PRESTON PRESSURE PS-500 Operating instructions

PS-500

Pitot-Static/Air Data Tester

OPERATION AND MAINTENANCE

MANUAL

For Model PS-500

PrestonPressure.com

1

Revision 0, August 2020

PRESTON PRESSURE LLC

PS-500

USER AND MAINTENANCE MANUAL

TABLE OF CONTENTS

Page

Warranty and Liability Statement---------------------------------------------------- 2

1. General Information------------------------------------------------------------------- 3

3. Specifications ------------------------------------------------------------------ 4

4. Power Supply ------------------------------------------------------------------ 5

5. Vacuum and Pressure Pumps ------------------------------------------------ 5

6. Front Panel Layout------------------------------------------------------------- 6

2. Theory------------------------------------------------------------------------------------- 8

1. Pneumatic Theory -------------------------------------------------------------- 8

2. Electronic Theory--------------------------------------------------------------- 9

3. Electrical Theory --------------------------------------------------------------- 9

3. Operation -------------------------------------------------------------------------------- 10

1. Preliminary Information ------------------------------------------------------- 10

2. Error Codes ----------------------------------------------------------------------10

2. Pre-testing ----------------------------------------------------------------------- 11

3. Testing Aircraft Pitot System ------------------------------------------------- 11

4. Testing Aircraft Static System ------------------------------------------------12

5. testing the Aircraft Pitot and Static systems simultaneously ------------- 13

6. Using the E.P.R. Function ---------------------------------------------------- 13

4. Calibration Procedures ---------------------------------------------------------------- 14

1. Altimeter Calibration ---------------------------------------------------------- 14

2. Airspeed Calibration ----------------------------------------------------------- 17

4. Calibration of Reservoir Gauges --------------------------------------------- 18

5. Maintenance Repairs and Troubleshooting --------------------------------------- 19

1. Annual Maintenance ----------------------------------------------------------- 19

2. Troubleshooting ---------------------------------------------------------------- 20

3. Pneumatic Diagram ------------------------------------------------------------ 21

6. Shipping and Storage ------------------------------------------------------------------ 22

2

WARRANTY AND LIABILITY STATEMENT

Preston Pressure LLC warrants its products against defects in workmanship and material

under normal, intended use for a period of two years from the date of purchase. The

battery is warranted for a period of 90 days from the date of purchase. Valves are

warranted for a period of 180 days.

Preston Pressure’s limit of liability shall be to repair or replace the product at their

discretion. Transportation shall be pre-paid to the Preston Pressure factory or authorized

service facility. Preston Pressure shall not be liable for any consequential damage

expense.

This warranty shall be void if the product has been repaired or altered in any way that

adversely affects its performance or reliability. This warranty shall be void if the product

has been subject to abuse, misuse, contamination, negligence, accident, shipping damage,

or improper operation.

Preston Pressure reserves the right, at its own discretion, to make changes in materials,

designs, finish, or specifications, without obligation to install or incorporate such changes

in products previously manufactured.

Preston Pressure reserves the right to revise this manual and to make changes to content

from time to time in the content thereof, without obligation to notify any person of such

revision.

This device complies with part 15 of the

FCC Rules. Operation is subject to the following

two conditions: (1) This device may

not cause harmful interference, and (2) this

device must accept any interference received,

including interference that may

cause undesired operation.

3

CHAPTER 1

GENERAL INFORMATION

Description of the PS-500 Pitot-Static Test Box

The PS-500 Air Data, pitot-static test box is a digital display tester used to test aircraft

altimeters, airspeed indicators, pitot-static systems, and other vacuum and low-pressure

devices. This test box incorporates transducer sensor technology that is largely immune

to the failures and costly repairs associated with analog instruments.

The PS-500 is battery powered and portable. The vacuum and pressure sources are

derived from independent internal pumps, and each has its own reservoir, thus

eliminating the complexity and maintenance of an additional pressure/vacuum selector

valve. The tester can simulate pressure and vacuum suitable for up to 35K ft and 650

Knots.

The PS-500 measures altitude in feet and meters. Airspeed is displayed in miles-per-hour,

kilometers-per-hour, and knots. Vacuum and pressure are also selectable in various units

of measure, including inches Hg, milliBars, mm Hg, and Psia.

Pressure Sensors

The sensors used in the PS-500 test box are proprietary transducer sensors. The pitot

sensor is not a differential pressure sensor as is most typically used. Instead, the pressure

information from the static sensor is sent digitally to the airspeed’s microprocessor,

where it is subtracted mathematically from the pitot pressure, thus giving the differential

pressure value. This design eliminates several components, with their associated costs

and maintenance.

