Primaflow CPA series Technical Document

EuP compliant high

efficiency heating

circulation pump

Installation, operation

and maintenance guide

Primaflow Pump booklet v4.indd 1 06/03/2013 10:36

2

Contents

1. Important information 3

2. Overview 4

3. Operating environment 5

4. Installation 6

5. Electrical connection 8

6. Control panel 9

7. Pump settings 10

8. Night mode 11

9. Use with a bypass valve 11

10. Commissioning 12

11. Settings and pump performance 13

12. Features 16

13. Technical specifications 17

14. Dimensions 18

15. Troubleshooting 18

16. Warranty 19

Primaflow Pump booklet v4.indd 2 06/03/2013 10:36

3

1. Important information

Please read before installing pump

• Primaflow will not be liable for damage or injury if the guidelines presented

in this booklet are not complied with in all respects

• It is the responsibility of the installer to ensure that any local building

regulations relating to the installation of this pump are fully complied with

• The pump must be installed by a competent person properly qualified to

carry out such work

• The installer is responsible for advising the end user how the pump should

be maintained with reference to this booklet. Failure to maintain the pump

properly in accordance with these guidelines will invalidate the warranty

• The electrical supply must be isolated prior to installation and maintenance

of the pump

• The pump must not be installed

- in places subject to high humidity or near open sources of water

- in poorly ventilated areas where condensation can occur causing

potential damage to electrical components

- outside or otherwise exposed to the elements

• The pump should be installed with service valves either side of the unit to

facilitate maintenance

• The pump warranty will be invalid if the heating system is not protected

with a suitable corrosion inhibitor

• The pump should not be operated without water in the system and should

be primed with water by opening the service valves prior to switching on

the electrical supply. Warranty will be invalid if a pump has been run dry

• To avoid burns and scalding the central heating system must be switched

off and allowed to cool prior to any servicing of the pump

• To avoid frost damage the pump should be completely drained of water

when exposed to a risk of freezing

• During long periods without use the electrical supply to the pump should

be isolated and the service valves closed

• Any damaged cables must be replaced by a competent person

• In case of malfunction the pump should be isolated from the electrical

supply and a competent heating engineer should be summoned

• The pump should be installed beyond the reach of small children

• This pump is not suitable for domestic drinking water

Primaflow Pump booklet v4.indd 3 06/03/2013 10:36

4

2. Overview

Primaflow CPA series pumps are designed to circulate hot water

around a domestic heating system and are suitable for

• Constant and variable flow

• Variable temperatures

• Systems with night mode requirements

These pumps use a permanent magnet motor and differential pressure

controller that monitors and adjusts the pump performance to meet

the system demands. The control panel allows the user to override the

automatic settings to the desired performance levels if required.

Primaflow CPA series pumps offer

• Easy installation and start up: the Auto setting allows the pump to be

installed, bled and set to the desired performance level of the system

without any adjustment by the installer

•

Low power consumption: the pump complies with EC directive 641/2009

• Low noise

• 2 year warranty: subject to the return of the enclosed warranty

card, see section 16

Primaflow Pump booklet v4.indd 4 06/03/2013 10:36

5

3. Operating environment

The CPA series pump is suitable for the following operating environment

• Ambient temperature: 0°C to +40°C

• Maximum relative humidity: 95%

• Water temperature range: +2°C to +110°C

• Maximum pressure: 10 bar

• Protection grade: IP42

Outside of these conditions a premature failure may be anticipated

and the warranty will be invalid.

In order to prevent condensation forming within the control box the

water temperature in the pump must always be higher than the ambient

temperature in the vicinity of the pump, see page 17.

To avoid cavitation corrosion within the pump the inlet pressure must

be kept as low as possible. Recommended pressures at different

temperatures are listed below:

Water temp <75°C 90°C 110°C

Inlet pressure 0.05 bar 0.3 bar 1 bar

The water within the system and the pump must be:

• Clean

• Non-corrosive

• Protected with a suitable corrosion inhibitor

• Non-viscous

• Free from solids and particles

Primaflow CPA pumps are not suitable for use with flammable liquids such

as oil and petrol. Use of pumps for viscous liquids will lead to high power

consumption and reduced service life.

