Parts and Drawing Instructions for HR90000 Series

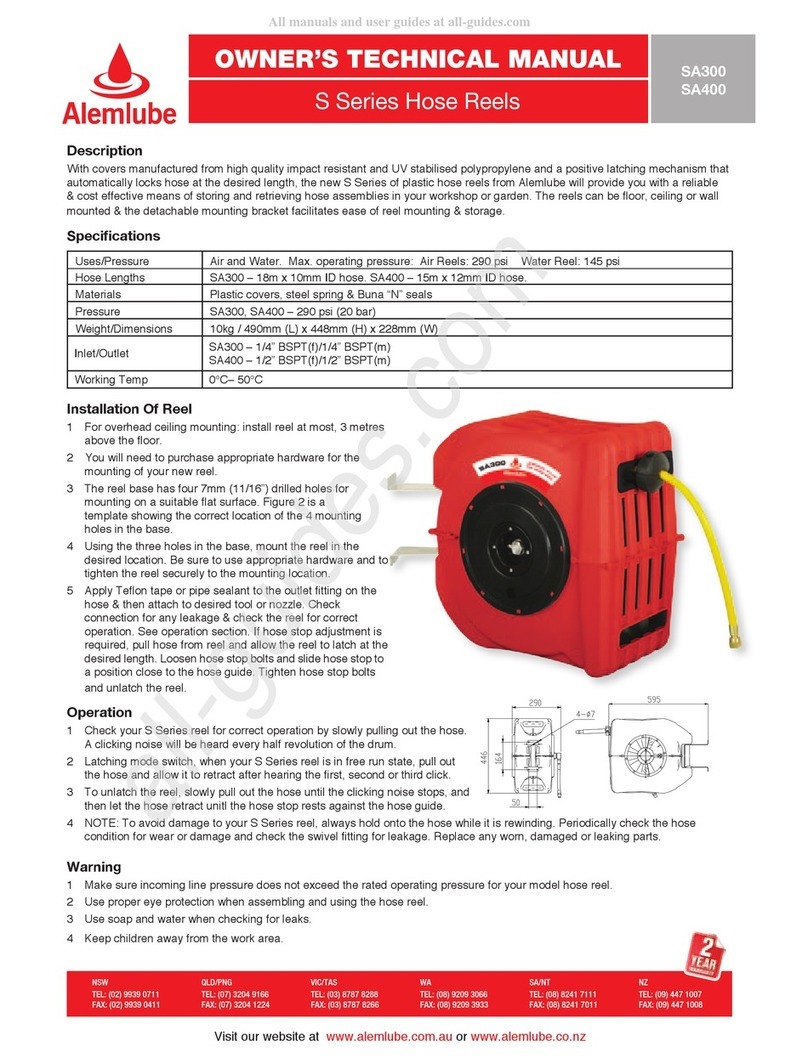

Specifications

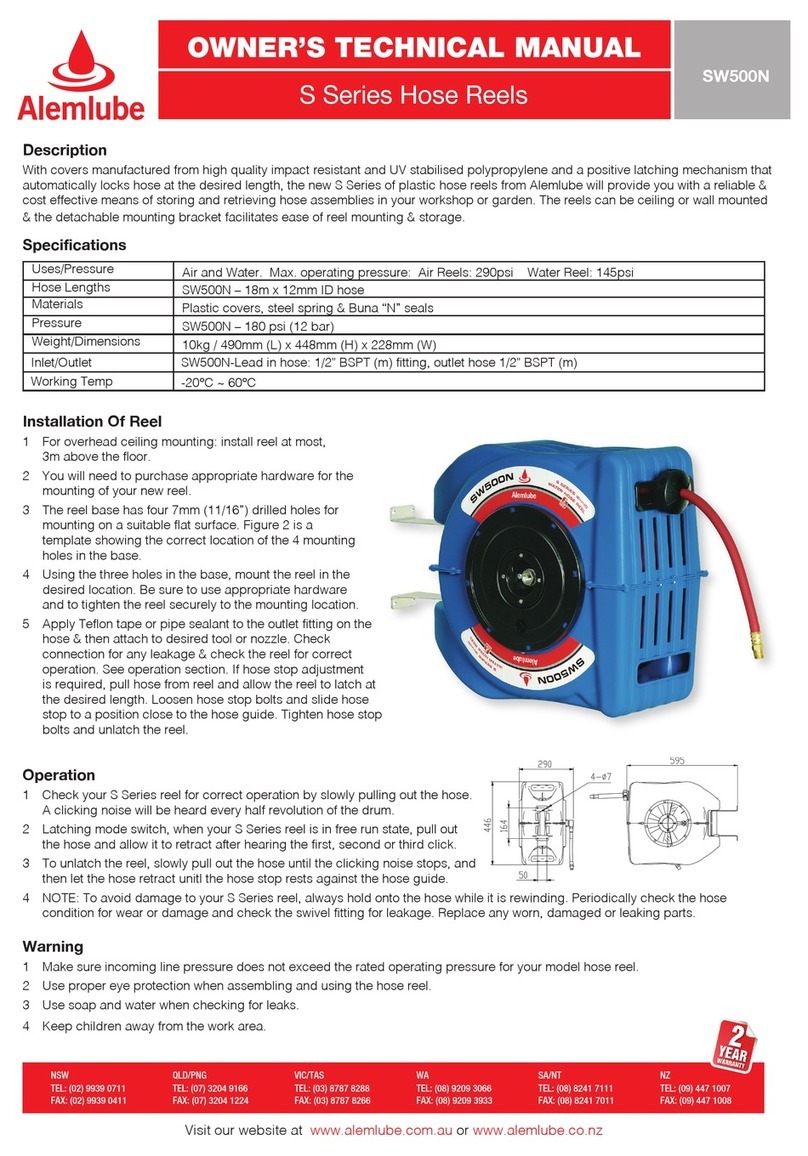

Spring driven drum: for automatic rewind.

Locking ratchet: to maintain the desired

length of hose in use.

Read the following precautions and instructions before you

begin assembly or using. Failure to comply with these

instructions could result in personal injury or property damage.

Keep these instructions in a convenient location for future reference.

Hose Reel Safety Precautions

1. Make sure incoming line pressure does not exceed rated operating pressure for your model

hose reel.

2. Use proper eye protection when assembling and using the hose reel.

3. Assemble the hose reel on a clean workbench.

4. Use soap and water when checking for leaks.

5. Keep children away from the work area.

WARNING:

Exposure of skin directly to pressurized air, or fluid could result in severe bodily injury.

Installation of Reel

1) For overhead ceiling mounting: Install reels at least 16.5 feet above the floor.

2) If the reel you have purchased does not have hose included, you will need to purchase and

attach. Refer to Specifications on box to determine appropriate hose size and length.

3) You will need to purchase appropriate hardware for mounting your new reel.

1. The reel base has four 1/2” (or 12.7mm) drilled holes for mounting on a suitable flat surface.

Figure 2 is a template showing the correct location of the 4 mounting holes in the bas

2. The reel is supplied with a hose guide roller bracket. The bracket position may be changed

depending on the reel mounting position. Figure 2 shows “ Typical Mounting Positions”. If

bracket position needs to be changed, do the following:

(1) Pull out some hose and let reel latch.

(2) Remove the bolts that attach the guide roller bracket to the support post.

(3) Rotate guide roller bracket to correct position, replace bolts and tighten.

3. Using the four holes in the base, mount the reel in the desired location. Be sure to use

appropriate hardware and tighten securely.

4. Apply Teflon tape or pipe sealant to supply line threads, attach to reel inlet and tighten. The

other end of incoming line can now be connected to desired supply source.

5. If hose has been supplied with reel: Apply Teflon tape or pipe sealant to outlet fitting on reel

hose, then attach to desired tool, or nozzle. Check connection for leakage, also check hose

reel for correct operation. (Details see Operation section.)

6. If hose stopper adjustment is required, pull hose from reel and allow to latch at desired

length. Loosen stopper bolts and slide stopper to a position close to the hose guide. Tighten

stopper bolts, and unlatch the reel.

