Presys TA-1200PLAB User manual

Q

Y

U

T

A

L

I

E

N

T

M

S

E

Y

G

S

A

T

N

E

A

M

M

Reference

Temperature Calibrator

TA-1200PLAB

®

EM0356-02

Technical Manual

presys

presys

Note: changes can be introduced to the instrument, altering the information contained in

this technical manual.

The warranty conditions are available in our sites:

www.presys.com.br/warranty

presys

PRESYS Instruments TA-1200PLAB

EM0356-02

Table of Contents

1 - Introduction ...................................................................................................................1

1.1 - Technical Specifications...........................................................................................3

1.1.1 - Input Technical Specifications...........................................................................3

1.1.2 - Special Software Features................................................................................4

1.2 - Order Code...............................................................................................................4

1.3 - Accessories ..............................................................................................................5

1.4 - Initial Usage..............................................................................................................6

1.4.1 - Mounting the Insert in the Calibrator - Vertical Model......................................6

1.5 - Parts Identification....................................................................................................7

2 - Calibrator Operation.....................................................................................................8

2.1 - Calibrator Menu........................................................................................................9

2.1.1 - Probe Reference..............................................................................................10

2.1.2. - Input Connections Diagrams..........................................................................14

2.1.3 - Saving Current Configuration (Memory Manager)..........................................14

2.2 - Data-Logger............................................................................................................14

2.3 - Help Desk...............................................................................................................16

3 - SETTINGS.....................................................................................................................16

3.1 - Date and Time........................................................................................................16

3.2 - Network...................................................................................................................16

3.3 - Services..................................................................................................................17

3.3.1 - Built-in Web Server..........................................................................................17

3.3.2 - Remote Access - VNC.....................................................................................18

3.3.3 - Command List SCPI........................................................................................18

3.4 - System....................................................................................................................21

4 - Safety Instructions......................................................................................................22

5 - Recommendations as regards Accuracy of Measurements .................................22

6 - Calibration (Adjustment)............................................................................................23

6.1 - Input Calibration .....................................................................................................23

6.2 - Probe Calibration....................................................................................................24

6.3 - PID Control Parameters.........................................................................................24

6.4 - Axial Homogeneity Adjustment..............................................................................25

presys

PRESYS Instruments TA-1200PLAB

Page 1

1 - Introduction

TA-1200PLAB

The TA-1200PLAB Calibration Furnace is state-of-the-art in the manufacture and

performance of high temperature furnaces for calibration of thermocouples.

Its design privileges fundamental technical characteristics in temperature

measurement and which are usually the predominant sources of uncertainty in a

calibration. Thus it has been designed and tested according to international standards to

perfect the following characteristics:

I. Low axial and radial gradients due to the use of differentiated heaters distributed

along the thermal well in order to minimize losses at the ends of the insert and to

extend the temperature constant region called the measurement zone.

II. High immersion of the sensors to be compared - it has an insert with 250 mm of

immersion in the conductive part and about 70 mm in the insulation part, making

about 320 mm of total immersion of the sensors, which minimizes heat losses by

conduction the rod.

III. High thermal stability or thermal inertia - The 400 mm long insert has a large mass

volume and stabilizes any temperature fluctuation due to insertion or removal ofthe

sensor in the insert.

The entire calibrator is enclosed in a thermal shield for operator and laboratory

protection from the high temperatures generated. Thus in an eventual blackout of energy

the cooling of the furnace happens naturally and surely.

Temperature Advanced Calibrator TA-1200PLAB generates temperature in the

insert in order to calibrate thermocouples. Besides providing high accuracy temperature

values, it also allows the measurement of signals generated by the thermo-element which

is being calibrated. This is possible due to an embedded calibrator specific for this type of

signal. Thus, they incorporate the functions of dry block, standard thermometer and

calibrator for TC.

presys

PRESYS Instruments TA-1200PLAB

Page 2

•TA-1200PLAB calibrator model generates temperatures from 50 ºC (122 ºF) to

1200 ºC (2192 ºF).

