pro bel Freeway User manual

I

.J

1

1

.1

1.2

1.3

1.4

1.5

r>.

2

) 2

.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

3

3

.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3

.11

3.12

3.13

6540T-00 Nov 97

Pro-Bel

ltd

FreewayRange

Contents

Introduction 4

4

Control

4

Environmental

5

Problems?

5

Theright

choice

5

General

points

General information 6

Important

safeguards

and

notices

6

I

nsta

Ilation 8

EMC

statement 8

Maintenance andwarranty 10

Telephone

support

11

Customer

support department 12

Repairs

12

Loans

12

Exchanges

13

Address

information 13

Installation

16

Door

removal

16

Power

supply

removal

16

Signal

rear

panel

removal

18

Removal

and

replacement

of

modules

18

20

Cable

connections

Control

rear

panel

connections

21

23

Video

references

-

BNC

sockets

(looping)

Setting the

AES

reference

-

PL

17

Settingthe

level

switch

Setting thedestination

assign

switch

24

26

28

28

LED

indications 30

Freewaycontrol

card

33

Setting the

reset

switch

FreewayRange Pro-Bel

ltd

4 Hardware configuration

34

4

.1

Router

details 34

4.2

Port

definitions 36

4

.3

Controller configuration 38

4.4

Software

controllable

processes

40

5 Control

system

operation

42

5.1

Master

and

slave

module

details 42

5.2

Master

router

dual

control

and

changeover

42

5.3

Operating

modes

43

5.4

Salvos

45

r:

6

Routing

46

6

.1

Setting

crosspoints

46

6.2

Salvo

switching

47

6

.3

Handshaking

and

errorreporting 47

6.4 Defining

stereo

analogue

audio

parameters

48

6.5 Configuring

general

remote

ports

50

6.6

Using

PC

based

editors

50

6.7

Configuring the

database

51

6.8

Understanding

the

database

57

7

Panel

details

64

7.1

Summary

of

panel

types

64

7

.2

General

panel

details 64

7

.3

Panel

features

65

7.4

Panel

types

74

7.5 Configuration via

panels

86

8 level types 92

8

.2

Normal

Freeway(64x64) 92

8.3

YUV

Freeway(5x5, 1

Ox1

0,15x15or

20x20)

92

8.4

Dual

channel

Freeway(8x8, 16x16,24x24 or32x32) 92

8

.5

Quad

channel

Freeway(4x4,8x8,12x12or16x16) 94

8.6

Machine

control Freeway(17x16, 33x32,49x48,65x64) 94

8.7

YUV

TM32

and

TM16

(5x5,

1

Ox5

or

lOx1

0) 94

8,8

Dual

channel

TM32andTM16(8x8or 16x16) 95

8.9

Quad

channel

TM32andTM16(4x4or8x8) 96

6540T-00

Nov 97

2

Pro-Bel

ltd

Technical manual

8.10

Normal

TM24

(24x6,

24x12 or24x24) 97

8

.11

Dual

channel

TM24(12x6or12x12) 97

8.12

YUV

TM24

(8x2

or8x8) 97

9 Terminal

command

set 98

9.1

98

Command

setdetails

9.2

Error

responses

112

10 Configuring dial-up

keypads

114

10.1

Example

keypad

layouts

114

10.2

Example

source

keypad

entry

sequence

us

ing

source

keypad

34

115

10.3

Example

destination

keypad

entry

sequence

using

destination

keypad

34

116

11

PC

support software 118

11.1

Software

installation

118

11

.2

Running

the

program

118

12 Downloading Motorola

S-record

HEX

files 122

13 Theoryof operation 124

13.1

Switching

duties

124

13.2

Freeway

block

diagrams

124

14

Problem

solving

128

15 Specification 132

6540T-00 Nov 97 3

FreewayRange

1 Introduction

The

Freeway

series

range

of

routing

switchers

addresses

today's

need

for

the

smaller

installation

whilst

offering

the

high

performance,

cost

effective,

multi

signal-format,

routing

offered by Pro-Bel.

This

guide

describes

the

common

features

of

Freeway

(chassis,

control

card,

PSU,

etc.). Part 1 of

this

User Guide

details

installation

and

configuration

information

irrespective

of

specific signal

type.

