8Presto Lifts PLS67-285 Manual

1.3

6

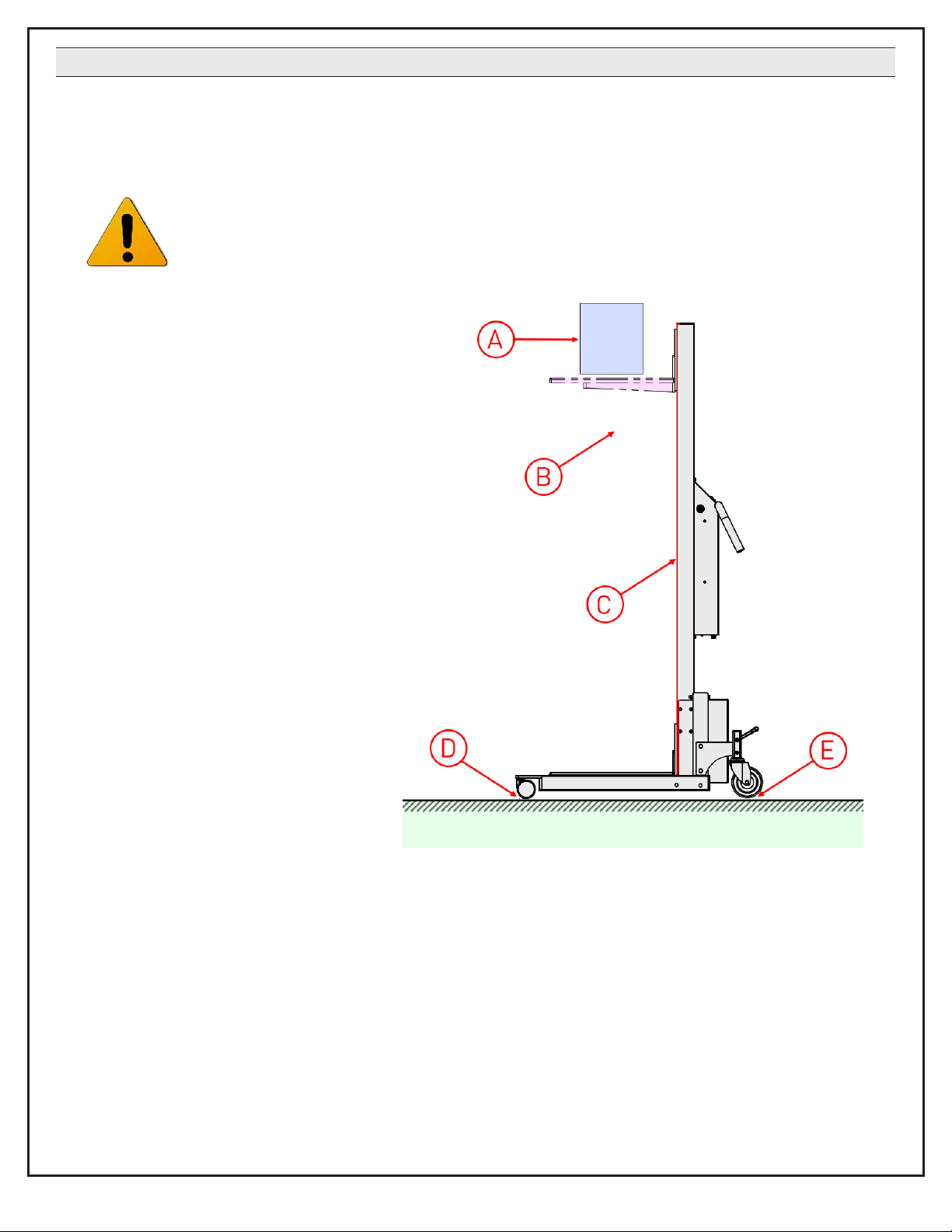

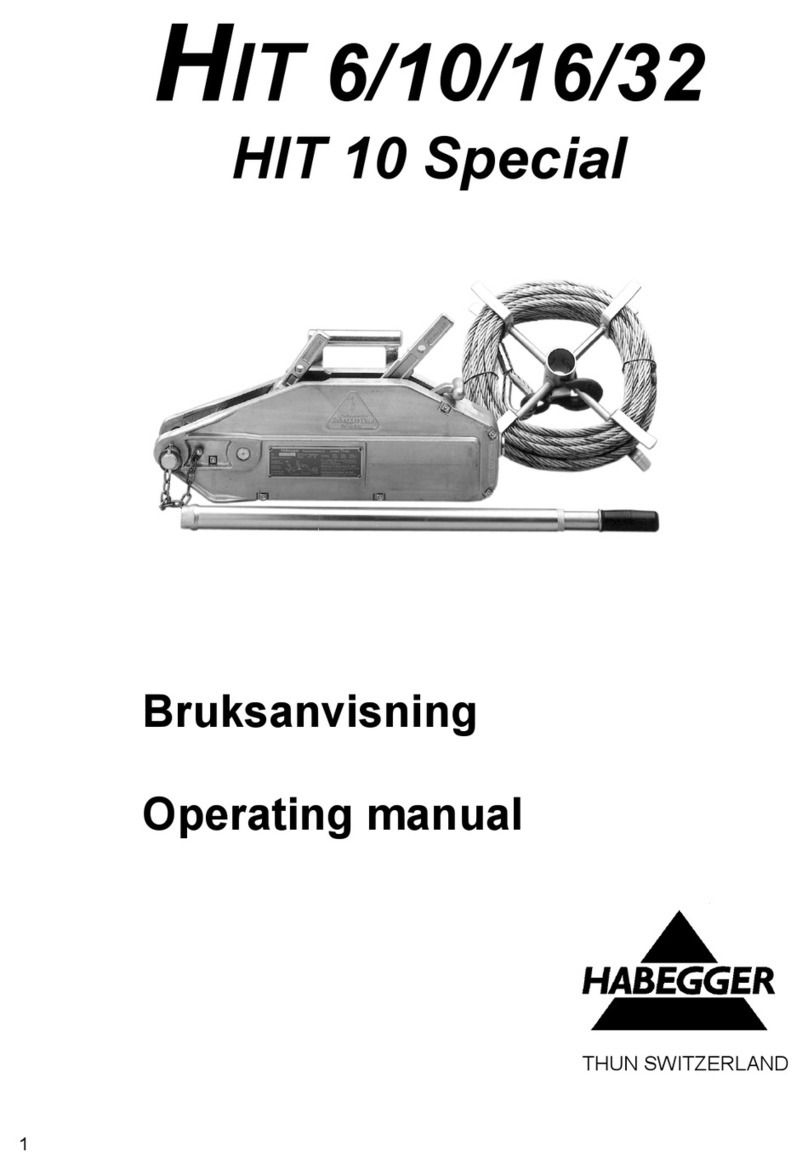

The Presto Lifts/ECOA lifter – general description

1. Mast:

2. Legs:

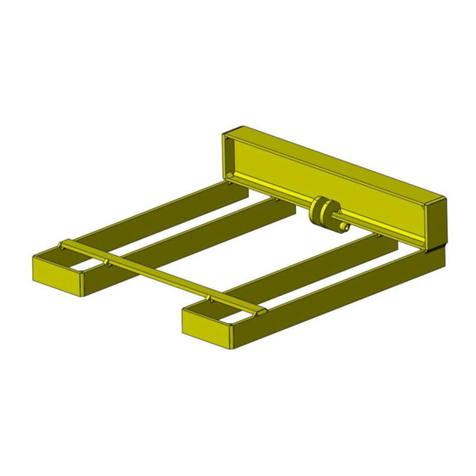

3. Tool:

lA Presto Lifts/ECOA lifter, is a battery-operated lifting device moved around manually, used to handle a

wide variety of items, to reduce heavy and unnatural lifting from personnel, the intention is to improve

work life in regards of personal health and safety.

lIt is of most importance, that the lifter as a whole, is configured correctly, to handle the required load,

with respect to the load type, the load center of gravity and the lifting height, to achieve a safe balance

and operation.

lThe lifter is in general consisting of 3 main components:

lThe mast is a lifting column, optional in different heights, which is mounted on a set of

“legs” and used to lift a “Tool”, suitable for the customers’ requirements.

lThe lifting function is gained from an electric motor, through a cambelt, which is mov-

ing a sledge inside the mast profile.

