PrepPal PPM-10 Owner's manual

1

OWNER /OPERATOR

MANUAL

Models

PPM-10 , Planetary Bench Mixer, 10 Qt

PPM-20 , Planetary Floor Mixer, 20 Qt

PPM-30 , Planetary Floor Mixer, 30 Qt

IMPORTANT NOTICE

This manual contains Important Safety

Instructions which must be strictly

followed when using this equipment.

Toll Free : 1-800-683-8660(USA)855-885-6518(Canada)

Email:warranty@atosausa.com

2

Safety Reminding

These precautions should be followed at all times. Failure to follow these precautions could

result in injury to yourself and others or damage the equipment.

Plug only into grounded electrical outlets matching the nameplate rated voltage.

Do not modify or tamper with safety switches.

Do not operate unattended.

Do not operate equipment in public areas and/or around children.

Do not use an extension cord with this equipment. Do not plug this equipment into a power

strip or multi-outlet power cord.

Non-PrepPal attachments are not recommended. They will not work properly and will void the

warranty.

Check equipment before each use to insure the equipment is clean.

Do not use a hose to clean mixer. Use a damp cloth to wipe down the exterior of the mixer.

Wear proper apparel! Do not wear loose fitting or hanging garments while operating this

equipment.

Have equipment installed by a qualified personnel in accordance with local codes and

ordinances.

Use equipment in a flat, level position.

Unplug equipment, turn off and let it cool before cleaning or moving.

Do not spray controls or outside of equipment with liquids or cleaning agents.

Do not clean the equipment with steel wool.

Keep equipment and power cord away from open flames, electric burners or excessive heat.

Do not operate if equipment has been damaged or is malfunctioning in any way.

Do not use the attachments on hub while mixing.

3

Product Description

4

Installation

Unpacking and Initial Setup:

Note: Do not plug mixer into a power strip or multi-outlet power cord.

Check the Planetary Shaft Rotate Direction

Operation Instruction

Carefully remove carton, crating or

package material from equipment. Mixers

on pallets are bolted on the pallet, insert

wrench under pallet to loose belt. When

no longer need, dispose of all packing

material in an environmentally responsible

manner.

Place the mixer on a solid, level

surface with sufficient space around mixer

to allow for the safe cleaning and service.

Plug only into grounded electrical

outlets matching the nameplate rated

voltage.

Make sure there is not anything in bowl, and no mixer

tool on the shaft, put speed lever on one speed and

turn on the mixer;

Observe the shaft rotate direction is comply with the

arrow showed on the planetary shaft or not

If shaft rotates in the wrong direction, have a licensed

electric technician switch the electrical connection

and reset.

DO NOT operate the mixer before reading the instruction

first;

ALWAYS disconnect or unplug electrical power before

leaning, servicing or adjusting any parts or attachments;

ALWAYS keep hands, hair, and clothing away from moving

parts.

5

Attaching the Agitator to the Mixer Shaft(Beater, Hook, Whip)

1. Rotate the bowl guard to the left so it rests in the open position. Excessive force used to open

and close the bowl guard may damage the spring lock and bowl guard micro switch, and will

void the warranty.

2. Slide the agitator slowly upwards onto the planetary shaft fitting the shaft pin through the slot

in the agitator .

3. Rotate the agitator clockwise to secure it onto the planetary shaft.

Attaching the Bowl to the Mixer

1. lower the bowl by pulling the bowl lift lever forward and down to its resting position.

2. lift the bowl by the bowl handles and

a) slowly position the locking pin (located on the rear of the bowl) into the hole in the middle

rear of the cradle.

b) lower the bowl onto the pins located on either side of the bowl cradle.

3. Once the bowl is positioned on the cradle, secure the bowl by pulling each bowl clamp forward

until the bowl is locked tight.

