Primedic RECK MOTOmed loop User manual

Table of contents

Other Primedic Medical Equipment manuals

Primedic

Primedic HeartSave AED User manual

Primedic

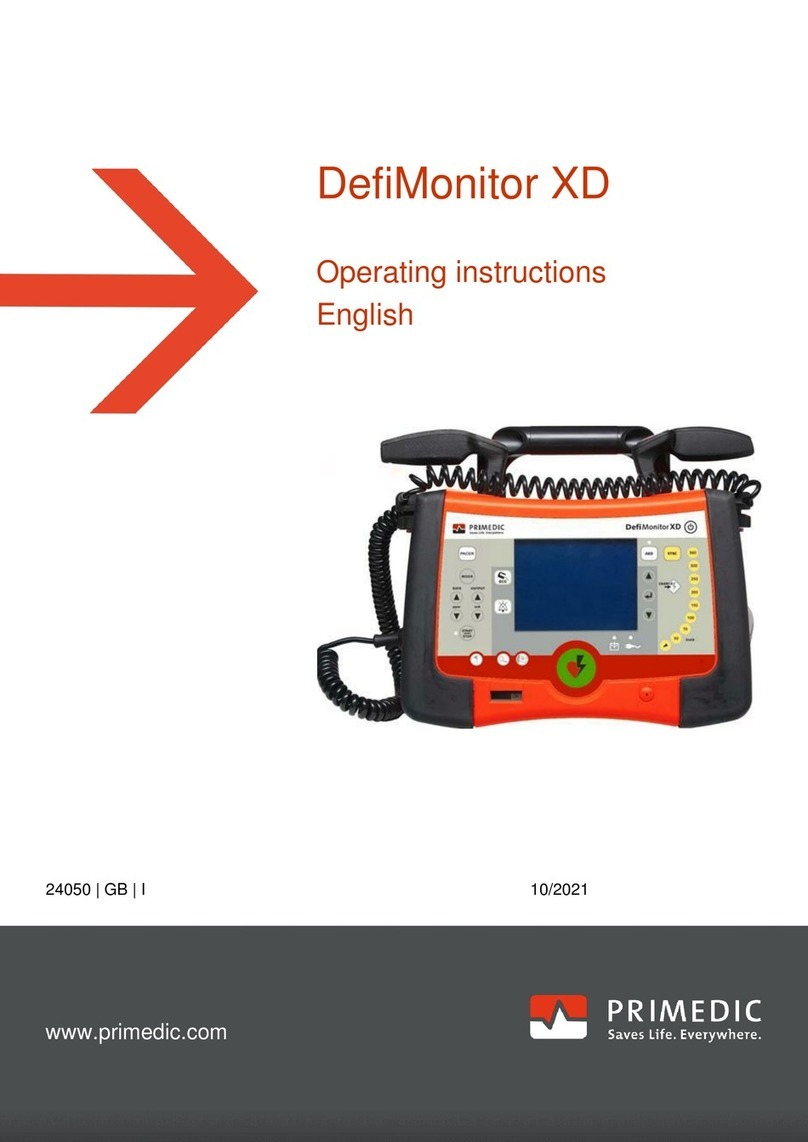

Primedic DefiMonitor XD User manual

Primedic

Primedic HeartSave 6 User manual

Primedic

Primedic HeartSave User manual

Primedic

Primedic Defi-Monitor ECO 1 User manual

Primedic

Primedic DefiMonitor XD Series User manual

Primedic

Primedic DefiMonitor XD User manual