Primaflow Pump booklet v4.indd 5 06/03/2013 10:36

6

4. Installation

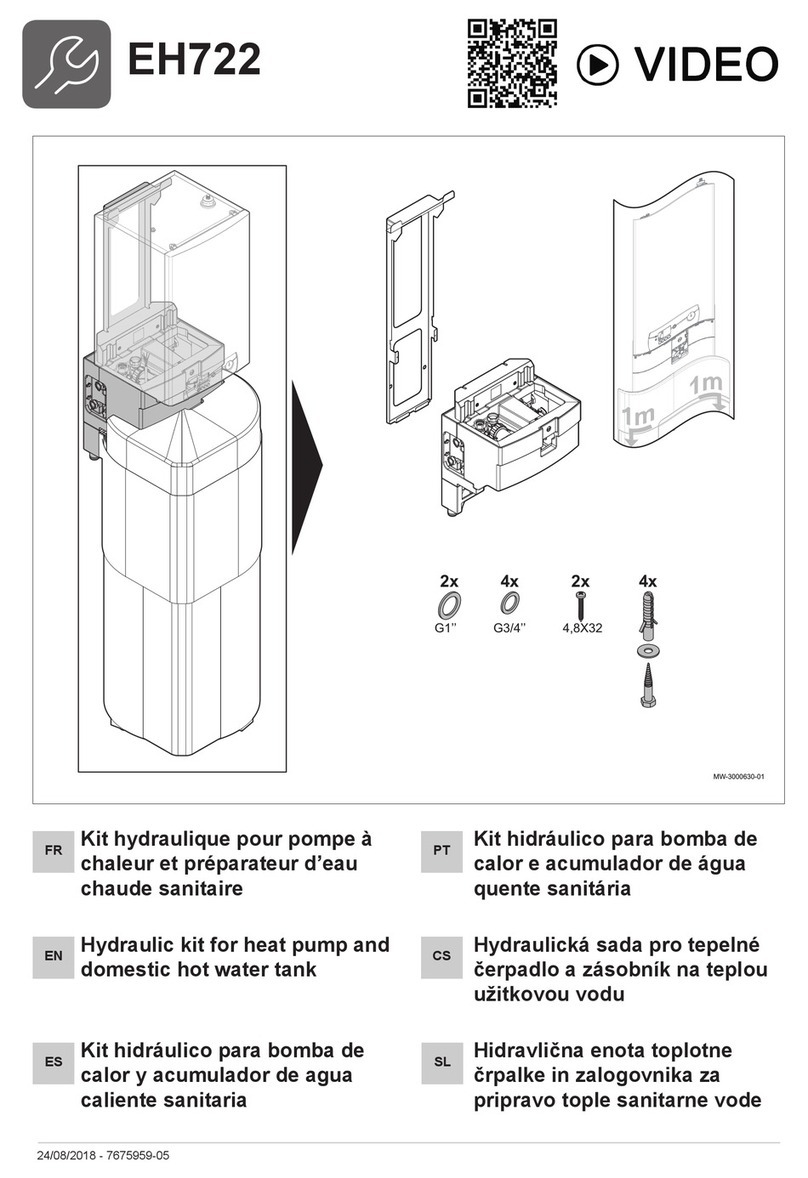

4.1 The pump shaft must be horizontal when installed as shown in the

images below. Flow will be in the direction of the arrow shown on the

pump body.

• Position the pump between 2 service valves and assemble with gaskets

• Hand tighten the union nuts ensuring that the pump is in the correct

orientation for the shaft, control panel and direction of flow. Realign if

required. The control panel can be adjusted as described in section 4.2

• Tighten the union nuts ensuring a watertight seal has been made

• Connect the electrical supply as described in section 5

Primaflow Pump booklet v4.indd 6 06/03/2013 10:36

7

4.2 The control panel can be oriented in 3 of the 4 positions shown below.

The panel can be adjusted to suit the requirement of the installation.

In order to do this the control panel can rotate through 90° as follows:

• If already installed

-Isolate the electrical supply and allow the pump and system to cool

- Close the service valves on either side of the pump

- Disconnect the cable from the control panel

Then follow instructions below

• Loosen and remove the 4 hexagonal screws attaching the pump body

to its base.

