PRESSCON LOX User manual

LOX - Low Oxygen System

User Manual

Type

:

User manual

Date

:

21 januari 2021

Version / Revision

:

Version 4.0, Revision 00

Status

:

Approved

Company

:

PRESSCON FX-Prevent

Location

:

Honselersdijk

2

3

Inhoudsopgave

1INTRODUCTION.............................................................................................................................................................4

THE GOALS OF THE INSTALLATION.................................................................................................................................4

REDUNDANCY .........................................................................................................................................................4

2PRECAUTIONS AND SAFETY INSTRUCTIONS FOR NITROGEN GENERATORS ....................................................................5

GENERAL SAFETY STANDARDS......................................................................................................................................5

WORKING WITH THE NITROGEN GENERATOR....................................................................................................................5

DESCRIPTION OF HAZARD SYMBOLS...............................................................................................................................5

3THE LOX INSTALLATION.................................................................................................................................................7

THE LOX SYSTEM BASICS ...........................................................................................................................................7

SYSTEM DESCRIPTION................................................................................................................................................9

Compressor............................................................................................................................................................ 9

Compressed air conditioning ................................................................................................................................. 9

Nitrogen generator................................................................................................................................................ 9

LOX opstelling...................................................................................................................................................... 10

Nitrogen inlet....................................................................................................................................................... 10

N2Control ............................................................................................................................................................ 11

Ox Control............................................................................................................................................................ 11

Oxygen sensors.................................................................................................................................................... 11

Informing and alerting ......................................................................................................................................... 12

The Color Display ................................................................................................................................................. 12

Emergency stop ................................................................................................................................................... 13

Humidity sensor................................................................................................................................................... 13

4BEDIENING VAN DE INSTALLATIE.......................................................................FOUT! BLADWIJZER NIET GEDEFINIEERD.

ECD DISPLAY .......................................................................................................................................................14

ECD Display front................................................................................................................................................. 14

Buttons on the ECD Display ................................................................................................................................. 14

Button functionality............................................................................................................................................. 15

Status LED’s ......................................................................................................................................................... 17

5ASSEMBLY INSTRUCTIONS...........................................................................................................................................18

6MEASURES DURING DECOMMISSIONING ....................................................................................................................18

7ERRORS .......................................................................................................................................................................19

ERRORLEVELS........................................................................................................................................................19

Error messages in general.................................................................................................................................... 20

Error messages from the N2Control.................................................................................................................... 24

Error messages from the ECD Display.................................................................................................................. 28

Error messages from the Ox Control ................................................................................................................... 32

Error messages from the FX Connect................................................................................................................... 36

TROUBLESHOOTING ................................................................................................................................................40

Reaction times..................................................................................................................................................... 40

8MAINTENANCE............................................................................................................................................................41

FX PREVENT.........................................................................................................................................................41

Compressor.......................................................................................................................................................... 41

LOX system .......................................................................................................................................................... 41

Oxygen sensors.................................................................................................................................................... 41

Pressure Equipment, examination of commissioning and reinspection during using phase............................... 42

MAINTENANCE CONTRACT........................................................................................................................................42

9APPENDIX....................................................................................................................................................................43

10 DOCUMENT HISTORY ..................................................................................................................................................43

11 TO CONCLUDE .............................................................................................................................................................44

4

1Introduction

The Goals of the installation

Fires can cause very great damage to the environment and to property. In addition, there is a high potential risk to humans.

The primary goal of the LOX system is to prevent fire in a specific area or to drastically reduce the risk of fire. A fire that does

start, despite of the precautions, will remain limited and will develop less quickly. This significantly increases the escape time

of those present and the intervention time for the emergency services.

The LOX system works on the basis of permanent oxygen reduction by supplementing additional nitrogen. The air around us

consists of approximately 20.8% oxygen, 78% nitrogen and 1% other gases. The LOX H.P. LOW OXYGEN system changes the

balance between oxygen and nitrogen. The optimum oxygen percentage depends on the nature of the flammable substances.

In the LOX system, a nitrogen generator is used. In this generator compressed air is separated into oxygen and nitrogen. The

oxygen is relieved into the surrounding area. The nitrogen is used to regulate the mixture of oxygen and nitrogen in the

protected room. The required compressed air is produced by means of a compressor.

Only FX Prevent or an authorized party is allowed to modify the installation. The installation should only be used for the

purpose for which it was designed. The system is designed and tuned for specific operating parameters. These may only be

changed by FX Prevent or its authorized party. The operating pressure of the installation is between 0 and 8 bar. The design

pressure is 10 bar. This pressure may not be exceeded under any circumstances. The temperature of the room where the

system is installed should be no lower than +3 °C and no higher than +40 °C.

Redundancy

The LOX system, like all other technical installations, has the risk of malfunctioning. When this happens, the prevention of fire

in a specific area can no longer be guaranteed. In order to still be able to give this guarantee, the concept of redundancy is

very important in the design of the LOW OXYGEN systems. FX-Prevent follows the Master/Slave principle for this.

