PRESSCON VERNIT N2 User manual

VERNIT - HORNIT N2(i) expansion

systems

User manual

Type

:

User manual

Date

:

18-09-2019

Version / Revision

:

Version 4.2, Revision 00

Status

:

Approved

Company

:

PRESSCON

Location

:

Honselersdijk

2

3

Table of content

Introduction ........................................................................................................................................................... 5

Important to know ................................................................................................................................................. 7

1.1.1 Working with the safety valve .............................................................................................................. 9

1.2 Description of hazard symbols .......................................................................................................................... 9

2 System components .................................................................................................................................. 11

2.1 Nitrogen generator type ECONOMY A ............................................................................................................ 11

2.2 Nitrogen generator type ECONOMY B ............................................................................................................ 12

2.3 Nitrogen generator type ECONOMY DUO ...................................................................................................... 13

2.4 Vacuum- overpressure safety valve and vacuum safety valve ....................................................................... 15

2.5 Vacuum- overpressure safety valve with tracing band ................................................................................... 16

2.6 Pressure sensor ............................................................................................................................................... 17

2.7 Pressure sensor with tracing ribbon ............................................................................................................... 17

3 General operation ....................................................................................................................................... 19

3.1 Operation of the expansion system ................................................................................................................ 19

3.1.1 Compressed air supply ....................................................................................................................... 19

3.1.2 Nitrogen production ............................................................................................................................ 19

3.1.3 Water monitoring ................................................................................................................................. 19

3.1.4 Systems that also regulate the water level (optional) .................................................................... 20

3.1.5 Protection against overpressure and vacuum with VERNIT systems ......................................... 20

3.1.6 Protection against vacuum with HORNIT systems ........................................................................ 21

3.1.7 Leak detection measurement (SLDM or CLDM) for VERNIT systems (optional) ...................... 22

3.1.8 Heating tape at the pressure sensors and vacuum overpressure relief valve (optional) .......... 22

3.1.9 Manual operation of the return valve (optional) .............................................................................. 23

3.2 Assembly of components on the buffer tank .................................................................................................. 24

3.2.1 Vertical buffer tank .............................................................................................................................. 24

3.2.2 Vertical buffer tank in a DUO setup .................................................................................................. 26

3.2.3 Horizontal buffer tank ......................................................................................................................... 27

3.2.4 Horizontal buffertank in a DUO setup .............................................................................................. 29

3.2.5 DUO system for a High and low temperature networks ................................................................ 29

3.3 Schematic overview of the expansion system ................................................................................................ 30

3.3.1 VERNIT 2.0 -30.0 N2(i) system ........................................................................................................ 30

3.3.2 HORNIT 2.0 -30.0 N2(i) system ........................................................................................................ 31

3.3.3 VERNIT 2.0 -30.0 N2(i) DUO system ............................................................................................... 32

3.3.4 HORNIT 2.0 -30.0 N2(i) DUO system .............................................................................................. 33

4 Touchscreen ............................................................................................................................................... 34

4.1 Main screen of the Touchscreen ..................................................................................................................... 34

4

4.1.1 Main screen lay-out VERNIT ............................................................................................................ 35

4.1.2 Main screen lay-out HORNIT ............................................................................................................ 35

4.2 Icons on the main screen ................................................................................................................................ 36

4.2.1 Compressor ......................................................................................................................................... 36

4.2.2 PSA generator ..................................................................................................................................... 37

4.2.3 Oxygen sensor .................................................................................................................................... 37

4.2.4 Valves ................................................................................................................................................... 37

4.2.5 Overpressure safety relief .................................................................................................................. 38

4.2.6 VERNIT tank malfunction status ....................................................................................................... 38

4.2.7 VERNIT tank water level status ........................................................................................................ 40

4.2.8 HORNIT tank malfunction status ...................................................................................................... 41

4.2.9 HORNIT tank water level status ........................................................................................................ 42

4.2.10 HORNIT pressure tank failure status ............................................................................................... 43

4.2.11 HORNIT druktank waterhoogte status ............................................................................................. 43

4.3 User menu ...................................................................................................................................................... 44

4.3.1 User menu schematic for Touchscreen type (ECONOMY A and ECONOMY DUO) ............... 44

4.4 Service menu ................................................................................................................................................... 45

4.5 Factory menu .................................................................................................................................................. 45

