PRESYS Instruments T-1200PIR

Page 1

1.0 - Introduction

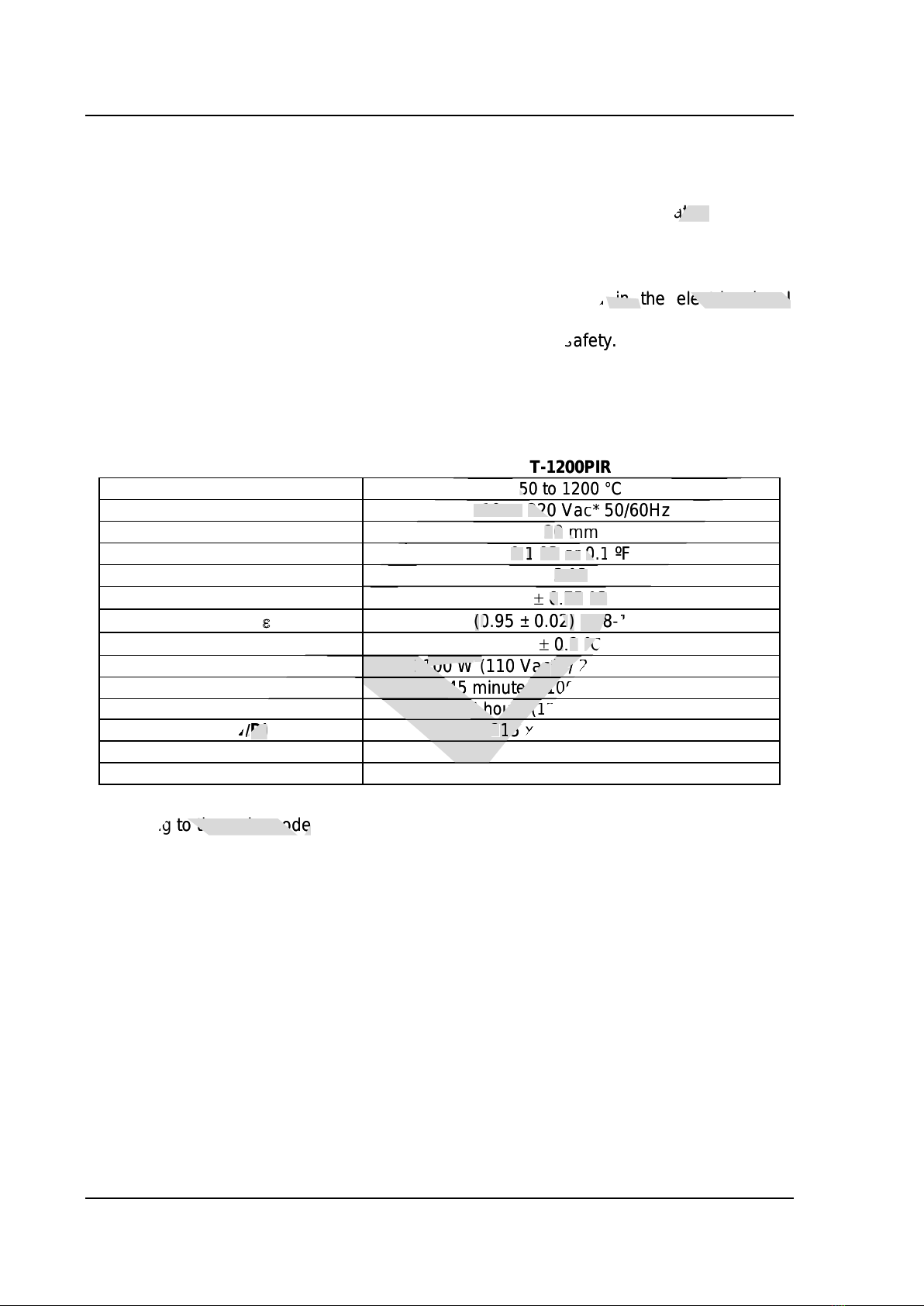

T-1200PIR

The Calibrator for Infrared Thermometer T-1200PIR generates temperature

values in order to enable the calibration of infrared thermometers. The temperatures

generated have high accuracy, in an area of uniform temperature and emissivity.

This calibrator also has input for thermocouples and resistance thermometers, as

well as current meter function. The T-1200PIR generates temperature from 50 to

1200 ºC.

Has input for thermocouples, RTDs and thermoswitches reading.

The use of external standard thermometer is not required*.

Carries out completely automatic calibrations with or without the use of a computer.

Accuracy of 3 ºC, 0.2 ºC stability and 0.1 ºC resolution.

Documenting capabilities: communication with computer and ISOPLAN Calibration

Software.

Portable and compact, has strap for easy transport.

*For higher performances, it is possible to make use of an external thermocouple sensor

type "N" connected to its own input.

It has extensive programming capabilities, where the calibrator is programmed to

generate pre-set temperature.

Compatible with automatic calibration and documenting software, with application

of ISOPLAN software on PC / Windows platform,using the serial port for connection

between the PC and the calibrator that communicate via RS-232 or RS-485. ISOPLAN

software can register thermometers and factory instruments, generate work orders,

produce and print calibration certificates and reports, that is, all the information of power

is brought into the environment of calibrations.

The Calibrator for Infrared Thermometer T-1200PIR generates temperature

presys

The Calibrator for Infrared Thermometer T-1200PIR generates temperature

values in order to enable the calibration of infrared thermometers. The temperatures

presys

values in order to enable the calibration of infrared thermometers. The temperatures

generated have high accuracy, in an area of uniform temperature and emissivity.

presys

generated have high accuracy, in an area of uniform temperature and emissivity.

This calibrator also has input for thermocouples and resistance thermometers, as

presys

This calibrator also has input for thermocouples and resistance thermometers, as

well as current meter function. The T-1200PIR generates temperature from

presys

well as current meter function. The T-1200PIR generates temperature from

Has input for thermocouples, RTDs and thermoswitches reading.

presys

Has input for thermocouples, RTDs and thermoswitches reading.

The use of external standard thermometer is not required*.

presys

The use of external standard thermometer is not required*.

Carries out completely automatic calibrations with or without the use of a computer.

presys

Carries out completely automatic calibrations with or without the use of a computer.

stability and 0.1

presys

stability and 0.1

resolution.

presys

resolution.

Documenting capabilities: communication with computer and ISOPLAN Calibration

presys

Documenting capabilities: communication with computer and ISOPLAN Calibration

Portable and compact, has strap for easy transport.

presys

Portable and compact, has strap for easy transport.

For higher performances, it is possible to make use of an external thermocouple sensor

presys

For higher performances, it is possible to make use of an external thermocouple sensor

type "N" connected to its own input

presys

type "N" connected to its own input

It has extensive programming capabilities, where the calibrator is programmed to

presys

It has extensive programming capabilities, where the calibrator is programmed to

generate pre-set temperature.

presys

generate pre-set temperature.

Compatible with automatic calibration and documenting software, with application

presys

Compatible with automatic calibration and documenting software, with application

of ISOPLAN software on PC / Windows platform

presys

of ISOPLAN software on PC / Windows platform

between the PC and the calibrator that communicate via RS-232 or RS-

presys

between the PC and the calibrator that communicate via RS-232 or RS-

software can register thermometers and factory instruments, generate work orders,

presys

software can register thermometers and factory instruments, generate work orders,

produce and print calibration certificates and reports, that is, all the information of power

presys

produce and print calibration certificates and reports, that is, all the information of power

is brought into the environment of calibrations.

presys

is brought into the environment of calibrations.