WARNING – there will be some water leakage if the pump has

been used

• Rotate the motor and control panel to the required position

• Replace the 4 hexagonal screws and tighten

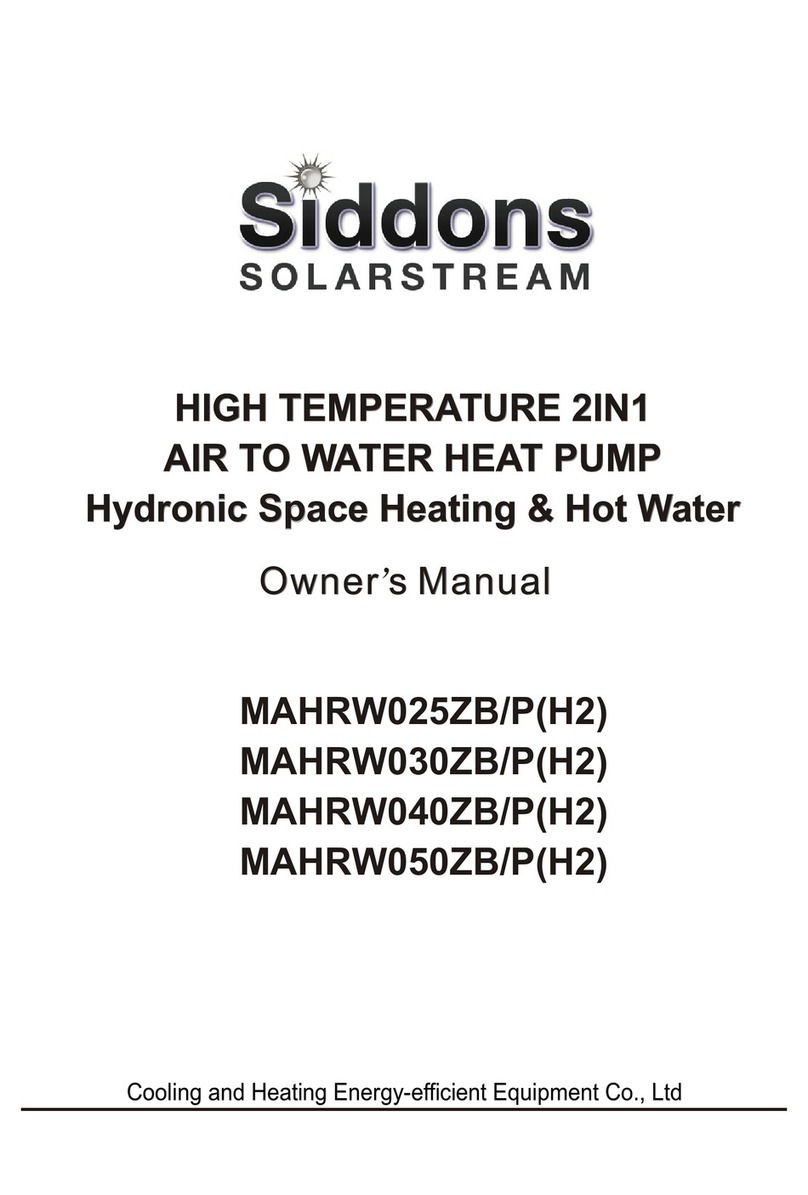

In order to reduce heat loss through the pump it can be insulated as

shown in the diagram below. WARNING - do not cover the control panel

or electric connections.

Primaflow Pump booklet v4.indd 7 06/03/2013 10:36

8

5. Electrical connection

WARNING:

• Electrical connection must be carried out only by a competent

person and the pump must be fitted in compliance with current

electrical regulations

• Supply voltage and frequency must match those shown on

the control panel

• The pump must be connected to the electrical supply using

the connector provided

• The control panel light will indicate when connected to the

power supply

Connect the pump to the electrical supply in the following sequence

Open the service valves to allow water into the pump before switching on

the electrical supply. Failure to do so may damage the pump reducing it’s

life and invalidating the warranty.

Primaflow Pump booklet v4.indd 8 06/03/2013 10:36

9

6. Control panel

The control panel and functions are as follows

1. Power consumption: When the pump is operating the power being

consumed by the pump will be displayed. The power consumption will

vary depending on the pump setting and the demand of the system.

If the display shows “E” refer to the troubleshooting guide on page 18.

2. Pump mode: Press the mode button to advance the setting one step.

Press eight times (with a 2 second gap) to cycle the pump through the

range of settings

3. Night mode: This function is available only if there is a night mode

setting on the boiler. Press the button to toggle night mode on and off

as indicated by the light.

NOTE: If the pump is set to Auto the night mode does not need to be activated.

If the pump is set on speeds I, II or III the night mode must NOT be switched on.

4. Pump settings: There are 8 settings as described below which

can be selected by sequentially pressing the pump mode button.

Label Description

1Power consumption (W)

2Pump mode indicator dial

3Night mode button

and indicator

4Pump mode button

Label Description

Auto

Fully automatic for optimum efficiency

BL1

Lowest proportional pressure curve

BL2

Highest proportional pressure curve

HD1 Lowest constant pressure curve

HD2 Highest constant pressure curve

III Highest constant speed curve

II Medium constant speed curve

ILowest constant speed curve

Primaflow Pump booklet v4.indd 9 06/03/2013 10:36

10

7. Pump settings

The pump should be set according to the type of heating system.

System type Pump settings

Recommended Alternative

Underfloor Auto HD1 / HD2

Two pipe Auto BL2

Single pipe BL1 BL2

Auto mode automatically adjusts the pump performance according to

the heating system demands. It is recommended the pump is set to Auto

when initially installed. If the desired performance is not achieved then

manual adjustment to the other settings can be considered.

Depending on the heat demand by the system the pump will adjust the

power requirements according to proportional pressure control (BL) or

constant pressure control curves (HD).

• Proportional Pressure Control: In this mode the pressure difference

across the pump is determined by the flow and is indicated by curves

BL1 and BL2 in the Q/H diagram shown in chapter 11

• Constant Pressure Control: In this mode the pressure difference

across the pump is constant regardless of the flow conditions within

the system and is indicated by HD1 and HD2 in the Q/H Diagram

shown in chapter 11

Primaflow Pump booklet v4.indd 10 06/03/2013 10:36

11

8. Night mode

If the night mode is selected the pump will automatically change between

normal and night mode. The night mode will automatically be activated if

the inlet pipe temperature drops 10°C to 15°C over two hour period at a

rate of 0.1°C/min. Once the temperature of the inlet pipe has increased

by 10°C the night mode switches off and the pump returns to Auto.