4.6 Standby ........................................................................................................................................................... 45

5. PRESS-display ............................................................................................................................................ 46

5.1 Buttons on the PRESS-display ......................................................................................................................... 46

5.1 Menu structure and access ............................................................................................................................. 47

5.2 User Menu ...................................................................................................................................................... 47

5.3.1 User menu for the VERNIT ECONOMY B systems ....................................................................... 48

5.4 Service Information screen ............................................................................................................................. 49

5.4.1 Service information screen for the VERNIT ECONOMY B ........................................................... 49

5.5 Factory information screen ............................................................................................................................. 50

5.5.1 Factory information screen for the VERNIT ECONOMY B ........................................................... 50

5.6 Service menu ................................................................................................................................................... 51

5.7 Factory menu .................................................................................................................................................. 51

5.8 Standby ........................................................................................................................................................... 51

6 PRESS-control ...................................................................................................................................................... 52

6.1 Types of PRESS-control ................................................................................................................................... 52

7 Alarms and error handling ........................................................................................................................ 53

7.1 Faults and alarms ........................................................................................................................................... 53

7.2 Overriding the boiler alarm relay ................................................................................................................... 54

7.3 Faults and alarm messages ............................................................................................................................. 55

5

7.3.1 Fault and alarm messages for the PressControl (ECONOMY A and ECONOMY DUO) ............................... 55

7.3.2 Fault and alarm messages for the Touchscreen ............................................................................ 57

7.3.3 Fault and alarm messages for the PRESS-Basic control(ECONOMY B) ....................................................... 60

8 Maintenance and service ................................................................................................................................ 63

8.1 Expansion system maintenance ............................................................................................................................ 63

8.2 Compressor maintenance ............................................................................................................................... 63

9 Warranty ....................................................................................................................................................... 63

10 Appendix .................................................................................................................................................. 65

11 Document history ................................................................................................................................... 65

12 To conclude ................................................................................................................................................... 71

Introduction

The VERNIT HORNIT expansion system monitors and controls the pressure that is present in the expansion chamber of

a central heating system. It is applicable for the central heating systems in the horticulture industry. The system is

comprised out of a nitrogen generator with an air compressor, a set of pressure sensors that measure the water level

and pressure in a buffer tank and a control module that controls the nitrogen generator.

The central heating systems that are used in the horticulture industry store their heat in a vertical or horizontal buffer

tank. The buffer tanks are not fully filled with water but have an expansion chamber above the water. When looking at a

vertical buffer tank the expansion chamber is right above the water inside the tank. When looking at a horizontal buffer

tank the expansion chamber is also right above the water inside the tank but it can also be located in a separate

expansion vessel. The expansion chamber is intended for the water in the central heating system to expand and shrink

when the water is heated up or cooled down. During this process the pressure in the expansion chamber also changes.

The VERNIT HORNIT expansion system monitors the pressure in the expansion chamber. When the pressure becomes

too high then an overpressure valve relieves the extra pressure. When the pressure becomes to low then the VERNIT

HORNIT expansion system will produce nitrogen in order to get the expansion chamber pressurized again. The nitrogen

generator of the VERNIT HORNIT expansion system produces an air mixture with a nitrogen concentration of 99,0 vol. %

N2. The system uses nitrogen because it is an inert gas. Inert gasses have the ability to prevent the formation of rust

when it is available in a high concentration. The VERNIT HORNIT expansion system makes sure that there is always a

blanket of nitrogen present in the expansion chamber within the buffer tank and that it is kept at a steady overpressure.

Next to the pressure management of the nitrogen blanket, the VERNIT HORNIT expansion system also acts as a

monitoring device for the water level in the buffer tank. By using pressure sensors the system determines the height of

the water level. Once the water level becomes too high or too low, the VERNIT HORNIT expansion system will generate

the appropriate fault or alarm messages and can also send a stop signal to other relevant devices. The water level

monitoring is important for the conservation of the buffer tank. It prevents the water level from becoming too high and

damaging the roof of the buffer tank.

6

It also prevents the water level from becoming too low, which leads to air in the heat supply spray tube and in the central

heating network.

These are important features for maintaining the buffer tank and preserving the central heating system.

7

Important to know

The expansion systems are produced in 2 different types. Namely, the VERNIT and HORNIT systems. These 2 types

have the following differences.