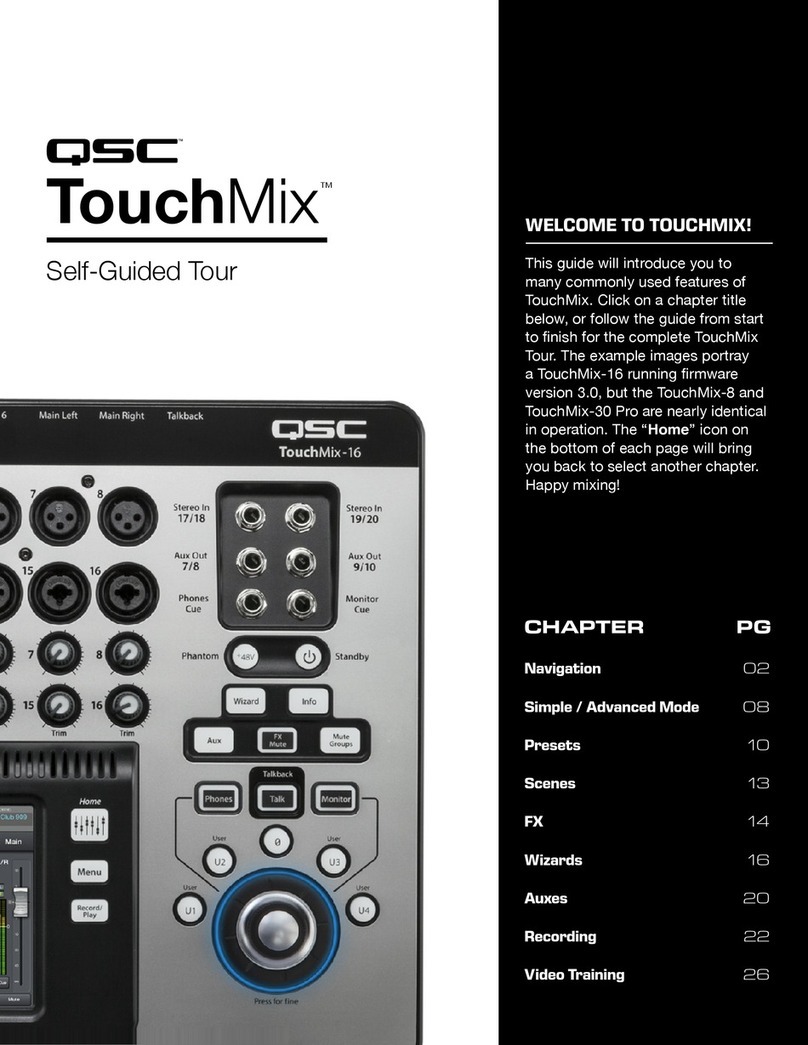

Setting Speeding

Select the appropriate speed setting by lifting or lowering

the speed control lever. Three fixed speeds are available

for use: first (1), second (2), and third (3).

Speed setting by different type of food and ingredient as

following:

Gear Speed

Product Type/ingredient

1 (low)

Heavy: mixing pizza, bread, pasta and

donut dough’s, waffle/cake batter,

mashing potatoes

2 (medium)

Medium: 2nd stage of mixing for donut

dough, etc.

3 (high)

light: whipping cream, egg whites,

meringue

Please follow the capacity chart to choose agitator

and speed.

NOTE: AlWAYS STOP the mixer before

changing speeds!