•Presents 02 inputs for thermocouples that can follow the parameterization of ITS90

or standard tables.

•Carries out completely automatic calibrations with or without the use of a computer.

•Accuracy to ± 2.5 ºC, stability of 0.01 ºC and resolution of 0.01 ºC.

The calibrator provides an input for an external probe to perform the temperature

measurement from a standard sensor (optional) inserted in the same measuring zone of

the sensor to be calibrated. The standard sensor calibration curve follows the

parameterization of ITS-90.

It presents a wide variety of programming resources, allowing the performance of

automatic calibrations. In this case, the sensor is placed in the insert and its electrical

terminals are connected to the embedded calibrator. The operator defines the calibration

points and the number of repetitions (task), then the process is started and all the

sequence is automatically accomplished. After completing the task, a Calibration Report

is issued and it can be printed directly in a USB connected printer or can be generated as

a PDF document.

TA-1200PLAB has also many other features, such as:

•Built in Web Server, Ethernet communication.

•USB port for software/firmware upgrade.

•The electric signal calibrator is independent from the dry block function.

•Display indication when the temperature reaches the desired value.

•5.7 inches touch screen display that eases the operation and configuration of the

calibrator.

•Thermocouple reading scaled to ITS-90 or IPTS-68.

•Independent circuit for over-temperature protection and safety.

•Insert to choose and test leads included.

presys

PRESYS │ Instruments TA-1200PLAB

Page 3

1.1 - Technical Specifications

TA-1200PLAB

Operating Range

50 to 1200 °C (122 to 2192 °F)

Power Supply

230 Vac 50/60Hz

Resolution

0.01 ºC or 0.01 ºF

Display Accuracy

± 2.5 °C

Stability

± 0.1 ºC

Power Consumption

2500 W

Stabilization Time

1 h

Heating Rate

± 6 ºC / min

Cooling Rate

10 h (1100 ºC to 200 ºC)

Calibration Volume

∅34 mm / 300 mm depth (immersion)

Radial Uniformity

± 0.1 ºC (for metallic insert)

Axial Uniformity (40 mm):

Axial Uniformity (100 mm):

± 0.20 full range

± 0.35 full range

Dimensions (H,W,D)

Horizontal Model:

600 mm x 470 mm x 450 mm

Weight

43.0 kg

Warranty

1 year

1.1.1 - Input Technical Specifications

Ranges

Resolution

Accuracy

Remarks

millivolt

0 to 70 mV

0.0001 mV

± 0.005 % FS

Rinput > 10 MΩ

TC-J

-210 to 1200 ºC / -346 to 2192 ºF

0.01 ºC / 0.01 ºF

± 0.10 ºC / ± 0.20 ºF

IEC-60584

TC-B

50 to 250 ºC / 122 to 482 ºF

250 to 500 ºC / 482 to 932 ºF

500 to 1200 ºC / 932 to 2192 ºF

1200 to 1820 ºC / 2192 to 3308 ºF

0.01 ºC / 0.01 ºF

0.01 ºC / 0.01 ºF

0.01 ºC / 0.01 ºF

0.01 ºC / 0.01 ºF

± 1.25 ºC / ± 2.50 ºF

± 0.75 ºC / ± 1.50 ºF

± 0.50 ºC / ± 1.00 ºF

± 0.35 ºC / ± 0.70 ºF

IEC-60584

TC-S

-50 to 300 ºC / -58 to 572 ºF

300 to 1760 ºC / 572 to 3200 ºF

0.01 ºC / 0.01 ºF

0.01 ºC / 0.01 ºF

± 0.50 ºC / ± 1.00 ºF

± 0.35 ºC / ± 0.70 ºF

IEC-60584

TC-L

-200 to 900 ºC / -328 to 1652 ºF

0.01 ºC / 0.01 ºF

± 0.10 ºC / ± 0.20 ºF

DIN-43710

TC-C

0 to 1500 ºC / 32 to 2732 ºF

1500 to 2320 ºC / 2732 to 4208 ºF

0.01 ºC / 0.01 ºF

0.01 ºC / 0.01 ºF

± 0.25 ºC / ± 0.50 ºF

± 0.35 ºC / ± 0.70 ºF

W5Re / W26Re

W5Re / W26Re

TC-Au-Pt

0 to 500 °C/ 32 to 932 °F

500 to 1000 °C/ 932 to 1832 °F

ºC / 0.01 ºF

0.01 ºC / 0.01 ºF

± 0.09 ºC / ± 0.12 ºF

± 0.06 ºC / ± 0.12 ºF

ASTM E1751

FS = Full Scale

presys

PRESYS Instruments TA-1200PLAB

Page 4

The thermocouple specifications are valid for standard curve.

Accuracy values are valid within one year and temperature range of 20 to 26 °C. Outside

these limits add 0.001 % FS / °C taking 23 °C as the reference temperature. For

thermocouples, using the internal cold junction compensation add a cold junction

compensation error of ± 0.2 °C or ± 0.4 °F max.

1.1.2 - Special Software Features

- Memory Manager: stores configuration types predefined by the user.

- Data Logger: monitoring of input or output signals, storage and visualization of data in

chart or table.

- Help Desk: storage and viewing videos and documents on the calibrator screen.

1.2 - Order Code

Notes:

* Changes can be introduced in the instrument, altering specifications in this manual.

presys

PRESYS │ Instruments TA-1200PLAB

Page 5

1.3 - Accessories

- Metallic Insert:

Inserts Holes

ORDER CODE

TA-1200PLAB-H

IN01

1 x 3/4"

06.04.0075-00

IN02

1 x 1/2"

06.04.0076-00

IN03 1 x 6.0mm and 3 x 1/4" 06.04.0077-00

IN04

3 x 6.0mm and 1 x 1/4"

06.04.0078-00

IN05

4 x 6.0mm

06.04.0079-00

IN06

2 x 6.0mm and 2 x 1/4"

06.04.0080-00

IN07 1 x 6.0mm, 1 x 8.0mm and 1 x 3/8" 06.04.0081-00

IN08 1 x 6.0mm, 1 x 3.0mm and 2 x 1/4" 06.04.0082-00

IN09

Without hole, to be drilled by the client

06.04.0086-00

IN10

Others, under ordering

06.04.0084-00

Note: When asked, the calibration certificate will be provided for the first insert ordered.

Fig. 01 - Inserts

Ceramic Insert:

Inserts

Holes

IN1C

2x 3.5 mm, 2x 4.0 mm, 2x6.0 mm and 2x 1/4" (Alumina)

IN2C 1x 1/4" and 6x 7.0 mm (Alumina)

IN10

under ordering (Alumina)

presys

PRESYS Instruments TA-1200PLAB

Page 6

1.4 - Initial Usage

Identify if the following parts are present:

•TA-1200PLAB Calibrator;

•Metallic or ceramic insert;

•Bottom insulation of the insert (only one central hole);

•Top insulation of the insert (same holes of the metallic insert);

In the core of the dry block TA-1200PLAB there is a ceramic tube. Therefore, for

safety purposes, the insert and the insulators are separated. A support is sent to protect

the block. Remove the screws indicated by the arrows and remove the support. Store it

and use it whenever you need to transport the dry block.

Finish the mounting using the grounding pin board and the frame with a grid.

1.4.1 - Mounting the Insert in the Calibrator - Vertical Model

To mount the insert inside the Calibrator, proceed as follows:

I) Place the Calibrator in its definitive place and spacing more than 25 cm from nearby

walls.