• VERNIT, the expansion system regulates the pressure of the nitrogen blanket in the vertical heat storage tank.

• HORNIT, the expansion system regulates the total system pressure in a horizontal heat storage tank. This is

done either directly or via an external expansion vessel.

In addition to VERNIT and HORNIT, there are a few additional indications that define the function of the expansion

system. These are:

2.0 – 30.0

The number in the type designation indicates the capacity of the nitrogen generator. This number

represents the flow rate in m³/h that the generator can produce with a purity of 99.0 Vol%N2. The

smallest capacity per generator is 2.0 m³/h and the largest possible capacity is 30.0 m³/h. Larger

capacities are also possible, but several nitrogen generators have to be combined with each other.

H.P.

"High Performance" stands for the design of the PSA tube. Indicates that the PSA applied to the

system was manufactured by PRESSCON. Nitrogen generators from before 2009 do not have this

addition.

ECONOMY

This indicates that the generator is equipped with a valve control system designed for high output

and energy efficiency.

N2i

N2i stands for direct injection of nitrogen. In this case, the expansion system will blow nitrogen

directly into the heat storage tank.

N2

N2 without the "i" stands for an expansion system without direct injection. In this case, the expansion

system uses a separate pressure vessel in which the nitrogen is first stored before it is blown into the

heat storage tank.

A (panel)

The addition "A" indicates that the expansion system is equipped with the A-type control panel which

is the most comprehensive version.

B (panel)

The addition of "B" indicates that the expansion system is equipped with the B-type control panel,

which is a simpler version than the A-type panel.

DUO(panel)

DUO means that the expansion system is suitable for monitoring 2 separate heat storage tanks.

ELC

The expansion system is prepared to operate in an Equal Level Control setup. This function allows

for control of the level difference in two tanks by controlling a pump. For this purpose, the expansion

system will work together with 1 or more expansion systems via CAN-bus.

SLC

The expansion system is prepared to use the Switching Level Control function. This function

generates a switching signal based on the level difference in two tanks. For this purpose, the

expansion system will work together with 1 or more expansion systems via CAN-bus.

SLDM

Leak detection measurement that works on the basis of a 3rd pressure sensor at the bottom of the

vertical buffer tank.

CLDM

Leak detection measurement that works on the basis of information that the system receives from

the horticultural computer. The horticultural computer then indicates the fill level of the vertical buffer

tank.

The type designations described above are compatible with each other according to the matrix below.

VERNIT

HORNIT

N2i

N2

A (panel)

B (panel)

DUO

(panel)

ELC /

SLC

SLDM /

CLDM

VERNIT

N/A

N/A

Yes

Yes

Yes

Yes

Yes

Yes

Yes

HORNIT

N/A

N/A

Yes

Yes

Yes

No

Yes

No

No

N2i

Yes

Yes

N/A

N/A

Yes

Yes

Yes

Yes

Yes

N2

Yes

Yes

N/A

N/A

Yes

Yes

Yes

Yes

Yes

8

A (panel)

Yes

Yes

Yes

Yes

N/A

N/A

N/A

Yes

Yes

B

(panel)

Yes

No

Yes

Yes

N/A

N/A

N/A

No

No

DUO (panel)

Yes

Yes

Yes

Yes

N/A

N/A

N/A

Yes

Yes

ELC / SLC

Yes

No

Yes

Yes

Yes

No

Yes

N/A

Yes

SLDM /

CLDM

Yes

No

Yes

Yes

Yes

No

Yes

Yes

N/A

Touchscreen and PRESS-Display

The touchscreen and the PRESS-display are both control units that can be used for the PRESSCON nitrogen

generators. Originally, the PRESS-display was conceived as a multi-purpose digital display showing the water level,

nitrogen blanket pressure and any alarms. The Touchscreen also performs these functions, but offers a more visual

overview of the system and more intuitive controls. The Touchscreen can also be universally used for multiple types of

nitrogen generators.

• The Touchscreen is used as standard for the types VERNIT - HORNIT ECONOMY A and ECONOMY DUO.

Optionally, this display can also be used with a VERNIT ECONOMY B.

• The PRESS-display is used as standard with the VERNIT ECONOMY B

If 2 or more expansion systems are connected to each other via CAN-bus, it is important that the displays within that

network are all of the same type. Touchscreen and PRESS-display do not work together within a CAN-bus network. This

could occur, for example, in an ELC setup.