6

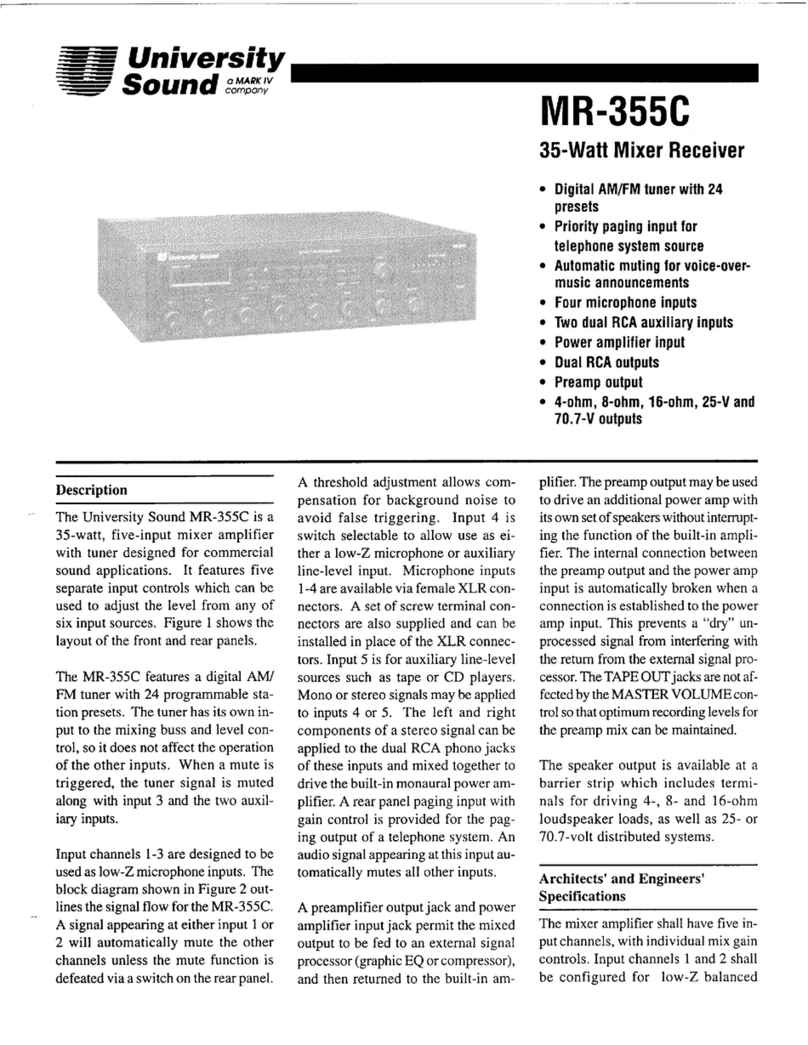

Setting Timer

Use the Attachment Hub

Set the timer for the appropriate mixing time or set

the mixer for non-timed operation.

a. Timed Operation: Turn the timer knob in

a clockwise direction at the position

between “5” to “30”, to get mixing time

between 5 mins to 30mins.

b. Non-Timed Operation: Turn the timer

knob in a counterclockwise direction to the

green “on” position.

NOTE: Heavy loads should not be mixed

longer than fifteen (15) minutes at this setting

without an equal amount of rest time for the mixer.

failure to adhere to these instructions may cause the

mixer to automatically shut off due to overloading.

Loosen and remove the attachment hub fasten screw.

Remove the plastic hub cover from the attachment hub.

lubricate the attachment shaft with a food quality grease or mineral oil.

Insert the attachment shaft into the hub making sure to line up the alignment pin with

the hub hole.

Tighten the thumbscrew back into the hub and securely tighten it.

Select the appropriate speed setting by lifting or lowering the speed control lever.

Recommended Speed while using attachments:

attachment recommended Speed

Vegetable Slicer 1 or 2

cheese Shredder/Grater 2 or 3

Meat Grinder 1 only

7

Cleaning & Maintenance Instructions

1. ALWAYS disconnect or unplug the electrical power from the mixer before cleaning.

2. The entire mixer, including removable parts, must be thoroughly cleaned and

sanitized using the procedures identified by your local health department and the

ServSafe Essentials published by the National Restaurant Association Educational

Foundation (NRAEF).

3. NEVER use a scruber pad, steel wool, or abrasive material to clean the mixer.

Recommended Cleaning Action as:

PART

REQUIRED ACTION

FREQUENCY

Agitators

hand-wash using mild soap and water, rinse, dry

and sanitize.

Clean after each use.

Removable

bowl Guard

hand-wash using mild soap and water, rinse, dry

and

sanitize or place in dishwasher.

Clean after each use.

Bowl

using a sponge or cloth, mild soap and water, apply

pressure to ensure the bowl is clean, rinse, dry, and

sanitize. The bowl can also be placed in a

dishwasher.

Clean after each use.

Rear Splash

Guard

hand-wash using mild soap and water, rinse, dry

and

sanitize.

Clean after each use.

bowl cradle

hand-wash using mild soap and water, rinse, dry

and

sanitize.

Daily

Planetary Shaft

Wipe with clean damp cloth, dry and sanitize. apply

a light quantity of Globe oil (mineral oil) to the

planetary shaft after cleaning.

Clean after each use.

exterior

hand-wash using mild soap and water, rinse, dry,

and sanitize. DO NOT use a water hose!

Daily

hub interior

Wipe with clean damp cloth, dry, and sanitize.

