Prior Scientific PureFocus850 User manual

PureFocus850 Installation Guide

Author

Simon Bush

Date

12th March 2021

Version

2.2

Status

Released

Aims

This document contains an in depth

guide to the PureFocus850, including a

full installation walkthrough for both

automatic and manual setup. The

troubleshooting section has been

greatly expanded and representative

signal morphologies are shown

throughout.

2

Thank you for purchasing this product from Prior Scientific – we are confident it will be a reliable and useful addition to

your microscope system. Please take the time to read and understand this manual before using this product – it contains

not only important operating instructions but also vital safety information. Use this product only as specified in this

manual. If you wish to use it differently, contact Prior Scientific beforehand.

Please do not hesitate to contact us with any comments or questions regarding this product.

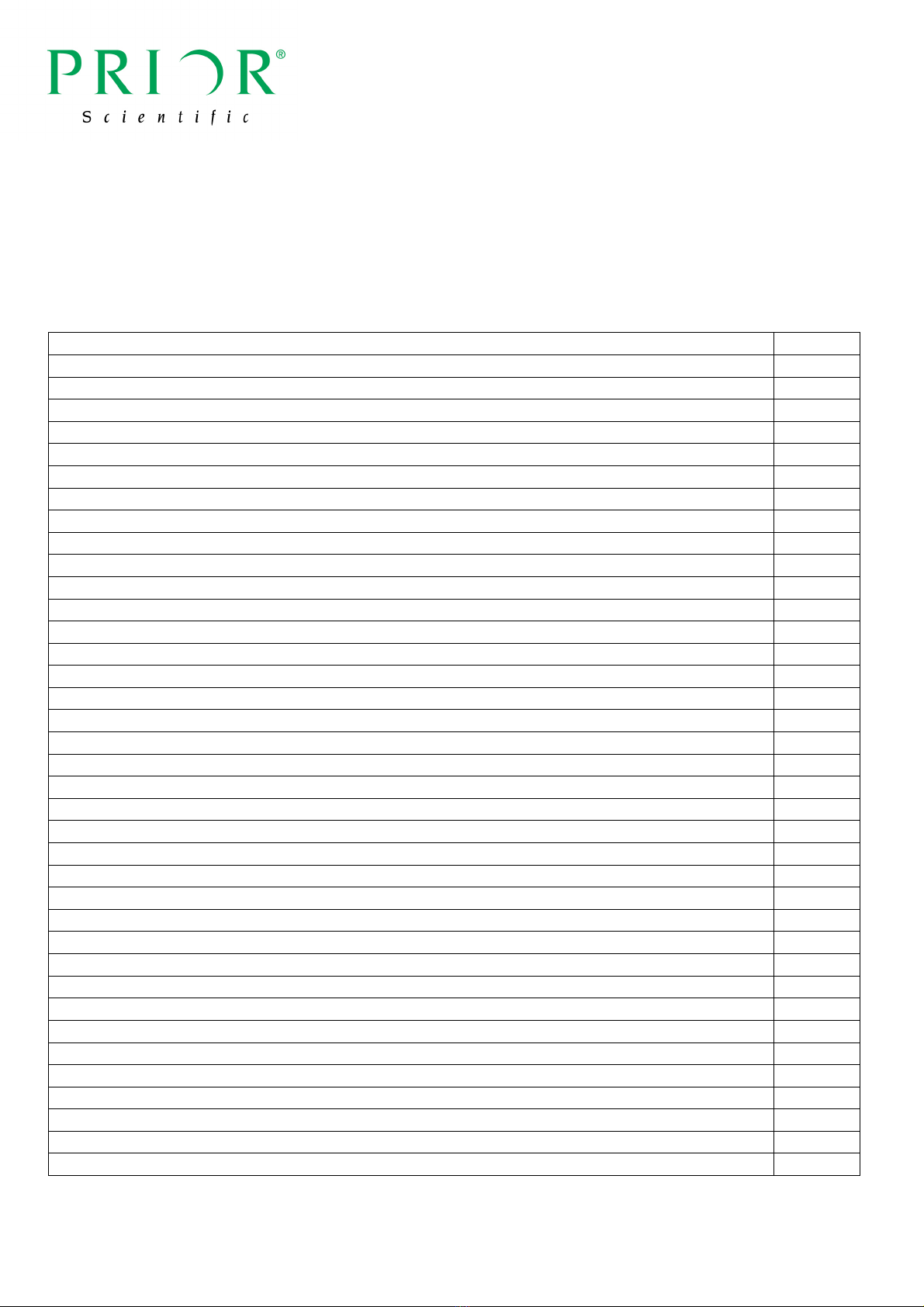

Contents

Section 1: Important Safety Information

4

1.1 Important Safety Information

4

Section 2: Product Description

5

2.1 What is the PureFocus850?

5

2.2 Working Principle

5

Section 3: Hardware Installation

7

3.1 Types of microscope system

7

3.2 Types of Illumination

7

3.3 Unpacking your system

7

3.4 Installing your PF850 mounting kit

10

3.5 Installing the PF850

10

3.6 PF850 Controller Guide

11

Section 4: Optical Alignment

13

4.1 Aligning the PF850 with the optical path

13

4.2 Laser setup considerations

16

4.3 Setting the sensor (pinhole) centre

16

4.4 Creating signal imbalance

20

4.5 Removing background signal

22

Section 5: Focusing System Setup

23

5.1 Stepper motor focusing system

24

5.2 Piezo nanopositioning focusing system

24

Section 6: Autofocus Parameter Setup

25

6.1 Installation Review

25

6.2 Objective selection

26

6.3 Setting the offset

27

6.4 Checking for back reflections

31

6.5 Setting focus recovery speed

33

6.6 Fine offset adjustments

36

6.7 Saving offset values

36

6.8 Parameter setup for remaining objectives

36

6.9 Saving your settings

