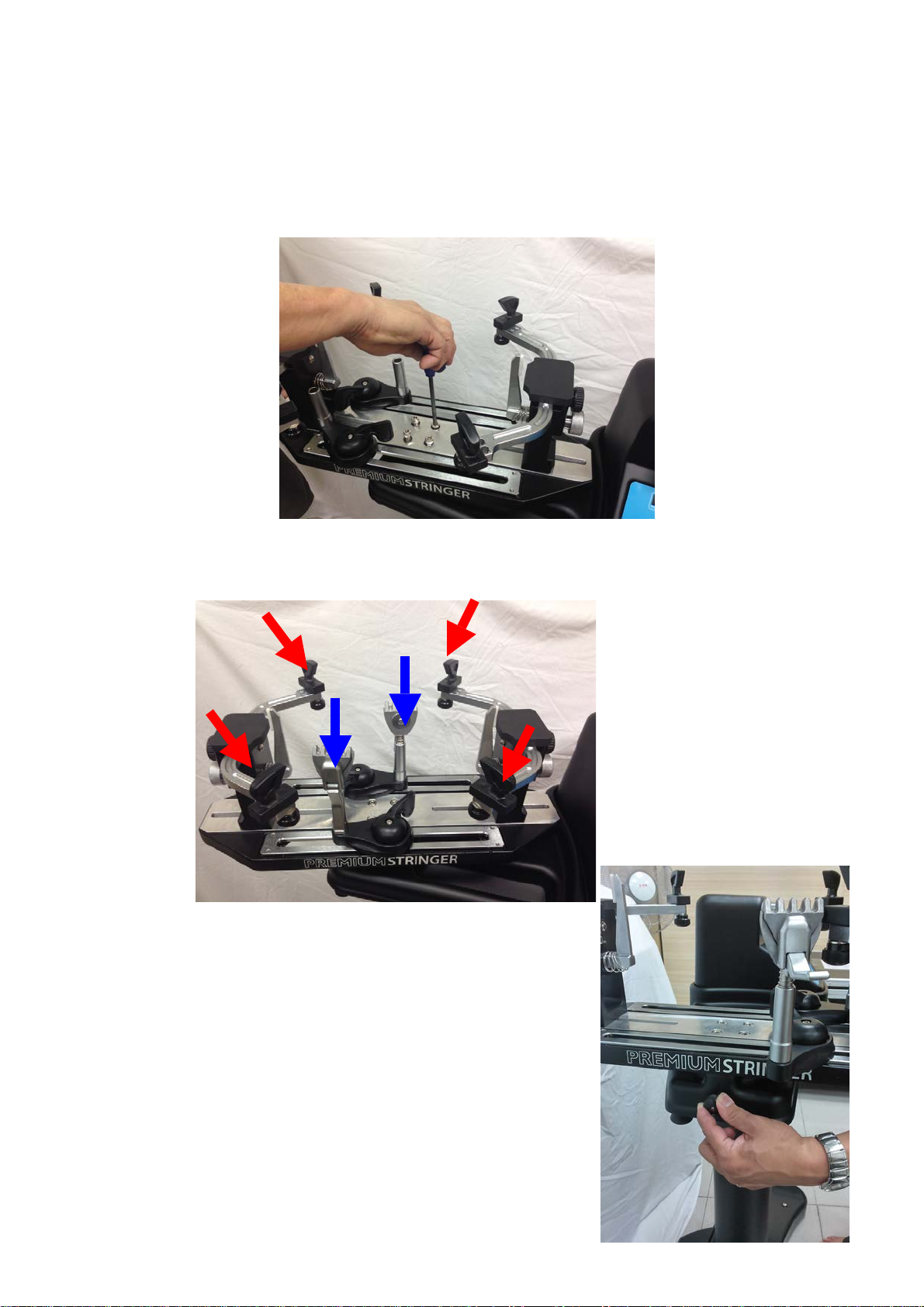

4. MOUNTING THE RACQUET FRAME

1. Begin by turning the black (side support adjustment) and chromed (center support

adjustment) knobs on the two mounting stocks counterclockwise to open the side

support arms and reduce the spread of the vertical supports.

2. Spread the mounting stocks so that the vertical centers supports fit within

the racquet head without touching it. The stocks are loosened from below the

turntable.

3. Locate the center points of the racquet at the head and throat and place them

next to the vertical supports on the mounting stocks. The turntable indicate

which stock the head and throat go on.

4. Turn the black side support arm adjustment knobs on each mounting stocks

clockwise to bring the side supports in contact with the racquet at all four points.

Note that the racquet levels and centers itself as the side supports cradle it.

Do not over tighten.

5. Now turn the chromed knob clockwise to tighten the vertical supports.

Ensure that the supports fit between the grommets in the center of the racquet.

Do not over tighten or the racquet may be difficult to remove at the end of

the string job.

An exclusive W-adapter is installed on your 8900 to spread stringing loads over

a wider area of the racquet at the head and throat. In cases where the W-adapter

doesn’t fit between the grommets of tennis racquet frame, it can be replaced with

a traditional straight support (I-adapter).