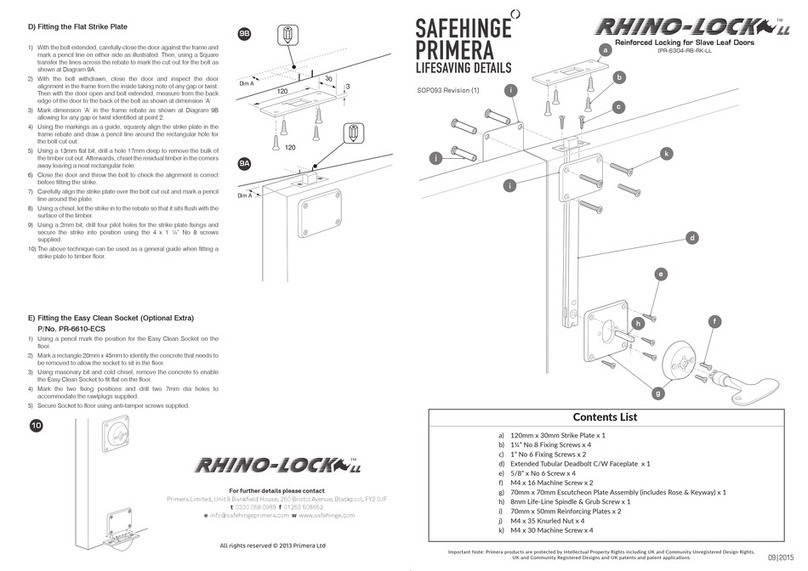

a) Drill

b) 18mm Auger, Forstner or Flat Steel Bit

c) 6mm HSS Drill Bit

d) 2.0mm HSS Pilot Drill Bit

e) 22mm Flat Bit

f) 13mm Flat Bit

g) Chisel 1”

h) Chisel ½”

i) Hex Socket Screwdriver

j) T15 Pin Torx Bit

k) T20 Pin Torx Bit

l) Hammer

m) Tape Measure

n) Pencil

o) 1.5mm Allen Key

q) Life-Line Key - Pn. PR-7320-LLZ-BK

(not included in the kit )