lThe connection between the motor and the cambelt, is through a “one way bearing”,

which is a built-in safety feature; hence the sledge is lowered only by gravity and not

forced downwards by the motor.

lThe tool is mounted on the sledge with bolts.

lThe legs are used to hold the mast in a vertical position and mounted with wheels, so

that the lifter can be manually moved around on a flat, level floor.

lThe legs come in a variety of configurations, in different lengths, widths, and wheel

configurations.

lIt is vital that the legs are configured correctly, with the main purpose of keeping the

lifter stable and safe on the floor, in the specific configuration of tool type, weight, and

center of gravity of the load and lifting height.

lThe mast is mounted on the legs with bolts.

lPresto Lifts/ECOA has a variety of tools to handle different items and loads.

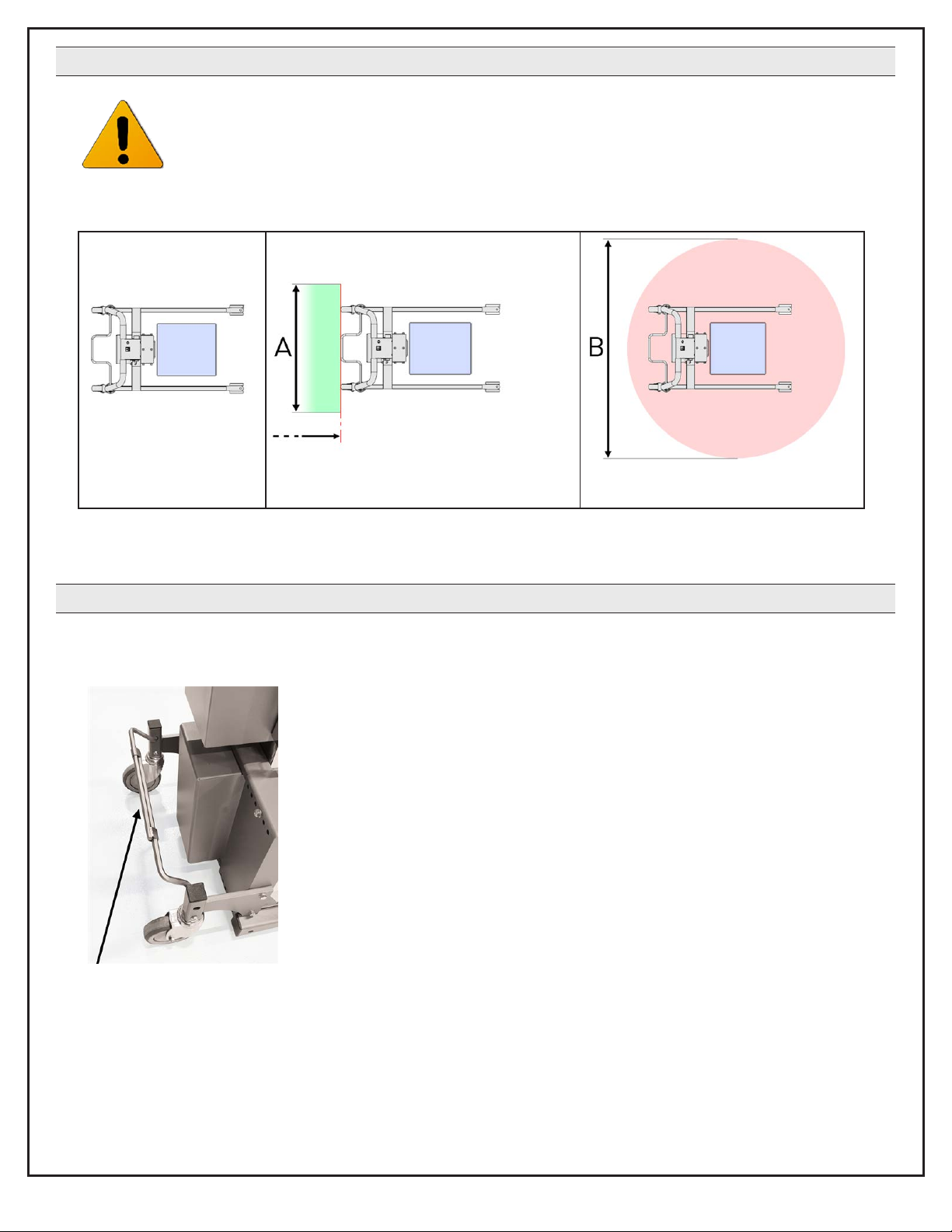

1.4

16

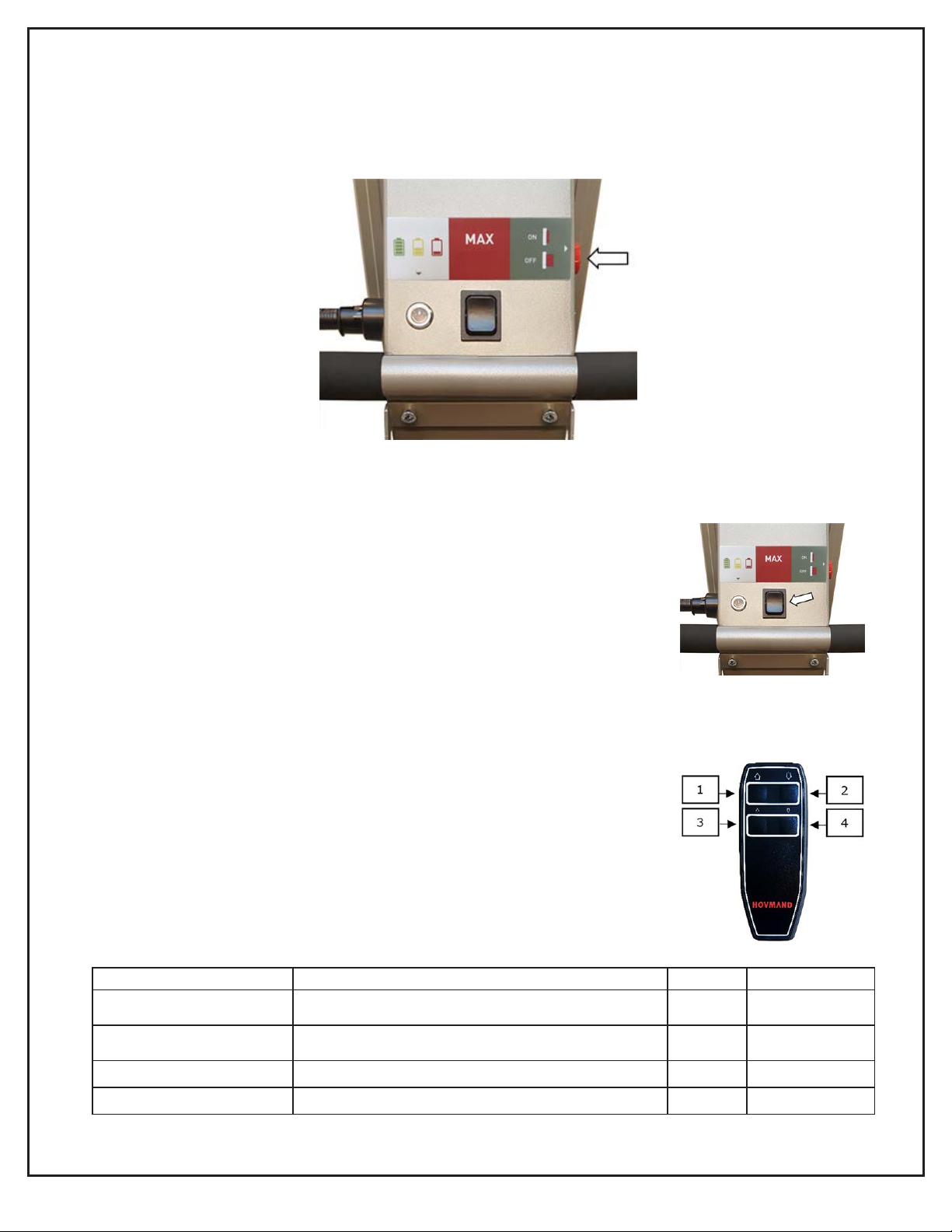

Central brake

The lifter is equipped with central brake on the rear wheels. The brake has 3 different positions, neutral,

brake and swivel lock.