The sensor has an overpressure rating of 10 times the normal range.

4

PS-500 SPECIFICATIONS

Digital Altimeter:

Display Range: -2000 to 35,000 feet (-610 to 10,700 meters)

Vacuum Pump Range: -2000 to 35,000 feet (-610 to 10,700 meters)

Resolution: from -2000 to 20,000 feet resolution is in 1-foot increments

from 20,001 to 30,000 feet resolution is in 2-feet increments

all metric resolution is in 1-meter increments

Temperature range: 32 degrees F to 120 degrees F (0 C to 50 C)

Altitude units: Feet or Meters

Other Measurement Units:

inHg (inches of mercury): 0.295 to 32.48 in increments of 0.01

mBar (milli bars): 10 – 1100 in increments of 0.1

PSIA (pounds/square inch): 0.145 to 15.95 in increments of 0.01

mm HG (millimeters of mercury): 7.5 – 825 in increments of 0.1

Digital Airspeed:

Range: 18 – 650 Knots, 34 –1204 KPH, 21 – 748 MPH, 0.00 – 1.00 Mach (Mach at altitude of 0ft only)

Resolution: 1 MPH, 1 KPH, 0.1 Knot, or 0.01 Mach

Temperature range: 32 degrees F to 120 degrees F (0 C to 50 C)

Other Measurement Units:

inHg (inches of mercury): 0.295 to 56.10

mBar (milli bars): 10 – 1900

PSI (pounds/square inch) 0.145 to 27.55

mm HG (millimeters of mercury): 7.5 – 1425

E.P.R. (engine pressure ratio): 0.07-6.00

Display Type: LCD Size: Altimeter and Airspeed: 99 x 24 mm

Physical Dimensions: 12.25”D X 15”L X 9.75”H (31x38x24.5 cm)

Weight: approximately 15 lbs (6.8 Kg)

Power Source:

External: 12 VDC (from a 110/220 VAC adaptor)

Internal: 12 VDC (from internal rechargeable battery)

Current draw: 540 mA with all systems operating

Other Features:

Leak test feature: 2 minutes, selectable down to 30 seconds

VSI (vertical speed indicator)

Note: The PS-500 does NOT have the precision required to test RVSM altimeter

systems.

5

Power Supply

The PS-500 power supply consists of an external transformer with an output of 12 volts

DC. This supply is plugged into the round connector on the front of the tester. The

transformer charges the 12-volt gel-cell lead acid battery that is internal to the PS-500.

The battery enables the test box to be used in a portable fashion without a need for

external power while the tester is in operation. The test box can be used while charging, if

so desired, and may be mounted in any position or angle.

A battery monitoring circuit is also incorporated. The display will flash a “Low Battery”

warning when the battery voltage is near 9 volts.

The useable charge duration of the battery will vary, depending on how long the vacuum

and pressure pumps are left on. In order to obtain maximum charge durability, as well

as extend pump and battery life, it is recommended that the pumps be left on only

for the amount of time needed to charge their respective reservoirs, as shown in the

gauges. Then the pumps should be cycled on and off as needed. When used properly,

the user should be able to obtain several hours of operation directly from the battery

before needing to re-charge. In factory tests, with a fully charged battery, the battery

lasted for over 8 hours when powering only the displays.

Vacuum and Pressure Pumps

The vacuum side uses two pumps, connected in series to achieve a vacuum level required

for high altitude tests. The pressure side uses one pump, which is sufficient to reach all

the pressures necessary for normal pressure tests.

Vacuum and Pressure pumps should not be

allowed to run continuously. Toggle the

switches as needed to re-charge the reservoirs

as seen on the vacuum and pressure gauges.

6

FRONT PANEL LAYOUT

Front Panel Description

The front panel’s Altimeter buttons function as follows:

The UNITS button is used to toggle between the various units of measurement available

from the vacuum/altimeter section. (Altitude – feet, Altitude – meters, mBar, mmHg,

inHg, PSIA)

The EXIT button is used to exit out of the leak check mode.

The LEAK CHECK button is functional only when in the Altimeter mode. Pressing this

button will begin a 120 second timer, and the display will also show the gain or loss of

altitude experienced during the displayed time period. If the operator wishes to select a

different length of time, the Leak Check button may be pressed repeatedly, which will

cause a reduction in the timer counter in 30-second increments. The timer will not toggle

7

above 120 seconds nor under 30 seconds. Pressing the Units button will start the counter

and display the leakage.

The front panel’s Airspeed buttons function as follows:

The UNITS button is used to toggle between the various units of measurement available

from the pressure/airspeed section. (Airspeed – MPH, Knots, KPH, mBar, mmHg, inHg,

PSIA, EPR)

NOTICE! The Mach airspeed is only accurate at the altitude of 0 feet (sea level)!

The EXIT button is used to exit out of the leak check mode.

The LEAK CHECK button is functional only when in the Airspeed mode. Pressing this

button will begin a 120 second timer, and the display will also show the gain or loss of

airspeed experienced during the displayed time period. If the operator wishes to select a

different length of time, the Leak Check button may be pressed repeatedly, which will

cause a reduction in the timer counter in 30-second increments. The timer will not toggle

above 120 seconds nor under 30 seconds. Pressing the Units button will start the counter

and display the leakage.

8

CHAPTER 2

THEORY

The PS-500 test box consists of two vacuum pumps linked in series, one pressure pump,

reservoirs for the pressure and vacuum, a system of metering valves, and digital displays

for indicating altitude, airspeed, and various other pressure measurements, based on

pressures sensed in the sensor transducers.

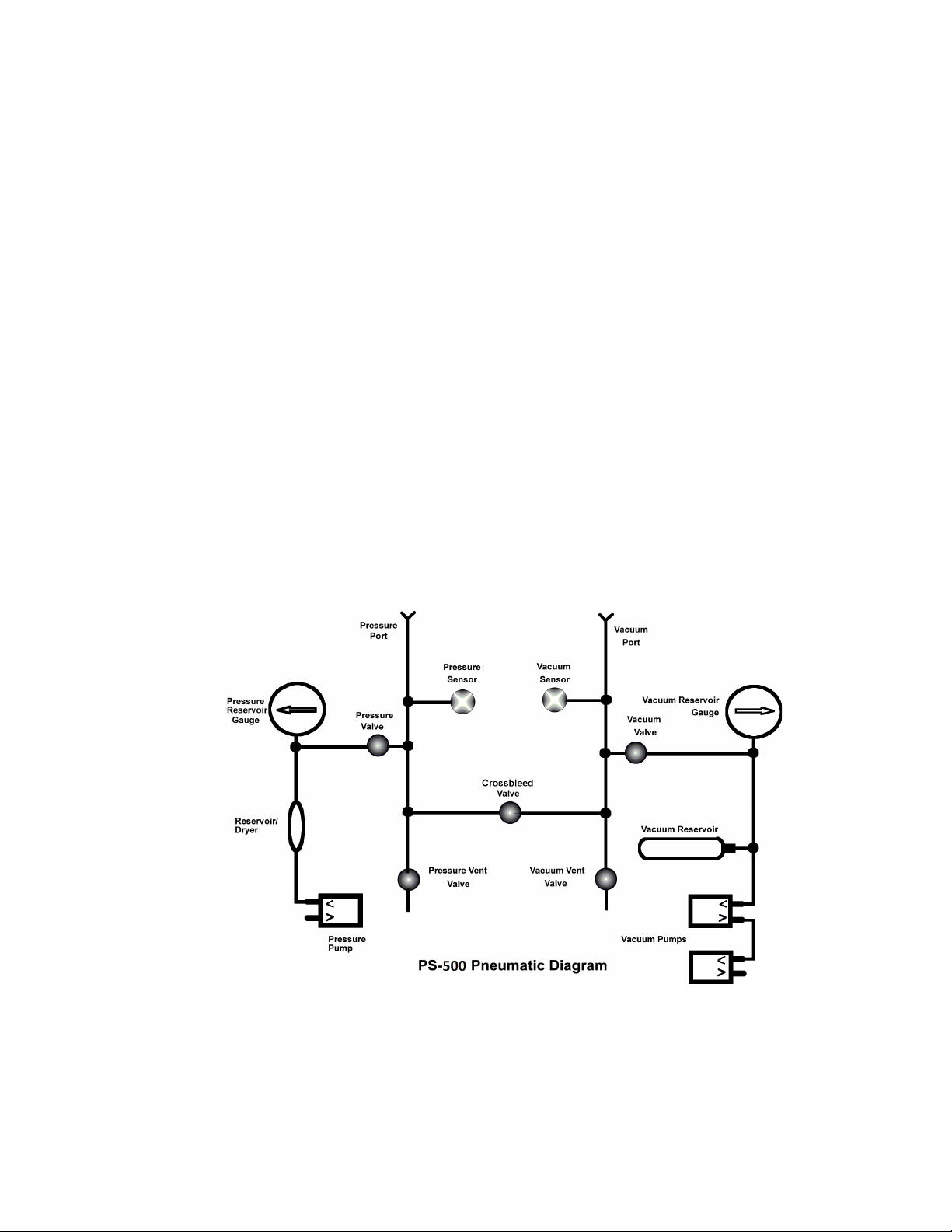

Pneumatic Theory

Metering valves allow the operator to control the rate of flow of the air from the pressure

or vacuum sources, exiting out through the vacuum and pressure ports. The vent valves

allow for metering the produced vacuum or pressure back into the atmosphere. One

Crossbleed valve permits the operator to isolate the pressure and vacuum sides, or to

allow the balancing of pressures, or even to reverse the normal flow of pressures.

The two round gauges allow the operator to monitor the level of pressure or vacuum that

is stored in the tester’s reservoirs. The switch corresponding to the pump for each

reservoir should be toggled to increase the reservoir’s level of vacuum or pressure as

needed. For maximum pump and battery life, do not leave pumps on continuously!

When the operator wishes to simulate an altitude, the Crossbleed, Vacuum, and Vacuum

Vent valves are gently closed. The vacuum pump is then energized until sufficient

vacuum is in the reservoir, as indicated on the Vacuum Reservoir Gauge. How much

vacuum will be needed depends on the desired altitude and is also affected by how long

9

the tubing and lines are between the test box and the altimeter. The vacuum and

pressure reservoir gauges serve only as general references of reservoir vacuum and

pressure; they are not used in the actual calibration of any instrumentation, and do

not require calibration. Once sufficient vacuum is obtained in the reservoir, the pump is

turned off, and the Vacuum Valve is gently opened to allow air to be suctioned into the

system through the vacuum port. Once sufficient altitude simulation is obtained, the