9

1.1.1 Working with the safety valve

The safety valve is commonly located on the roof of the buffer tank. When working on the safety valve, the following

hazards should be considered.

Symbol

Description

Applies to

HOT PARTS,

Do not touch parts with bare hands.

Use heat-resistant clothing.

The housing of the safety valve and relieved nitrogen from the

buffer tank. The upper layer of water can heat up the nitrogen in

the safety valve. The housing can then be too hot to touch. The

relieved nitrogen from the vacuum- overpressure safety valve on

top of a vertical buffer tank can also contain steam with a

temperature of 90°C which could cause burn injury. Vacuum safety

valves on the horizontal buffer tanks do not release nitrogen.

ATTENTION! WORKING AT HIGHTS,

Working on the roof of a vertical or horizontal buffer tank is

considered working at heights. Fall protection is recommended

when working on the safety valve.

HIGH PRESSURE, Relief pressure

from components before work is

conducted.

The safety valves on both the vertical and horizontal buffer tanks.

The safety valve on a vertical buffer tank can be depressurized by

hand. The pressure is not higher than 28 mBar. The safety valve

on a horizontal buffer tank can only be depressurized by relieving

water pressure for the buffer tank. The pressure is not higher than

1200 mBar.

1.2 Description of hazard symbols

In addition to the identified risks for the nitrogen generator, compressor and safety valve, the following symbols can also

be applied. When a hazard symbol is encountered, please observe its meaning carefully before further commencing the

work.

Symbol

Description

Symbol

Description

1. OVERPRESSURE VALVE,

Be aware of the sudden relief of

overpressure.

7. HIGH PRESSURE,

Relief pressure from components before work is

conducted.

2. DANGEROUS VOLTAGE,

Forbidden to work on the system if the

power is on.

8. HOT PARTS,

Do not touch parts with bare hands. Use heat-

resistant clothing.

3. DANGEROUS TO INHALE GAS,

Avoid the specified area or wear

appropriate breathing equipment.

9. MOVING PARTS,

Risk of getting stuck or injuries to limbs. Turn the

machine off completely before working on it.

10

4. NOISE,

Wear ear protection to prevent hearing

damage.

10. ROTATING FAN,

Risk of getting stuck or injuries to limbs. Turn the

machine off completely before working on it.

5.MACHINE WITH AUTOMATIC START,

Machine stops and starts automatically when it

is operating normally. Turn off the machine

completely before working on it.

11. ATTENTION,

Special situation occurs, follow additional instructions.

6. READ THE OPERATING AND

MAINTENANCE INSTRUCTIONS,

It is advised that the maintenance instructions

are read before continuing work.

11

2 System components

The PRESSCON expansion systems consist out of the following components: a nitrogen generator, compressor, safety

valve and 2 or more pressure sensors. This chapter describes these components by giving an image of each device and

by numbering the most important parts. The compressor is not described because different brands and types can be

applied and it is delivered with its own manual.