9. Use with a bypass valve

Installation and application: The pump should be installed according

to the diagram below.

If all the thermostatic radiator valves in the system are closed, a bypass

valve allows water to continually circulate eliminating unnecessary heat

and pressure build up.

If the system has a manual bypass valve (non TRV radiator) select speed

I and adjust the flow rate of the system to the minimum specified by the

boiler manufacturer’s specifications. Once the flow is adjusted set the

pump to AUTO.

For systems with a thermostatically controlled bypass valve select speed

I and adjust the flow rate of the system to the minimum specified by the

boiler manufacturer’s specificatons. Once the flow is adjusted set the

pump to BL1 or BL2 to suit the system demands.

bypass valve

Primaflow Pump booklet v4.indd 11 06/03/2013 10:36

12

10. Commissioning

The liquid in the heating system must be clean. It is recommended that

a proprietary magnetic filter be fitted to ensure that the system remains

clear of potentially damaging contaminants and debris.

Before operating the pump:

• Open both service valves and prime the system with water

• Bleed the system (not the pump) to ensure no air is trapped

• Pressurise the system to its lowest recommended level

Bleeding the pump: The CPA series pump has an automatic bleed

function and does not require manual intervention. In order to bleed

the pump carry out the following steps:

• Connect the pump to the electrical supply and switch on

• The pump will now automatically vent any air within it. Whilst doing

this the pump may appear as though it is not operating properly.

However normal operation will begin once the air has been vented.

This may take a few minutes

• To speed the venting process up the pump may be set to speed III

• Once the air has been removed the pump display will begin to show

that power is being used and the pump should be set up as in section 7

NOTE: Do not run the pump without water in the system as this will lead

to premature failure and invalidation of the warranty.

NOTE: Do not rely on the pump to vent air from the system once

commissioned. It is recommended that an automatic air vent is installed

to maintain an air free system.