The

remaining

parts

cover

each

of

the

specific

signal

types

in

turn

.

•

1.

1 General points

A

Freeway

frame

can

accommodate

a

total

of

four

signal

cards

;

each

providing

a

16x16 SWitching

module

.

These

modules

may

be

interconnected

within

the

frame

(using

the

internal

expansion

bus)

to

produce

router

sizes

of 16x16, 32x32,

48x48

and

64x64. By

designing

each

signal-type

module

to

require

identical

PSU

and

support

functions,

any

combination

of signal

type

may

be

housed

in

the

same

3U

chassis.

So

that,

for

instance,

a

32x32

SOV

and

stereo

audio

switcher

can

be

housed

within

the

same

frame. And Freeway's

modularity

ensures

that

your

switcher

can

change

as

your

requirements

do.

Switcher

sizes

below

64x64

may

be

plug

and

play

upgraded

in

the

field. Similarly a

predominantly

analogue

router

can

gradually

be

transformed

into

a digital

router

(by

swapping

analogue

sixteen

square

modules

for digital

alternatives)

as

your

installation

requirements

evolve.

In

Chapter

3 we'll tell you all you

how

to

get

your

router

up

and

running

and,

in

Chapter

4,

how

to

configure

the

system

for

your

present

needs

and

future

expansion

.

•

1.2

Control

Control for

the

router

is

provided

by an

internal

daughter

card.

Optionally

a

second

control

card

can

be

fitted

thereby

providing

a

back-up

controller

should

the

primary

card

fail. Freeway's

control

system

offers

extensive

facilities,

supporting

up

to 32

panels

or

under

monitor

displays.

Panel

types

may

be

XY,

button-per-crosspoint

or

multibus.

Internal

database

editing

functions

provide

extensive

system

configuration

options

including;

programmable

salvos,

source

and

destination

associations,

marrying,

route

protects

and

inhibits,

audio

channel

configurations

and

overrides. Up to 8 levels

of

Freeway

routing

may

be

slaved

to

6540T-00

I\lov 97

4

Pro-Bel

Ltd

Technical

manual

the

main

frame

by

means

of

a parallel

control

link. A special

version

of

this

parallel link is

also

available to slave existing TMSeries

routers.

Extensive

details

of

the

Freeway

control

system

(and

how

to

edit

the

internal

database

information)

are

given in

Chapters

4

and

5.

•

1.3

Environmental

By utilising

advanced

PSU

circuit topology

and

the

latest

signal

switching

technologies,

Freeway

offers a

very

compact

router

with low

power

dissipation,

ensuring

fit

and

forget reliability. For

extra

security, each frame has

provision

for

two

PSU

modules

so

that

one

may

act as a

backup

in

the

event

of

a

PSU

fail.

The

high-speed

converter

technology

in

the

PSU

is

monitored

by two

on-board

microprocessors

that

assess

the

condition

of

the

mains

and

of

the

supplies

leaving

the

power

unit

. Should

any

of

the

PSUs

vital-signs

show

a

warning

condition

these

are

monitored

and.

if

appropriate,

an

external

warning

alarm

may

be

activated.

Freeway

PSUs

may

be

withdrawn

from

the

unit

from

the

front

and

a

replacement

hot-plugged;

thereby

ensuring

continuous

service. For details,

see

Chapter

3.

•

1.4

Problems?

We

hope

you

won't

have them! Perhaps it's finger

-trouble

or

something

more

serious?

In

Chapter

14 you'll find a

problem

solving

guide

to

help

you with

possible

questions.

You'll also find

contact

information

for

our

Customer

Service

department

in

Chapter

2.

Note: This

product

contains no user servicable parts; should this product require

servicing please

refer

to Pro-Belor

your

local

agent

.

•

1.5

The right choice

Choosing a

switcher

is an

important

decision, no-one

wants

to get it

wrong

. With

all the

changes

in television

production

today

,

you

need

a

router

that

can evolve

and

change.

That's

why

we

developed

Freeway,

the

future-proofed

modular

multi-format

routing

system

that

provides

the

smoothest

ride to the future.