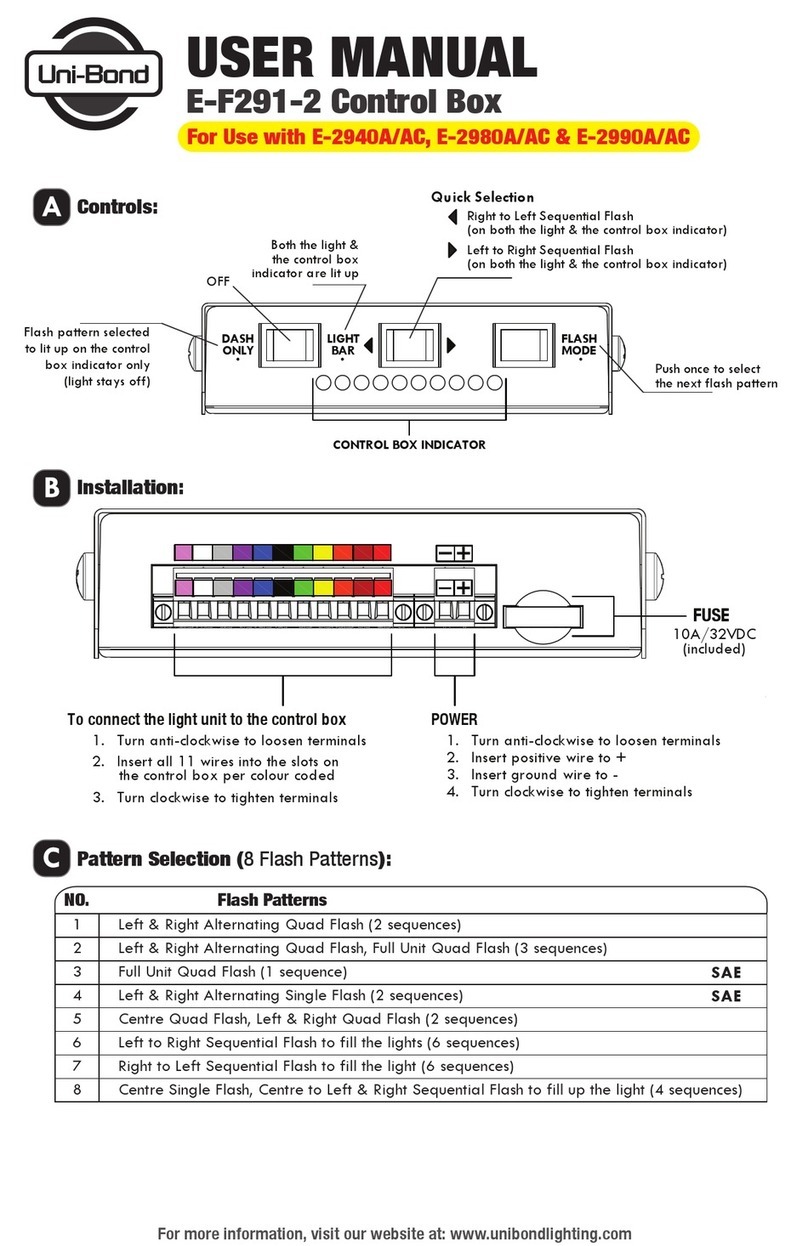

2.1 Nitrogen generator type ECONOMY A

N2 system

N2i system

Figure 1. N2 ECONOMY A system

Figure 2. N2i ECONOMY A system

3.

3.

5.A

4.

6.

8.

10.

7.

9.

2.

11.

1.

1. 2.

3.1

3.1

4.

3. 3.

5.A

6.

8.

10.

7.

9.

1.

11.

1.

3.1 3.1

12

2.2 Nitrogen generator type ECONOMY B

N2 system

N2i system

Figure 3. N2 ECONOMY B system

Figure 4. N2i ECONOMY B system

3. 3.

5.B

6.

8.

10.

7.

9.

2.

4.

11.

1.

1. 2.

3.1

3.1

4.

3. 3.

5.B

6.

8.

10.

7.

9.

1.

11.

1.

3.1 3.1

13

2.3 Nitrogen generator type ECONOMY DUO

N2 system

N2i system

Figure 5. N2 ECONOMY DUO system

Figure 6. N2i ECONOMY DUO system

3. 3.

8.

10.

7.

9.

1.B

2

4.

5.A

6.

1.A

11.

1A. 2. 1B.

3.1 3.1

4.

3. 3.

8.

10.

7.

9.

1.B

5.A

6.

1.A

11.

1B.

1A.

3.1 3.1

14

Legend

Legend for the nitrogen generator of the types: ECONOMY A, ECONOMY B, ECONOMY DUO.

Ref.

No.

Description

Function

1.

Nitrogen output connection

Tube which puts out the nitrogen mixture that is produced by the nitrogen

generator. This outlet will be connected to the piping that runs to the buffer tank.

Please note that this connection is located differently when comparing the N2 and

N2i systems. Also note that the N2 and DUO systems have solenoid valves in the

tubing while the N2i systems do not.

1.A/B

Nitrogen inlet tank 1 and tank 2

Same connection as the standard Nitrogen output connection. Connection 1.A is

used for supplying nitrogen to tank 1 and connection 1.B is used for supplying

nitrogen to tank 2.

2.

Nitrogen HP vessel connection

Tube which puts out the nitrogen mixture that is produced by the nitrogen

generator. This outlet is specially fitted for connecting a nitrogen HP vessel.

3.

PSA vessels

High pressure vessels with active carbon inside. The Pressure Swing Adsorption

process takes place within these vessels. The ST BASIC systems also uses the

nitrogen HP vessel for the Pressure Swing Adsorption process.