A master version of the LOX system controls a complete single system. This can consist of a compressed air production

system, nitrogen generator system, sensors and a measurement and control module. The capacity is calculated in such a way

that the installation can independently control the percentage of the protected area.

A slave version of the LOX system controls a complete or partially complete installation. This can consist of a compressed air

production system, nitrogen generator system, sensors and a measurement and control module. The machine is designed in

such a way that it can independently maintain the percentage in the protected area if there is a problem in the master

system.

The composition of the Master and Slave system and the level of redundancy are tailored to the user's requirements and can

therefore be different for each installation.

5

2Precautions and safety instructions for nitrogen generators

General safety standards

When working with the nitrogen generator of FX Prevent, there are some safety risks that have to be considered. The risks

involve subjects such as dangerous voltage, high pressure and dangerous gas to inhale. This is addressed in this chapter. It is

highly recommended that the safety risks are observed before work on the devices is commenced.

Working with the nitrogen generator

The nitrogen generator is commonly located in the technical room of the facility. When operating or when working on the

nitrogen generator, the following hazards should be considered.

Symbool

Omschrijving

Geldt voor

HIGH PRESSURE, Relief

pressure from components

before work is conducted.

The external components of the nitrogen generator which are:

•Valves;

•Hoses;

•PSA vessels.

DANGEROUS VOLTAGE,

Forbidden to work on the

system if the power is on.

The internal parts of the control cabinets, UPS control cabinets, junction

boxes and sensors. These parts are:

•PCB’s within the control cabinets;

•PCB of UPS control cabinet;

•DC batteries of UPS control cabinet;

•The applied voltages are: 24V AC, 24V DC, 230V AC, 380V AC.

DANGER OF INHALATION,

danger of asphyxiation if

breathing high concentration

of nitrogen.

Avoid the specified area to

avoid health hazards.

The nitrogen output connection. The mixture produced by the nitrogen

generator consists of 95% or more nitrogen. Inhalation directly from the

output connection may cause intoxication. The nitrogen quickly mixes with

the ambient air so that at a distance of >0.5m from the nitrogen output

connection it no longer poses a health risk.

Description of hazard symbols

In addition to the identified risks for the nitrogen generator, the following symbols can also be applied within the system of

which the nitrogen generator is part of. When a hazard symbol is encountered, please observe its meaning carefully before

further commencing the work.

Symbool

Omschrijving

Symbool

Omschrijving

1. OVERPRESSURE VALVE,

Be aware of the sudden relief of

overpressure.

7. HIGH PRESSURE,

Relief pressure from components before work

is conducted.

2. DANGEROUS VOLTAGE,

Forbidden to work on the system if the

power is on.

8. HOT PARTS,

Do not touch parts with bare hands. Use heat-

resistant clothing.

3. DANGEROUS TO INHALE GAS,

Avoid the specified area or wear appropriate

breathing equipment.

9. SUFFOCATION,

If the oxygen concentration is to low then do

not enter the room, risk of suffocation.

4. MACHINE WITH AUTOMATIC START,

Machine stops and starts automatically

when it is operating normally. Turn off the

machine completely before working on it.

10. ROTATING FAN,

Risk of getting stuck or injuries to limbs. Turn

the machine off completely before working on

it.

5. NOISE,

Wear ear protection to prevent hearing

damage.

11. ATTENTION,

Special situation occurs, follow additional

instructions.

6. READ THE OPERATING AND

MAINTENANCE INSTRUCTIONS,

It is advised that the maintenance

instructions are read before continuing

work.

12. MOVING PARTS,

Risk of getting stuck or injuries to limbs. Turn

the machine off completely before working on

it.

6

For the precautions and safety instructions of miscellaneous components that are related to the nitrogen

generator, please refer to the enclosed instructions of those components that are provided by the

respected manufacturers. These can be found with the specific components upon delivery or are included

within the technical file of system of which the nitrogen generator is part of.

7

3The LOX installation

The LOX system basics

The LOX oxygen reduction system is delivered as a complete installation. On the next page a schematic overview of the

complete system and its components can be found. The drawing also shows that a distinction can be made between the LOX

unit and the area(‘s) to be protected.

The LOX system is usually installed separately from the room(s) to be protected, for example in the technical room. A

complete LOX system consists of:

•Compressed air facility;

•Water and oil separators;

•Compressed air buffer tank;

•One or more air dryers;

•Liquid and residual dust filters;

•Moisture detection sensor;

•The nitrogen generator(s);

•Dust filter(s);

•Nitrogen flow and purity measurement;

•Control cabinet;

•Piping for nitrogen supply;

•Flashing light;

•Acoustic alarm (slowwhoop / evacuation alarm);

•Door display at each access door;

•Communication equipment for communication with the supplier's failure department;

•Electrical cabling for the control centre(s), oxygen measuring equipment, alarm detectors and access control

equipment.