Central brake

Brake operation

The three different positions for the brake is pictured below.

lNeutral position: The rear wheels can turn and swivel without limitations

lBraked position: Rear wheels are locked in both rotation and swivel

lSwivel lock position: Rear wheels can rotate but are locked and cannot swivel

Neutral position Braked position Swivel lock position

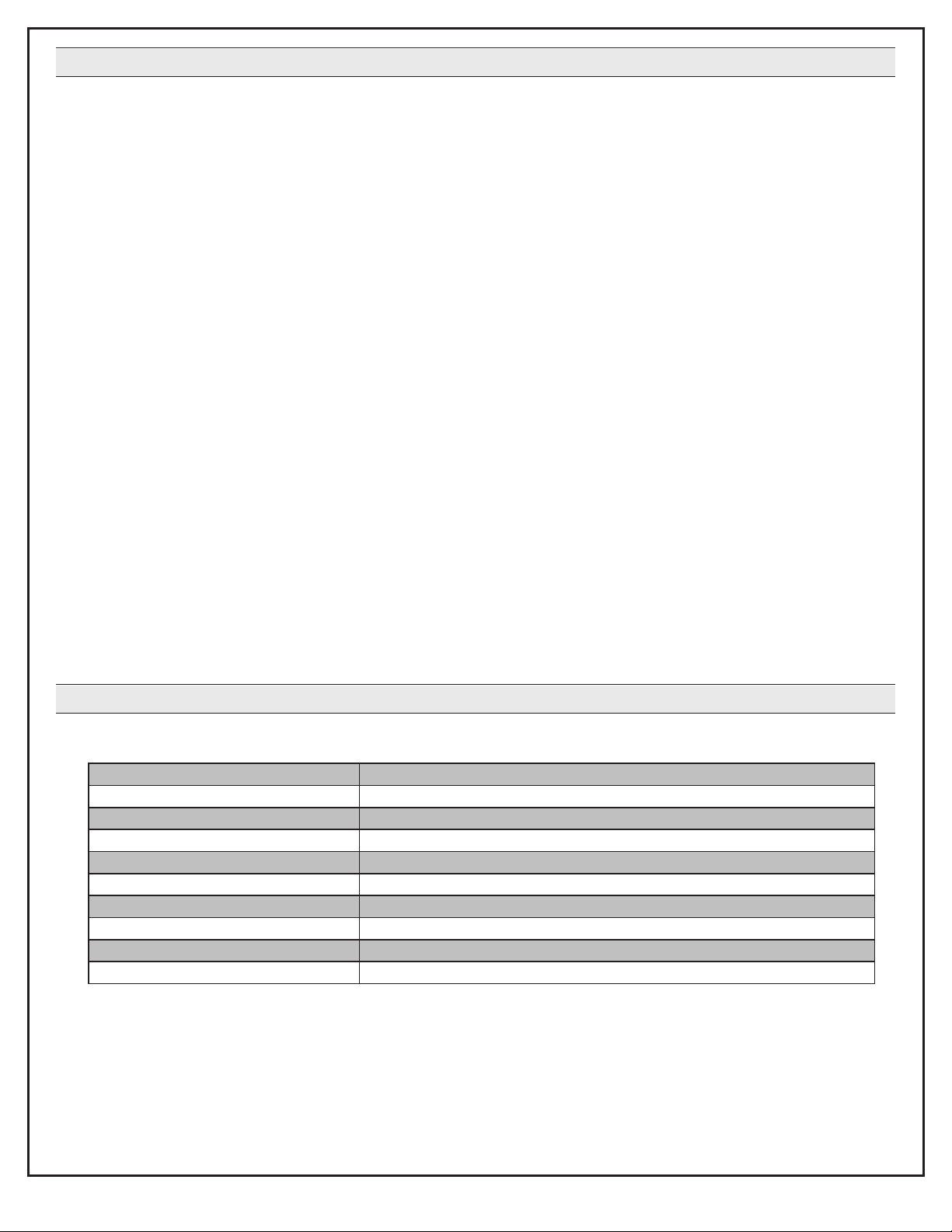

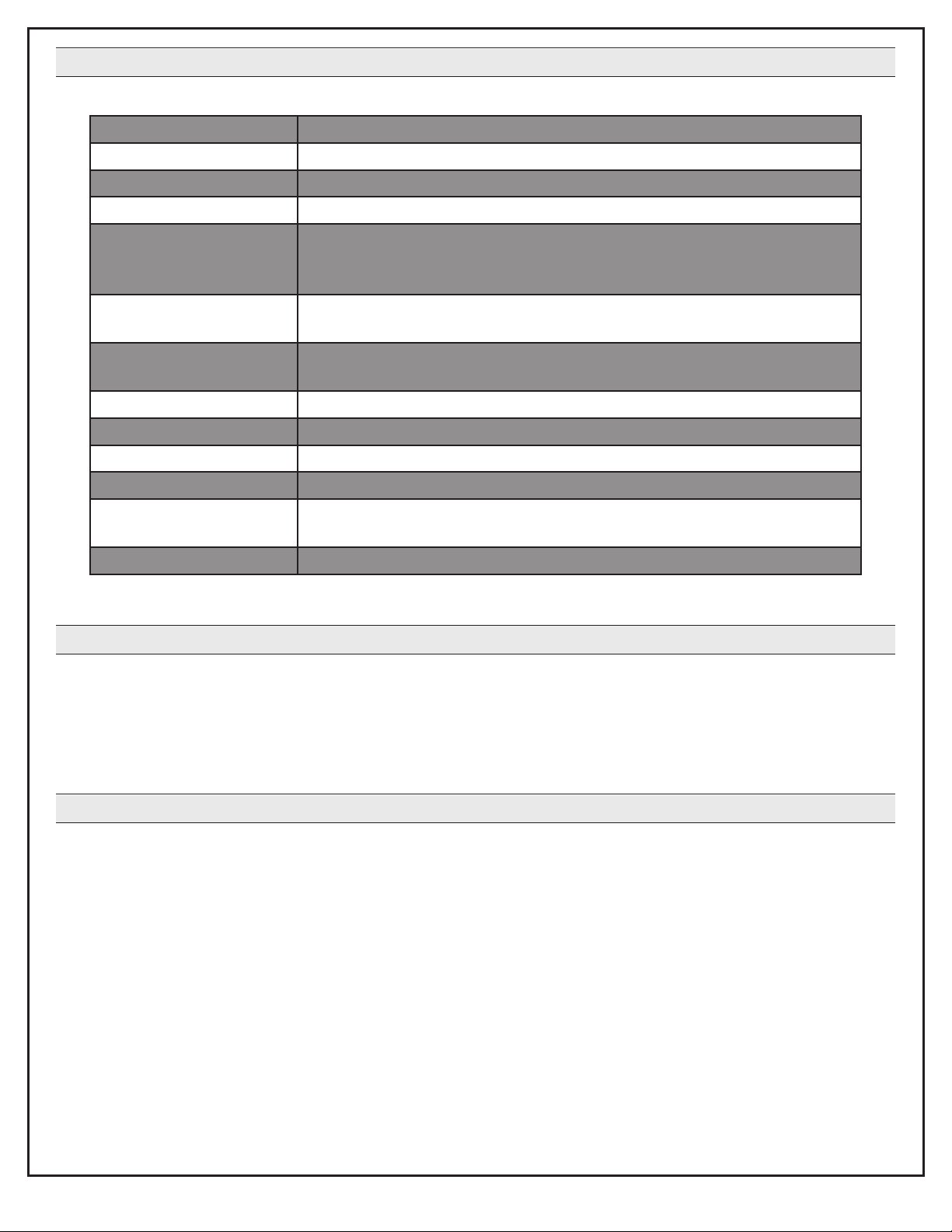

9 Construction and materials

All materials are suitable for use in production, retail, service and distribution.

Part Material

Mast Aluminium (AlMg3).

Handle Powder-coated steel (1.0037 / S235)

Sledge Electro-galvanized steel (1.0037 / S235)

Cover for control box Powder-coated steel (1.0037 / S235)

Remote Polyamide 6

Wheel frame Powder-coated steel (1.0037 / S235)

Front wheels Polyurethane

Back wheels Polyamide and Polyurethane