Installation of Hose

1. Securely stabilize the reel.

2. Facing the swivel fitting side of reel: Turn the drum clockwise, by hand, until the rewind

spring is tight, and drum has latched. As an extra precaution while installing new hose,

secure drum in the latched position.

Industrial Hose Reel 286X Series Instruction

4 OF 9

3. Insert end of the hose through guide roller bracket, and feed through the opening in the drum

flange.

4. Use Teflon tape or pipe sealant on hose fitting threads, screw fitting into swivel and tighten.

Note: To avoid damage to the swivel, use a wrench to support the swivel fitting while

tightening the hose.

5. Attach hose stopper on the other end of hose, near the outlet fitting.

6. Carefully release drum latch, and slowly allow hose to wind onto the reel.

Note: Final spring tension adjustment is accomplished by adding wraps of hose around the

drum (to increase tension) or taking off wraps of hose (to decrease tension). Refer to:

Adjustment of Spring Tension.

Industrial Hose Reel 286X Series Instruction

5 OF 9

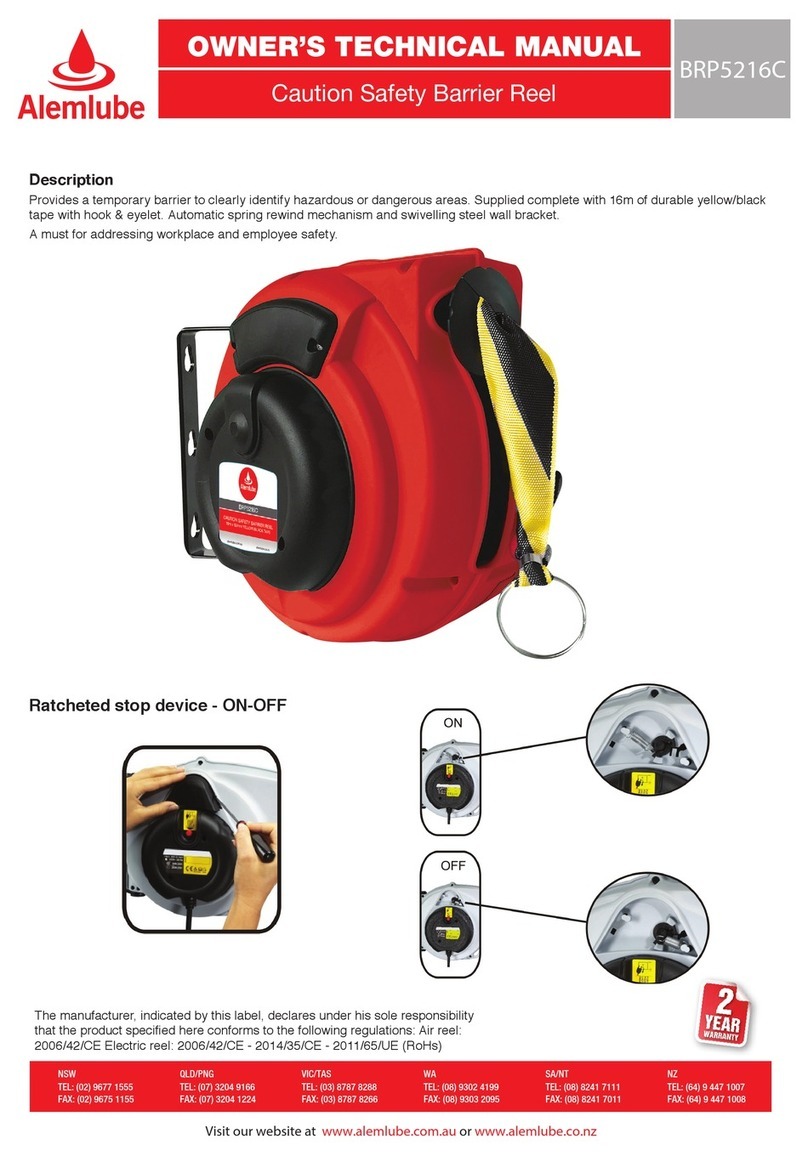

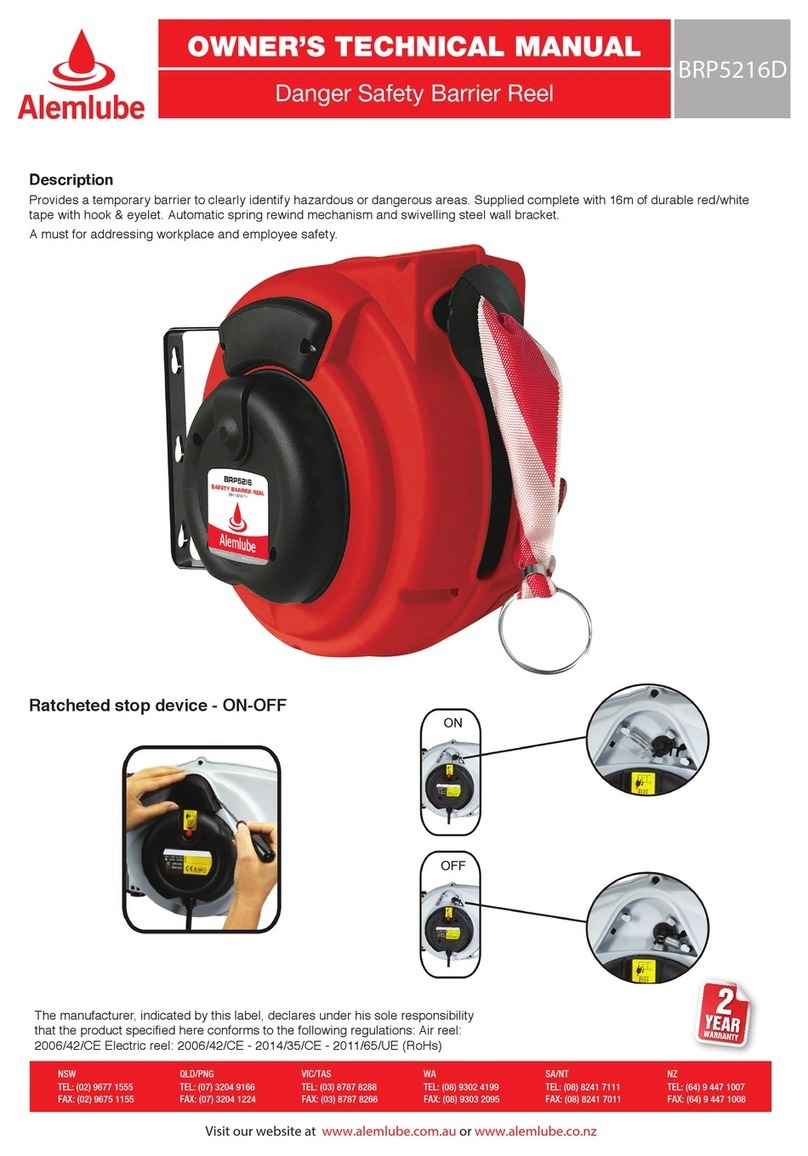

Wall Floor Ceiling

HR90015 / HR90030 / HR90045 / HR90065 / HR90075

& HR90010 / HR90025 / HR90040 / HR90050 / HR90055 / HR90060 / HR90070

Wall & Floor & Ceiling

HR90005 / HR90020 / HR90035 Wall & Floor

Wall Floor

5

Visit our website at www.alemlube.com.au or www.alemlube.co.nz

NSW

TEL: (02) 9677 1555

FAX: (02) 9675 1155

QLD / PNG

TEL: (07) 3204 9166

FAX: (07) 3204 1224

VIC / TAS

TEL: (03) 8787 8288

FAX: (03) 8787 8266

WA

TEL: (08) 9302 4199

FAX: (08) 9303 2095

SA / NT

TEL: (08) 8241 7111

FAX: (08) 8241 7011

NZ

TEL: (64) 9 447 1007

FAX: (64) 9 447 1008