The LOX oxygen reduction system serves a maximum of 24 rooms. The following components are installed in each of these

rooms:

•Supply points for nitrogen;

•3 oxygen sensors (minimum 3 according to EN 16750);

•Flashing light;

•Acoustic alarm (slowwhoop / evacuation alarm);

•Door display at each entrance door except for automatic sluices.

If the LOX oxygen reduction system is used to protect a refrigerated area where the temperature is below 0 °C, an alternative

assembly is used. In this application, the following components are placed outside the protected areas:

•Flashing light;

•Acoustic alarm (slowwhoop / evacuation alarm);

•Door display at each entrance door except for automatic sluices.

8

Figure 1: Schematic setup of the LOX system basics.

9

System description

Compressor

For the operation of the nitrogen generator, a compressor with the necessary compressed air conditioning is available. The

compressor produces compressed air for the nitrogen generator. The compressor must be able to provide sufficient capacity

and keep the compressed air pressure in the buffer tank at the required level at all times to keep the system operational.

As soon as there is a temporary voltage drop, the compressor must be activated manually. The compressor switches off for

safety reasons and may not be switched on automatically. The LOX system switches itself on again and reports a power

failure in the log.

For further explanations on the operation of the compressor, please refer to the respective instructions.

Compressed air conditioning

Compressed air conditioning components are installed between the compressor(s) and the nitrogen generator set(s). These

are selected depending on the situation of the respective installation. The functioning of the LOX system depends on the

quality of the supplied compressed air. FX Prevent sets high demands on the compressed air quality in order to guarantee the

lifespan of the nitrogen generators. If condensate forms in the compressed air supply, this will lead to damage to the nitrogen

generators of the installation. FX Prevent has taken measures to permanently monitor the quality of the compressed air by

using a moisture detection sensor. The compressed air conditioning section consists of the following components, depending

on the installation:

•Water separator (per compressor)

•Compressed air buffer tank

•Oil and water filtration

•Dryer(s)

•Oil, water and fine dust filtration

Nitrogen generator

The nitrogen generator produces nitrogen using PSA (Pressure Swing Absorption) techniques.

High Performance PSA nitrogen generator

A High Performance PSA set consists of two vessels filled with activated carbon. The active carbon has the ability to absorb

oxygen molecules at a high pressure, meanwhile the nitrogen molecules will pass through.

The process operates as follows:

One of the two PSA vessels is in operation. The nitrogen is produced until the activated carbon in the HP-PSA vessel is

saturated with the oxygen molecules. When this is achieved, the control system will automatically switch to the second PSA

vessel so that both tubes are equalised with compressed air. The first PSA vessel is relieved of its pressure which causes the

active carbon to lose its ability to absorb oxygen molecules. The oxygen molecules that are released will be vented into the

surrounding. This cycle can repeat itself as many times as necessary.

10

LOX setup

Depending on the requirements, a single system or a redundant system with several HP-PSA units is used. The diagram below

shows both systems.

Single system

Redundant system

Compressor

Dryer

Compressed air

pressure vessel

Filtration

Filtration

PSA-

Unit

Filtration

Protected Area

Compressed air

pressure vessel

Filtration

Filtration

Filtration

Protected Area

PSA-

Unit

PSA-

Unit

Dryer

Dryer

Compressor

Compressor

Figure 2: Basic set-up of a nitrogen generator. Single set-up and redundant Master/Slave set-up.

Nitrogen inlet

For optimum fire safety, it is important that the necessary oxygen content is achieved throughout the protected area.

Depending on the dimensions, the shape of the room and the objects present, nitrogen is injected at one or more locations. If

several rooms are protected with one LOX installation, the distribution is regulated by means of valves.

The supply of nitrogen is automatically controlled via the LOX control software and is not described separately in this manual.

LOX controller

The LOX controller is the nerve center of the installation. The basic functions of the controller are:

•the control of the nitrogen production units;

•taking care of the communication between the various components;

•registering and correcting any deviations.

The LOX controller can be connected in a number of ways.

•The installation functions as a stand-alone unit. The control takes place via the ECD display;

•The installation is connected to, for example, a PC and/or network. This offers the possibility to collect data about

the functioning of the installation and to carry out extensive analyses with the help of the LOX studio software;

•The LOX controller is linked to other fire protection systems and/or a building management system. Via this

connection it is possible to send messages to, for example, the own technical service, an external alarm centre

and/or the FX Prevent service.

11

N2Control

The N2 Control monitors and controls the devices related to the production of nitrogen, such as the nitrogen generator and

the compressor. The N2 Control receives information from the Ox Control that determines whether nitrogen is needed in the

protected area. The N2 Control reacts to this signal by activating the nitrogen generator and the compressor. It also controls

the valves in the nitrogen supply lines, so that the nitrogen is blown into the right room. During nitrogen production, the N2

Control monitors whether production is proceeding as it should. For example, it measures the flow of compressed air to the

nitrogen generator (when used) and measures the nitrogen flow to the protected room. It also checks for errors in the related

devices such as the compressor, dryer, filters and humidity sensor by means of sensors and switches.