Daily

8

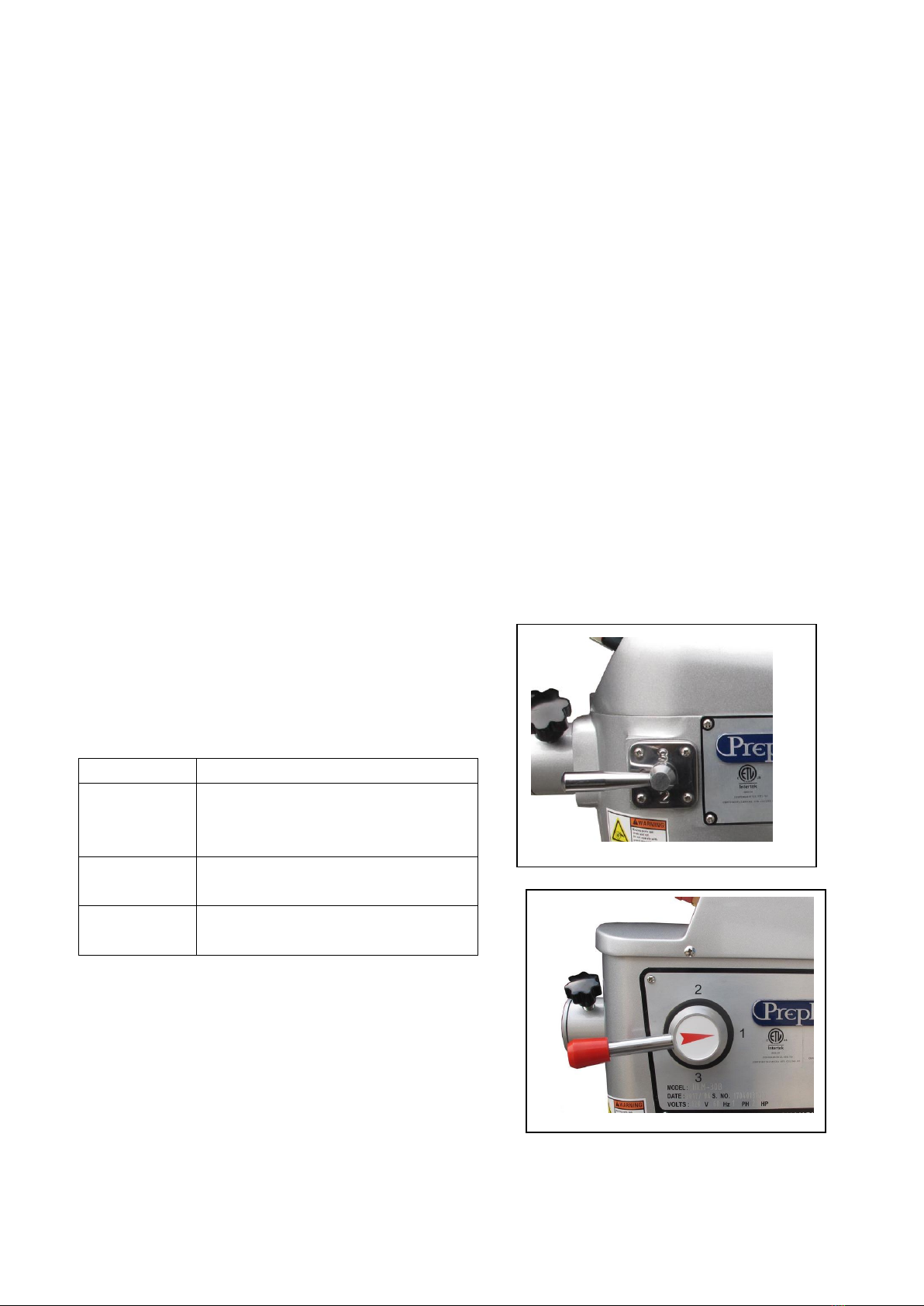

Mixing Capacity Chart

Product

Agitator

Speed

PPM-10

10Quart

PPM-20

20Quart

PPM-30

30Quart

PPM-40

40Quart

PPM-60

60Quart

Bread and Roll

Dough-60% AR

Dough Hook

1st speed

only

5 lbs.

25 lbs.

45 lbs.

50 lbs.

90 lbs.

Heavy Bread

Dough-55% AR

Dough Hook

1st speed

only

3 lbs.

15 lbs.

30 lbs.

40 lbs.

70 lbs.

Pizza Dough,

Thin-40% AR

Dough Hook

1st speed

only

3 lbs.

9 lbs.

14 lbs.

25 lbs.

40 lbs.

Pizza Dough,

Medium-50% AR

Dough Hook

1st speed

only

4 lbs.

10 lbs.

20 lbs.

32 lbs.

60 lbs.

Pizza Dough,

Thick-60% AR

Dough Hook

1st speed

only

5 lbs.

20 lbs.

40 lbs.

50 lbs.

70 lbs.

Raised Donut

Dough-65% AR

Dough Hook

1st speed

only

2 lbs.

9 lbs.

15 lbs.

25 lbs.

40 lbs.

Pie Dough

Flat Beater

All Speeds

4 lbs.

18 lbs.

30 lbs.

35 lbs.

60 lbs.

Mashed Potatoes

Flat Beater

All Speeds

5 lbs.

15 lbs.

23 lbs.

30 lbs.

45 lbs.

Cake

Flat Beater

All Speeds

8 lbs.

20 lbs.

30 lbs.

12 lbs.

60 lbs.

Waffle or Hot Cake

Batter

Flat Beater

All Speeds

4 qts.

8 qts.

12 qts.

16 qts.

24 qts.

Eggs Whites

Wire Wish

All Speeds

1 pt.

1 qts.

1-1/2 qts.

2 qts.

3 qts.

Meringue

Wire Wish

All Speeds

3/4 pt.

1 qts.

1-1/2 qts.

2 qts.

3 qts.

