Fing Guide

Primera an-ligature locksets are not a DIY product. Installaon should be carried out by a qualified trades

person suitably equipped to facilitate a professional installaon. These guidelines assume that the installer is

familiar with the general principles of lock installaon and as such, serve only to provide addional guidance

on some of the more specific issues relang to the installaon of Primera an-ligature lock sets.

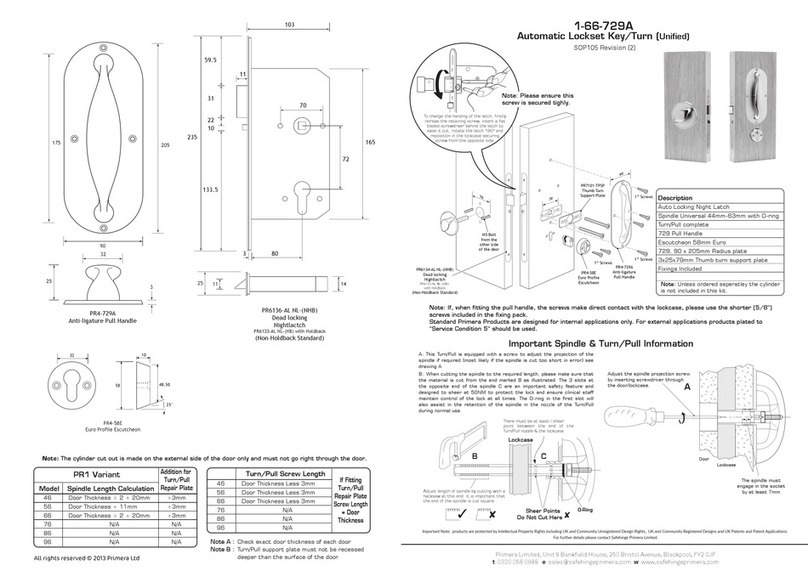

1) Decide the opmum posion for the lock on the door. Then mark out and prepare a morse hole 18W

x 110D x 175H (mm). The hole must be vercal and central to the core of the door and there must be

sufficient clearance for the lock to centrally align in the morse pocket. Adjust accordingly for doors with a

leading edge. Ensure that the morse is free from all debris.