II) Observe in the following figure the type of gap in the lower part ofthe metallic insert

with the type offittingin the grounding pin inside the furnace well. Note: The ceramic

insert does not have this gap.

Fig. 02 - Insert Background (Horizontal Model)

I) Screw or fix the extractor to the insert and holding the insert with both hands slowly

insert the heavy insert into the very fragile ceramic well. Orient yourself by the mark

of a point on the insert to keep this side up.

II) It is essential to ensure an effective grounding if the gap coincides with its fitting on

the grounding pin. It is necessary to repeat the movement of the insert back and

forth a few times in the well to hear the click noise between the insert and the

grounding pin. Unscrew the extractor.

III) Then insert the top insulation in line with the holes in the insert. Use a ceramic rod

for it.

IV) Finally, tighten the metal cap by aligning it with the other holes in the top of the

calibrator well.

Note that the sensors to be tested must pass through the insulation and deepen

inside the metal insert to obtain a correct temperature measurement.

presys

PRESYS │ Instruments TA-1200PLAB

Page 7

1.5 - Parts Identification

Fig. 03 - Parts Identification

presys

PRESYS Instruments TA-1200PLAB

Page 8

2 - Calibrator Operation

When powered on, the calibrator goes through a self-test routine and shows the

last adjustment date. In case of failure, it displays a message to indicate error; if that

occurs, the instrument should be sent to the manufacturer for repair.