Whipped Cream

Wire Wish

All Speeds

2 qts.

4 qts.

6 qts.

8 qts.

12 qts.

Cake,Pound

Flat Beater

All Speeds

8 lbs.

20 lbs.

30 lbs.

40 lbs.

60 lbs.

When mixing dough check the “AR”(Absorption Ratio) = Water weigh divided by flour weight.

The capacities listed above are based on 12% flour moisture at 70 °F(21℃) water temperature. If high gluten

flour

is used reduce batch size by 10%.

1 gallon of water = 8.3 lbs.

1 quart of water = 2.1 lbs.

Example :

If a recipe calls for 5 lbs. of water and 10 lbs. of flour, then 5 divided by 10 = 0.50x100=50% AR.

Do not use 2nd speed with mixtures with below 50% AR.

9

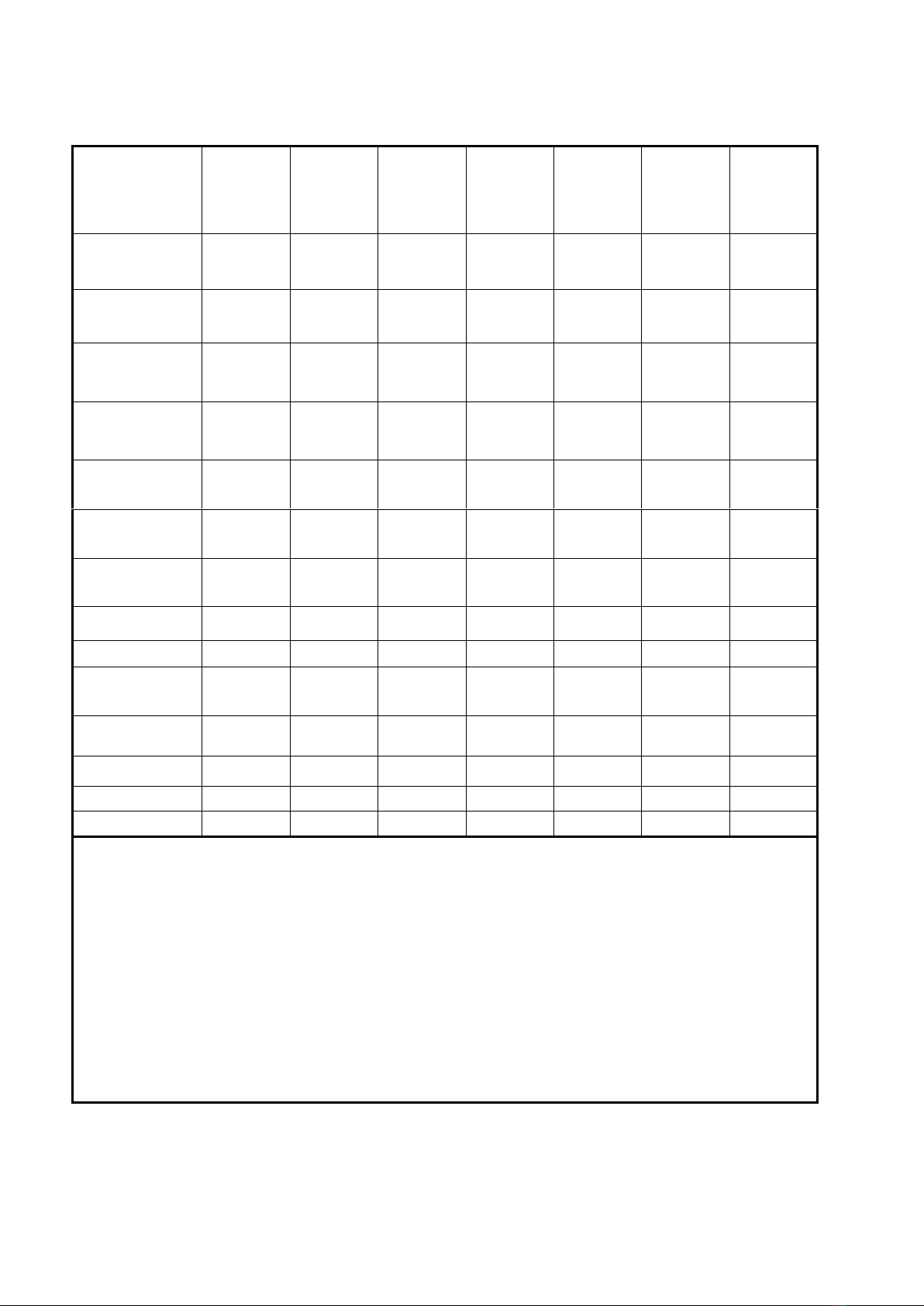

Troubleshooting

Problem

Possible Causes

Action Required

Mixer will not run.

bowl guard not in closed

position.

rotate guard to the right until fully closed.

bowl not raised.

raise bowl to highest position.