Vacuum Valve is gently closed. Reduction in altitude is accomplished by gently opening

the Vacuum Vent Valve and allowing atmospheric air pressure to enter into the lines.

If the operator needs to go to an altitude below atmospheric pressure, pressure must be

introduced into the pressure reservoir. Opening the Crossbleed Valve will enable pressure

to flow from the pressure reservoir to the altimeter. Open the Crossbleed valve, and then

the Pressure valve to pressurize the vacuum side.

When airspeed is to be simulated, the Crossbleed, Pressure and Pressure Vent valves will

first be closed until the operator establishes a pressure build-up in the pressure reservoir

by turning on the pressure pump. Then the Pressure Valve will be gently opened,

allowing air pressure to flow through the pressure port to the airspeed indicator. To

reduce pressure, the Pressure Vent valve is opened to leak the air pressure into the

atmosphere.

Electronic Theory

The main circuit board of the PS-500 incorporates all the electronics for the altimeter and

airspeed displays. The power for the altimeter and airspeed circuits is regulated from 12

VDC to 5 VDC and 3.3 VDC.

The sensors used in the PS-500 test box are proprietary. The pitot sensor is not a

differential pressure sensor as is most typically used in airspeed measurements. Instead,

the pressure information from the static sensor is sent digitally to the microprocessor

where it is subtracted mathematically from the pitot pressure, thus giving the differential

pressure value. This design eliminates several components with their associated costs and

maintenance. It also allows the Altimeter side to be used at any altitude with the

Crossbleed valve closed, without damaging the airspeed sensor.

Warning: Even though the pressure sensors will not be damaged due to a high

differential pressure between the vacuum and pressure sides, damage can still occur

in external instruments connected to the test box.

Electrical Theory

The internal gel-cell lead-acid battery provides the power to the PS-500 test box. The

battery is charged via the power connector on the front of the test box. Full charging time

is about 10 hours. The test box can be used while it is being charged.

10

CHAPTER 3

OPERATION

Preliminary Information

Prior to using the PS-500 tester the user should become familiar with the unit by reading

this manual and operating the tester independently of any other attached devices.

For greater accuracy, the tester should be powered on for 10 minutes before use.

The test procedures described in this manual are general in nature, for reference

use only. The operator may substitute these procedures with others, as applicable to the

tests to be performed, or according to other specific documentation.

Error codes display as follows:

The display will indicate “Too Cold” or “Too Hot” if the sensor temperature is below

32F or 0C, or above 122F or 50C. Beyond these limits the accuracy should not be

trusted.

