PRESSCON ExitOxy User manual

ExitOxy

User manual

Type

:

Usermanual

Date

:

22-05-2019

Version / Revision

:

Versie 2.2, Revisie 00

Status

:

Accepted

Company

:

PRESSCON

Location

:

Honselersdijk

Page 2of 12

Table of Contents

Introduction .........................................................................................................................................................................3

Description of the hazard symbols ......................................................................................................................................3

1System overview ........................................................................................................................................................4

2Surface.......................................................................................................................................................................5

3Water-side connection................................................................................................................................................5

4Elektrical connection...................................................................................................................................................6

5Commissioning...........................................................................................................................................................7

6Operation....................................................................................................................................................................8

7First use......................................................................................................................................................................8

8Malfunction.................................................................................................................................................................9

9Maintenance...............................................................................................................................................................9

10 Waranty................................................................................................................................................................10

11 Technical data......................................................................................................................................................11

12 Appendix..............................................................................................................................................................12

13 Document history.................................................................................................................................................12

14 Final.....................................................................................................................................................................12

Page 3of 12

Introduction

Foremost we congratulate you on your purchase of a PRESSCON ExitOxy degasser system. This manual describes how

to install a PRESSCON ExitOxy degasser system. If there, despite our explanation in this manual, is a lack of clarity with

regard to the installation or if there are any questions in another way, don’t hesitate to contact us through the information

below.

Veilingweg 27 A

2675 BR Honselersdijk

Tel:

Web:

E-mail:

Description of the hazard symbols

Symbol

Description

Symbol

Description

1. OVERPRESSURE VALVE,

Be aware of the sudden relief of

overpressure.

7. HIGH PRESSURE,

Relief pressure from components before

work is conducted.

2. DANGEROUS VOLTAGE,

Forbidden to work on the system if the

power is on.

8. HOT PARTS,

Do not touch parts with bare hands. Use

heat-resistant clothing.

3. DANGEROUS TO INHALE GAS,

Avoid the specified area or wear

appropriate breathing equipment.

9. MOVING PARTS,

Risk of getting stuck or injuries to limbs.

Turn the machine off completely before

working on it.

4. NOISE,

Wear ear protection to prevent hearing

damage.

10. ROTATING FAN,

Risk of getting stuck or injuries to limbs.

Turn the machine off completely before

working on it.

5.MACHINE WITH AUTOMATIC START,

Machine stops and starts automatically

when it is operating normally. Turn off the

machine completely before working on it.

11. ATTENTION,

Special situation occurs, follow additional

instructions.

6. READ THE OPERATING AND

MAINTENANCE INSTRUCTIONS,

It is advised that the maintenance

instructions are read before continuing

work.

Page 4of 12

1 System overview

2.

3.

4.

5.

6.

7.

9.

10.

1. 8.

11.

8.

12.

10.

7.

1.

7.

8. 13.

1. Air vent

2. Level sensor stop

3. Vacuum-overpressure

manometer

4. Degassing tank

5. Level sensor start

6. Level sensor minimal

7. Disk valve

8. Ball valve

9. Control cabinet

10. Centrifugal pomp

11. Supply terminal “Inlet”

12. Retour terminal “Outlet”

13. Dirt trap

Figure 1. System overview

Page 5of 12

2 Surface

Because the ExitOxy is permanently attached to the central heating system, it’s important to have hardened subsoil for

the system to prevent the system from tilting. On a soft surface like sand or gravel the ExitOxy can tilt and cause

mechanic stresses on the inlet and outlet.

Figure 2. ExitOxy on a hard surface

Figure 3. ExitOxy on a soft surface

3 Water-side connection

Figure 4. Connection to return pipe

The ExitOxy has to be connected on the return pipe of the greenhouse heating system. Normally the temperature of the

water in the return pipe doesn’t exceed 40°C which benefits the life span of the machine. If the water temperature is

higher than 40°C it is possible that this is detrimental to the life span. In this case it is advised to install the ExitOxy

together with PRESSCON or a licensed installer. For the waterside connection of the ExitOxy apply the following steps.

-Connect the inlet (Figure 4. No. 2) to the return pipes of the central heating system (Figure 4. No. 1). The

size of the inlet is usually 1”BSP internal thread.

-Connect the outlet (Figure 4. No. 3) 1 metre further than the inlet to the return pipe. The size of the outlet

connection is usually 1”BSP internal thread.

-Mount ball valves (Figure 4. No. 4) in the inlet and outlet pipes on the side of the return pipe of the

greenhouse heating system. These can be put to use in an emergency to cut off the system.

2.

3.

4.

1.

Return pipe

Waterstream

H2O

Max 40°C

1"

1"

Page 6of 12

4 Electrical connection

3L21L1 5L3

4T22T1 6T3

(N) 8T4

(N) 7L4

L1 L2 L3 N Grnd

1.

2.

3.

4.

Figure 5. ExitOxy switch panel

The ExitOxy needs a supply of ± 400V AC + N 16A

Before the ExitOxy can be supplied, the following points must be checked:

-Is there a correct main power cable supplied?

The ExitOxy is delivered without its own power cable. It is therefore desirable the an authorized electrician provides

a correct main power supply cable to the location of the ExitOxy.

-Is the supplied power cable voltage-free?

Use a fitting voltmeter or multi-meter to check if the cable is voltage-free. Is there a voltage? Let an authorized

electrician shut off the power.

-Is the head switch in the ‘OFF’ position? (Figure 5. No. 1 & Figure 6)

Put this, if needed, in the desired position.

If the above points are met, the supply can be safely connected.

I ON

O OFF

Figure 6. Main switch

Step 1. Insert the supplied power cable into the ExitOxy switch panel.

Finish the cable with a suitable cable tray or PVC pipe.

Step 2. Connect the phases 1, 2 and 3 to the contacts 2T1, 4T2 and 6T3 of the main switch (Figure 5).

Step 3. Connect the neutral wire to the contact (N)8T4 of the main switch (Figure 5).

Step 4. Connect the green/yellow wire to the first ground terminal of the terminal strip. (Figure 5. No. 2).

Page 7of 12

5 Commissioning

4.

3.2.

1.

6.

5.

Figure 7. ExitOxy back view

When the ExitOxy is delivered it is already tested and adjusted. The ExitOxy is adjusted by adjusting the disc valves

properly. The disc valves as in Figure 7. No. 2 are therefore sealed when the system is delivered. The disc valve on the

inlet connection has to be newly adjusted since the water pressure of the system is different on every location. The seal

on the inlet disc valve (Figure 7. No. 2) can be removed before the adjustment is made. Afterwards, this has to be

returned.

Starting with putting the system into service.

-Open the ball valves in the inlet and outlet connections (Figure 7. No. 1).

-Open the disc valves in the inlet by turning the red drain to the left. The system will fill up with water.

-The air vent (Figure 7. No. 2) on the top side of the degasser tank will blow of air as the tank is filled up. When

the air vent stops blowing off, the degasser tank is filled.

Now, first check the direction of the pump. Pay attention! The degasser tank has to be filled with water. Under no

circumstance it is allowed to let the pump run dry. This will damage the pump.

-Put the switch (Figure 7. No. 6) on position 1 (manual on) and push the reset button (Figure 7. No. 5). The

pomp will turn. Pay attention to the turning direction of the pump.

-Put the switch (Figure 7. No. 6) back to position 0 (Off) after 1 second turning to prevent damage to the pump.

-If the pump turns in the same direction as the arrow (Figure 7. No. 4) the direction is correct.

-If the pump turns in the opposite direction of the arrow (Figure 7. No. 4) the direction is incorrect. To correct this,

2 of the 3 phases have to be swapped. Refer to the directions in chapter 4 ‘Electrical connection’.

Page 8of 12

If the pump turns in the correct direction, then the putting into service can be continued.

-Turn the disc valve in the inlet (Figure 7Figure 7. ExitOxy back view. No. 2) to the left, completely open.

-Put the switch (Figure 7. ExitOxy back view. No. 6) to position 1 (manual on) to make the pump turn.

-Now, turn the disc valve (Figure 7. No. 2) in the inlet slowly to the right to close it until the pressure is between

--0,85 Bar and -0,9 Bar.

-If the pressure continues to -1 bar the disc valve in the inlet is closed too far. In that case, open the disc valve

again until the pressure is between -0,85 and -0,9 Bar.

-Put the switch (Figure 7. No. 2) on position 0 (OFF) so the pump stops and the pressure slowly increases. The

pressure will increase to ± 1 Bar, which is usually the system pressure. Because of the increasing pressure the

air vent won’t blow off. (Figure 7. No. 3).

-If the system pressure is reached and the air vent doesn’t blow off anymore, it is allowed to put the switch back

to position 1 (manual on). This will make the pump turn again and a vacuum is created in the degasser tank

again. The pressure needs to be set between -0,85 Bar and -0,9 Bar again.

-Adjust the disc valve in the inlet if the vacuum pressure yet stays too low or becomes too big.

