electrical Connections

8

BI-DIRECTIONAL TOOL TURRET

1

4

2

3

1. Torque Motor 2. Proximity Switch 3. Absolute Encoder 4.Thermal Relay

BTP-100 : 1.9 KVA

BTP-80 : 1.6 KVA

BTP-63 : 1.2 KVA

BTP-125 : 2.3 KVA

PROXIMITYSWITCH

(TURRETCLAMPSIGNAL)

BI-DIRECTIONAL TOOL TURRETS

9

415/

380

220

110

BTP-125 3.2 6.3 8.0

BTP-100 2.6 4.5 7.4

BTP-80 2.3 3.9 6.3

BTP-63 1.6 3.0 5.0

BTP-50 1.3 2.6 3.3

VOLTAGEAC

MODEL

1. Unused electrical entry points to be properly plugged.

2. Electrical wiring should be brought in through water proof conduit connection. Wire braided hydraulic

hoses can serve as conduits. They also give excellent protection against damage by hot chips.

FIG 6.2 DETAILS OF ELECTRICAL TERMINALS

MOTORCURRENT(Amps)

USEFUSERATINGABOUT

THREETIMESMOTOR

CURRENT. MINIMUM6AFUSE

TO BE USED.

6. Electrical motor wiring details

MF

TC MR SSR1 SSR2

MF

MR 0V

0V

24 VDC

E

T

T

MMM

MR

TC

TC

MF

TC

Q4.0 Q4.1I3.1

OUTPUT

INPUT

PROGRAMABLE CONTROLLER (PLC)

MOTOR

3~

FUSES

R

Y

B

N

E

TORQUE MOTOR

FORWARD REVERSE SOLID STATE

RELAYS

THERMAL RELAY

130˚ C

NORMALLY CLOSED

415 VAC 2 A

SSR

415 VAC 25 A

FIG 6.1 WIRING DIAGRAM FOR MOTOR

2

1

10

BI-DIRECTIONAL TOOL TURRET

Following points should be noted while selecting control system for turret :

1. Direction of rotation of motor for shortest indexing time is to be decided by control system.

2. Indexing times of these turrets are short. It is necessary to select particularly fast PLC

(programmable logic controller) for the control of turret operations.

3. Referring to the signal diagram, value of T3 is particularly critical. Motor must come to a physical

haltwithinthistime.Otherwise,theturretwillgetde-clampedandtheproximityswitchsignalwillbe

lost.Followingmeasures aresuggested for stoppingthe motorinminimum possibletime.

a. Control should be capable of detecting the proximity switch signal within 3 to 6 ms.

b. Solid state relays should be incorporated in the motor circuit to ensure fastest possible dis-

connection.Regular contactors can beused for motor directionselection, followed by solidstate

relays, at least in two phases.

7. Electrical Signals

123456789101112

101010101010

011001100110

000111100001

000000011111

111111111111

110100110010

POSITION NUMBER

BIT 1

BIT 2

BIT 3

BIT 4

STROBE

PARITY

T1 T2 T3

ms ms ms

max

FAST

STD

FAST

STD

STD

BTP-100

BTP-80

BTP-63

110 60 50

135 75 60

100 55 45

110 60 50

80 45 35

TABLE 1 ENCODER SIGNALS TABLE 2

CCW CW

TURRET

CLAMP

SWITCH 1

0

1

0

1

0

1

0

1

0

1

0

1

0

ENCODER

BIT 1

BIT 2

BIT 3

BIT 4

STROBE

PARITY

T1T2

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaa

CAM ANGLE

MOTOR 1

0

1

O˚ 180˚ 360˚ 360˚

180˚

POSITION 4 POSITION 5

TURRET CLAMP

POSITION 3

START

T3

T1 ms T2 ms

BTP-125 175 135

BTP-100 150 115

BTP-80 125 95

BTP-63 100 75

BTP-50 75 60

Turretcanbeindexedbycrankingtherotorofelectricmotorbyhand.Handcrankingisrequiredforinspecting

the setting of encoder and proximity switch. It is also necessary for inspecting the clamping function of disc

springs.