We re glad you

agree

with us.

ee

7e

6540T-00 Nov 97 5

FreewayRange Pro-Bel

ltd

2 General information

• 2.1

Important

safeguards and notices

Before use

If

this

equipment

is

being

used

for

the

first time, is

being

installed

in a new

location or

has

not

been

used

for a long

time

then

the

following

checks

should

be

carried

out.

Check

that

the

equipment

is

not

mechanically

damaged

; if it is

the

unit

should

be

checked

by a qualified

engineer

and,

if

necessary,

returned

to Pro-Bel Limited or to

its

agent.

Safety

All Pro-Bel

equipment

meets

the

requirements

of

specification

:

BS

EN60950:1992

Safety of

Information

Technology

Equipment

including Electrical Business

Equipment

.

Pro-Bel

equipment

is

designed

to be

used

in a

rack

mounted

frame

and

all

external

metal

work

should

be

earthed.

High temperatures

Under

normal

circumstances

certain

internal

components,

such

as

heat

sinks

and

mains

transformers,

may

be

too

hot

to

touch

; also, if a fault

develops

one

or

more

components

may

become

unusually

hot.

However

no

part

that

can

be

touched

in

normal

use

should

ever

exceed 65°C;

nevertheless

always

take

care.

6540T-00 l\Iov 97

6

Pro-Bel

ltd

Technical

manual

Disposal

None of

the

active devices or

other

components

in

this

unit

contains

any

hazardous

or

dangerous

chemicals or

substances

and

therefore

there

are

no

special

precautions

that

need to be

observed

if this

equipment

is

disposed

of.

High voltages

To

prevent

electrical

shock

when

working on this

equipment

disconnect

the

a.c.

line cord from

the

a.c.

source

before

working

on

any

internal

components.

ESD warning

WARNING: All

of

the

modules

fitted

contain

static

sensitive

components

and

full

anti-static

precautions

should

be

taken

when

handling

them.

Warnings

• heed all

warnings

on

the

unit

and

in

the

operating

instructions

• do

not

use

this

product

in or

near

water

•

disconnect

a.c.

power

before installing

any

options

•

route

power

cords

and

cables so

that

they

are

not

easily

damaged

•

disconnect

power

before

cleaning

• do

not

use

liquid or aerosol cleaners;

use

only a

damp

cloth

•

dangerous

voltages exist at several

points

in this

product

-to avoid

personal

injury, do

not

touch

exposed

connections

and

components

while

the

power is

on

• do not

wear

hand

jewellery

or

watches

when

troubleshooting

high

current

circuits,

such

as

the

power

supply

• to

prevent

damage

to

equipment

when

replacing fuses, locate

and

correct

the

trouble

that

caused

the fuse to blow

before

applying

power

• to avoid fire

hazard,

replace fuses only with

the

specified type, voltage

and

current

rating -always refer fuse

replacement

to qualified service

personnel

• to avoid explosion, do

not

operate

this

product

in an explosive

atmosphere

unless

it

has

been specifically certified for

such

operation

•

during

installation, do not

use

the

door

handles

or front

panels

to lift the

equipment

because

they

may

open

abruptly

and

injure

you

6540T-00 Nov 97 7

FreewayRange Pro-Bel

ltd

• have qualified

personnel

perform

safety

checks

after

any

completed

service

Cautions

•

use

only

specified

replacement

parts

•

the

front

door

of

the

cabinet is

part

of

the

fire

enclosure

and

should

be kept

closed

during

normal

operation.

• this

product

should

be

powered

only as

described

in

the

user

guide.

•

2.2

Installation

Any Pro-Bel

equipment

may be

mounted

next to

other

equipment

provided

it is

not

subjected

to excessive heat

from

that

equipment.

In

order

to

maintain

a cool,

internal

temperature

, make

sure

that

the fans (if fitted)

and

vents

on

either

side

of

the

equipment

are

unobstructed.

Proper air circulation

requires

that

both

the

fans

and

vents

have

access

to

the

ambient

temperature

room

air

mass

.

•

2.3

EMC

statement

General

Pro-Bel

equipment

has

been

tested

against

the

European

standards

EN50081-1

and

-2. In all

cases,

the

results

depended

heavily on

the

use

of

the

correct cables

and

connectors,

and

their

correct

assembly.