3.1

PSA pressure gauges

0 – 10 bar (0,0 – 1,0 MPa) pressure gauges that indicate the pressure within the

PSA vessels. The left pressure gauge is for the left PSA vessel and the right

pressure gauge is for the right pressure vessel.

4.

Digital nitrogen HP vessel

pressure regulator.

Digital pressure switch with a start and stop setting. At default, the pressure

regulator will generate a start signal below 4.0 Bar. At 6.5 Bar, the signal will turn

off and the text on the display will turn green. If the pressure then drops below 4.0

Bar, the text on the display will turn red and a new start signal is generated.

5.A

Touchscreen

Standard for ECONOMY A and ECONOMY DUO systems. This is the most

important monitoring device for reading the statuses and values of the system. The

touchscreen is used to navigate and adjust the settings.

5.B

PRESS-display

LCD display with buttons. Standard for ECONOMY B systems. This is the most

important monitoring device for reading the statuses and values of the system. The

buttons are used to navigate and adjust the settings.

6.

Control cabinet

Control cabinet containing all the electronic components needed to manage the

nitrogen generator, compressor and sensor measurements of 1 buffer tank. This

type of control cabinet has enough space for all standard components and

additional components required for any further expansion of the control cabinet.

7.

Compressed air regulator and

pressure switch.

Composition of pressure control valve and pressure switch. The maximum air

pressure for the nitrogen generator is manually setup by adjusting the pressure

control valve. The pressure switch notifies the system if there is a pressure drop.

8.

Compressed air inlet

Push-in connection that is used for connecting the compressor to the nitrogen

generator. This is commonly done with a 16mm nylon air hose.

9.

PSA control manifold

A pneumatically controlled manifold block that regulates the flow of air and nitrogen

during the Pressure Swing Adsorption process.

10.

Compressed air filters

2 filters that filter out dirt and moisture that comes with the compressed air.

11.

Nitrogen inlet manifold

A pneumatically controlled manifold block that regulates the flow of nitrogen to the

nitrogen storage vessel and one or two buffer tanks.

15

2.4 Vacuum- overpressure safety valve and vacuum safety valve

Figure 7. PV 80/25/20-2, PV 150/25/20-2, PV 200/25/20-2 (VERNIT

systems)

Figure 8. PV 50-2F, PV 80-2F, PV 100-

2F.(HORNIT systems)

Legend

Legend for the safety valves of the types: PV 80/25/20-2, PV 150/25/20-2, PV 200/25/20-2, PV 50-2F, PV 80-2F, PV

100-2F.

Ref.

No.

Description

Function

1.

Maximum overpressure valve

A mechanically operating valve plate with calibrated lead slices that relieves

nitrogen at the maximum allowed pressure. It is protected with an additional

cover.

2.

Operating overpressure valve

A mechanically operating valve plate with calibrated lead slices that relieves

nitrogen at the maximum operating pressure. It is protected with an

additional cover.

3.

Safety valve housing

Assembly housing that holds the vacuum valve and overpressure valves.

4.

Vacuum pressure valve

A mechanically operating valve plate without lead slices that is lifted when a

vacuum occurs.

16

2.5 Vacuum- overpressure safety valve with tracing band

For cold environments it is possible to install tracing ribbon around the vacuum- overpressure safety valve to prevent it

from freezing. Although the safety valve is designed to withstand a certain level of frost, the additional tracing ribbon is an

optional feature that is advisable for environments with long periods of frost.

Figure 9. Vacuum- overpressure safety valve

Legend

Ref.

No.

Description

Function

5.

Tracing band

Band that is heated when powered with electricity.

6.

Thermostat

Thermostat that monitors the surrounding temperature at the sensor and

activates the tracing ribbon when the temperature becomes too low.

7.

Insulation material

Insulation material that prevents the loss of heat that is generated by the

tracing band. By preventing loss of heat to the surrounding, more heat is

induced into the safety valve.

8.

Finishing plating

Plating that keeps the tracing band and insulation material in place and

protects them against external influence.

17

2.6 Pressure sensor

Figure 10. Sensor 0-600mBar, 0-1000mBar, 0-1500mBar, 0-1600mBar, 0-2500mBar.

Legend

Legend for the pressure sensors of the types: 0-600mBar, 0-1000mBar, 0-1600mBar, 0-2500mBar,

Ref.