37

6.10 Flags

37

Section 7: Advanced features

37

7.1 Non-typical sample types

37

7.2 Signal to noise

37

7.3 Enhanced focus control via Focus Flag

41

7.4 Sample detection via Sample Flag

43

7.5 Using multiple offsets

43

3

7.6 Software Limits via Range Flag

43

Section 8: OEM features

44

8.1 Interface selection

44

8.2 Focus search

46

Section 9: ASCII commands

48

9.1 Signal settings commands

48

9.2 Focus signal commands

48

9.3 Servo settings commands

49

9.4 Flag settings commands

50

9.5 Objective parameters commands

51

9.6 Digipot settings commands

52

9.7 Focus commands

53

9.8 System commands

55

9.9 Advanced commands

55

Section 10: Troubleshooting

56

10.1 No laser line emitted visible on the target

56

10.2 Laser signal is too high or too low in setup mode

57

10.3 Additional peaks are visible in setup mode

58

10.4 Background signal in setup mode is high or uneven

59

10.5 No or imbalanced error value swing

60

10.6 Focus recovery is too fast or focus unstable

61

10.7 Focus recovery is too slow

61

10.8 Focus recovery does not occur despite a good error value swing

61

10.9 Performance is good but the flags are inactive

62

10.10 Focus locks when my sample is not in focus

62

10.11 A suitable offset cannot be calculated for an objective

63

10.12 Z Scan

66

Section 11: Spare parts, repairs and returns

66

Section 12: Controller Z connector Pinout

67

Appendix 1: Windows USB Driver Update

68

4

Section 1: Important Safety Information

1.1 Important Safety Information

Class 1 laser product, laser wavelength 850 nm, laser output < 0.77 mW

CLASSIFIED TO BS EN 60825-1:2014

It is important to follow these safety warnings to avoid potential injury or damage. Please read and

understand these warnings, operating instructions and specifications before using the PureFocus850.

If you have any questions do not hesitate to contact Prior Scientific. If you intend to use this unit in a

manner not specified by Prior in this manual, contact Prior Scientific beforehand.

SAVE THIS MANUAL AS IT CONTAINS IMPORTANT INFORMATION AND INSTRUCTIONS.