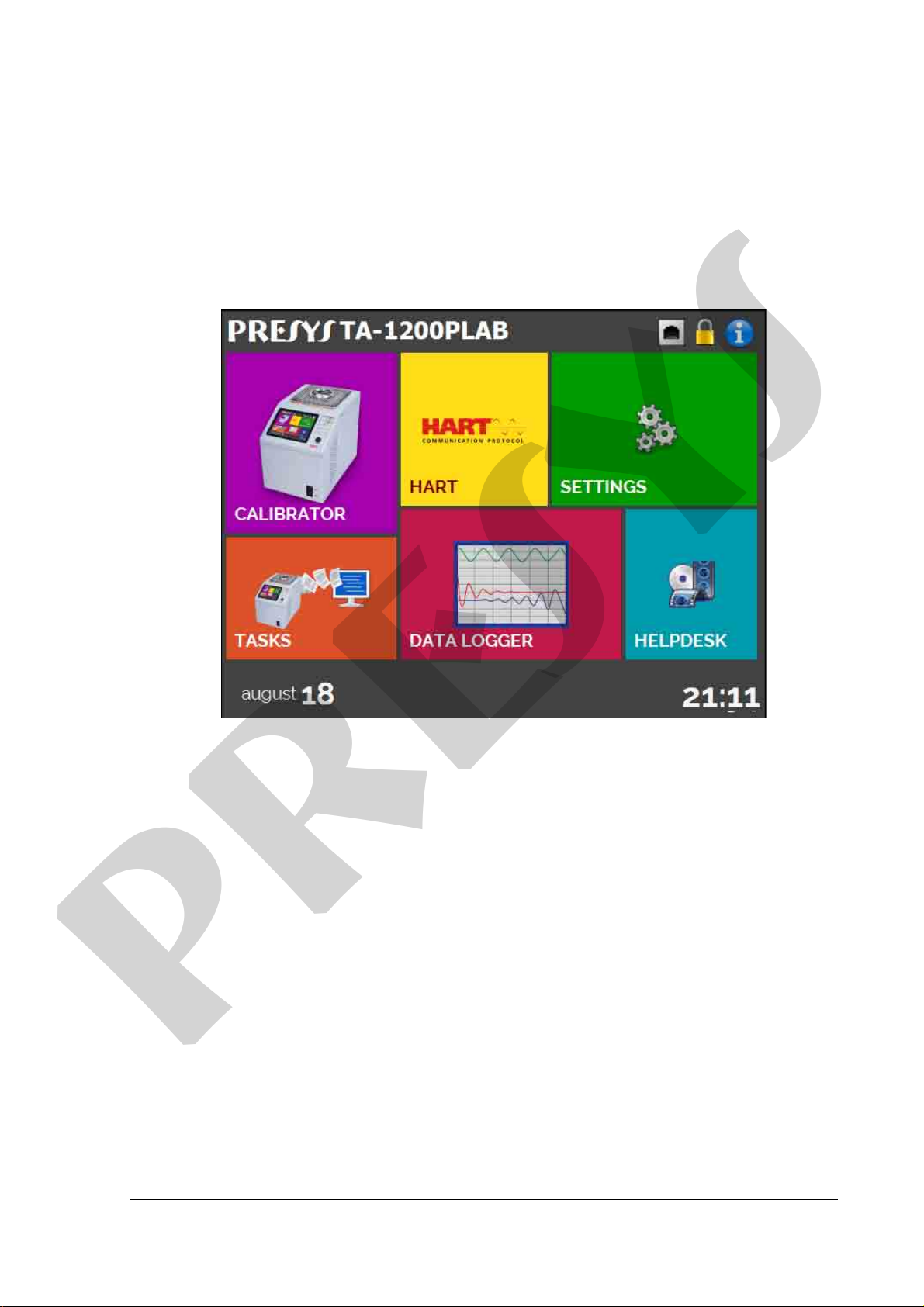

After the self-test is completed, the display shows the main menu:

Fig. 04 - Main Menu

The main menu is divided in four functions:

CALIBRATOR - selects the probe and input functions, see section 2.1

HART®- not available for this model.

TASKS -not available for this model.

DATA LOGGER - record measurements, enabling visualization in chart or table, see

section 2.2.

HELP DESK - features videos and documents to assist in the use of the calibrator, and

can also store files made by the user, see section 2.3.

SETTINGS - general instrument settings, see section 3.

