2 of 40

TABLE OF CONTENTS PAGE

1. SAFETY INSTRUCTIONS ................................................................................................3

2. SAFETY WARNING DECALS .........................................................................................5

3. SPECIFICATIONS..............................................................................................................6

4. CONTENTS..........................................................................................................................7

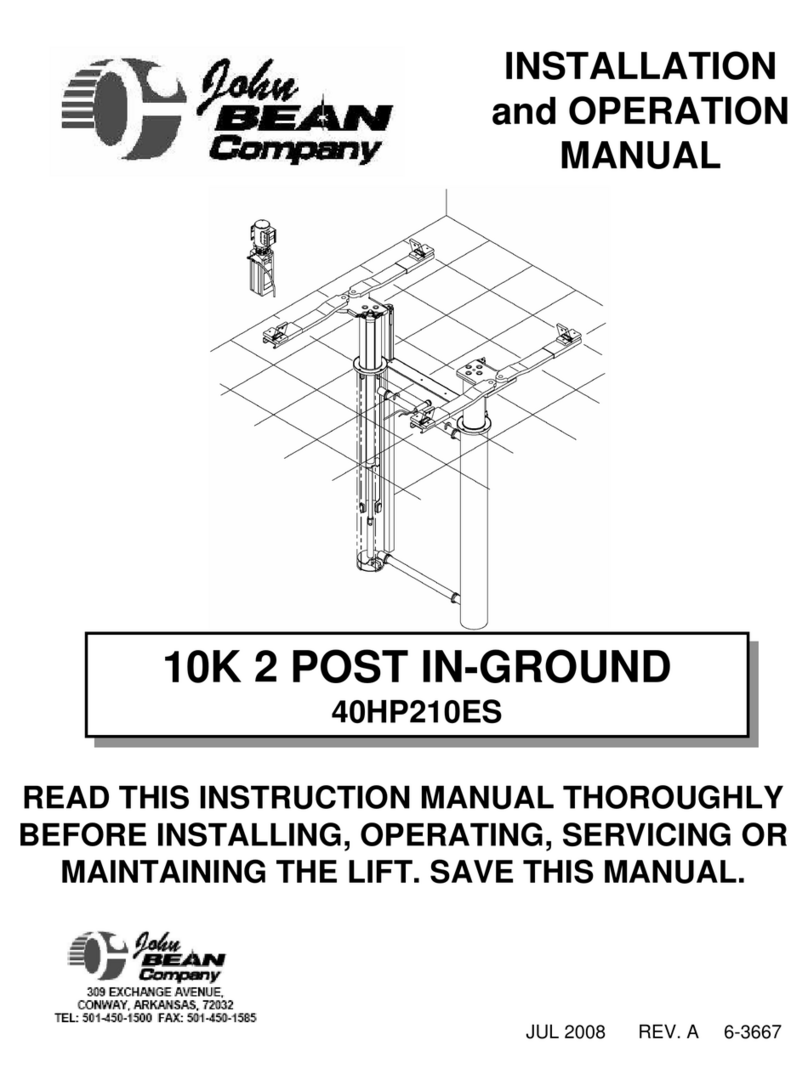

5. TOOLS REQUIRED FOR INSTALLATION..................................................................7

6. INSTALLATION INSTRUCTIONS .................................................................................8

6.1 BAY LAYOUT..................................................................................................................9

6.2 UNPACKING PROCEDURE.......................................................................................10

6.3 HYDRAULIC INSTALLATION..................................................................................11

6.4 ELECTRICAL INSTALLATION................................................................................13

6.5 BLEEDING PROCEDURE...........................................................................................14

6.6 AIR LINE INSTALLATION ........................................................................................14

6.7 MECHANICAL SAFETY INSTALLATION: ............................................................15

6.8 PNEUMATIC SYSTEMS INSTALLATION ..............................................................17

6.9 LEVELING PROCEDURE...........................................................................................18

6.10 ANCHORING PROCEDURE...................................................................................19

6.11 COVERS, WHEEL STOPS AND APPROACH RAMPS.......................................21

7. OPERATING INSTRUCTIONS......................................................................................22

7.1 RAISING THE LIFT .....................................................................................................22

7.2 LOWERING THE LIFT................................................................................................23

8. FINAL CHECK OF ASSEMBLED LIFT.......................................................................24

9. OPERATION TEST WITH VEHICLE ..........................................................................25

10. RECOMMENDED MAINTENANCE.............................................................................26

11. PARTS MANUAL .............................................................................................................28

11.1 BAYSAVER ASSEMBLY..........................................................................................28

11.2 BAYSAVER - PART LIST........................................................................................29

11.3 BAYSAVER HYDRAULICS.....................................................................................31

11.4 BAYSAVER - HYDRAULICS PART LIST.............................................................32

11.5 BAYSAVER OPTIONS..............................................................................................33

11.6 BAYSAVER - OPTIONS PART LIST......................................................................34

11.7 BAYSAVER CONSOLE ............................................................................................35

11.8 BAYSAVER CONSOLE PART LIST ......................................................................36

11.9 9000 LB BAYSAVER POWERPACK......................................................................37

11.10 9,000 LB BAYSAVER POWERPACK PARTS LIST.............................................38

11.11 12,000 LB BAYSAVER POWERPACK...................................................................38

11.12 12,000 LB BAYSAVER POWER PACK - PARTS LIST........................................39