Primaflow Pump booklet v4.indd 12 06/03/2013 10:36

13

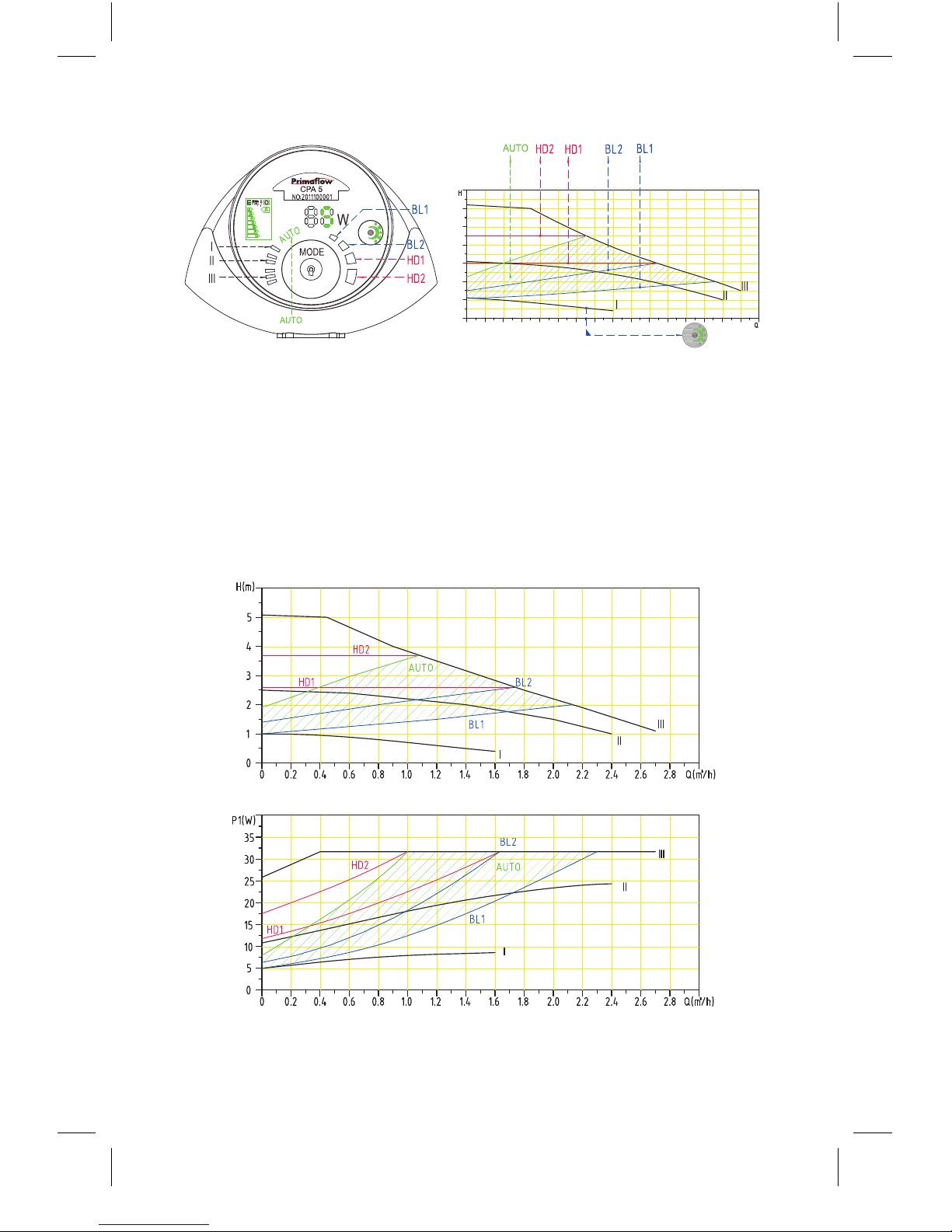

11. Settings and pump performance

The table below describes each of the pump settings and its function.

For each setting the pump has its own performance (Q/H) curve, but in

Auto mode the pump can adjust to anywhere in its operating range within

these curves. Input power curve P1 covers every Q/H curve, this is the power

consumption in any given condition within the curves. Power consumption

is measured in Watts (W) and displayed on the pump control panel.

Setting Performance curve Function

Auto Maximum rate to

minimum rate

The auto function will adjust the pump

performance to anywhere within the

standard range to obtain the optimum

setting for the demand of the system.

BL1 Lowest proportional

pressure curve

Dependant on the demand of the

system the pump will adjust itself up

and down this curve. As demand

increases so does the pressure.

BL2 Highest proportional

pressure curve

Dependant on the demand of the

system the pump will adjust itself up

and down this curve. As demand

increases so does the pressure.

HD1 Minimum constant

pressure curve

Dependant on the demand of the

system the pump will adjust itself

up and down this curve. The pump

will maintain a constant pressure

regardless of the system demands.

HD2 Maximum constant

pressure curve

Dependant on the demand of the

system the pump will adjust itself

up and down this curve. The pump

will maintain a constant pressure

regardless of the system demands.

III Speed III The pump will operate on the

maximum curve in all conditions.

II Speed II The pump will operate on the

medium curve in all conditions.

ISpeed I The pump will operate on the

minimum curve in all conditions.

Night

mode

Night mode The pump will operate at a minimum

performance and power levels if certain

conditions are met.

Primaflow Pump booklet v4.indd 13 06/03/2013 10:36

14

The pump curves relate to the following characteristics:

• Water with air fully vented from system

• Adaptive density (ρ) is 983.2 kg/m3 with a liquid temperature of +60°C

• All curves show average values and variation between pumps may

exist. Tests should be conducted on individual pumps if a specific

curve is required

• Adaptive kinematic viscosity is 0.474 mm2/s (0.474 cST)

Performance curve for CPA5 pump (5 bar)

Pressure

Volume flow

Volume flow

Power

Primaflow Pump booklet v4.indd 14 06/03/2013 10:36

15

Performance curve for the CPA6 pump (6 bar)