presys

PRESYS │ Instruments TA-1200PLAB

Page 9

2.1 - Calibrator Menu

Toselecttheprobesetpointorelectricalinputfunctions,fromthemainmenu,press

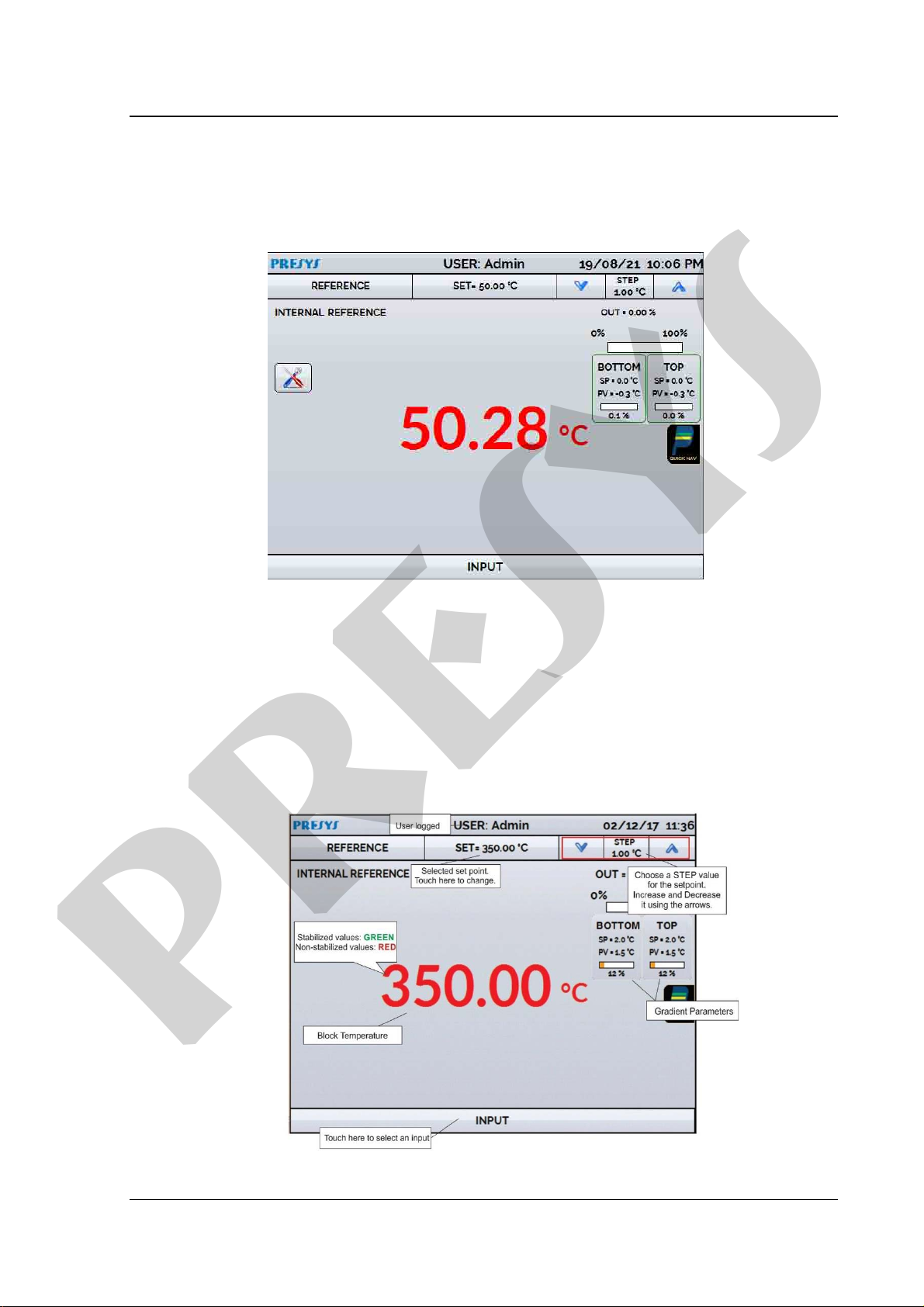

the CALIBRATOR button. The following screen is displayed.

Fig. 05 - Calibrator Function

At the top is shown the probe settings and values.

The centered value shows the block temperature. The GREEN color indicates that

the temperature is stable, otherwise it is RED.

The set point value appears on the top. Touch in the SET bar or in the block

temperature value to change it. Pressing on the temperature unit it can be changed

between °C (Celsius), °F (Fahrenheit) or K (Kelvin).

Fig. 06 - Calibrator Mode

presys

PRESYS Instruments TA-1200PLAB

Page 10

In the STEP function, a step value can be configured, and the steps can be changed

through the up and down arrows.

In the Temperature Generation Configuration button , it is possible to

change the block setpoint rate in ° C / seconds.

In REFERENCE menu, you can configure the type of probe reference (see section

2.1.1 Probe Reference). The chosen reference appears just below the REFERENCE

button.

At the bottom, an input can be configured. When the input is selected, the screen

will split automatically. To select an input, just touch the INPUT bar (see section

2.1.2 INPUT MENU).

The icon shows a Quick Navigator, with the options for Main Menu (HOME),

Data-Logger and Tasks (not available for this model). Pressing MENU, there are options

for the selection of display Brightness and Memory Manager (see section 2.1.3).

Furthermore, it brings information about the auxiliary input configuration and IP address.

Press BACK to return to Calibrator Mode or HOME to go to the Main Menu.

Fig. 07 - Quick Navigator and Secondary Menu

2.1.1 - Probe Reference

There are two different references to the thermal block: Internal Reference and

External Reference.

The Internal Reference is a sensor built into the block.