Procedure for hand cranking is as follows :

1. Disconnect 3 phase power supply to the motor.

2. Remove end cover (119) of motor. Hexagon head of motor shaft is now approachable.

3. Use a suitable cranked spanner to crank the motor.

4. After cranking, do not forget to place cover (119), back in position.

119 118 114

HEX.END

FIG 8.1

FIG 9.1

9. Lubrication :

Turretislubricatedbymediumviscositygearbox

oil.

Oilcanbefilledafterremovingthefillingplug(161)

as shown in the fig (9.1). A drain plug (160) has

been provided to drain out the oil, if so required.

Oil quantity required for different turret models is

listedbelow:

MODEL Oil Qty Lit.

BTP-125 1.75

BTP-100 1.25

BTP-80 1.00

BTP-63 0.75

BI-DIRECTIONAL TOOL TURRETS

11

DRAINPLUG

160

FILLINGPLUG

161

8. Hand cranking :

12

BI-DIRECTIONAL TOOL TURRETS

D

E

T4 > 4 Sec.

’TIME FAULT’

ALARM

NO

YES

TURRET

CLAMP SWITCH

ON ?

DELAY T5 ms. DELAY T5 = T3 + 5 ms.

CYCLE COMPLETE

SIGNAL

END

’TURRET NOT

LOCKED’ ALARM

NO

X=Y

TURRET

CLAMP SWITCH

ON ?

STOP MOTOR

E

E

D

D

B

NO

NO

YES

YES

X=Y ’POSITION FAULT’

ALARM

NO

YES

YES

ALARM ’INVALID

TOOL DEMAND’

START

POSITION ’X’

DEMAND

POSITION ’Y’

’N’ = NUMBER OF INDEX

POSITIONS 8,12 OR 24

DEMAND

VALID ?

1<Y<N

NO

YES

X<Y

(Y-X)<N/2 (X-Y)<N/2

START TORQUE

MOTOR ’CCW’ START TORQUE

MOTOR ’CW’

TURRET

CLAMP SWITCH

OFF ?

E

D

B

NO

NO NO

NO

YES

YES

YES

X=Y

START 4 Sec.

TIMER T4

A

NO

YES

YES

Monitor Turret clamp switch signal on

continuous basis. Generate FEED-HOL

D

if clamp signal missing.

Note :

A

10. Flowchart for turret control

NOTE:MONITORTURRETCLAMPSWITCHSIGNALON

CONTINUOUSBASIS.GENERATEFEED-HOLD

IFCLAMPSIGNALMISSING

BI-DIRECTIONAL TOOL TURRETS

13

11. Requirements of turret control :

11.1 Sequence of operation :

Suggested flow chart is given in the diagram on page 12. It might be necessary to modify the program

dependingonindividualapplications.However,followinggeneralpointsshouldbenotedwhileselecting

the control system and its program :

* Indexing times of these turrets are short. It is therefore necessary to select a particularly fast PLC

(programmable logic controller) for the control of turret operation.

* Referring to the electrical signal diagram on page 10 ; time ‘T3’ is particularly critical. Motor must come

toaphysicalhaltwithinthistime.Otherwise,theturretwillgetdeclamped,andtheturretclampswitchsignal

willbelost.

For stopping the motor in minimum possible time, following measures are required :

* Control should be capable of detecting the turret clamp switch signal within a period 5 ms.

* Motorshouldbeswitchedoffbysolidstaterelays,whichgivefastestpossibleoperation.Contactorstake

much longer time (30 to 40 ms). Suggested electrical circuit is on page 9.

* Incaseofdoubt,timedelaybetween'turretclampsignal'and'motorswitchoffsignal'shouldbemonitored

on a dual beam oscilloscope, with memory.

11.2 Safety interlocks :

11.21. 'MOTOR OVERHEAT' SIGNAL

Thermalrelayhasbeenprovidedinthemotorwindingtogiveindicationofmotoroverheating.Intheevent

ofoverheatingrelayshouldtripthemotorcontactor,andalsogive‘Motoroverheating’signaltothecontrol

circuit.Motorcontactor shouldbetripped withoutdependingon PLCsoftware.Typical circuitdiagramis

given in page 9.