PressurePower

Volume flow

Volume flow

Primaflow Pump booklet v4.indd 15 06/03/2013 10:36

16

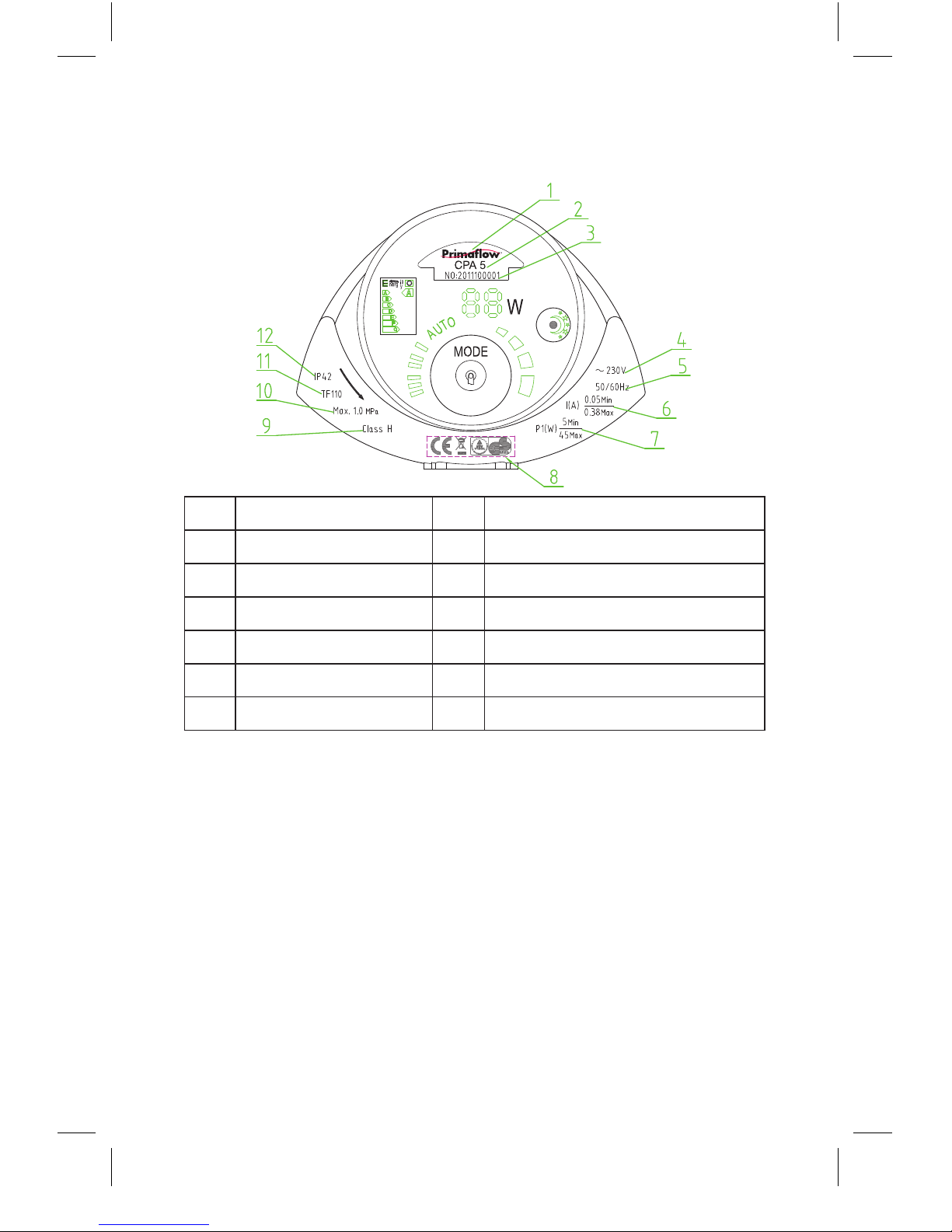

12. Features

Name plate information

Pump designation:

Pumps are designated as follows: CPA5 / CPA6

CP: Circulating pump

A: A-Rated / EuP compliant

5/6: Head of pump in meters

No. Description No. Description

1Primaflow 7Watts (min & max)