Precautions

applicable

to

each

common

signal

type

are

specified below. Installation

provisions

must

be followed in

order

that

compliance

is

maintained

in service. Normal

practice

as

regards

pushing

cards

fully

home

and

ensuring

that

connectors

are well

seated

is essential to

good

EMe

performance

.

6540T-00

l\Jov

97

8

Pro-Bel

Ltd

Technical

manual

Digital audio connections

Cable

should

be of

good

lIOn

design

with a foil shield,

such

as Canford

DST.

This

shield

must

make

contact

all

round

at

the

entry

to the

mating

connector

body

.

Pro-Bel

equipment

with

AES3

interfaces

is fitted with

'0'

type

connectors

and

the

shield

is

grounded

to

the

chassis

at

the

point

of

entry.

The

'0'

type shield

should

be

of

the

tinned

type

fitted with screw-locks

and

with

dimples

on

the

male

part.

Where a

number

of

channels

use

the

same

connector,

an

overall

shield

is

preferred

in

addition

to individual

shields

and

this

must

also be firmly

grounded

at

both

ends

.

Serial digital video inputs and outputs

Cable

should

be good

quality

75n

design

with

double

braided

screens

such

as

PSFl/3

or

Belden 8281. Pro-Bel

equipment

with Digital Video ('501' or

SMPTE

259M)

interfaces

is

fitted

with

BNC

type

connectors

where

the

shield

is

grounded

to

chassis

at

the

point

of

entry.

BNC

plugs

must

be

of

the

best

quality

as

this

type

is

prone

to

EMC

leakage if

contact

is not good all

round

the

shell.

It is

possible

to

improve

the

emissions

caused

by

this

leakage by

using

cables

with

ferrite collars. This

prevents

leakage affecting

adjacent

cables

in

the

installation

space.

Analogue audio (including time-code)

This

causes

the

least

problem

as

the

signal

spectrum

is

benign

and

the

circuit

designs

generally

reject

most

unwanted

signals. Some

interference

could

occur

if

the

equipment

contains

processors,

etc; so all

screens

are

grounded

at

the

point

of

entry

. Good

quality

cables

with foil

shields

should

be

used

with the shield

carried

through

from

end

to end,

and

connected

to

the

chassis

earth

at

the

point

of

entry

using

a very

short

tail.

Analogue video

As

with

analogue

audio

the

risk lies with

processors

within

the

same

equipment.

All

output

BNCs

have

the

shield

grounded

at the fixing

point

and

most

inputs.

However,

some

inputs

have floating

connectors

for

maintenance

of

common-mode

rejection. Again, only

good

double-screened

cable

such

as

PSFl/3

should

be

used.

6540T-00

l'Jov

97

9

FreewayRange Pro-Bel

ltd

Other signal formats

MAD!

and

binary

high-bit-rate

telecom

signals

should

be

treated

as digital video.

Other

telecom

signals, eg

HDB3

signals

at

34Mbit/s,

8448

and

2048kbit/s

are

more

akin to

analogue

video,

but

the

presence

of

high

frequency

clock

signals

inside

the

frame is

more

likely.

The

installation

of

telecom

equipment

may

require

reference

to

telecom

standards.

These

usually

use

unbalanced

BNC

connections,

but

occasionally

balanced

120Q

circuits

will be

used,

and

should

be

treated

as

AES3

.

Other

balanced

signals

such

as X21

(64,128,384,728

and

2048kbit/s)

should

be

treated

as RS422/y11

control

ports,

and

generally

use

'D'

type

connectors.

Equipment

with

control ports

Cable

should

be

of

good

quality

with

a foil shield.

This

shield

must

make

contact

all

round

at

the

entry

to

the

mating

connector

body

at

both

ends

of

the

cable. Pro-

Bel

equipment

with

control

interfaces

are

fitted

with

'0'

type

connectors

and

the

shield is

grounded

to

chassis

at

the

point

of

entry.

The

'D'

type

shield

should

be

of

the

tinned

type

fitted with screw-locks

and

with

dimples

on

the

male

part.

Ribbon

cables

are NOT

suitable

under

any

circumstances

outside

of

the

equipment

frames

.