11.22. 'TIME FAULT'’ SIGNAL

Timerequiredforindexingthrough180°isbetween1.3secondsto3.1secondsdependingonthemodel.

Thisis the maximum timerequiredforcompletingtheindexingoperation.Ifthe‘cyclecomplete’signalis

notreceivedevenafterthistime,thiswillbeanindicationofsomefaultintheindexingcycle.Controlcircuit

should be programmed to give a ‘Time Fault’ signal, if the ‘Cycle complete’ signal is not received within

a specified time (say 1 second more than the maximum expected time) after the ‘Cycle Start’ signal.

11.23.'TURRET NOT LOCKED' SIGNAL.

Turretclampswitchshouldbecontinuouslymonitored.Iftheclampsignalismissing,aFeedHoldsignal

should be generated to stop the machine movements. Simultaneously, ‘Turret not locked’ alarm signal

shouldalsobegenerated.

11.24. 'POSITION FAULT' SIGNAL

Attheendofindexingcycle,acheckshouldbemadetoensurethattheturrethasindexedtothedemanded

position.Iftheactualpositionanddemandedpositiondonotmatch,then‘Positionfault’alarmsignalshould

begenerated.

11.25. 'INVALID DEMAND' SIGNAL

An eight position turret cannot react to a tool demand other than 1 to 8. If any other tool position

(say 12) is demanded, the control should give out 'INVALID DEMAND' signal.

All these signals should stop the operation of the machine, and an indication should be available on the

control panel regarding the nature of the fault.

11.3 Manual mode of turret control

Control panel should have a facility to change over the turret control to manual mode. Following facilities

should be available in this mode :

11.31.’Inching’themotorineitherdirection:Duringservicing,itissometimesnecessarytorotatethemotor

for checking the functioning of the turret mechanism. Push button switches should be provided to allow

‘inching’ of the motor in either direction.

11.32. Toolindexingcycleon manual demand:Controlsystemshouldprovideafacilitytoindextheturret

into desired position by manual data entry of ‘tool demand’. This can be either by a ‘thumb wheel’ switch,

or by push button data entry through CNC panel.

Indexingcyclethroughmanualtooldemandwillbeidenticaltothenormalindexingcycle,exceptforthefact

the cycle will start even if initial signal conditions are not satisfied.

Turretcanstopinanunclampedposition,ifthepowerfailsduringtheindexingcycle.Itisthenpossiblethat

validencoderfeedbackisnotavailablebecausetheturrethasstoppedinanintermediateposition.Insuch

acase,inMDImode,thecontrolshouldchooseafixeddirectionofmotorrotation(i.e.defaultdirection)and

thenindexthe turretto demandedposition.

14

BI-DIRECTIONAL TOOL TURRETS

12. Replacement or adjustment of rotary encoder

Rotary encoder is fitted on flange (19) with the help of clamps (20). Encoder can be removed easily by

removing these clamps.

However, care should be taken while mounting the encoder back in its position. Angular position of the

encoder is important. Procedure for setting the encoder in proper angular orientation is as follows :

* Index the turret to any working position by hand cranking the motor shaft. Proper clamped position is

indicated by lighted LED on proximity switch (152).

* Aligntheslotofthedrivedog(23)withpin(22)onmainspindle(31)andmounttheencoderontheflange(19).

* Now rotate the encoder such that marks on encoder matches the marks on flange.

* Clamp the encoder in this position by tightening clamps (20).

FIG 12.1

A,B REFERENCE SLOTS

AB

31 22 23

SLOTONTHEMOUNTING

BLOCK(A) 19

b

13. Proximity switch adjustment and replacement (fig. 13.1)

Proximityswitchisoperatedbytheprojected‘switchingarea’ongearwheel(85);andindicatesthattheturret

is in clamped position. Actuation of the switch is indicated by built in LED (light emitting diode).

Operation of the switch can be checked by hand-cranking the turret. (refer page 11), crank motor shaft to

indexthe turret through360°. Turret willpass throughcycles of declamp-index-clamp;and your handcan

feel the pressure during ‘clamp’ phases.