-Repeat the pressurizing and the vacuum pulling until the pressure during the pumping is between the -0,85 Bar

and -0,9 Bar and stays like that during 3 or more cycles.

-The ExitOxy is now ready for use. Seal the disc valve (Figure 7. No. 2) again so it’s not possible to simply adjust

it.

6 Operation

When the pump is functioning, it will create a vacuum in the degasser tank (Figure 1. No. 4). Water will be sprayed in the

tank and because of the under pressure, air bubbles will be released. These are stored in the top of the system. If a lot of

air gets into the system, the pump will stop and the system will be filled off with water and blows all the oxygen through

the air vent on the top of the ExitOxy.

If there is no air present in the system, the pump will turn on/off less easily. The system will also blow off less or nothing.

This is a sign that almost no air is present in the heating system anymore.

The pump needs to be turned on (using the time clock) in connection with the oxygen entry in the heating system (this

can occur because of diffusion).

7 First use

The ExitOxy can be put on mode 1 (manual) in the first week. The ExitOxy will degas most of the water in its first week in

this way. After a week can the ExitOxy be put on mode 2 (automatic on).

It is advised to check if the ExitOxy is degassing properly in its first week. This can be done in the following way:

-Put the switch (Figure 7. No. 6) on mode 0 (OFF) while the pump is turning. The pump will stop turning so the

degasser tank can fill up with water. If the water is not completely degassed, the released air will cause an

overpressure in the degasser tank. This air will be blown off through the air vent on the degasser tank (Figure 7.

No. 3).

As more water is degassed, the pump will turn on/off less fast and less and less air will be relieved through the air vent.

This indicates a proper operation of the ExitOxy.

If after a week there is still hardly any air coming through the air vent, the ExitOxy can be put on mode 2 (automatic on).

The ExitOxy will from that moment on turn on/off according to the settings of the time clock.

*The time clock is by default set to turn on the machine for 1 hour in the morning and 1 hour in the evening. If desired, it

can be customized in the switch panel. (Figure 5. No. 3)

Page 9of 12

8 Malfunction

The ExitOxy is designed as a quality and a trustworthy product. It can however, not be ruled out that the ExitOxy can get

defect. When this happens, a malfunction in the operational process of the machine is created. In that case the machine

will let the user know.

On the side of the switch cabinet is a red push-button (Figure 8. No. 1). When a malfunction occurs, the light behind the

push-button will start burning. This indicates a malfunction in the machine. By pushing the button, it can be attempted to

reset the malfunction. If the cause of the malfunction is fixed, the light after the button will turn off. If the cause isn’t fixed,

the lamp will keep burning and the cause will have to be fixed manually.

1.

Figure 8. Reset button

If there is a malfunction of the ExitOxy system then there may be the following issues.

Malfunction

Description

Pump thermally inoperative

The thermal protection of the water pump is addressed because the power

usage of the pump has been too high. Open the switch panel of the ExitOxy

and reset the thermal protection (Figure 5. No. 4). Research then the cause of

the high power usage of the pump.

Water level minimal

The water in the degasser tank has been too low because the water has been

sucked out too fast or is supplied to slowly. Check the dirt trap and the tap of

the supply line. Check the pump and the tap in the drain.

9 Maintenance

To ensure a proper working of the ExitOxy the owner must provide the system of its essential maintenance. A part of the

maintenance can be performed by the owner or his/hers technical staff. Other annual maintenance has to be performed

by a service mechanic. See table hereunder.

Activity

Conducted by

Weekly

Monthly

Annually

Every 2

years

Visual inspection

Owner

X

Cleaning the dirt trap

Service

mechanic

X

Cleaning measurement pins

Service

mechanic

X

Check the pump

Service

mechanic

X

Page 10 of 12

10 Waranty

PRESSCON offers a warranty on the components of the ExitOxy for 1 year, in the assumption that the following

conditions are met:

•The equipment is installed by PRESSCON or under direct or indirect supervision of PRESSCON;

•The equipment is undamaged and unprocessed and is not defect as a result of improper use;

•The equipment is not damaged as a result of insufficient maintenance or other procedures;

•The equipment is not defect or in an unreasonable state encountered because of negligence, accidents etc.

The warranty includes compensation of defect components and equipment if the defect is proved. Defect parts and

equipment that are replaced become property of PRESSCON.

With regard to the products supplied by PRESSCON in the Netherlands, PRESSCON refers to the general terms and

conditions. All terms and conditions for supply of goods and / or services within the Netherlands are subjected to the

terms and conditions for the technology industry, lastly submitted by the FME-CWM at the court in The Hague. A Dutch

copy of these terms and conditions is included in any Dutch offer and agreement. Other terms are explicitly denied.