The External Reference is an option for more accurate measurements. The

reference comes from a Standard Thermocouple Sensor placed inside the insert, among

the DUT (devices under test). This Standard Sensor should be a noble metal thermocouple

(R, S, B or Au-Pt types). To increase accuracy to the measurements, ITS-90 parameters

can be used to correctthe thermocouple electromotive force in reference to the IEC-60751

table.

presys

PRESYS │ Instruments TA-1200PLAB

Page 11

The configuration of the thermocouple calibration coefficients (C0, C1, C2 e C3

corrects the electromotive force (E) given by the linearization table of the thermocouple by

the IEC-60751 standard. After correction, the electromotive force of the thermocouple

follows this formula:

E’ = E + C0 + C1.t + C2.t² + C3.t³, where t is the temperature in °C and E’ and E the

electromotive force in mV.

When using External reference, the probe indication is displayed on the screen and

the control is made by the internal probe.

Fig. 08 - Choosing the Type of Temperature Reference

To select the Reference between Internal and External, touch the REFERENCE

bar. Select a reference between the registered sensors. To add a new sensor, select

MANAGER and ADD. When selecting External Reference, the ITS-90 parameters must

be set. If the sensor does not have parameters, use the value “zero” for all the coefficients.

ID: Sensor Identification

TYPE: Thermocouple type (R, S, B)

Scale: Reference table for the thermocouple

MIN and MAX: Operating range for the thermocouple

CJC: Type of Cold Junction Compensation. If MANUAL is chosen, inform the

temperature.

C0, C1, C2 and C3: Thermocouple coefficients.

presys

PRESYS Instruments TA-1200PLAB

Page 12

The coefficient values can be found in the Reference Sensor Certificate.

Fig. 09 - Adding a new Reference Sensor

After filling the blanks, click on SAVE button and confirm. The new sensor is now

available to be chosen in the list. To edit data from a sensor, select it and press MANAGER

button. To remove a sensor, select it and press REMOVE.

Fig. 10 - Connecting the Standard Sensor for the External Reference

Note: the values corresponding to controlled temperatures appear in GREEN / RED.

Values that show only the sensor indication appear in BLACK.

presys

PRESYS │ Instruments TA-1200PLAB

Page 13

2.1.2 - Input Settings

The INPUT menu has the following options:

Fig. 11 - Input Menu Options

For TC (thermocouple), you must select the thermocouple type and the type of cold

junction compensation (CJC): Internal or Manual. In Internal option, the compensation is

done internally; In Manual you must provide the value of the temperature of the cold

junction to the calibrator.

Fig. 12 - TC Menu Options

presys

PRESYS Instruments TA-1200PLAB

Page 14

2.1.2. - Input Connections Diagrams

Fig. 13 - Input Connections

2.1.3 - Saving Current Configuration (Memory Manager)

The TA Series calibrators admit several special functions that may become of

frequent use. In these situations, it is useful to store such settings in the instrumentin order

to save time.

After setting the desired calibration mode (input type or special function), press the

icon →MENU, and the button MEMORY MANAGER. On the option CREATE NEW

can be given a name for this configuration and a description. Press the SAVE button.

The operation that was being performed by the TA Calibrator shall be stored in

memory identified by the name given to it. To useit again, even after the calibratoris turned

off and on, select the name of the desired setting and press the LOAD button. The SAVE

AS DEFAULT button sets the current configuration as the default configuration of the

calibrator. Thus, every time the calibrator is turned on, this will be the initial configuration

of the calibrator.

2.2 - Data-Logger

The TA Series Calibrators allow you to record a series of measurements over time

to display data in chart or table format.

Select CALIBRATOR from the main menu and select the desired configuration for

Probe and Input.

Press the icon and select DATA LOGGER.

The calibrator automatically starts the measurements and displays each measured point

on the chart.

For measurements to be saved, you must press the REC button (see Figure 22).