Timer is not engaged.

Turn timer to desired time or set time to the “on”

position.

Power not connected properly.

check all power connections. Plug into a live

socket.(Do not use extension cord!) Test socket

with another item

building circuit breaker is off.

check breaker box.

internal overload tripped.

Press stop button then press reset button.

(If overload continues to trip, reduce batch size

and/or adjust recipe!)

Gear not engaged.

Switch gear fully into position. (Mixer will not

operate if the speed control lever is positioned in

between speeds)

Mixer stops during

mixing .

internal overload tripped.

Press stop button then press reset button.

(If overload continues to trip, reduce batch size

and/or adjust recipe!)

Motor temperature is too high

Voltage is too low, or use wrong agitator or set

incorrect speed.

Mixer is noisy.

Mixer is not installed on level

surface.

adjust surface or relocate mixer. Make sure rubber

feet are installed.

bowl not seated correctly or

clamps not in place.

ensure bowl is seated into bowl cradle correctly

and bowl clamps are locked into place.

Agitator not fitted properly.

Remove and attach agitator into position properly.

Overloading bowl.

reduce batch size. (See Capacity Chart)

Planetary ring gear needs more

grease.

Technician to inspect for source of noise.

reapply high-pressure grease. contact technician.

Safety guard seized

(will not move

freely).

clean & lubricate slide

sheath.

Technician must drop down planetary assembly to

access mat & sheath. contact technician.

agitators won’t go

onto the planetary

shaft easily.

lack of lubrica

lack of lubrication and/or

cleaning of the planetary shaft.

Wipe planetary shaft with a clean damp cloth and

lubricate the shaft with mineral oil or food quality

grease.

agitators touching

bottom or sides of

bowl.

Defective or dented bowl.

remove dents or replace bowl.

Defective agitator.

replace agitator.