Altitude displays “Too High” if it exceeds 35,500 feet.

“Inverse Pressure” will be indicated on the airspeed side if the static pressure exceeds

the pitot pressure by more than approximately 0.1 mbar. Due to its independent

pressure and static sensors, no damage will occur to the tester due to inverse pressure.

However, damage could occur to any system attached to the tester, therefore the

warning is to alert the user of the condition.

“Max Speed” will be indicated on the airspeed side if the pressure exceeds the

equivalent of 650 knots. Due to independent pressure and static sensors, no damage

will occur to the tester from this condition. However, damage could occur to any

system attached to the tester, therefore the warning is to alert the user of the

condition.

“Low Battery” will blink on displays if the battery voltage is less than approximately

9 volts.

Pre-Testing

Pre-test the static system of the PS-500 test box according to the following steps:

1. Ensure the PS-500 is not connected to any external hoses or devices.

2. Close the Vacuum Control, Vacuum Vent, Pressure Control, and Pressure Vent

valves. Open the Crossbleed valve.

3. Turn on the power, and then turn on the Vacuum Pump switch until the Vacuum

Reservoir gauge reads -15 inHG or greater vacuum.

11

4. Open the Vacuum Control valve to make the Altimeter section climb. This climb

may be done rapidly without damage to the sensor.

5. When the Altimeter reads at least 18,000 feet, gently close the Vacuum Control

valve.

6. Wait for 2 minutes or more for the internal pressure to stabilize. Note: a rapid

climb will not damage the tester. However, the internal tubing needs time to

contract due to the applied vacuum, and this will give the appearance of a small

leak for the first 2 minutes or more. Rapid temperature changes will also mimic a

leak.

7. Perform a leak check to monitor the leak rate. Verify that the PS-500 does not

leak exceeding 100 feet per minute. Write down the leak rate for future reference.

(Subtract this value from the total leak rate when testing the aircraft, to arrive at

the aircraft’s leak rate.)

8. Open the Vacuum Vent valve to bring the test box back to ground (ambient)

pressure.

Pre-test the pressure system of the PS-500 test box according to the following steps:

1. Turn on the power to the PS-500.

2. Ensure the PS-500 is not connected to any external hoses or devices.

3. Close the Vacuum Control, Vacuum Vent, Pressure Control, Crossbleed valve,

and Pressure Vent valves.

4. Turn on the Pressure Pump switch until the Pressure Reservoir gauge reads 10

PSI or more.

5. Open the Pressure Control valve to make the Airspeed section climb. This climb

may be done rapidly without damage to the sensor.

6. When the Airspeed reads at least 300 knots, gently close the Pressure Control

valve.

7. Wait for about 15 seconds for the internal pressure to stabilize. Activate the leak

check function to monitor the leak rate. Verify that the PS-500 does not leak

exceeding 2 knots per minute. Write down the leak rate for future reference.

(Subtract this value from the total leak rate when testing the aircraft, to arrive at

the aircraft’s leak rate.)

8. Open the Pressure Vent valve to bring the test box back to ground (ambient)

pressure.

Testing Aircraft Pitot System Only

NOTICE! The Mach airspeed reading is only accurate at the altitude of 0 feet (sea level)!

1. Turn on the power to the PS-500.

2. Connect the Pressure Port to the aircraft Pitot system.

3. Close Pressure Control, Pressure Vent, and Crossbleed valves. Open Vacuum

vent valve.

12

4. Turn Pressure Pump switch on until the Pressure Reservoir indicates 10 PSI or

more.

5. Gently open Pressure Control valve until desired speed(s) are achieved.

6. Compare the airspeed of the PS-500 box to the airspeed indicated in the aircraft.

7. Go to approximately 75% of the maximum airspeed of aircraft indicator (or the

speed specified by the manufacturer). Close the Pressure Control valve and after

allowing a few seconds for stabilization, perform a leak check. The pitot system

should not leak more than two knots per second, plus the leakage previously noted

in the pressure system pre-test.

8. Gently open the Pressure Vent valve to return the pitot pressure to ambient

pressure.

Testing of Aircraft Static System (independent from the pitot system)

Note: If the previous pitot system test indicated an excessive leak, do not proceed until

that leak is repaired. Damage to aircraft airspeed indicator could result.

1. Turn on the power to the PS-500.

2. Disconnect the static line to the airspeed indicator and cap the line.

3. Connect the Vacuum Port to the aircraft static port. Set the aircraft altimeter to

29.92 inHg (1013.3 mB).