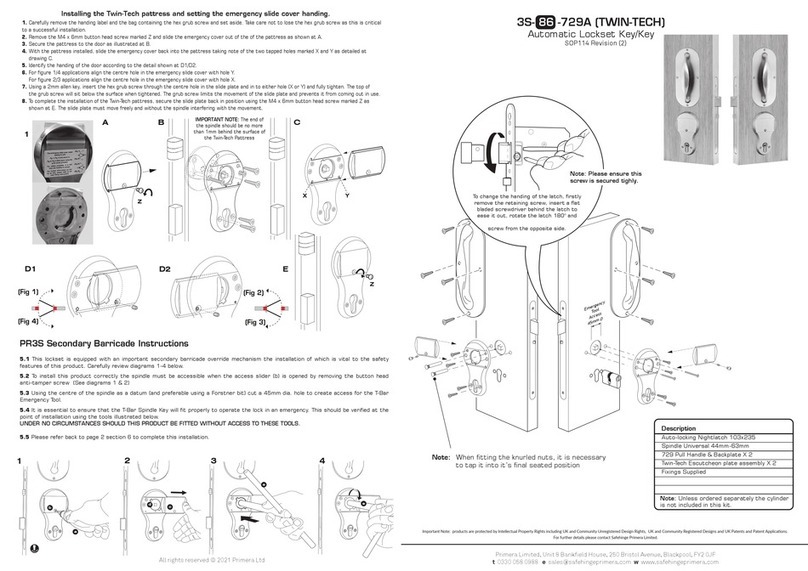

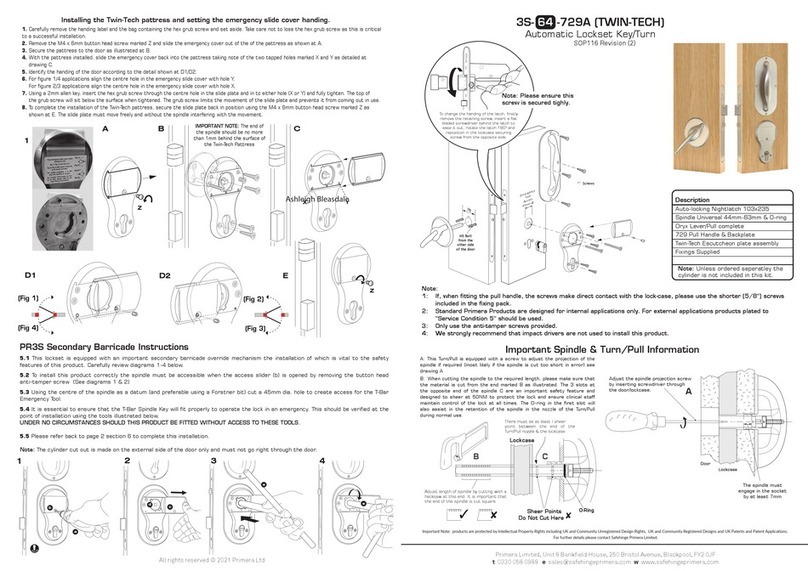

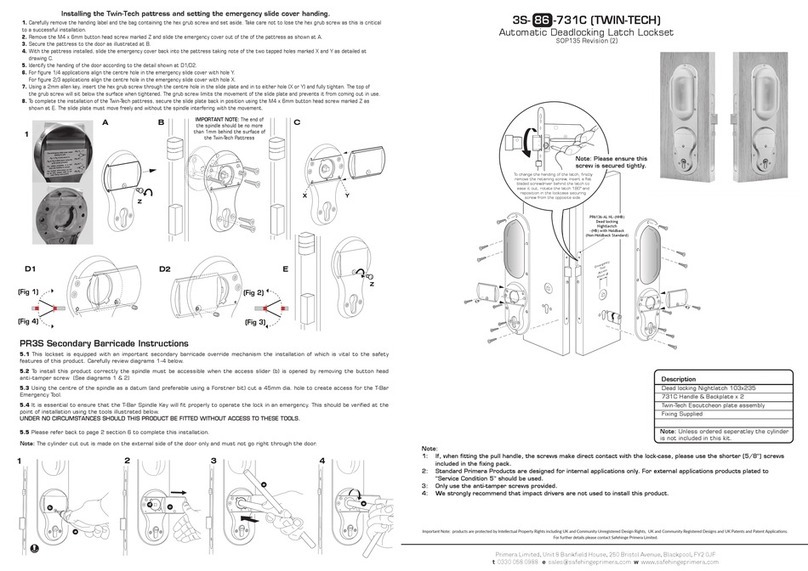

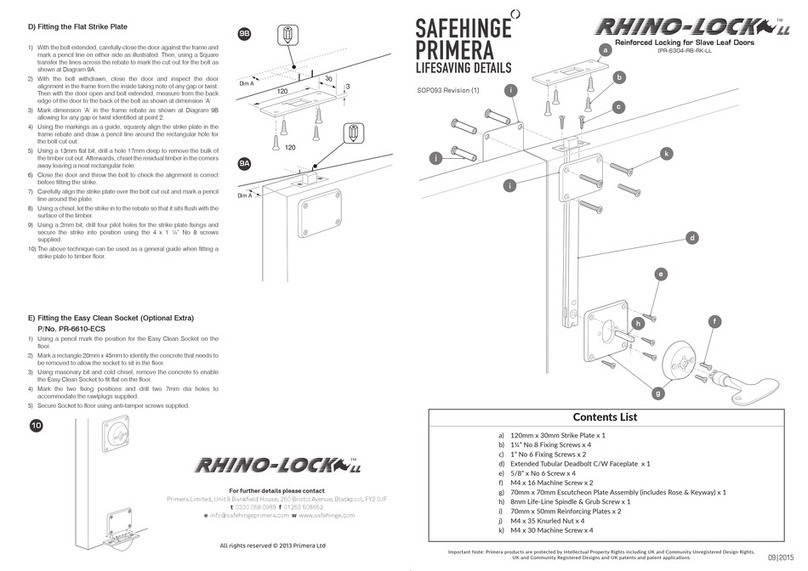

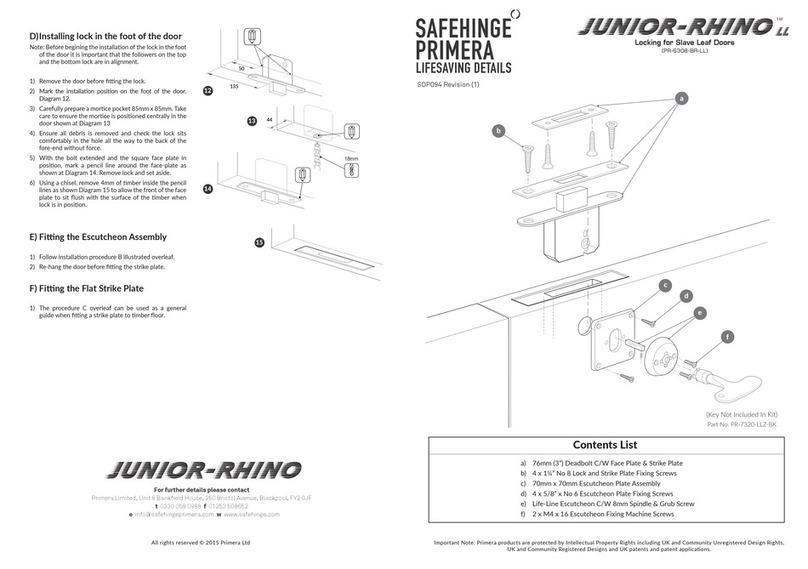

2) Carefully review the exploded view on page 1. For models 76 , 86 & 96 please go straight to secon 4.

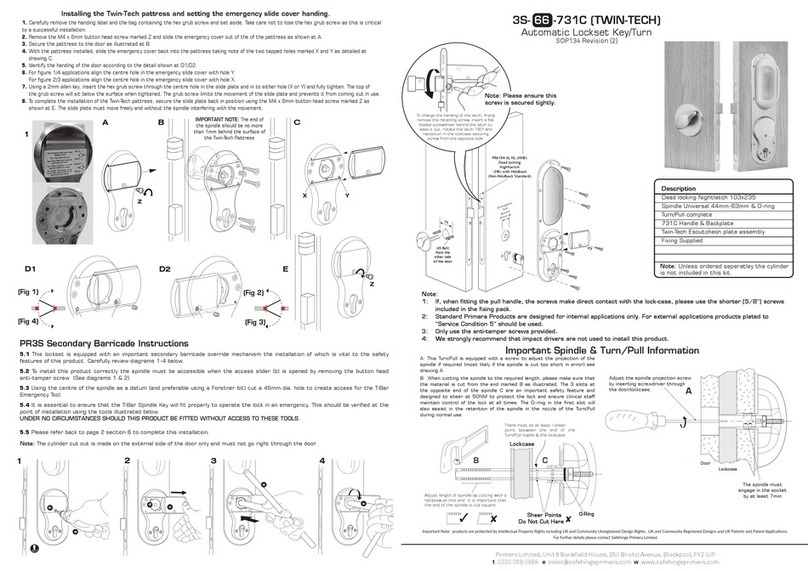

3) For models 46 , 56 & 66 (where Turn/Pull PR4-728-TP is supplied) using the template provided, mark

the 5 internal and 3 external reference points and drill the door to the size detailed. Care should be taken to

ensure accuracy and that the holes are in horizontal alignment. Place the lock back in the morse to check

alignment and adjust if required.

4) Connuing with the template, mark out and neatly drill for the installaon of the locking cylinder ensuring

that the hole is in horizontal alignment. Do not remove more material than is absolutely necessary. Please

ensure sufficient clearance for the back of the single Euro cylinder on models 46 , 56 , 66 & 76 as shown

in figure 1A.