Proximity switch LED should light up during all these ‘clamping’ phases. Flickering of the light, or

inconsistency of LED operation will be an indication of faulty proximity switch.

14. Replacement of proximity switch :

* Bring the turret in clamped position by hand cranking.

* Proximityswitchisapproachableafterremovingbackcover(60).Switchisheldinaclamp(153),andthe

clamp is bolted to the turret body by socket head screw (154).

* Removescrew(154),andtakeoutproximityswitchalongwithitsclamp.Measuredistance‘a’byvernier,

and note it down. Loosen clamping screw (155), and remove switch from the clamp.

* Measuredistance‘b’ betweentheclampseating surface,andthe sensingsurfaceon gear(85)byusing

avernieroradepthgauge.Distance‘a’bywhichtheproximityswitchprojectsoutfromtheclampshould

be adjusted to give a gap of 0.8 to 1 mm.

* Placenewswitchinposition.Crankturretbyhand,andcheckthefunctionofswitchbywatchingthesignals

on the built in LED.

a

152

153

156

LED

III

III

V

V

85

GAP 0.8 mm

154

155

60

FIG 14.1

MODEL Dist 'a'

BTP-125 25.5

BTP-100 25.5

BTP-80 22.5

BTP-63 23.5

BI-DIRECTIONAL TOOL TURRETS

15

16

BI-DIRECTIONAL TOOL TURRETS

FIG 15.2 VIEW WITH BACK COVER AND MOTOR REMOVED.

ACTUAL ORIENTATION OF AXES IS VISIBLE IN THIS VIEW

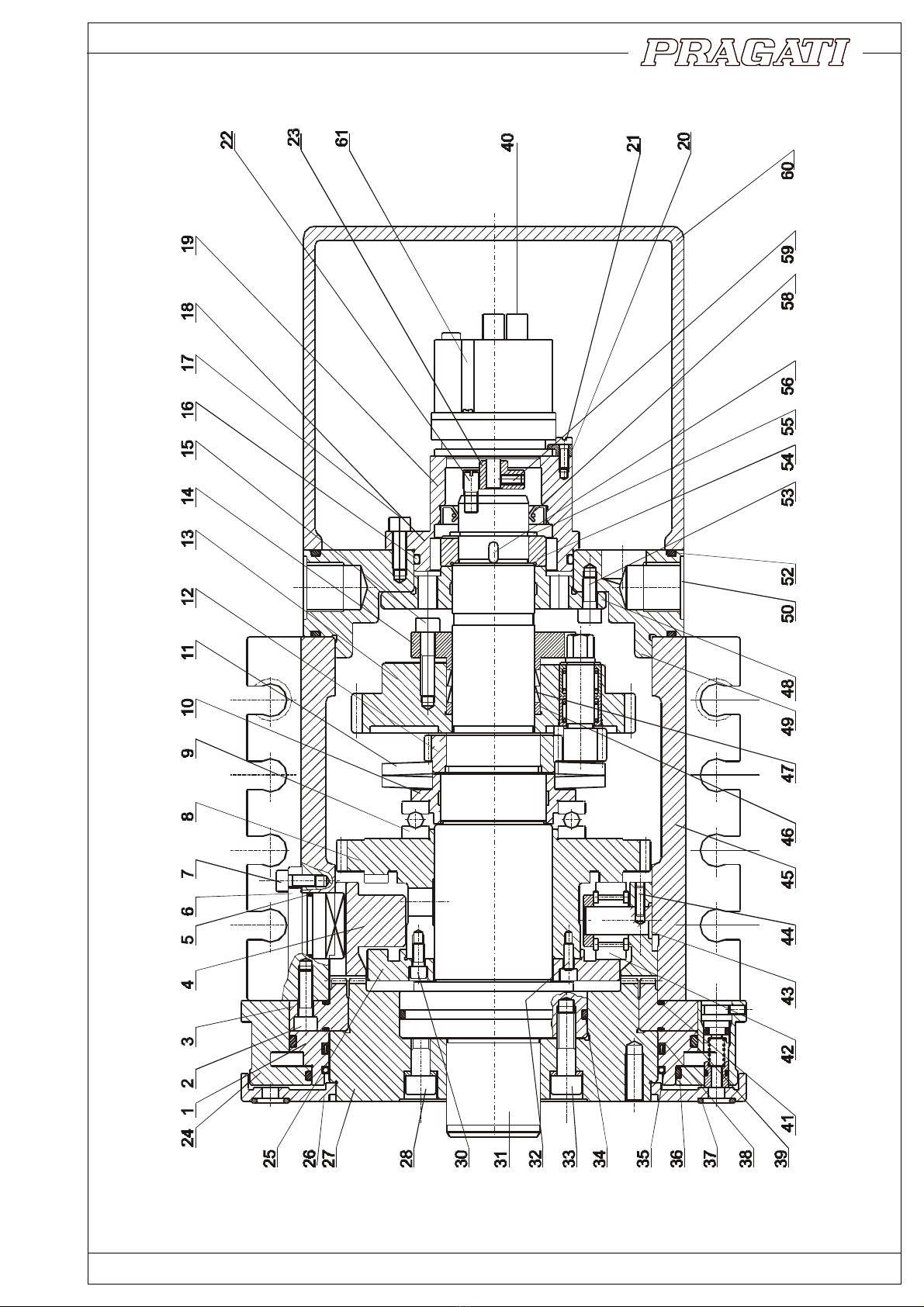

15. Assembly Drawings

FIG 15.1 OVERALL ASSEMBLY

ALL AXES ARE SHOWN IN ONE PLANE FOR CLARITY

140

141

142

151

91

90

152

153

154

86

150

FIG 15.3 MAIN SPINDLE ASSEMBLY

BI-DIRECTIONAL TOOL TURRETS

17

18

BI-DIRECTIONAL TOOL TURRETS

FIG 15.4B INDEXING DRIVE (BTP-125, BTP-100)

FIG 15.4A INDEXING DRIVE (BTP-80, BTP-63)

BI-DIRECTIONAL TOOL TURRETS

19

FIG 15.6 MOTOR ASSEMBLY

FIG 15.5 COOLANT VALVE ASSEMBLY

1. COOLANTRING(INNER)

2. SOCHD. SCR.

3. FIXEDCOUPLING

4. SLIDINGCOUPLING

5. ‘O’RING

6. ANTIROTATIONKEY

7. SOC.HD.SCR.

8. CAMGEAR

9. THRUSTBEARING

10. SPRINGSEAT

11. DISCSPRING

12. LOCKNUT

13. INDEXINGGEAR

14. RINGFEDERFLANGE

15. SOC. HD.SCR.

16. ‘O’RING

17. SOC.HDSCR.

19. FLANGE

20. CLAMP

21. SOC. HD.SCR.

22. PIN

23. DRIVEDOG

24. COOLANTRING(OUTER)

25. CAMFLANGE

26. COOLANTFLANGE

27. INDEXINGFLANGE(COUPLING)

28. SOC. HD.SCR.

30. SOC. HD.SCR.

31. SPINDLE

32. CYL.PIN

33. SOC. HD.SCR.

34. ‘O’RING

35. SPHAGHETTI HOUSE

36. ‘O’RING

37. SEAL

38. QUADRING

39. ‘O’ RING

40. CONNECTERSTRIP

41. ‘O’RING

42. CAMFOLLOWERBEARING

43. PIN

44. GRUBSCR.

NO. NAME

Note: Please specify the model and turret number, while ordering the spare parts.