10

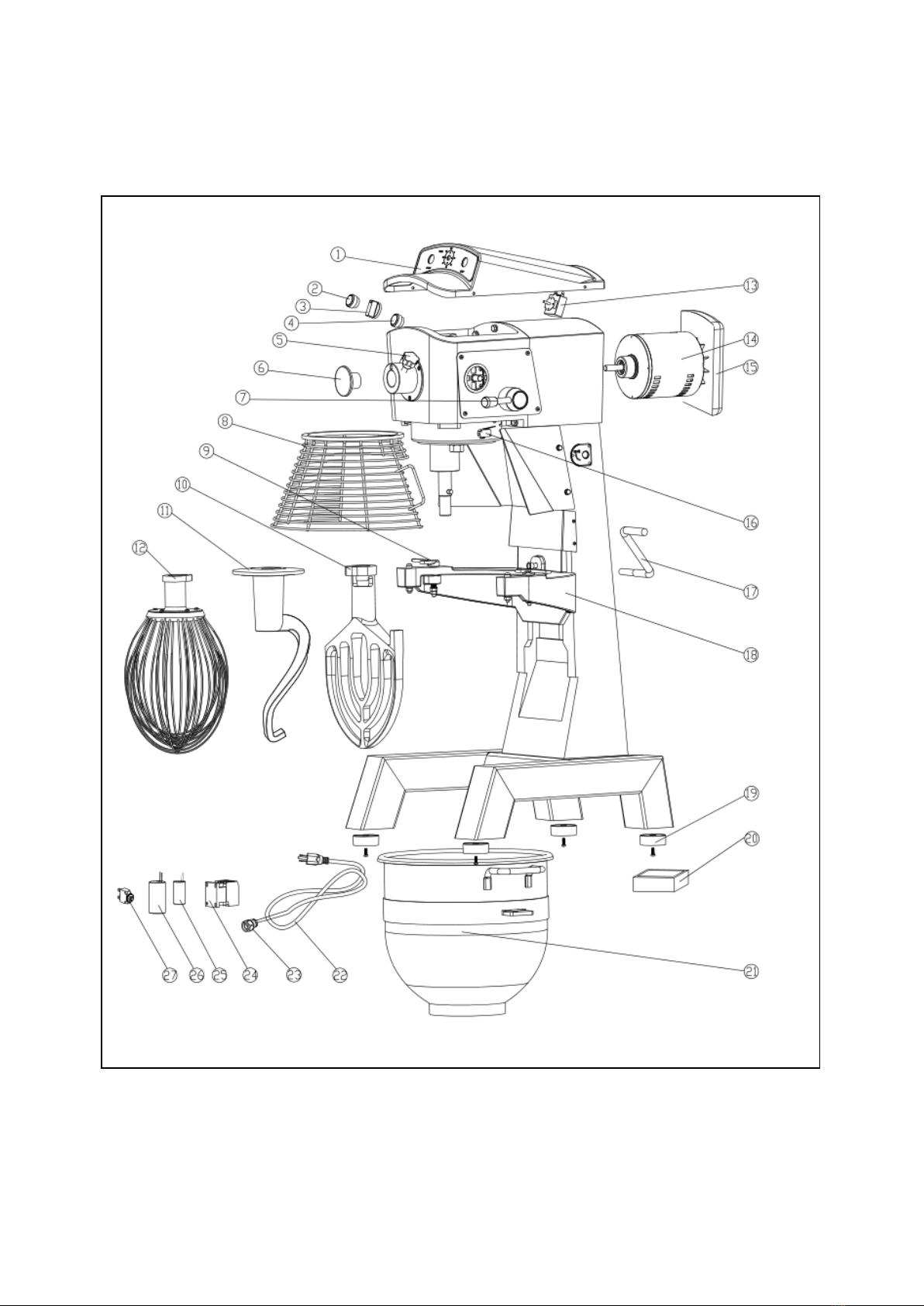

Service Parts

Exploded View of PPM-30

11

Parts list of PPM-30

Ref. No. on

exploded view

Part Number

Description

Qty

1

PPM3001

Top cover(with six screws)

1

2

PPM0001

Start button(Green) for 20/30

1

3

PPM0002

Timer knob for 10/20/30

1

4

PPM0003

Stop button(Red) for 20/30

1

5

PPM0004

Hub fasten screw for 20/30

1

6

PPM0005

Attachment hub cover for 20/30

1

7

PPM3002

Speed handle assy

1set

8

PPM3003

Bowl safety guard

1

9

PPM3004

Bowl hold clamp

2

10

PPM3005

Beater

1

11

PPM3006

Hook

1

12

PPM3007

Wire Whip

1

13

PPM0006

Timer(with four screws)

1

14

PPM3008

110V/60HZ Motor(with tool)