The N2 controller can control up to three nitrogen generators. If it is necessary to control several nitrogen generators, this is

done with additional N2 controllers.

Ox Control

The Ox Control monitors and controls the devices in and around the protected space that are related to the oxygen reduction

process. It receives its information from the Oxysensors located in the protected space. According to the measurements of

the Oxysensors, the Ox Control determines how much nitrogen is required to maintain the oxygen-reduced atmosphere. This

nitrogen demand is then communicated to the N2 Control. The Ox Control also uses the measurements from the Oxysensors

to monitor deviations. If the oxygen level becomes too high or too low, the Ox Control generates an error or alarm message

that is visible on the ECD display and indicated by a flashing light and/or a slow whoop. The Ox Control also checks the status

of the power supply. The Ox Controls installed as a leading or redundant controller are not different from each other and are

always constructed in the same way.

Oxygen sensors

Accurate monitoring of the oxygen concentration in the protected area is essential. On the one hand, the oxygen content

must not become too low because of accessibility for people. On the other hand, the oxygen content must not become too

high in order to ensure fire safety.

High-quality oxygen sensors are used to measure the oxygen content. The measuring principle is based on zirconium

elements that measure the oxygen content.

Depending on the size, shape of the room and the objects in the protected area, several oxygen sensors are used. The

measuring signal is sent to the Ox controller(s). There are always at least three sensors applied.

FX Prevent

Number: 500

Serial: 12345678

VdS FX Prevent

Oxygen sensor

Figure 3: Image of the oxygen sensor

The oxygen measurement is registered and interpreted by the Ox controller. If the oxygen percentage in the protected area

rises above the trigger level, additional nitrogen is blown in. The oxygen percentage is controlled within an adjustable

bandwidth.

If a single sensor shows a large deviation, this may indicate an abnormal oxygen content or a defect. This is immediately

indicated by an alarm message.

The oxygen sensors are part of the LOX installation and are therefore not described separately in this manual. Operation

takes place via the LOX controller.

12

Informing and alerting

If an abnormal atmosphere (low oxygen atmosphere) is created in the protected area, those present must be informed. To

ensure that those present are informed, a number of safety measures have been taken:

•Door display with actual oxygen content indication;

•Flashing light and acoustic signal;

•Door registration (door open or closed)(when applied);

•Email notifications to relevant persons.

The safety devices are specifically selected per installation on the basis of regulations and user requirements.

The Color Display

The Color Display is a software-based display that is placed at an entrance to the protected area. It is equipped with a main

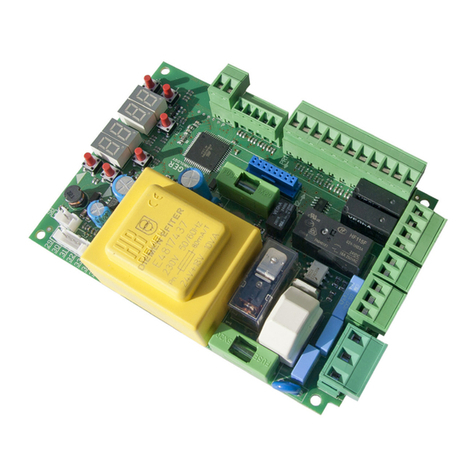

PCB (JGA1063C) with input, output and CAN-bus connections. Via the CAN-bus connection it receives information from the

LOX Control (ECD) about the situation in the protected room. The LOX Control collects this information with the help of the

Oxysensors that are located in the protected area. Via the CAN bus connection, the LOX Control also monitors the availability

of the colour display. The Color Display has a redundant CAN bus connection, so that it can also receive the necessary

information from the redundant LOX Control in the event of a fault in the master controllers.

The Color Display monitors and controls the accessibility of the entrance to the protected room. Via switches at the entrance

door, the Color Display can detect if the entrance door is opened and notify the user when it is opened to long.

O2: 18,0 %

101

FxPrevent 10:09

21,0 °C

Figure 4. Color Display landscape for 1 protected room

O2: 18,0 %

101

FxPrevent 10:09

21,0 °C

O2: 20,5 %

101

FxPrevent 10:09

21,0 °C

Figure 5. Color Display landscape for 2 protected rooms.

O2: 16,0 %

101

FxPrevent 10:09

21,0 °C

Figure 6. Color Display with warning color.

Door switch

For the proper functioning of the system, it is important that the access doors are kept closed as much as possible. To register

the use of the access doors and to warn the people present if a door is left open, it is optional to equip these with door

contacts. If a door is left open for longer than the set time, an alarm will activate.

The door switch monitoring is part of the LOX system and is therefore not described separately in this guide. It is operated via

the LOX controller.