No.

Description

Function

1.

Protection cap cover

Plastic cover that slides over the pressure sensor. It clamps onto the

protection cap sensor holder.

2.

Pressure sensor

Electrical transmitter that translates a pressure measurement into a

readable 4…20mA signal over a 2 wire connection.

3.

Rubber ring

Rubber ring that seals leakage from air and water between the pressor

sensor and protection cap of the sensor.

4.

Protection cap sensor holder

Plastic isolated holder with tubing that holds the pressure sensor. The

sensor holder functions as additional protection against heat and moisture.

It also allows the pressure sensor to be easily exchanged.

5.

Threaded end of sensor cap

1/2” threaded end through which the protection cap is fitted onto the

buffertank.

6.

Welded threaded socket

1/2” Socket that is welded onto the buffertank and in which the pressure

sensor protection cap is fitted. (fitted by a third party company)

2.7 Pressure sensor with tracing ribbon

For cold environments it is possible to install tracing ribbon around the sensor to prevent it from freezing. Although the

protection cap of the sensor can protect the sensor against freezing to a certain level, the additional tracing ribbon is an

optional feature that is advisable for environments with long periods of frost.

4.

2.

1.

6.

5.

3.

18

Figure 11. Sensor with tracing ribbon

Legend

Ref.

No.

Description

Function

7.

Tracing ribbon

Ribbon that is heated when powered with electricity.

8.

Thermostat

Thermostat that monitors the surrounding temperature at the sensor and

activates the tracing ribbon when the temperature becomes too low.

8.

7.

19

3 General operation

3.1 Operation of the expansion system

The expansion systems can be applied in two different ways. The VERNIT type systems take care of regulating the

pressure of the nitrogen blanket and monitor the water level in the vertical buffer tank. It also has the capability to

regulate the water level if so desired. The HORNIT type systems take care of regulating the total system pressure and

monitor the water level in the horizontal buffer tank. To further explain the operation and functionality of the expansion

systems, the following steps describe how these systems work.

3.1.1 Compressed air supply

Step 1. The compressor takes the air from the surrounding and compresses it to a pressure of 10 Bar. The compressor

has a compressed air HP vessel that holds the compressed air and will continuously maintain the pressure.

From the HP vessel, the air is fed to the nitrogen generator through a hose. At the nitrogen generator, the water

and oil residue is filtered from the compressed air by two filters. This process is the same for all type of nitrogen

generators that are described in this manual.

3.1.2 Nitrogen production

Step 1. The pressure sensors on the buffer tank measure the pressure of the nitrogen blanket and the height of the

water level. This data is sent to the nitrogen generator control cabinet and is displayed on the Touchscreen or

the PRESS-display. The VERNIT systems monitor the pressure of the nitrogen blanket, when it is too low a start

command is generated and nitrogen production starts. The HORNIT systems monitor the total system pressure,

which consists of both the water pressure and the nitrogen pressure. If this is too low, a start command is

generated and nitrogen production starts.

Step 2. Nitrogen production starts with drawing in compressed air from the compressor. The compressed air is

transported to the PSA tubes where the Pressure Swing Adsorption process takes place. The ECONOMY -A -B

and - DUO systems have 2 PSA tubes for this process. Any remaining nitrogen from the Pressure Swing

Adsorption process is blown back into the immediate environment. The remaining mix of oxygen and nitrogen

has a purity of 99.0 vol. % N2. The nitrogen mix is fed to the vertical or horizontal buffer tank and the pressure of

the nitrogen blanket or total system pressure is increased. The nitrogen mix can be sent directly to the buffer

tank if necessary. But it is also possible to first store the nitrogen in the nitrogen storage tank after which it is

sent from here to the buffer tank.

Step 3. The pressure sensors on the buffer tank measure the increased pressure of the nitrogen blanket in the VERNIT

system. In the case of a HORNIT system, the increased system pressure is measured. When the pressure is at

the desired level according to the settings in the Touchscreen or PRESS-Display, the nitrogen production is

stopped. The compressor will continuously keep the air pressure constant. When no more air pressure is being

used by the nitrogen generator, the compressor will also stop.