Page 11 of 12

11 Technical data

Appearance

Description

Unit

Value

Dimension L x W x H

[mm]

750 x 350 x 900

Voltage/frequency

[V/Hz]

400AC / 50

Number of phase

[-]

3 fase + N

Electrical power of the pump

[kW]

1,5

Protection value

[A]

16A

Water inlet dimension

[“]

1”

Water outlet dimension

[“]

1”

Max allowable water inlet temperature

[°C]

40°C

Max capacity water inlet / pump flow rate

[m³/h]

400 m³/h

Number of level sensors

3

Type level sensors

Meetpen elektrode

Noise level

[dB(A)]

76

Allowed stance

The ExitOxy only functions in a straight standing stance. The ExitOxy

is securely attached to the local pipe network and can therefore not

move after mounting. The ExitOxy can however still function properly

when it is turned over the yaw-axis or slightly tilted over de roll-axis or

the pitch-axis.

Angle

Picture

Maximal rotation over roll-axis

+/- 10°

Roll

Maximal rotation over pitch-axis

+/- 10°

Pitch

Maximal rotation over yaw-axis

360°

Yaw

Page 12 of 12

12 Appendix

In addition to this document, the description of the content extends to the following appendixes:

Appendix ID

Description

Versie

-

-

-

13 Document history

Version 1.0 to 2.0 indicates : Modification, in lay-out, structure or other major modifications;

Version 1.0 to 1.1 indicates : Supplement, a chapter of paragraph has been added to the document;

Revision _R01 to _R02 indicates : Correction, an image, language error or text error has been corrected.

Version

Date

Modification

1.0_R00

21-01-2014

First release

2.0_R00

28-10-2016

Manual released in renewed template

Chapter 3. Text modified for the description of the allowed temperature.

2.1_R00

07-02-2017

Chapter 3. Description provided with the size of the inlet and outlet connection.

Chapter 8. Malfunction added to the manual.

Chapter 9. Maintenance added to the manual.

Chapter 10. Warranty added to the manual.

Chapter 11. Technical data added to the manual.

2.2_R00

22-05-2019

Chapter 4. Added description about the power supply cable at the pre-checkpoints.

14 Final

This manual has been written in order to support the mechanic, installer or customer in adjusting, modifying or working

with a product of PRESSCON. Its aim is to maintain and possibly improve the quality of its products. If additional

information or support is requested then PRESSCON can be consulted through the following information.

Veilingweg 27 A

2675 BR Honselersdijk

Tel:

Web:

E-mail:

Table of contents

Other PRESSCON Control System manuals

Popular Control System manuals by other brands

Pocket Wizard

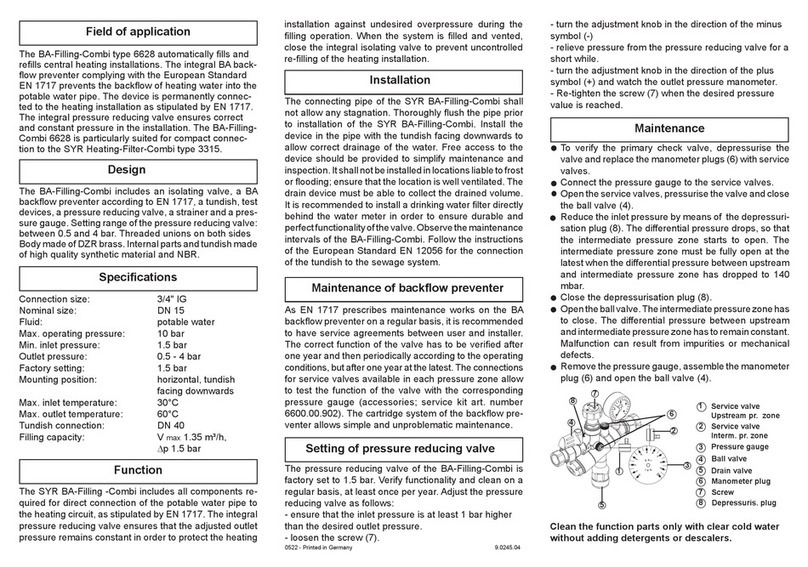

Pocket Wizard MiniTT1 manual

SYR

SYR BA-Filling-Combi 6628 Instructions for use and installation

Madel

Madel KCA-SUB installation manual

Siemens

Siemens SINUMERIK 802S Start-up

Magnetic Autocontrol

Magnetic Autocontrol MAGSTOP MBE35 operating instructions

Oase

Oase InScenio FM-Master WLAN operating instructions