4. Close Vacuum Control, Vacuum Vent, Pressure Control, and Pressure Vent

valves. Open Crossbleed valve.

5. Operate the Vacuum Pump switch until a desired level of vacuum is seen on the

Vacuum Reservoir gauge (generally -15 to -20 inHG). Turn Pressure Pump switch

on until the Pressure Reservoir indicates 10 - 15 PSI or more.

6. Gently open the Vacuum Control valve to cause the altitude to climb.

7. DO NOT exceed the climb rate of the aircraft VSI indicator, or the airspeed

indicator limits. The VSI is a very delicate instrument.

8. Climb to the desired altitude(s) per the test to be performed.

9. Close the Vacuum Control valve, and after allowing a few seconds for

stabilization, compare the aircraft altimeter with the test box.

10. When at the appropriate altitude (generally 18,000 feet) perform a leak check. If

the static system shows leakage, be careful to not exceed the VSI rate. Be

prepared to open the Vacuum Control valve if needed, to prevent excessive VSI

indication.

11. Gently open the Pressure Vent valve to return the system pressure to ambient

pressure. Do not exceed the VSI or airspeed indicator limits.

12. Re-connect airspeed indicator static line and do a leak check test.

Note: if an altitude lower than ambient pressure is desired, do steps 1-4 above. Gently

open the Pressure Control valve to pressurize the system, thereby causing the

altimeter to decrease in altitude. Open the Vacuum Vent valve to return to ambient

pressure.

13

Testing the Aircraft Pitot and Static systems simultaneously

Note: First ensure pitot system does not leak by performing Pitot system test on page 14.

1. Turn on the power to the PS-500.

2. Connect the Vacuum Port to the aircraft static port, and the Pressure Port to the

aircraft pitot port. Set the aircraft altimeter to 29.92 inHg (1013.3 mB).

3. Close Vacuum Control, Vacuum Vent, Pressure Control, and Pressure Vent

valves. Open Crossbleed valve.

4. Operate the Vacuum Pump switch until a desired level of vacuum is seen on the

Vacuum Reservoir gauge (generally -15 to -20 inHG). Turn Pressure Pump switch

on until the Pressure Reservoir indicates 10 PSI or more.

5. Gently open the Vacuum Control valve to cause the altitude to climb.

6. DO NOT exceed the climb rate of the aircraft VSI indicator, or the airspeed

indicator limits. The VSI is a very delicate instrument.

7. Climb to the desired altitude(s) per the test to be performed.

8. Close the Vacuum Control valve, and after allowing a few seconds for

stabilization, compare the aircraft altimeter with the test box.

9. When at the appropriate altitude (generally 18,000 feet) perform a leak check. If

the static system shows leakage, be careful to not exceed the VSI rate. Be

prepared to open the Vacuum Control valve if needed, to prevent excessive VSI

indication.

10. To display an airspeed, close Crossbleed valve and gently open Pressure valve

until desired airspeed is indicated. Close Pressure valve.

11. To return system to ambient pressure, ensure Crossbleed valve is open. Then

gently open the Pressure Vent valve to return the system pressure to ambient

pressure. Do not exceed the VSI or airspeed indicator limits.

Note: if an altitude lower than ambient pressure is desired, do steps 1-4 above. Gently

open the Pressure Control valve to pressurize the system, thereby causing the

altimeter to decrease in altitude. Open the Vacuum Vent valve to return to ambient

pressure.

Using the E.P.R. function

The EPR function is used to test engine pressure ratios. This ratio is the mathematic result

of: High Pressure/Low Pressure. The PS-500 test box will display the low pressure, the

high pressure (both in PSI), and the resulting EPR. To use the EPR function, proceed as

follows:

1. Turn on the test box.

2. Close all of the valves, including the Crossbleed valve.

3. Connect the Vacuum port to the low pressure to be tested.

4. Connect the Pressure port to the high pressure to be tested.

5. Cycle through the Units on the Airspeed side until in the EPR mode. Read the

EPR values displayed.

Note: Do not exceed 16.75 PSI on the high pressure side, to avoid sensor damage.

14

CHAPTER 4

CALIBRATION PROCEDURES

The recommended calibration interval for the PS-500 test box is one year. If at any

time during regular use the unit becomes unreliable or out of correct operating

calibration, it must be repaired and/or re-calibrated before continuing its use.