With this option selected, all points (measurement and time) are saved in an internal file in

TA Calibrator, which can be used to generate a table or chart.

presys

PRESYS │ Instruments TA-1200PLAB

Page 15

Fig. 14 - Data Logger

In configuration menu (icon , you can edit the background color of the chart,

color and line thickness, sampling rate (in seconds) and set the x (time) and y

(measurements) axis of the chart.

Fig. 15 - Data-Logger Configuration Menu

Recording can also be programmed to start at a certain date and time in the

LOGGER option. Just set the start time and end time of recording. During the defined

range, the measured points are saved in an internal file in TA Calibrator.

To view a saved file press the OPEN button, select the desired file, and press

LOAD. The file name contains the date and time of the measurements.

The SHEET buttonallows the visualizationof data in table format, with the date and

time of the measurement and the measured values.

If the user wants to export the current data to a .csv file that can be opened in

spreadsheet softwares, press the SAVE button and indicate the name and where it will be

saved. The button saves the current screen image as a .png file. All saved screens can

be viewed in the IMAGE menu. These files are saved in the internal SD card of the

calibrator. To access the files saved on the TA Calibrator, connect the USB cable to the

computer (type A USB) and to the TA Calibrator (Type-B USB, see Figure 5).

presys

PRESYS Instruments TA-1200PLAB

Page 16

2.3 - Help Desk

The calibrator allows viewing of videos and documents. The videos can be viewed

while a calibration is performed and are intended to assist in the use of the calibrator. The

documents can be calibration procedures orinstructions that can be stored and viewed on

the calibrator itself.

From the main menu, when selecting HELP DESK and the VIDEOS tab, a list of

video categories will appear. Select the desired category and video. Press the FULL

SCREEN optiontoview the videoin full screen, orWINDOW for reduced screen.Selecting

the window option, it is possible to watch the video while using the calibrator functions.

To insert new videos in the calibrator, connect the USB cable to the computer (USB Type

A) and to the Calibrator (USB Type-B, see figure 05). Open the VIDEOS folder. Copy the

video to some subfolder (category) in the VIDEOS folder. If you prefer to create a new

category, just create a new folder within VIDEOS with the name of the desired category

and copy the file to this folder.

To insert documents, such as procedures or instructions, the files must be

converted into PDFfiles and mustbe saved inside the HELPfolderon the SD card;Create

a folder with the same name as the document and insert it into this folder.

3 - SETTINGS

The SETTINGS menu has 4 divisions (tabs at the bottom): DATE AND TIME,

NETWORK, SERVICES and SYSTEM.

3.1 - Date and Time

The date, time and time zone for the calibrator can be set in the date and time bar.

You can also set the decimal separator for .CSV files between commas and periods.

3.2 - Network

In the NETWORK tab it is possible to configure the IP address of the calibrator for

communication with the computer and the Wi-fi (wireless) network. The IP address can be

configured dynamically (DHCP) or it can have a fixed address (Disable the DHCP option

and change the desired addresses).

Communication via Wi-fi is carried out via USB/WIFI adapter (optional item). In the

NETWORK tab it is possible to configure the device name (name that calibrator will be

displayed on the network). By selecting CONFIGURE WIRELESS NETWORK (WIFI) the

user can view the available networks and configure which network he wants to connect to.

Connecting the calibrator to the network it is possible to view and print Reports /

Certificates of the tasks through the computer. Press the indicated network icon to access

the configured IPaddress after connected to the network.When connected to the wireless

network, the icon will be the Wi-fi network

fi network

presys

Table of contents

Other Presys Test Equipment manuals

Presys

Presys T-25N User manual

Presys

Presys MCS-12-IS User manual

Presys

Presys PCON-Y18-LP User manual

Presys

Presys PCA-570-RM User manual

Presys

Presys T-500PIR User manual

Presys

Presys PC-507-IS User manual

Presys

Presys MCS-XV User manual

Presys

Presys T-1200PIR User manual

Presys

Presys TA-1200P User manual

Presys

Presys T-350P User manual