1

15

PPM3009

Back cover

1

16

PPM3010

Distance switch

1

17

PPM3011

Bowl lift lever handle

1

18

PPM3012

Support

1

19

PPM3013

Rubber feet

1 set

20

PPM3014

Sleeve rubber feet

1 set

21

PPM3015

Bowl

1

22

PPM3016

Power cord

1

23

PPM3017

Power supply proof connectors

1

24

PPM3018

Contact relay

1

25

PPM3019

Running Capacitor

1

26

PPM3020

Starting Capacitor

1

27

PPM3021

Overload switch

1

12

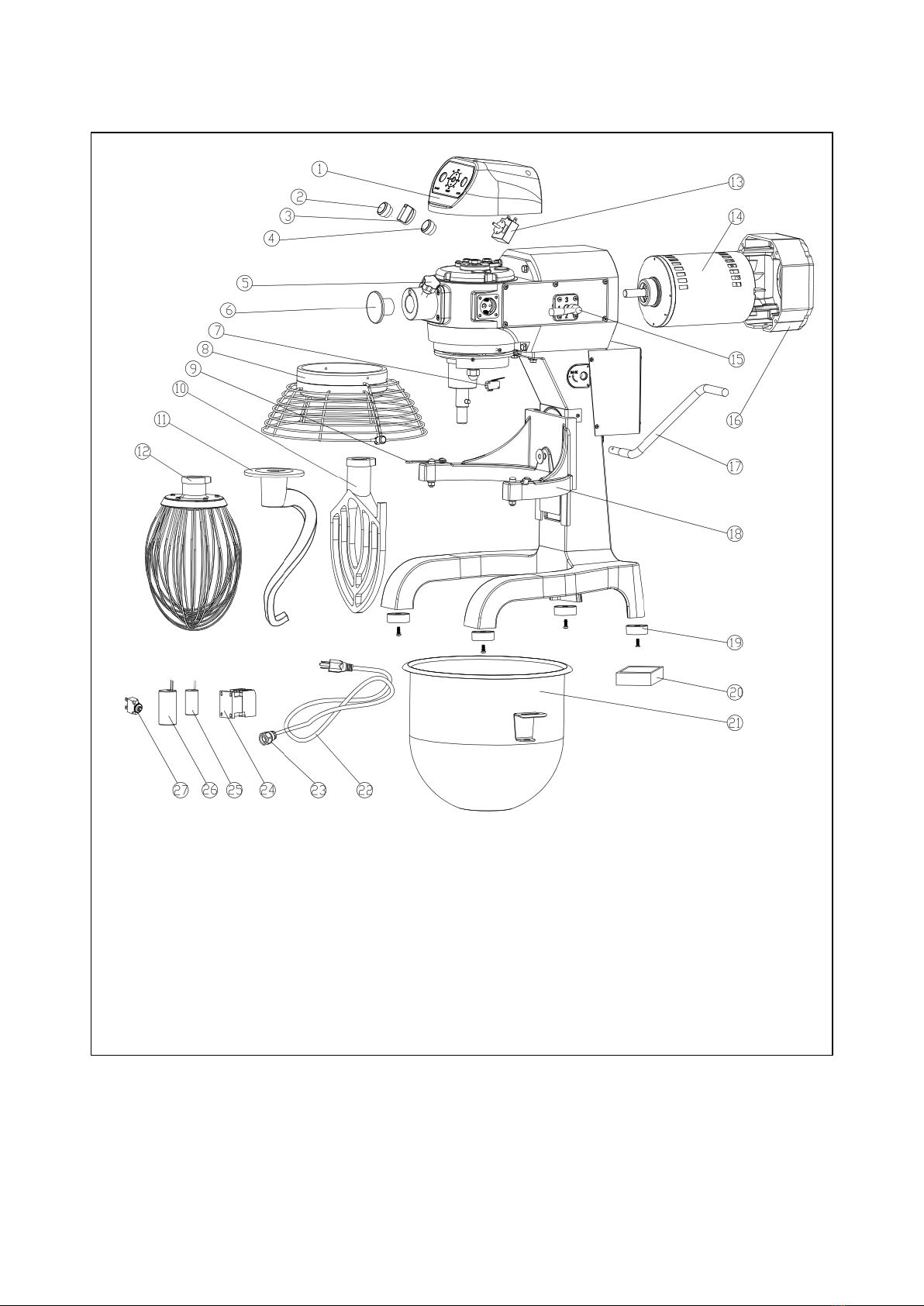

Exploded View of PPM-20

13

Parts list of PPM-20

Ref. No. on

exploded

view

Part No

Description

Qty

1

PPM2001

Top cover(with screws)

1

2

PPM0001

Start button(Green) for 20/30

1

3

PPM0002

Timer knob for 10/20/30

1

4

PPM0003

Stop button(Red) for 20/30

1

5

PPM0004

Hub fasten screw for 20/30

1

6

PPM0005

Attachment hub cover for 20/30

1

7

PPM2002

Distance switch

1

8

PPM2003

Safety guard

1

9

PPM2004

Bowl hold kits /Clip

2

10

PPM2005

Beater

1

11

PPM2006

Hook

1

12

PPM2007

Wire Whip

1

13

PPM0006

Timer(with four screws)

1

14

PPM2008

110V/60HZ Motor(with tool)

1

15

PPM2009

Speed handle assy

1set

16

PPM2010

Back cover

1

17

PPM2011

Handle-shifter

1

18

PPM2012

Support

1

19

PPM2013

Rubber feet

1 set

20

PPM2014

Sleeve rubber feet

1 set

21

PPM2015

Bowl

1

22

PPM2016

Power cord

1

23

PPM2017

Power waterproof connectors

1

24

PPM2018

Contact relay

1

25

PPM2019

Running Capacitor

1

26

PPM2020

Starting Capacitor

1

27

PPM2021

Overload switch

1

14

Exploded View of PPM-10

15

Parts list of PPM-10

Ref. No. on

exploded view

Part No

Description

Qty

1

PPM1001

Gear box

1

2

PPM1002

Distance switch

1

3

PPM1003

Back shield

1

4

PPM1004

Safety guard

1

5

PPM1005

Beater

1

6

PPM1006

Hook

1

7

PPM1007

Wire Whip

1

8

PPM1008

Back cover

1

9

PPM1009

110V/60HZ Motor(with tool)

1

10

PPM1010

Speed handle assy

1set

11

PPM1011

Start button(Green)

1

12

PPM1012

Stop button(Red)

1

13

PPM0006

Timer(with four screws)

1

14

PPM0002

Timer knob

1

15

PPM1013

Handle-shifter

1

16

PPM1014

Support

1

17

PPM1015

Rubber feet

1 set

18

PPM1016

Sleeve rubber feet

1 set

19

PPM1017

Bowl

1

20

PPM1018

Power cord

1

21

PPM1019

Power waterproof connectors

1

22

PPM1020

Contact relay

1

23

PPM1021

Running Capacitor

1

24

PPM1022

Starting Capacitor

1

25

PPM1023

Overload switch

1

16

17

18

This manual suits for next models

2

Table of contents

Other PrepPal Mixer manuals