The PS-500 test box is easy to calibrate. There are 5 set points used in the calibration of

the altimeter side. Calibrating at multiple setpoints enables the altimeter to have a greater

degree of accuracy, allowing it to self-correct to the nearest calibrated set point.

The altimeter side should normally be calibrated first, as the airspeed side reads the static

pressure through the altimeter circuitry. However, if the altimeter side has been tested

and found satisfactory, the airspeed side can be calibrated at any time.

Note: the calibration factors are stored in the microcontroller’s EEPROM memory. This

memory does not need battery back-up. The calibration will not be lost if the unit’s

battery is disconnected or replaced.

PS-500 Altimeter Side Calibration Procedures

1. Apply power to the PS-500 and allow unit to warm up for a minimum of 10 minutes.

2. Gently close the Vacuum Control valve, Vacuum Vent valve, and Crossbleed valve.

3. Connect a known altitude pressure standard to the Vacuum Port.

4. Set the PS-500 altimeter measurement units to read in mbar by pressing the Units

button.

5. Press the Exit and Leak Check buttons simultaneously. The display will change to:

Enter Cal Mode?

6. Press the Leak Check button to proceed with calibration or select the Exit button to

exit out of the calibration mode without any changes being made.

7. At this point the display will read:

Go To 0 Feet

Next

15

8. Now the display will show

XXX

In YY

Where XXX is the sensed altitude and YY is the internal correction factor currently

stored in the calibration memory.

Using the pneumatics of the PS-500 or an attached pressure standard, go to a

pressure of 0 feet (referenced from 29.92 inHg), as read from the pressure standard.

When the altitude is stable for approximately 30 seconds, note the altitude displayed

on the PS-500 display in calibration mode.

If the displayed altitude is higher or lower than the standard, press the Exit or Leak

Check button as needed to incrementally change the altitude to be equivalent to the

standard.

As the altitude is adjusted, note that the displayed correction factor also changes. Use

this to fine-tune the altitude as close as you can to the standard.

When the PS-500 altitude matches the standard as close as possible, wait another 30

seconds to ensure that the internal mathematical filtering corrections have been done.

If satisfied with the results, press the Units button to proceed to the next calibration

level.

Note: Allowable error tolerances are as follows (these are the allowable errors per

AC43 Appendix E, not the accuracy of the PS-500):

Altitude

+/

-

Error

Altitude

+/

-

Error

-1000

0

500

1000

1500

2000

3000

4000

6000

8000

10000

12000

5

5

5

5

6

7

7

8

10

15

20

22

14000

16000

18000

20000

22000

25000

30000

35000

40000

25

27

30

32

35

38

45

51

57

Note: Make a written note of each calibration correction value. In the very rare

case that a calibration factor is lost from the memory, it can be re-programmed

without a complete calibration procedure. The correction values can also serve as a

16

record to see if the sensors are drifting with age. A good place to keep the calibration

correction values is in this manual.

9. After pressing the Units button, the display will change to display Go to 10000 feet.

10. Repeat the procedure in step 8 at each requested altitude: 10000, 20000, 30000 and

40000, feet.

11. After entering the calibration value of the highest altitude, pressing the Units button

will change the calibration to the VSI calibration mode. Select a vertical descent speed

(5,000 feet is suggested) on the calibration test equipment and activate it. The display will

indicate the calculated VSI value. Adjust if needed by pressing the Exit or Leak Check

buttons. When finished, press the Units button. The VSI calibration value will be saved.

12. After the VSI calibration has been entered, the display will briefly read

Calibration

Saved

and then re-start in the altitude mode. There is no need to re-cycle power.

13. Bring the PS-500 box back down to ground level pressure, then test each calibration

point as specified in the chart. Enter the corrected value at each point. (The correction

chart may be photocopied, cut out, and fixed to the test box for handy reference.)

Maximum allowable error at any altitude is 70 feet. (Generally, a maximum error of less

than 20 feet should be expected.)

PS-500 S/N

FOR TEST

ALTITUDE DISPLAY

ALTITUDE FOR TEST

ALTITUDE DISPLAY

ALTITUDE

-

1000

10000

-500

11000

0

12000

500

14000

1000

16000

1500

18000

2000

20000

3000

22000

4000

25000

6000

30000

8000

35000

Calibrated by: ___________ Date: __________

Next Calibration Due Date: ________________

17

Airspeed Calibration Procedures

1. If not already powered on, apply power to the PS-500 and allow unit to warm up for a

minimum of 10 minutes.