Primedic

Primedic HeartSave AED User manual

Popular Medical Equipment manuals by other brands

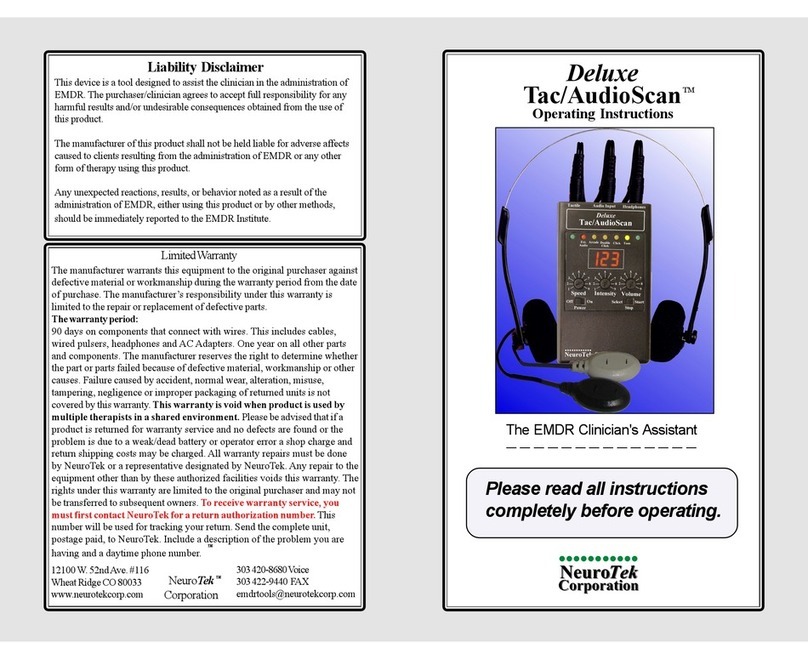

NeuroTek

NeuroTek Deluxe Tac/AudioScan operating instructions

DEPISTEO

DEPISTEO VT1 Series user manual

Basic American

Basic American Slide-W-I-D-E ZZ98674 Supplemental service manual

Otto Bock

Otto Bock 28L10 Instructions for use

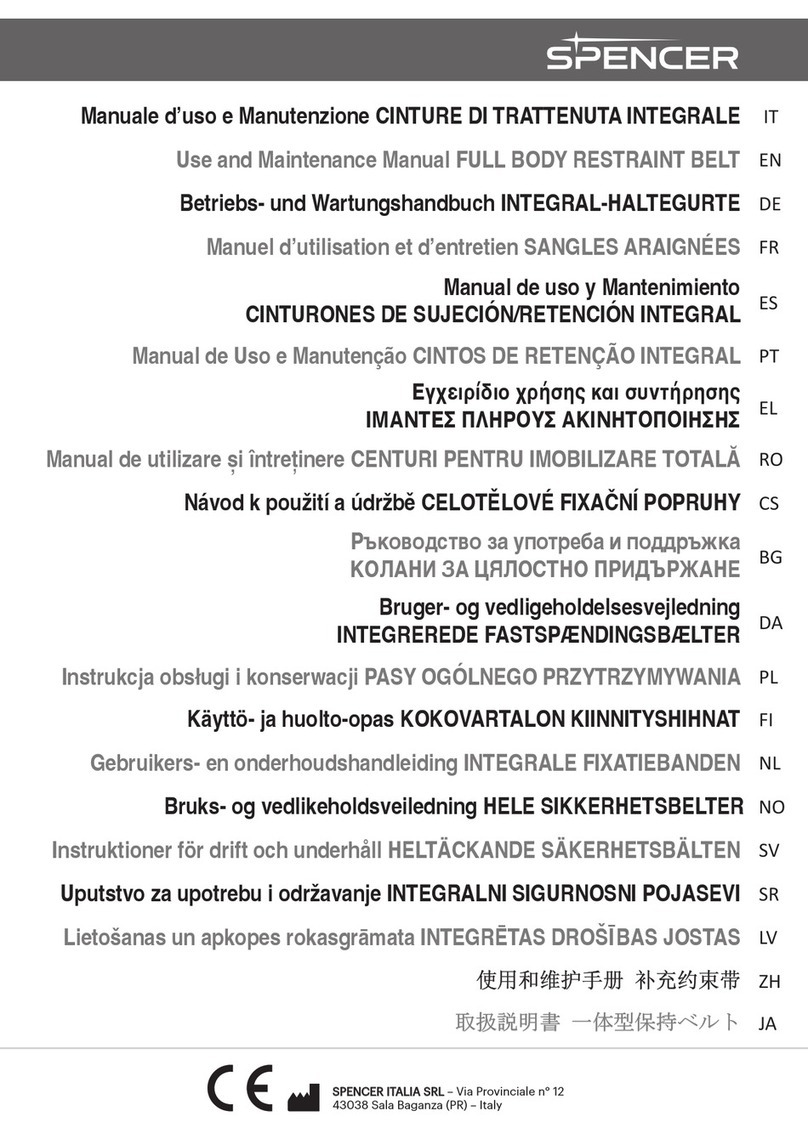

Spencer