Before using the system, please follow and adhere to all warnings, safety and operating instructions

located either on the product or in this User’s Manual.

•Do not expose the product to water or moisture.

•Do not expose the product to extreme hot or cold temperatures.

•Do not expose the product to open flames.

•Do not allow objects to fall on or liquids to spill on the product.

•Do not touch the glass plate fitted between the circular dovetail and the top plate. Any dust,

dirt, fingerprints will cause degradation of image quality.

•Do not poke inside the open aperture in the base plate of the unit. There are delicate optical

components which are easily damaged if touched.

WARNING. This unit emits non-visible laser radiation at 850 nm from the dichroic aperture as

indicated by a warning label on the unit. The total output power is below the class 1 emission limit of

770uW and is therefore eye-safe. However, staring into the aperture should still be avoided.

The supplied mains adaptor must always be used with an earthed mains socket. The equipment

should be positioned in such a way that the mains switch, power supply and system power switch are

easily accessible.

If the equipment is used in a manner not specified by the manufacturer, the protection provided by

the equipment may be impaired.

Only the exterior of this product should be cleaned using a damp lint-free cloth. If internal

contamination is suspected, please contact your supplier for advice.

DANGER. Under no circumstances unscrew the lid of the unit. Disassembly of the unit will void the

warranty. This product does not contain consumer serviceable components. Service and Repair

should be performed by authorised service centres only.

Use only the proper type of power supply cord set (provided with the system) for this unit. Failure to

do so could instantly destroy the electronics and laser diode. The unit requires 24 VDC at 2 Amperes.

5

Always switch off the unit using the on/off switch SW1 or unplug the PSU (CON3) when plugging/

unplugging the stepper motor (CON4) or DIGIPOT (CON2). It is safe to plug/unplug the USB

connector (CON1) with the unit powered.

Keep this manual in a safe place as it contains important safety information and operating instructions.

Section 2: Product Description

2.1 What is the PureFocus850?

The Prior Scientific PureFocus850 is an advanced, integrated, unit comprising of an IR laser diode,

precision optical components, detector and signal processing electronics with on-board micro

controller. The system allows optimum visual focus to be found and maintained on a microscope

system for a range of different sample types, microscope objectives and imaging methods.

The PureFocus system allows powerful automated autofocus functionality to be added to existing

microscope systems by installing the unit into the infinity space (between objective and tube lens).

The system has been designed to fit on many popular microscopes using infinity corrected optics,

both upright and inverted types, using the relevant mounting kit. The PureFocus controller outputs

signals suitable for controlling piezo or motor focus drives and is compatible with Prior piezo actuators

and Prior stepper motors, by simply attaching to the fine focus knob of the microscope.

With the laser autofocus system the user has the ability to work with a range of sample types with a

reflective surface, including permanently mounted glass slides, live specimens in aqueous solution,

metallurgical, semiconductors and other samples with multiple reflective layers. The system can also

work with plastic vessels such as well plates.

PureFocus works with both epi and transmitted illumination, and can be used for fluorescence

applications with the 850 nm source being outside of most fluorescence bands.

A fully standalone system gives the end user the option of using the PureFocus controller with digipot,

display and buttons allowing all basic functionality options without the need for a host PC. The inbuilt

signal processing electronics generates focus correction information internally every 1 ms allowing for

fast focus capture and tight closed loop action. For more advanced functionality PureFocus can be

fully remote controlled via USB communication, using our ASCII commands set.

2.2 Working Principle

The PureFocus operates using a sensor with multiple pixels. Half the aperture of a collimated laser

beam is blocked via a knife edge and directed into the back of the microscope objective. The laser

light is focussed to a line on a reflective surface at the sample and then reflected back through the

objective and directed towards the sensor forming a corresponding line on the sensor at the centre

point. Due to half the aperture of the laser being blocked, motion of the reflective sample up or down

causes this line to move either left or right on the sensor, giving information to automatically control

the focus of the microscope and keep the sample in focus (Fig. 1).

Table of contents

Other Prior Scientific Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual