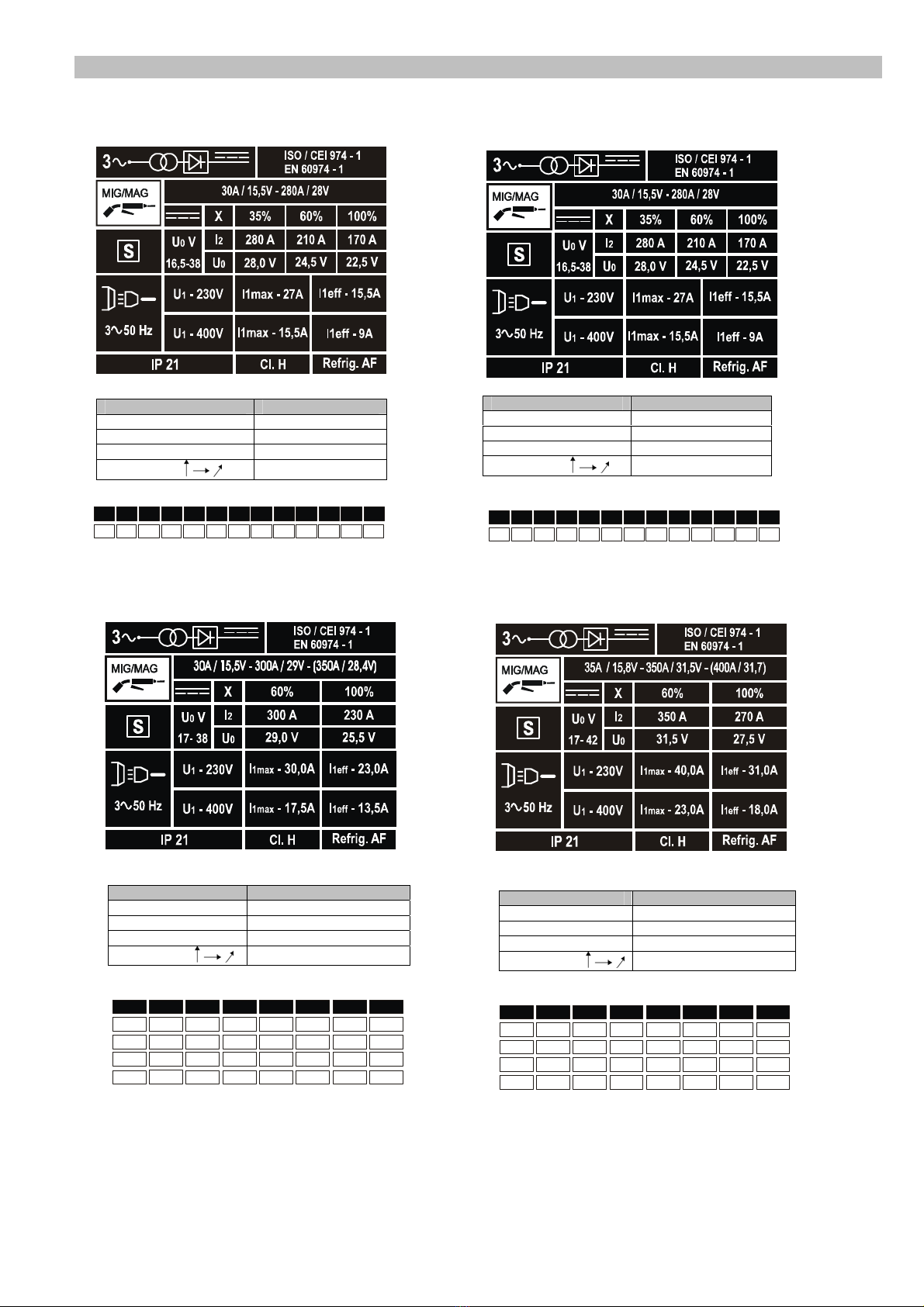

MIG COMPACT 220H/2R / 250H/2R / 290H/2R / 300H/4R / 350H/4R / 400H/4R

3

1 - SAFETY PRESCRIPTIONS FOR ARC WELDING GENERATORS

The Safety Prescriptions given in this manual do not replace but summarise the obligations for compliance with the current safety and accident-

prevention regulations. Before install, operate or maintain the welding equipment, read and understand carefully the current safety and accident-

prevention regulations.

In any case, the personnel involved in the use of the welding machine must be adequately trained with regard to use of the machine and

observance of the fundamental welding rules.