Via the outputs on the main PCB of the Color Display it is optional to

lock the access door. If, for example, both the leading and the

redundant LOX Controllers are not available, the Color Display will

malfunction. If a user then wants to enter the protected area, the "Door

Open" button must be pressed. For this purpose a separate button has

to be connected to the Color Display inputs. If the “Door Open”button

is pressed, the Color Display determines whether the protected area is

safely accessible. Assuming that the LOX-controllers are not available,

the Color Display does not receive any information about the protected

room and locks the entrance because there might be an unsafe

environment. Assuming that the Color Display receives good

information from the LOX controllers about a safe environment in the

protected room, the entrance door is unlocked as soon as the "Door

Open" button is pressed. The Color Display also has an additional input

connection for a manual emergency button. This allows the user to

unlock the access door directly in case of emergency, without having to

consider the hazardous situation.

The digital display of the Color Display informs the user about the

situation in the protected area by showing a value of the measured

oxygen level and temperature. Depending on the measured oxygen

value, the display can change colour to inform the user of a hazardous

situation. It turns green during normal operation and red when a

hazardous situation such as a low oxygen level occurs. The Color Display

can also notify the user by activating a flashing light or slowwhoop via

the outputs on the display's circuit board.

13

Flashlight and acoustic alarm

The flashing light and the acoustic signal generator are located in the protected area, with the exception of refrigerated areas

where the temperature is below 0 °C. If the flashing light and the acoustic signal generator cannot be placed in the protected

area, an equivalent alternative location will be determined. With the flashing light and the acoustic signal generator it is

possible to give a low and high level alarm.

•The low level alarm (flashing light only) means that there is a fault in the installation, but that the deviation from

the set oxygen level remains small.

•The high level alarm (flashing light and acoustic signal) means that the oxygen content is threatening to decrease

too much. The room should be evacuated.

The flashing light and acoustic signal are part of the LOX basic system and are not described separately in this manual.

Operation takes place via the LOX controller.

A second possibility is that the LOX system is connected to the fire alarm system or is part of a quick release system. In these

cases, the details are given in the relevant manual.

Emergency stop

The LOX system can be equipped with an emergency stop facility as an option. It is not a requirement for the LOX system to

have an emergency stop as stopping the system does not immediately create a safe situation in the protected area. In order

to create a safe situation, ventilation is required to increase the oxygen level to its normal value. If it is still desired, it is

possible to apply an emergency stop device to the system. This ensures that the whole LOX system can be stopped by

pressing the emergency stop button once. When the user does this, the following will happen:

•The power supply to the LOX nitrogen generator is interrupted;

•The power supply to the compressors for the LOX system is interrupted;

•The LOX Control panels, Oxysensors, Color Displays and the nitrogen generator switch to the 'Uninterrupted Power

Supply' (UPS). These components are supplied with power by the UPS for 24 hours until the batteries are empty.

•The compressed air supply to the nitrogen generator of the LOX system falls silent and eventually drops to 0 bar (g).

•The LOX nitrogen generator will continue to function and will stop proportional to the compressors when the

compressed air pressure has dropped to 0 bar (g).

Humidity sensor

The humidity detection sensor has a humidity reservoir that contains

a humidity sensor. As soon as an unwanted amount of condensate

arises in the compressed air supply, the reservoir fills with moisture

and the moisture sensor detects this. The moisture sensor then

generates a visual signal in the form of a red LED and sends an

external signal via a potential-free contact. The LOX system responds

with an alarm signal. To prevent further damage from the moist

compressed air, the LOX system switches off the nitrogen generators.

When the formation of the condensate has been resolved, the

moisture detection sensor can be drained and the alarm signal can

then be reset.

The Moisture Detection Sensor is usually located in the filtration

section of the compressed air supply, in front of the nitrogen

generators. Every LOX installation has a filtration line which consists

of at least one super mist filter, odour filter or a multiple thereof. The

Moisture Detection Sensor is mounted under the super mist filter

whenever possible.

Figure 7. Humidity sensor

14

4Operation of the installation

ECD Display

The ECD Display is the main control device that the operator can use to work with the LOX system. It is included in the leading

N2 Controller and is connected to the LOX Control (ECD) components. With the ECD display, the user can do several things,

such as view the status of the LOX system, view active measurements, view settings and adjust settings with the buttons on

the display. If something goes wrong with the LOX system, for example a defective component, alarms are generated and

shown on the display. Below the display there are also two rows of LED lights that give a more direct indication of the status

of the LOX system. This makes it possible to immediately inform the user of the presence of a malfunction, alarm or special

status without having to navigate through the ECD display program.

ECD Display front

The following figure shows the appearance of the ECD display. The display and the columns of LEDs are both part of the PCB.

Info Prog Esc +

-

Alarm

Reset Netherlands

Power ok

Alarm

Fault

Disabled

Transmission path fault

Nitrogen generator fault

N2production active

O2level minimum

O2level maximum

Power supply fault

Program fault

Figure 8. ECD Display

Buttons on the ECD Display

Reset button

The reset button is used for restoring the LOX Control (ECD) back to its normal operation after the occurrence of a fault or

alarm. The reset button is provided with a light bulb behind the button which will light up when a fault or alarm occurs. Once

the fault or alarm has been fixed, the reset button is pressed to discharge the fault and alarm messages and the LOX Control

(ECD) is restored to its normal operation conditions.