2Pump type 8Certifications

3Serial number 9Insulation class

4Voltage 10 Maximum system pressure

5Frequency 11 Maximum temperature

6Amps (min & max) 12 Protection grade

Primaflow Pump booklet v4.indd 16 06/03/2013 10:36

17

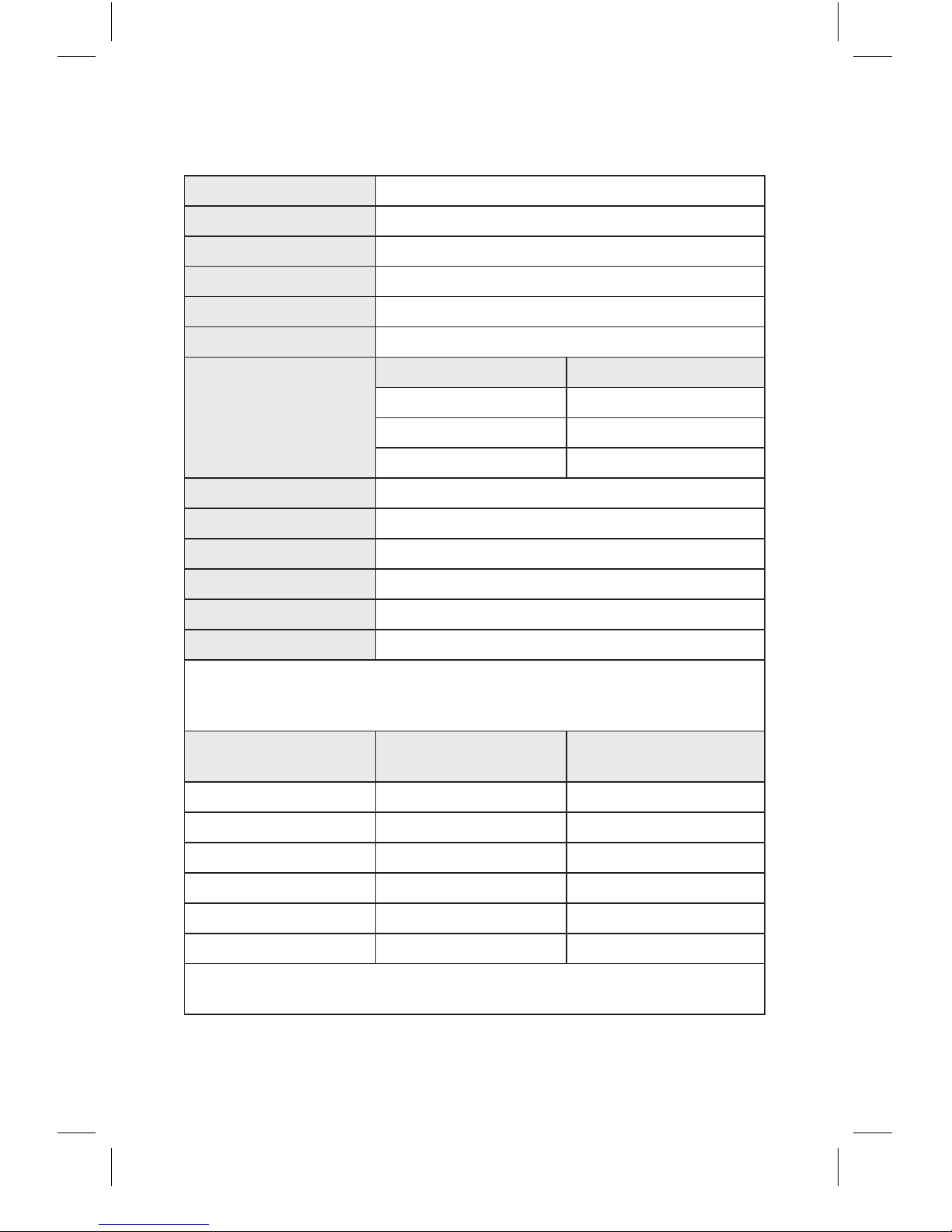

13. Technical specifications

Voltage 230V +6% / -10%, 50Hz, PE

Protection No external protection

Protection grade IP42

Insulation class H

Air humidity Max 95%

System pressure 1.0 Mpa

Inlet pressure

Liquid temp Min pressure at Inlet

<75°C 0.05 MPa

<90°C 0.025 MPa

<110°C 0.108 MPa

EMC standard EN61000-6-1 and EN61000-6-3

Acoustic level <42dB (A)

Ambient temperature 0°C to 40°C

Temperature grade TF110

Surface temperature <125°C

Liquid temperature 2°C to 110°C

In order to prevent condensation inside the control box and stator it is

recommended the water being pumped is always at higher temperature

than the ambient temperature.

Ambient

temperature (°C)

Minimum

pumped temp (°C)

Maximum

pumped temp (°C)

0 2 110

10 10 110

20 20 110

30 30 110

35 35 90

40 40 70

It is recommended that the water in domestic hot water systems is kept

below 65°C to reduce the risk of scalding.