2. Gently close the Pressure Control valve, Pressure Vent valve, and Crossbleed valve.

3. Connect a pressure standard to the Pressure Port. Maintain the altimeter side at 0 feet.

4. Press the Units button to set the airspeed measurement units to read in mbar.

5. Press the Exit and Leak Check buttons. The display will change to:

Enter Cal Mode?

6. Press the Leak Check button to proceed with calibration or select the Exit button to

exit out of the calibration mode without any changes being made.

7. At this point the display will read:

Go to 50 Knots

Next at 0 Feet

Using an attached pressure standard, go to an airspeed 50.0 knots (while always

maintaining the static pressure of 0 feet), as read from the pressure standard.

8. X.X Knots

Enter YY

Where X.X is the sensed knots and YY is the internal correction factor currently stored in

the calibration memory.

9. When the pressure is stable for approximately 30 seconds, note the pressure displayed

on the PS-500 airspeed display in calibration mode.

If the displayed speed is lower or higher than the standard, press the Exit or Leak Check

button as needed to incrementally raise or lower the pressure to be equivalent to the

standard.

As the pressure is adjusted, note that the displayed correction factor also changes. Use

this to fine-tune the pressure as close as you can to the standard.

If satisfied with the results, press the Units button to save the calibration and exit back to

the mBar mode.

18

10. After the calibration point has been entered, the display will briefly read

“Calibration Saved” and then exit the calibration mode.

11. When a satisfactory calibration is obtained at this test point, go through each test

point in the following chart and enter the corrected value at each point. (The correction

chart may be photocopied, cut out, and fixed to the test box for handy reference.)

12. Make a written note of the calibration correction value. In the very rare case that a

calibration factor is lost from the memory, it can be re-programmed without a complete

calibration procedure. The correction value can also serve as a record to see if the sensors

are drifting with age.

Maximum allowable error at any airspeed is 2 Knots. (Generally, a maximum error of 1

Knot should be expected.) The airspeed has only one calibration point.

PS-500 S/N

FOR TEST

AIRSPEED DISPLAY

AIRSPEED FOR TEST

AIRSPEED DISPLAY

AIRSPEED

20 Kts

275 Kts

40 Kts

300 Kts

60 Kts

325 Kts

80 Kts

350 Kts

100 Kts

375 Kts

120 Kts

400 Kt

s

140 Kts

425 Kts

160 Kts

450 Kts

180 Kts

500 Kts

200 Kts

550 Kts

225 Kts

600 Kts

250 Kts

650 Kts

Calibrated by: ___________ Date: _________

Next Calibration Due Date: _______________

Calibration Notes:

Do not forget to wait the minimum of 10 minutes before calibrating.

The calibration procedure can be entered only when the mbar mode is selected.

Do not forget to check bead colors in the air pressure reservoir/dryer. If they are

pink or clear, it is time to change the unit to avoid a build-up of moisture in the

pressure system. Replacement air dryers can be purchased at many hardware

stores, or on the internet (do a search for “mini desiccant dryer”).

Calibration of Reservoir Gauges

The reservoir gauges are for reference only, and do not need calibration. The operator

merely references these gauges as an indication of how much reserve pressure or vacuum

there is in the reservoirs, and as a guide to know when to turn on the pump(s).

19

CHAPTER 5

MAINTENANCE REPAIRS AND TROUBLESHOOTING

Note: Refer to the Theory of Operation section as a reference on how the various systems

function.

Annual Maintenance

The following annual maintenance is recommended:

1. Check color of beads in air reservoir/dryer. Change if pink or clear. The dryer is a

common in-line dryer used in small air compressor systems. A new dryer can be

purchased from Preston Pressure, or an internet search for “mini inline desiccant air

dryer” may lead to an alternate source.

2. Feel fuses to verify tightness. If a fuse feels loose, remove the fuse, squeeze fuse clip

slightly and re-install fuse.

3. Tug on motors to verify motors are mounted tightly. If play is noticed, disconnect

battery and connectors. Remove bottom assembly panel by removing the four screws

holding the bottom assembly. Tighten the motor mount screws and re-assemble.

4. Verify vacuum reservoir tank is mounted tightly.

5. Verify electrical connectors are seated completely.

6. Verify battery holding clamp is tight.

7. Verify switches and valves on front panel are mounted tightly.

8. Test for leaks.

9. Perform calibration checks and re-calibrate if necessary.

Table of contents

Other PRESTON PRESSURE Test Equipment manuals