Reset

Figure 9. Reset button

The light bulb behind the reset button can indicate various statuses. The following applies to the light bulb behind the reset

button.

•Light is on continuously : There is a fault- or alarm message on the display that was notified;

•Light is flashing : There has occurred a new fault- or alarm message on the display.

15

Keyboard with control buttons

Next to the reset button on the ECD Display there is a keypad with six control buttons. These buttons are used for navigating

through the software of the ECD Display and for adjusting the parameters.

Info Prog Esc +

-

Alarm Netherlands

Figure 10. Control buttons

Button functionality

Each button on the ECD display can be pressed in two different ways. A button can be pressed shortly or a button can be held

down. The way in which a button is pressed results in a different reaction on the ECD Display. In general, the following

applies:

Action

Description

Button pressed shortly

The button is pressed for approximately 1 second and then released immediately.

Button held down

The button is held down for approximately 3 to 5 seconds without releasing it. The display

generates two short bleeps and then the secondary functionality is utilized.

Although this functionality applies to all buttons on the ECD display, not all buttons will have 2 or more functions

programmed to it.

Overview of primary and secondary functionalities

The following table gives an overview of the functionalities that the buttons have. With some buttons, the Guest menu,

Operator menu and Factory menu are mentioned. These three menus are basically the same but are renamed and expanded

each time that the user is logged in into a higher access level via the ECD display. The higher the access level gets, the more

settings become available in this menu.

Button

Action

Description

Reset

Pressed shortly

Only the internal buzzer of the ECD display is silenced.

Held down

If the user is logged in into access level 1 it is not possible to reset the current faults and

alarms. The message ‘Reset not allowed in access level 1!’ is shown on the display.

If the user is logged in into access level 2 or 3 then after 2 seconds, the message ‘Reset

errors in … 3 s’ is shown on the display. The reset button must be pressed down. The display

will then continue to count down the seconds that are displayed. If the counter has reached

0 seconds all current fault and alarm messages are discharged.

Prog

Pressed shortly

At the main screen:

Press this button once to enter the Guest menu, Operator menu or Factory menu.

At the Guest, Service and Factory menu:

Press this button once to enter one of the sub-menus of the Guest, Operator or Factory

menu.

At the sub-menu:

Press this button once to start adjusting a setting in one of the sub-menu’s.

When adjusting a setting:

Press this button once to confirm the adjustment of a setting.

Held down

No secondary action is programmed.

16

Button

Action

Description

Esc

Pressed shortly

At the Guest, Operator, Factory menu or in one of the sub-menu´s:

Press this button once to leave the current menu and return to the previous menu. By

repeating this action, the main screen is eventually reached.

When adjusting a setting:

Press this button once to cancel the adjustment of a setting.

Held down

At the Guest, Operator, Factory menu or in one of the sub-menu´s:

If a user is logged in into access level 2 or 3 then the user is logged out from these access

levels. The message ‘User logged out’ is displayed on the screen for 3 seconds after which

the display is returned to the main screen.

When adjusting a setting:

The user is also logged out from access level 2 or 3. But because the user was in the process

of adjusting a setting, the message ‘configuration not saved’ is displayed instead of ‘User

logged out’. The display is also returned to the main screen during this action.

Alarm

Pressed shortly

Press this button shortly to directly access the ‘Alarm / fault’s’ menu where the active error

messages can be viewed.

Held down

No secondary action is programmed.

Info

Pressed shortly

General company information of FX Prevent is shown. Information such as: Company name,

system type, telephone number and website.

Held down

No secondary action is programmed.

+

Pressed shortly

At the main screen:

The Guest menu, Operator menu or Factory menu is accessed and the first line of that menu

is selected directly.

At the Guest, Operator, Factory menu or a sub-menu:

Press this button once the select the next menu screen.

When adjusting a setting:

Press this button once the increase a value or to select the next possible setting during

adjustment of a parameter.

Held down

At the Guest, Operator, Factory menu or a sub-menu:

The next menu screen or submenu is selected sequentially. If the button is held down

longer, the scrolling speed is increased.

When adjusting a setting:

The value that is adjusted is increased sequentially. If the button is held down longer, the

increasing speed is increased.

-

Pressed shortly

At the main screen:

The Guest menu, Operator menu or Factory menu is accessed and the last line of that menu

is selected directly.

At the Guest, Operator, Factory menu or a sub-menu:

Press this button once the select the previous menu screen.

When adjusting a setting:

Press this button once to decrease a value or to select the next possible setting during

adjustment of a parameter.

Held down

At the Guest, Operator, Factory menu or a sub-menu:

The previous menu screen or submenu is selected sequentially. If the button is held down

longer, the scrolling speed is increased.