Primaflow Pump booklet v4.indd 17 06/03/2013 10:36

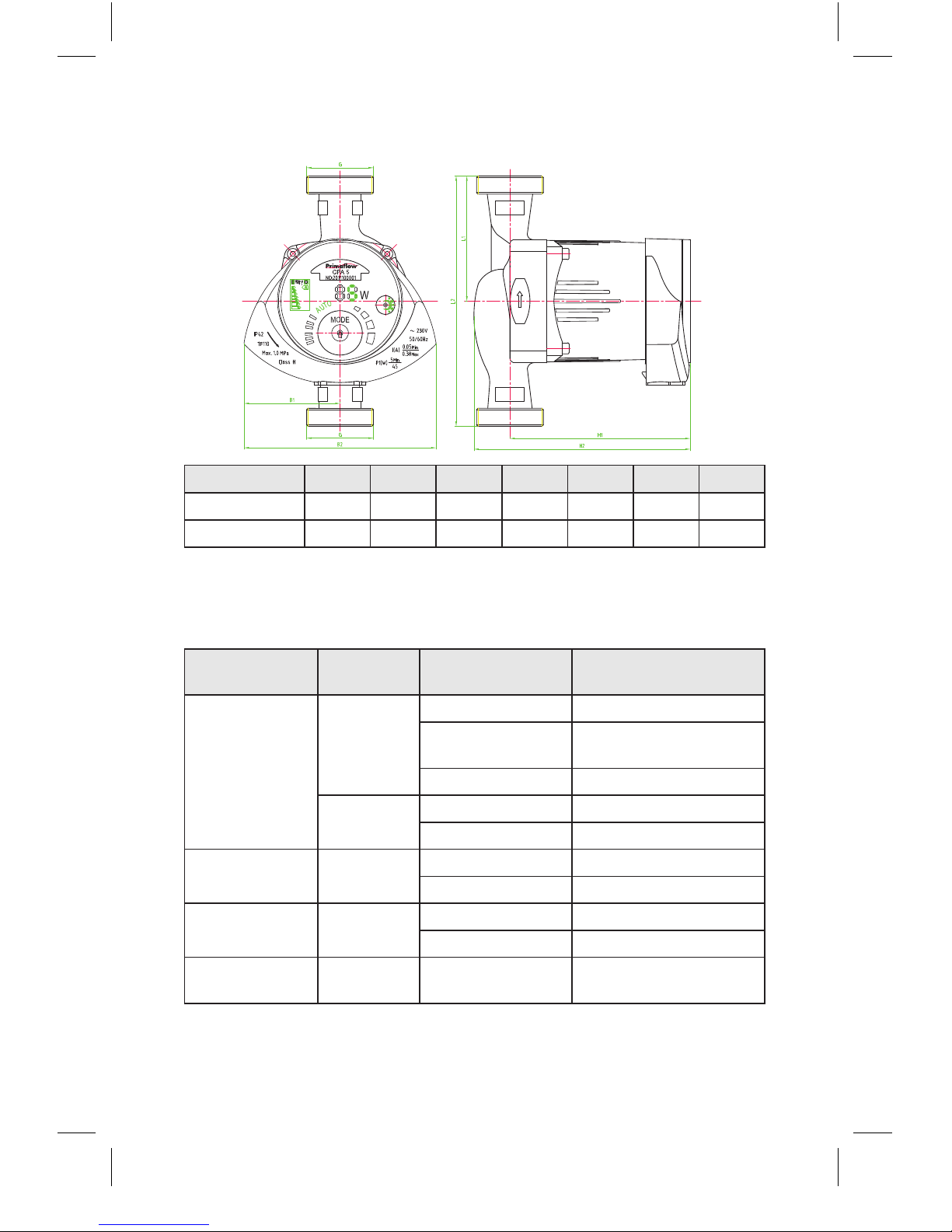

18

15 Troubleshooting

Ensure the electrical power is isolated before carrying out any repairs.

14. Dimensions (in millimetres)

Model L1 L2 B1 B2 H1 H2 G

CPA5 65 130 69 138 129 156 1.1/2”

CPA6 65 130 69 138 129 156 1.1/2”

Problem Control

panel

Possible reason Actions

The pump is

not running

Power

indicator is

not lit

Blown fuse Replace fuse

Circuit breaker

has been tripped

Reset circuit breaker

Faulty pump Replace pump

Display

shows “E”

Low voltage Check supply voltage

Impeller is blocked Clear impeller

Excessive noise

in the system

Normal Air in the system Bleed system

Excessive flow rate Lower inlet pressure

Noisy pump Normal Air in the pump Bleed air from pump

Low inlet pressure Increase inlet pressure

Insufficient heat

from the system

Normal Pump setting

is too low

Adjust pump setting

Primaflow Pump booklet v4.indd 18 06/03/2013 10:36

19

16. Warranty

The Primaflow CPA pump is sold with a 2 year warranty effective from

the date of installation, subject to the return of the enclosed warranty card

within 15 days of the installation date. If the warranty card has not been

returned the warranty will expire 2 years after the date of manufacture.

This warranty covers any manufacturing defect which causes premature

failure of the pump whilst within its warranty period. The warranty is valid

on the assumption that

• the product has been installed and used as specified in the

Installation, operation and maintenance guide

• the installation complies with all local building regulations

• the installation was carried out by a competent and qualified person

The warranty is invalid if the pump

• has not been installed by a competent person

• has been used other than for the purpose for which it was designed

• has not been used in accordance with the Installation, operation

and maintenance guide

• has not been installed correctly in accordance with the Installation,

operation and maintenance guide

• has not been removed from the heating system in a workmanlike fashion

• has been damaged by outside interference e.g. physical damage or

inappropriate dismantling

• has failed outside the warranty period specified

Primaflow does not accept any liability for damage caused by a third

party, nor will Primaflow be responsible for malfunction caused by

inappropriate operating conditions or force majeure.

Primaflow reserves the right to reject any warranty claims not covered

in this statement.

Primaflow Pump booklet v4.indd 19 06/03/2013 10:36

Primaflow Pump booklet v4.indd 20 06/03/2013 10:36

Table of contents

Popular Heat Pump manuals by other brands

joule

joule HEATBANK OPERATING AND INSTALLATION Manual

IDM-Energiesysteme

IDM-Energiesysteme Terra CL 08-HGL Technical documentation and installation instructions

Beretta

Beretta HYDRONIC UNIT Series Instructions for installation, use and maintenance

Bryant

Bryant 569J 08G Series Installation, Start-Up and Service Instructions

Carrier

Carrier 48VR Owner's information manual

Hoval

Hoval BelariaSRM Series installation manual

Bryant

Bryant Magna VF750C Service manual

Genesis

Genesis BYC-007TG1 Installation & operation manual

Panasonic

Panasonic WH-MXC09J3E5 installation manual

LG

LG Therma V R32 Gen3 Installation and setup

Dimplex

Dimplex SI 5BS Installation and operating instructions

Daikin

Daikin Altherma CHYHBH-AV32 Installation