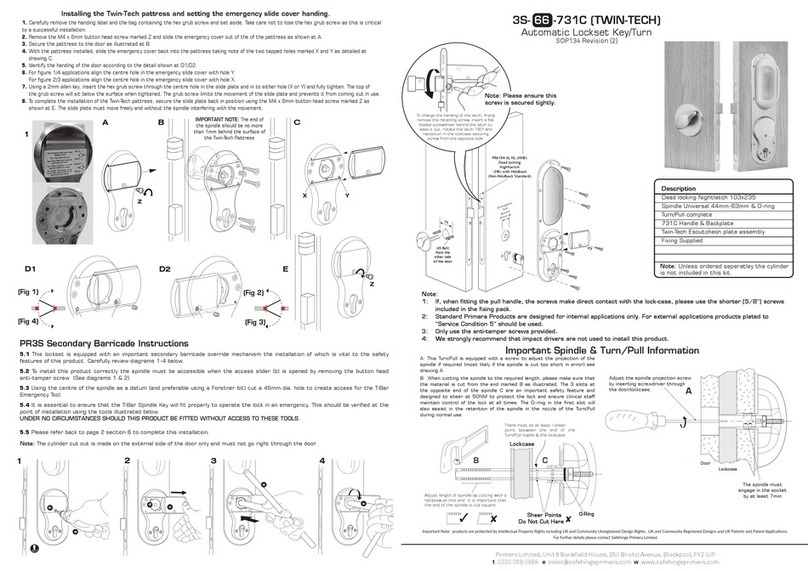

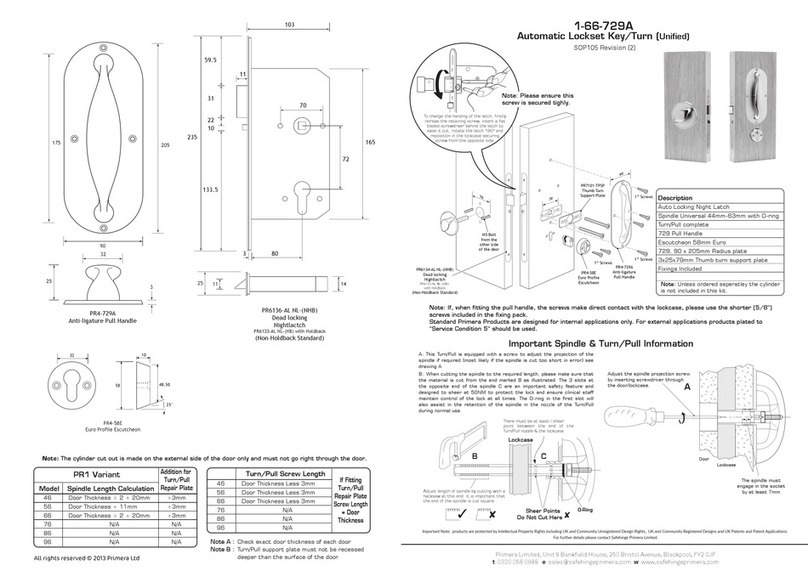

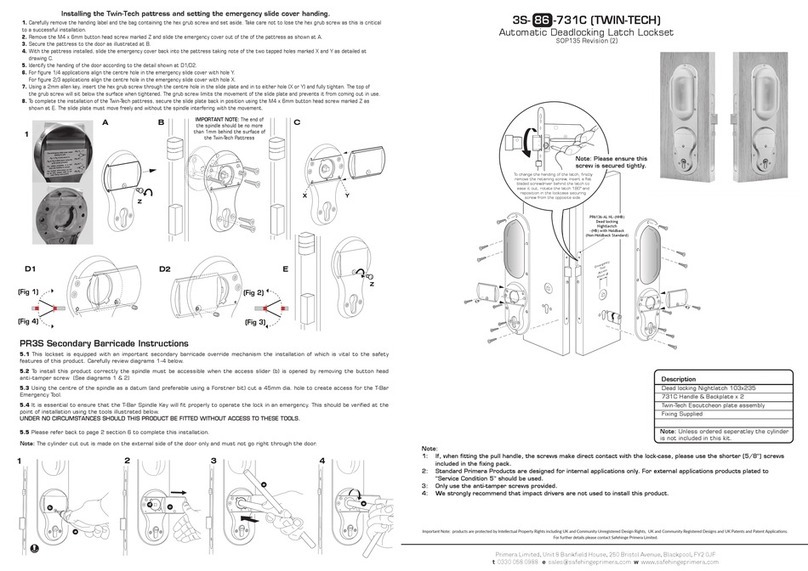

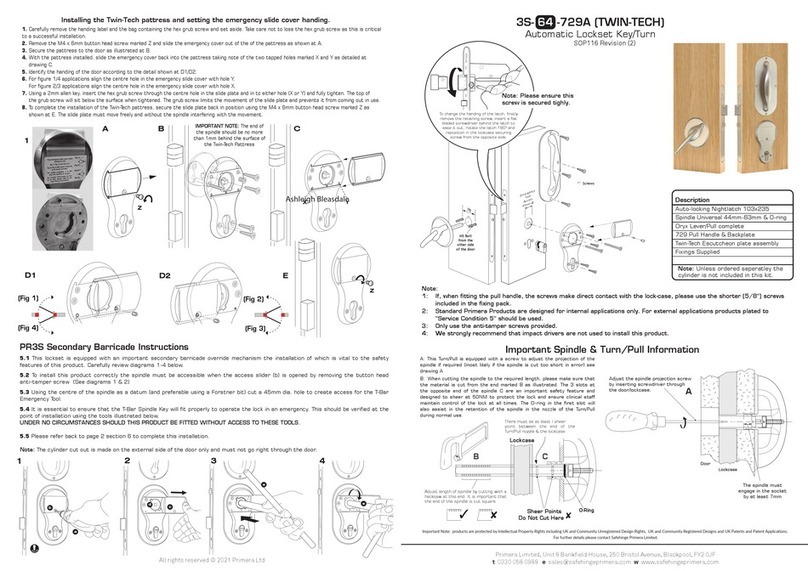

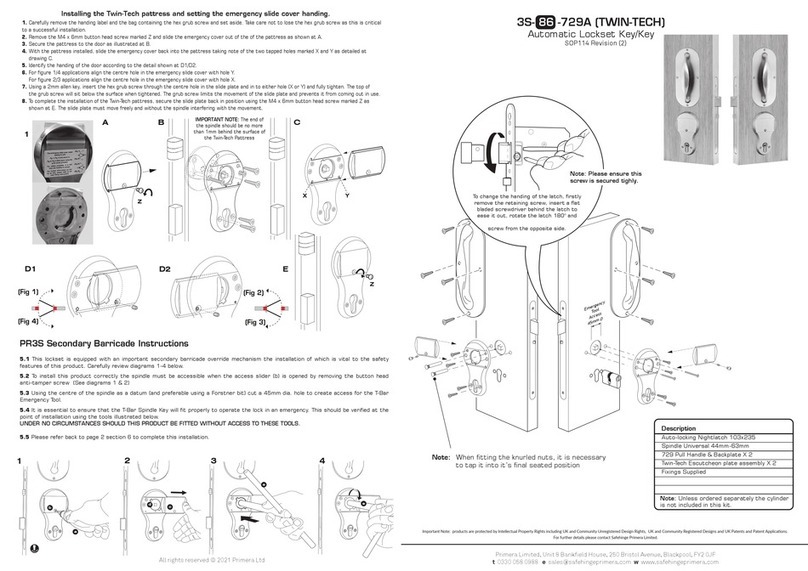

A) Installing lock in the head of the door

1) Mark the installaon posion on the top edge of the door.

Diagram 1.

2) Carefully prepare a morce pocket 85mm x 85mm x

18mm. Take care to ensure the morce is posioned

centrally in the door as shown at Diagram 2

3) Ensure all debris is removed and check the lock sits

comfortably in the hole all the way to the back of the

fore-end without force.

4) With the bolt extended and the square face plate in

posion, mark a pencil line around the face-plate as shown

at Diagram 3. Remove lock and set aside.

5) Using a chisel, remove 4mm of mber inside the pencil line

as shown at Diagram 4, to allow the front of the face plate

to sit flush with the surface of the mber when lock is in

posion.

B) Fing the Escutcheon Assembly

1) Mark a pencil point 57mm from the top of the door and

110mm from the edge of the door as shown at Diagram 5

Using a 22mm flat bit, drill a hole to receive the spindle and

key-drive housing. (Not a through hole - drill one side only).

Re-fit the lock and check to ensure the hole is perfectly

aligned centrally to the square follower.

2) Offer the escutcheon assembly up to the door and mark

the posion of the protruding machine screws. Drill two

appropriate holes (6mm) that will enable the plate to sit flat

against the surface of the door as shown at Diagram 6.

3) Using the spindle formula in figure (7) cut the spindle to the

required length, taking care not to trim the end with the through

hole. Align the spindle in the escutcheon assembly and secure

using grub screw supplied. Ensure that the grub screw is fully

ghtened using 1.5mm Allen Key as shown at Diagram 8.

4) With the key indent at the 12.00 o’clock posion and with the bolt

withdrawn, offer the escutcheon assembly on to the door aligning

the spindle in to the follower on the lock. Test the key to ensure lock

works properly.

5) Using the 2mm drill, carefully drill four pilot holes for the plate

fixings as shown at Diagram 9.