When adjusting a setting:

The value that is adjusted is decreased sequentially. If the button is held down longer, the

decreasing speed is increased.

17

Status LED’s

Below the ECD display there are 2 columns of LED lights which give the user direct information on the status of the LOX

system. Which LED lights are featured at the ECD display and what their functions are is described in the following table.

LED

Col.

Description

Power OK

If this LED is on then the power supply from the UPS Schrack Control to the LOX Control (ECD)

is in order. If this LED is off then the power supply has been interrupted.

N2 production

active

If this LED is on then the nitrogen generator is activated and nitrogen is produced.

Alarm

If this LED is on then one or more alarms have occurred within the LOX system.

O2 level minimum

If this LED is on then the oxygen level has become lower than the minimum allowed

concentration. This is considered to be a dangerous situation which is indicated as an alarm.

Fault

If this LED is on then one or more faults have occurred within the LOX system.

O2 level

maximum

If this LED is on then the oxygen level has become higher than the maximum allowed

concentration. This means that the prevention of fire by oxygen reduction is no longer

guaranteed.

Disabled

If this LED is on then there has been one or more inputs or outputs manually disabled. Once

there are no more inputs or outputs disabled then this LED is off.

Power supply

fault

If this LED is on then the main power supply to the UPS Schrack Control has failed. The main

power, batteries or a fuse of the UPS Schrack Control has failed. The LOX Control (ECD) is still

provided with power through the main power line or backup batteries.

Transmission path

fault

If this LED is on then one or more of the monitored transmission paths within the LOX Control

(ECD) have failed. The line is broken or shorted.

Program fault

If this LED is on then there is a problem within the software of the LOX Control (ECD). The

software has crashed or a bug has occurred.

Nitrogen

generator fault

If this LED is on then there is a fault or defect detected within the nitrogen generator or one of

its peripherals. The fault or defect prevents the production of nitrogen or has reduces the

capacity.

18

5Assembly instructions

The LOX system uses a nitrogen generator. The nitrogen generator uses the air from the environment and separates the

oxygen and nitrogen, leaving a high concentration of nitrogen. The nitrogen is used to condition the area to be secured. The

oxygen is released into the immediate surroundings and then ventilated to the outside. Active fans must be used if the

natural air circulation is not sufficient.

Het LOX systeem is een samenstel van meerdere machines. Het gezamenlijke doel van de samengestelde machines is het

conditioneren van de te beveiligen ruimte doormiddel van suppletie van stikstof. Om het doel van zuurstofreductie te

bereiken is het noodzakelijk om het systeem op de juiste manier te monteren. Hiervoor zijn er een paar voorschriften van

toepassing:

The LOX system is a combination of several machines. The joint purpose of the combination of machines is to condition the

room that needs to be secured by means of nitrogen supplementation. To achieve the goal of oxygen reduction, it is

necessary to assemble the system in the right way. For this purpose, a few regulations apply:

-The ventilation capacity of the technical room in which the LOX system is installed must be considered. Sufficient

ventilation of oxygen-enriched air is necessary to avoid a fire hazardous atmosphere.

-The assembly and positioning of the components of the LOX system must be in accordance with the pre-fabricated

installation drawing. The installation drawing is worked out specifically for each system and is available in the

technical file of the system.

-Part of the connections between the components can be fixed pipe connections. Fixed pipe connections must

always be manufactured in accordance with the manufacturer's specifications.

6Measures during decommissioning

The moment that the LOX Low Oxygen system is decommissioned, the oxygen content in the protected area will gradually

increase to the regular atmospheric value. This means that the fire protection by oxygen reduction is no longer functional.

It is advisable for the user to take appropriate (organisational) measures for such situations in order to ensure fire safety in an

alternative way. These precautions could be included in the emergency response plan.

In addition to restoring the LOX system, one or more of the following measures can be taken:

-Lock the secured section to make sure that the oxygen reduced atmosphere is maintained as long as possible;

-Maintain the reduced oxygen atmosphere by connecting an external nitrogen provision ( by example a tank truck);

-Extra checking rounds by fire guards;

-Prohibiting work that could result in an increased fire risk;

-Keeping the emergency response organization and / or the fire brigade continually on standby.

19

7Errors

The LOX Controllers (ECD) are software-controlled devices. This means that in case of a defect, error or alarm, a message is

generated to inform the user that something is wrong. If an error or alarm occurs, there are several ways in which the LOX

system will inform the user. The LOX Control (ECD) is equipped with an ECD display that shows the error messages on a

screen as soon as they occur. It has 11 LED indicators. The error messages are also displayed in the LOX studio software if

there is a Windows device on which the software is running and which is connected to the LOX Control (ECD). In addition, the

LOX Control (ECD) also has a flashing light and a slow-warning light that indicate an error or alarm.

Errorlevels

These warnings and fatal errors are subdivided into 4 error levels. How the system reacts and which outputs are controlled

depends on the error level.