3.1.3 Water monitoring

Step 1. The pressure sensors on the buffer tank measure the pressure of the nitrogen blanket and the height of the

water level. This data is transferred to the control box of the nitrogen generator and is displayed on the

Touchscreen or the PRESS-display. The water level sensor also measures the pressure of the nitrogen blanket

because the blanket is on top of the water column. The measurement of the nitrogen blanket pressure is

therefore used to calculate a correct water level. To monitor the water level correctly, the VERNIT HORNIT

expansion system is set with multiple error and alarm limits.

Step 2. When the water in the buffer tank is heated or cooled down, the water level will increase or decrease. Under

normal circumstances, the VERNIT HORNIT expansion system will do nothing and only show the

corresponding water level. The error- and alarm limits are set in such a way that they are not triggered under

normal circumstances.

Step 3. When the water level in the buffer tank becomes higher or lower than desired, the VERNIT HORNIT expansion

system will report an error. A pre-alert is generated on the Touchscreen or PRESS-display indicating that the

water level is higher or lower than it should be but that it is not yet problematic. The error message also

indicates whether water should be added or released to remedy the situation.

20

It is important to note that these pre-alerts could indicate that the buffer tank is overfilled or that water is leaking

from the system.

If the water level in the buffer tank continues to fall or rise after the pre-warning is given, the VERNIT HORNIT expansion

system will sound an alarm for a too high or too low water level. This indicates that the water level has risen or fallen to a

problematic level and should not be allowed to rise or fall any further. If it were to rise or fall further, the buffer tank could

be damaged or air could enter the supply spray tube of the central heating network. The VERNIT HORNIT expansion

system will now stop nitrogen production and also generate a stop signal for all relevant devices such as the boiler.

Please note that the relevant devices connected to the stop signal are different in each individual system and depend on

the preferences of the system owner.

3.1.4 Systems that also regulate the water level (optional)

The PRESSCON expansion system of the ECONOMY –A and –DUO types has the possibility to regulate the water level

automatically. This is an optional function that can be used to automatically replenish or drain water from the buffer tank

when needed.

Step 1. The pressure sensors on the buffer tank measure the height of the water level. This data is sent to the control

box of the nitrogen generator and is displayed on the Touchscreen or the PRESS-display. When the water level

is below the minimum height, an electric start signal is generated that turns on an external water pump.

Step 2. The water pump adds water directly to the buffer tank, increasing the water level.

Step 3. The pressure sensors on the buffer tank measure the increased water level. When the water has reached the

minimum height, in accordance with the settings of the Touch Screen or the PRESS-display, the water pump

stops.

The water level regulate function can disguise a water leakage in the central heating

system. This should always be considered when this function is applied.

3.1.5 Protection against overpressure and vacuum with VERNIT systems

These steps only apply to the VERNIT type systems. These systems operate on a pressure of 10 mBar to 28 mBar at

which the overpressure protection can be regulated with a mechanical safety valve.

Step 1. If the pressure of the nitrogen blanket in the buffer tank is at the desired nominal pressure, the nitrogen

generator stops and the vacuum- overpressure safety valve is closed. Under influence of heat, water expands

and the pressure of the nitrogen blanket increases. When the pressure of the nitrogen blanket is at its maximum

operating pressure, the operating overpressure valve will open. The nitrogen is relieved until the water in the

storage tank is not heated any more.

Step 2. If the pressure of the nitrogen blanket is at its maximum operating pressure it is still possible that the pressure

can further increase under special circumstances. It can increase to the maximum allowed pressure. If this

happens, the maximum overpressure valve will open in addition to the operating overpressure valve. With both

valves open, the pressure is relieved with the maximum flow that the safety valve can handle. This will prevent

that the pressure increases any further.

Step 3. If water in the buffer tank is not heated anymore and cools then the pressure of the nitrogen blanket also drops.

It is possible that the pressure drops below 0 Bar and turns into a vacuum. The vacuum pressure valve will

open and will let surrounding air into the tank. This will undo the vacuum.

This manual suits for next models

3

Table of contents

Other PRESSCON Control System manuals

Popular Control System manuals by other brands

SAI

SAI Connect Operation manual

Kessler

Kessler SECOND SHOOTER quick start guide

Airzone

Airzone iQ Zone installation manual

Dormakaba

Dormakaba BEST Wi-Q ONGUARD Interface User Guide

CNC-Step

CNC-Step RaptorX-SL1200-S15 operating instructions

ASCO POWER TECHNOLOGIES

ASCO POWER TECHNOLOGIES 5010 Operator's manual