Spencer T-STRAPS Use and maintenance manual

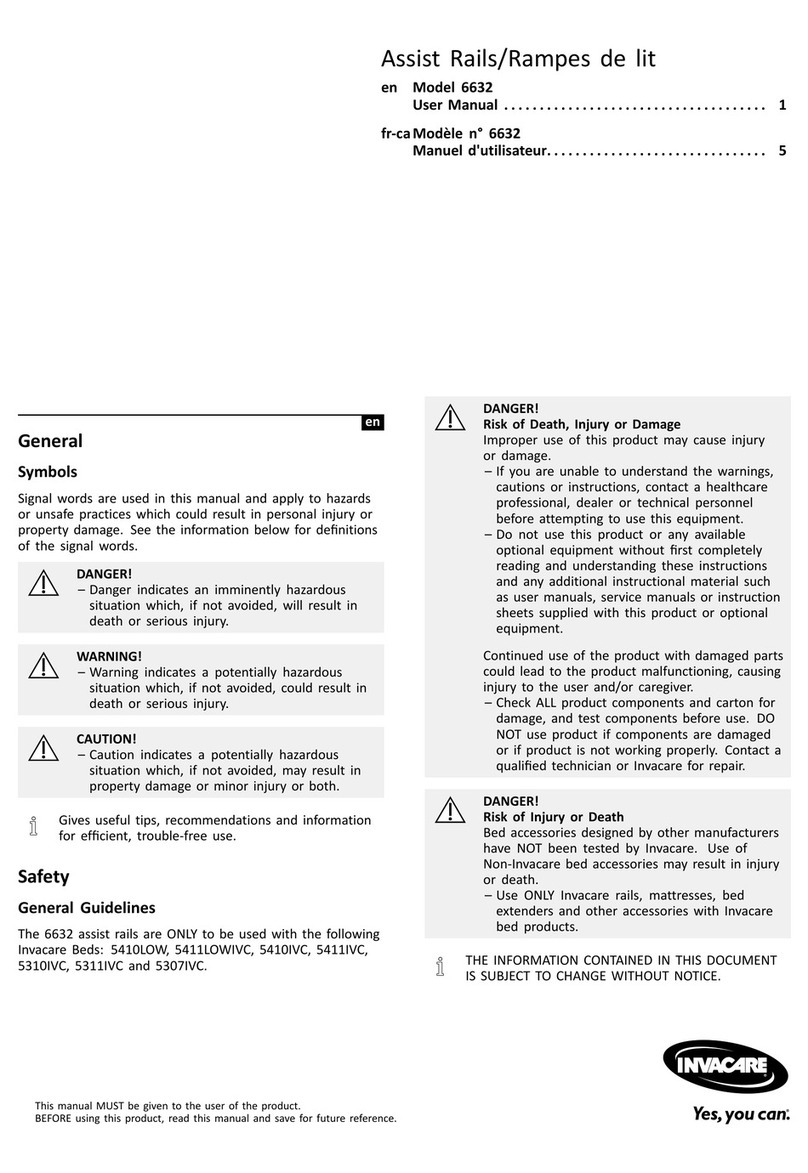

Invacare

Invacare 6632 user manual

Invuity

Invuity PhotonBlade Instructions for use

Zimmer

Zimmer Z Lipo Instructions for use

Orliman

Orliman LUMBITEC FX-213 INSTRUCTIONS FOR USE AND PRESERVATION

Bard

Bard MAX-CORE MC1410 Instructions for use

Nonin

Nonin NoninConnect Elite 3240 Instructions for use

Mettler Electronics

Mettler Electronics Sys*Stim 294 instruction manual