6) Fasten the Escutcheon Plate to the door using 4 x 5/8” No 6 screws.

The plate must be sat firmly back to the surface of the door to

prevent any potenal ligature risk.

7) Using the key, operate the lock again to ensure the bolt can be

thrown and withdrawn easily.

8) Using the lock fore-end as a guide, pilot drill two holes and secure

lock and faceplate in posion using 2 x 1”¼ No. 8 screws as shown

at Diagram 9.

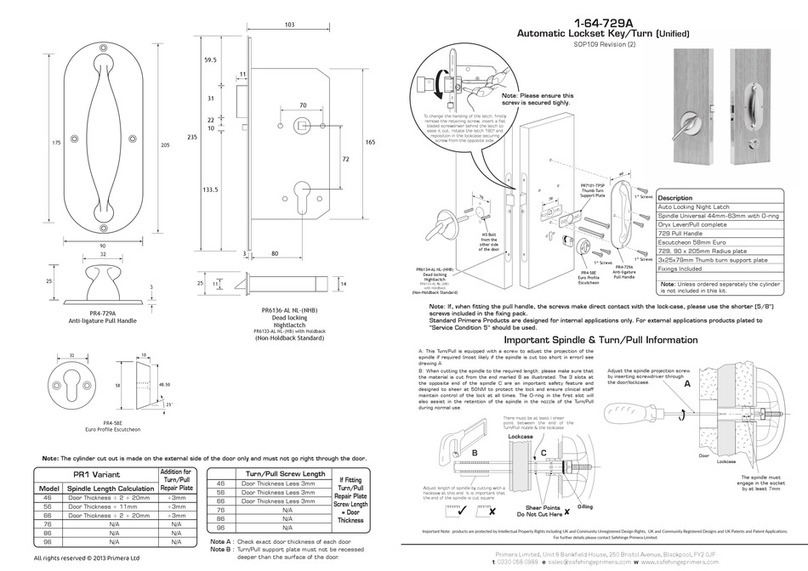

Door Thickness ÷ 2 + 7mm = Spindle Lgth

Example where door is 44mm

44mm ÷ 2 + 7mm = Spindle Lgth of 29mm

Installaon Procedure

Spindle Formula

44

18

85

85

50

135

57

110

= Mark with pencil = Drill Pilot Hole

2

4

6

5

1

18mm

22mm

6mm

3

13mm

25

95

Dim A

1.5

C) Fing the Flat Strike Plate

1) With the bolt extended, carefully close the door against the frame

and mark a pencil line on either side as illustrated at 10. Then, using

a Square transfer the lines across the rebate to mark the cut out for

the bolt.

2) With the bolt withdrawn, close the door and inspect the door

alignment in the frame from the inside taking note of any gap or twist.

Then with the door open and bolt extended, measure from the back

edge of the door to the back of the bolt as shown at dimension ‘A’

3) Mark dimension ‘A’ in the frame rebate as shown at Diagram 11

allowing for any gap or twist idenfied at point 2.

4) Using the markings as a guide, squarely align the strike plate in the

frame rebate and draw a pencil line around the rectangular hole for

the bolt cut out.

5) Using a 13mm flat bit, drill a hole 17mm deep to remove the bulk of

the mber cut out. Aerwards, chisel the residual mber in the

corners away leaving a neat rectangular hole.

6) Close the door and throw the bolt to check the alignment is correct

before fing the strike.

7) Carefully align the strike plate over the bolt cut out and mark a pencil

line around the plate.

8) Using a chisel, let the strike in to the rebate so that it sits flush with

the surface of the mber.

9) Using a 2mm bit, drill four pilot holes for the strike plate fixings and

secure the strike into posion using the 4 x 1 ¼” No 8 screws

supplied.

10) The above technique can be used as a general guide when fing a

strike plate to mber floor.

See overleaf for installing the lock in the foot of the door.

2 mm Pilot

Dim A

Tools Required

8

9

10

11

7

2 mm Pilot