Setting up of the work area must comply with certain fundamental principles. Basic safety of persons and things depends on the observance of

these minimum requires.

1. Personal Protection

The skin or eyes burns resulting from the exposure to the electric arc welding radiations or metal fusion can bring more dangerous effects

than sunburn. Therefore:

a) Use a protection mask equipped with the respective inhatinic filter to protect the eyes, face, neck and ears from the projections and the arc

welding radiation. Prevent the persons near the welding places of the negative effects provoked by the arc welding radiations or metal fusion.

b) Use non-inflammable gloves, long sleeves shirt, trousers without folds, boots, welding mask, apron and hat to protect the hair. These

protections are needed to insure that the skin stays protected from the referred radiations.

Avoid using clothes with pockets or folds so that in case of occurring any projection of hot metal these will not deposit in the clothes’ folds or

pockets.

c) To protect the persons near the welding place, separations of non-inflammable curtains ought to be installed.

d) Always use safety glasses when standing in a place where metal projections can occur. Persons that circulate in the working area ought to use

safety glasses.

2. Preventing Fires

The projections can cause fires when in contact with combustible substances, liquids or gaseous. Therefore:

a) Every combustible material must stay far from the working place. When possible the combustible materials must be covered with non-

inflammable covers. These materials include wool, clothes, sawdust, natural gas, acetylene, propane and similar materials.

b) The metal projections can penetrate in wall or floor cracks causing non detectable latent fire. These cracks must be conveniently protected

from the metal fusion projections.

c) Welding, cutting or any kind of hot operation should not be made in recipients, deposits, tanks or other kind of used containers that haven’t

been carefully cleaned from substances that can produce toxic or inflammable vapours.

d) For protection against fire must exists a fire extinguisher system nearby, that can be used quickly like a water hose, a water recipient, sand or a

portable extinguisher.

e) Once the welding operations are concluded, the working area must be inspected to insure the absence of metal fusion projections that can

cause further fires.

3. Electric Discharge

Burns or mortal electrocution can be caused by 110 voltages or less. The gravity of this kind of discharges is determined by the intensity of

electric current that passes through the human body. Therefore:

a) Do not permit contact of the skin with metal pieces or even the use of wet or humid clothing. Wear only well dry gloves.

b) If it’s really needed to make welding operations in humid places the operators must wear very well dry gloves, rubber shoes or boots and

stepping the dry floor in order to be isolated from the electric current.

c) The welding machine must be connected to an electrical board equipped with an appropriate differential and earth connection. The earth

connection wire’s section must be correct according the norms about electric cables.

d) Do not use damaged welding cables. Do not overload the cable. Cable extensions or connections must be always correctly isolated.

e) The equipment must remain disconnected when not in use because an accidental electrical discharge can cause overheating and provoke a

fire. Do not roll the welding cable around the body.

f) The earth cable must be connected to the welding piece closest from the welding area. Welding current must passes through metallic elevations

or crane cables if long distance earth cable connections are made.

4. Ventilation

The smoke produced by the welding, mainly in closed spaces can provoke irritations if breathed during a long period of time.

a) Always take special care having proper ventilation in the welding places by the means of natural or forced ventilation systems. Do not weld

over zinc galvanised materials, cadmium, lead or beryllium, without prevent the needed ventilation to avoid smoke provoked by the welding of

these materials.

b) Do not weld near places containing chlorinated hydrocarbon vapours resultants from degreasing operations. Reactions can be provoked from

the vapours of dissolvents with the resultant heat of electric welding arc producing toxic or irritating gas.

c) Eye, nose or throat irritations during the welding process means that the ventilation system isn’t proper. In this case the ventilation should be

increased in the welding area. Stop the welding operation if the irritations persist.

5. Equipment maintenance

The quality of the welding process depends on the good condition of the welding equipment. To maintain it’s good condition and protect the

operator, maintenance reviews should be made periodically. If reviews aren’t made, accidents can occur due to fire or electric discharges.

Therefore:

a) The equipment installation and maintenance operations must be done by qualified personal. Do not proceed with electric repairs if you are not

properly qualified.

b) Before starting with any maintenance operation the welding equipment must be disconnect from the power supply.

c) The welding cables and the power supply cable and even the welding machine must be kept in good working conditions. This equipment must

never be used in less proper working conditions.

d) The welding equipment and its accessories must be treated carefully. Keep the machine far from heating sources, ovens or hothouses, from

humid places as water wells, oils or lubricants, from corrosive environments or intemperate weather.

e) Keep the safety systems and the chassis of the machine in proper working conditions.