94. LOCKNUT

95. GEAR

105. CIRCLIP

106. CIRCLIP

107. OILSEAL

108. ‘O’RING

109. MOTORFLANGE

110. SOC.HD. SCR.

111. SOC.HD. SCR.

112. STATOR

113. ROTOR

114. PINIONSHAFT

115. BEARING

116. CIRCLIP

117. THREADED

118. SOC.HD. SCR.

119. COVER

120. ‘O’ RING

121. MOTORBODY

130. COOLANTVALVEBUTTON

131. ‘O’RING

132. SPRING

133. ‘O’RING

134. PLUG

135. GRUBSCR.

136. PLUG

137. CLAMP

138. CSKSCREW

140. CLAMP

141. SOC.HD. SCR.

142. SOC.HD. SCR.

150. SOC.HD. SCR.

151. CYL.PIN

152. PROXIMITYSWITCH

153. CLAMP

154. SOC.HD. SCR.

155. SOC.HD. SCR.

156. 'O'RING

160. PLUG

161. PLUG

NO. NAME NO. NAME

45. MAINBODY

46. SPACER

47. RINGFEDERELEMENT

48. BEARINGFLANGE

49. ENDPLATE

50. PLUG

51. WASHER

52. ‘O’RING

53. SOC. HD.SCR.

55. CIRCLIP

56. KEY

58. OILSEAL

59. GRUBSCR.

60. BACKCOVER

61. ENCODER

62. PINION

63. CIRCLIP

64. NEEDLEBEARING

65. 'O'RING

70. CIRCLIP

71. BEARING

72. PINIONSHAFT

73. CAMSHAFT

74. KEY

75. INDEXINGCAM

76. ROLLERHOUSING

77. PIN

78. TRACKROLLER

79. NEEDLEBEARING

80. BINDINGRING

81. GRUBSCR.

82. INDEXINGPINION

83. KEY

85. GEAR

86. BEARINGCOVER

87. KEY

88. CIRCLIP

89. SOC. HD.SCR.

90. BEARINGCOVER

91. BEARINGCOVER

92. LOCKWASHER

93. KEY

20

BI-DIRECTIONAL TOOL TURRETS

15.1 Partlist

BI-DIRECTIONAL TOOL TURRETS

21

16. Instructions for dismantling of the mechanical components

Turret may have to be opened up in following circumstances :

Mechanicaljamoftheturret.Ifturretcannotbeindexedevenbyhandcranking,itwillbenecessarytoopen

up the turret for inspection.

Unusualknockingsoundduringindexingisalsoanindicationofmechanicalproblem.Thiscanbecaused

due to accidental collision with lathe chuck or other components. If the turret does not function properly

immediately after an accident, internal component damage can be suspected.

16.1 Instructions for dismantling (fig 15.1, 15.2, 15.3)

* Remove the turret from the lathe after draining lubrication oil.

* Remove coolant flange (26) and coolant ring (24,1).

* Remove rear cover (60).

* Removemotor.

* Remove encoder (61) and mounting flange (19).

* Removegear (95).

* Removeproximity switch(152),along withits clamp(153).

* Remove circlip (55).

* Remove screws (150). Use extraction screws and pull out the end plate (49).

* Remove gear (85) after removing circlip (88), fig.15.4.

* Loosen clamping screws (15) of friction ring coupling and pull out the index gear (13).

* ShaftsII,III&IVcannowbepulledout.Ifnecessary,usethreadedholesattheshaftcentreforattaching

apuller.

* Removeanti-rotationkey(16).

* Releaseclamping bolts (2),use extraction screwsand pullout the spindleassembly.

16.2 Dismantling of disc spring and drum-cam assembly (fig 17.5)

* Considerableforceisrequiredtoloosenthenut(12).Toreleasethenut,clamptheindexgearassembly

(fig 17.5) back in position. This will engage the pinion (162) onto the gear teeth of the nut (12). Now, the

nut can be released by turning the pinon with the help of a spanner.

* In models BTP-50,BTP-63,BTP-80,the nut can be losened using a 'C'-spaner

* Drum cam assembly (fig 17.1) along with the sliding coupling (4) can now be removed.

* Remove screws (30) to seperate two parts of drum cam as well as the sliding coupling.

16.3 Inspection of mechanical components (fig 15.4, 15.3)

* Check that the cam follower bearing (42) and (72) are in good condition (8,25).

* Check that the working surfaces of indexing cam (75) and drum cam are in good condition.

* Check that wiper seals (35) and (39) are in good condition.

This manual suits for next models

3

Table of contents

Other Pragati Lathe manuals