5) Models 86 & 96 require a through hole for the key-key cylinder. Locks with a PR2, PR3 & PR3S prefix

are supplied with an important Secondary Barricade Override safety feature. They must be configured to

ensure nursing staff can gain access to the spindle concealed under the external escutcheon plate. This is

achieved by removal of the an-tamper screw(s) and moving the slider on the escutcheon plate to access the

spindle. Please refer to page 4 for specific informaon on the installaon of this model.

6) Aer following the specific door preparaon guidelines for this model detailed overleaf, please install the

remainder of the ironmongery according to the exploded view and, where Turn/Pull PR4-728-TP is supplied,

in the following order:

A) With the lock inserted (not screwed) in to the morse hole,

offer the round Turn/Pull and 8mm spindle on to the door. The

spindle should go in to the lock follower and allow the Turn to

sit flat against the surface of the door without force. If the Turn

does not sit freely against the surface of the door then the lock

is out of alignment in the morse which should be adjusted

accordingly. Important: If force is used to pull the Turn/Pull

back to the door this will lead to binding, difficult operaon and

possibly premature failure.

B) Cut the 2 x M5 Torx Pin machine Screws to the correct length to ensure sufficient penetraon in to the

Turn/Pull screw ports. If the screws are cut too long the Turn/Pull will not pull firmly back against the surface of

the door resulng in a ligature risk! Secure the Turn/Pull on to the door fastening the screws through the

Twin-Tech escutcheon assembly.

Take care not to over-ghten the fixing screws!

IMPORTANT: When installed correctly the

Turn/Pull should not pass through the horizontal

posion.

C) Install the locking cylinder using the screw

provided again ensuring horizontal alignment. Do not over ghten the cylinder retaining screw as this will

restrict the movement of the key and, in extreme cases can cause the cylinder to collapse. We recommend

that final adjustment is undertaken by hand. Check that the key turns freely and will throw and withdraw the

lock bolt. Important: With the Turn/Pull held rigid the key should withdraw the bolt.

WARNING: This lock should only be used with

cylinders where the cam comes to rest as shown at

Fig ‘A’ when the key is removed.

If using mul-posioned cam cylinders it is

essenal that the cam is posioned accordingly.

Without this the emergency override feature may

not work which could cause damage to the lock.

D) Secure the lock in the morse hole with the an-tamper screws provided and aach face-plate.

Reconfirm that the Turn/Pull and key sll operate the lock freely.

E) According to the exploded view, align all remaining fings and fasten to door using the an-tamper screws

provided. All plates should be secured flat to the surface of the door to prevent ligature risk! Shorter 5/8ths

screws are provided in the fixing pack for circumstances where the 1” screws clash with the lockcase.

F) Finally, mark out and install the strike plate. To adjust the roller catch please refer to magnified view on

page 1. With the door in the closed posion, operate the lock to ensure that the bolt travels freely between

the locked and unlocked posions.

C

L

C

L

14

110

1825

83

Backset

Clearance required for

back of cylinder on locksets.

( 46 , 56 , 66 , 76 )

For further guidance please contact our Technical Help Line on:

0044 (0) 1253 508643

IMPORTANT: If the strike plate included in this kit does not carry the logo it is not a genuine part.

Fing an unbranded strike plate will invalidate the warranty of the lock. In such circumstances please refer to

your supplier.

Fig.1 Fig.6 Fig.7

Fig.4 Fig.5

Fig. 2

Fig.1a

B

A

Posion of the cam when key removed.

IMPORTANT: When fing strike plates to suit locksets

incorporang Primera’s PR-6103 & PR-6104 night-latch

(applicaons 66 & 86) it is important to ensure that the latch-bolt

can fully extend in to the strike plate when the door is closed. This

is to ensure that the dead-locking funcon works correctly and

prevents the latch from being manipulated which is especially

important on outward opening doors. Depending on the gap

between the door and the frame, the latch-bolt recess behind the

strike plate may need to be cut as deep as 12.5mm to facilitate

this. (see fig. 8)

Fig.8

Up to

12.5mm