Error

Level

Message

Responds of the system

1

Warning

Warning is shown on the display:

•The alarm relay of the N2 or OX controller reacts.

2

Warning

Warning is shown on the display:

•The alarm relay of the N2 or OX controller reacts.

•The flashlight on the Section controller is on.

3

Fatal error

Error is shown on the display:

•The alarm relay of the N2 controller reacts;

•The flashlight on the Section controller is on;

•The system stops with providing nitrogen to the room.

4

Fatal error

Error is shown on the display:

•The alarm relay of the N2 controller reacts;

•The flashlight on the Section controller is on;

•The system stops with providing nitrogen to the room.

•A text message / alarm message is send or other notification is activated.

20

Error messages in general

The following table shows which error messages can be generated in general.

No.

Error message display row 1

Error message display row 2

Description

Source message

0

No ECD display message

No connection to device

ERROR_DEVICE_NOTAVAILABLE

1

AnIN01: sensor fault

Analogue sensor 1 fault

ERR_ANALOGIN_SENSOR01

2

AnIN02: sensor fault

Analogue sensor 2 fault

ERR_ANALOGIN_SENSOR02

3

AnIN03: sensor fault

Analogue sensor 3 fault

ERR_ANALOGIN_SENSOR03

4

AnIN04: sensor fault

Analogue sensor 4 fault

ERR_ANALOGIN_SENSOR04

5

AnIN01: disabled

Analogue sensor 1 disabled

ERR_ANDISABLED_SENSOR01

6

AnIN02: disabled

Analogue sensor 2 disabled

ERR_ANDISABLED_SENSOR02

7

AnIN03: disabled

Analogue sensor 3 disabled

ERR_ANDISABLED_SENSOR03

8

AnIN04: disabled

Analogue sensor 4 disabled

ERR_ANDISABLED_SENSOR04

9

Analog sensor(s)

span fault

Error at span points

ERR_SENSOR_SPANERROR

10

HardwareFault extAdc

communication fault

Communication error with ADC on print. Error in

print / software

ERR_EXTADC_COMM

11

DcIN01: cable fault

Transmission path error input 1

ERR_TPFAULT_INPUT01

12

DcIN02: cable fault

Transmission path error input 2

ERR_TPFAULT_INPUT02

13

DcIN03: cable fault

Transmission path error input 3

ERR_TPFAULT_INPUT03

14

DcIN04: cable fault

Transmission path error input 4

ERR_TPFAULT_INPUT04

15

DcIN05: cable fault

Transmission path error input 5

ERR_TPFAULT_INPUT05

16

DcIN06: cable fault

Transmission path error input 6

ERR_TPFAULT_INPUT06

17

DcIN07: cable fault

Transmission path error input 7

ERR_TPFAULT_INPUT07

18

DcIN08: cable fault

Transmission path error input 8

ERR_TPFAULT_INPUT08

19

DcIN09: cable fault

Transmission path error input 9

ERR_TPFAULT_INPUT09

20

DcIN10: cable fault

Transmission path error input 10

ERR_TPFAULT_INPUT10

21

DcIN11: cable fault

Transmission path error input 11

ERR_TPFAULT_INPUT11

22

DcIN12: cable fault

Transmission path error input 12

ERR_TPFAULT_INPUT12

23

DcIN01: disabled

Transmission path input 1 disabled

ERR_TPDISABLED_INPUT01

24

DcIN02: disabled

Transmission path input 2 disabled

ERR_TPDISABLED_INPUT02

25

DcIN03: disabled

Transmission path input 3 disabled

ERR_TPDISABLED_INPUT03

26

DcIN04: disabled

Transmission path input 4 disabled

ERR_TPDISABLED_INPUT04

27

DcIN05: disabled

Transmission path input 5 disabled

ERR_TPDISABLED_INPUT05

28

DcIN06: disabled

Transmission path input 6 disabled

ERR_TPDISABLED_INPUT06

29

DcIN07: disabled

Transmission path input 7 disabled

ERR_TPDISABLED_INPUT07

30

DcIN08: disabled

Transmission path input 8 disabled

ERR_TPDISABLED_INPUT08

31

DcIN09: disabled

Transmission path input 9 disabled

ERR_TPDISABLED_INPUT09

32

DcIN10: disabled

Transmission path input 10 disabled

ERR_TPDISABLED_INPUT10

33

DcIN11: disabled

Transmission path input 11 disabled

ERR_TPDISABLED_INPUT11

34

DcIN12: disabled

Transmission path input 12 disabled

ERR_TPDISABLED_INPUT12

Table of contents

Other PRESSCON Control System manuals

Popular Control System manuals by other brands

Gerriets

Gerriets KABUKI instruction manual

Roger

Roger H70/104AC Instruction and warnings for the installer

Mantracourt

Mantracourt T24-ACMi-SA user manual

Siemens

Siemens SIMATIC PCS 7 Programming manual

BIOS

BIOS Professional 200TC instruction manual

IPAS

IPAS DALI Series Operating and mounting instructions