•

2.4

Maintenance and

warranty

Warranty

statement

The

warranty

period

covering Pro-Bel

hardware

is 5

years

from

the

date

of

shipment.

During

the

first two

months

of

this

period,

any

defective

product

will

be

exchanged

free

of

charge.

For

the

remainder

of

this

period

any

defective

product

returned

carriage

paid

will

be

repaired

or

replaced

free of

charge

within

our

normal

turnaround

period

of 21

days. Where

the

defect

is

attributable

to

misuse

or

physical

damage

the

warranty

will be

deemed

void with all

costs

associated

with

the

repair

or

replacement

subject

to

charge

.

Standard

repair

charges

will

apply

to

bought

in

items,

power

supplies,

etc.

Repairs

required

in

less

than

the

normal

21

day

period

will

incur

additional

charges.

6540T-00

Nov 97

10

Pro-Bel

ltd

Technical manual

The

warranty

period

covering

software

products

is 90

day

s. Beyond

this

support/maintenance

contracts

are

available

and

depending

on

the

equipment

may

be

mandatory

for a 3

year

period

.

WARNING:

Ensure

that

any

returned

unit

is

adequately

and

appropriately

packed;

for

example

, do

not

pack

static

sensitive

products

in

common

polythene.

•

2.5

Telephone support

If technical

help

or advice is required,

then

in

the

first

instance,

Customers

are

advised

to

contact

their

local sales office.

Customers

with

equipment

directly

supplied

from Pro-Bel,

are

advised

to

contact

Customer

Support,

which

has

been

set

up to

provide

hardware,

systems

and

product

support

for all Pro-Bel

supplied

equipment.

To

use

this

service

please

ensure

you have the following

information:

•

order

acknowledgement

no./System

product

type

no./Your

order

no.

Any

of

these

numbers

will

help

us to quickly

identify

the

equipment

referred

to.

Product

type

numbers

- 4 digits

System

type

numbers

- 4 digits

beginning

with 7

or

8 found on

top

of

rear

panel

of

(custom

equipment)

frames

or on

system

handbooks

•

any

module

numbers

relevant

to

the

fault

and

their

serial

numbers

(e.g.

03/0017/05)

• a clear

description

of

the fault

•

any

relevant historical

information

•

any

other

information

that

might

help

diagnose

the

fault

•

2.6

Custom

Telephone

number

-

er support

depa

44 (0)

118986-612

3

rtment

'.'

.

,,~,'

Fax

number-

44 (0)

118975-5787

Internet

addre

ss -

support

@pro-bel.co.uk

The

department

is

staffed

from

9.00am

to 5

.30pm

Monday to Friday

Additional

support

is available

outside

these

hours

by

purchasing

a

support

contract -

det

ails from

the

abo

ve

number.

6540T-00 Nov 97 11

FreewayRange Pro-Bel

ltd

•

2.7

Repairs

If

the

fault

can

be

isolated

to a single

module,

then

the

module

can

be

sent

for

repair

in

the

following

way

:

•

please

contact

Customer

Support

for a

repair

number

BEFORE

sending

your

repair

to us

•

supply,

with

the

repair

,

the

following information:

•

the

repair

number

• an

order

number

(for

out

of

warranty

repairs)

• a

contact

name

and

telephone

number

• a

description

of

the

fault

symptoms

• a list of

modules

supplied

with

their

serial

numbers

For

correct

address

to

send

your

repairs

to,

see

'Address

Information'

•

2.8

Loans

If a loan

module

is

required

to

cover

a

repair

being

sent:

•

please

contact

Customer

Support,

who

will

arrange

the loan

• a

small

charge

is

made

to

cover

administration,

so

please

have an

order

number

ready

•

the

loan will be

sent

to you in

the

normal

way (urgent deliveries will be

charged

at cost)

•

when

returning

the

loan

please

provide

the

following:

•

the

loan

reference

number,

supplied

with

the

loan

• a

contact

name

and

telephone

number

• a list

of

modules

with

their

serial

numbers

For

correct

address

to

send

your

loan

returns

to, see 'Address

Information'

It is

very

important

that

you

advise

us if you

need

to keep

the

loan

beyond

the

'return

by'

date

.

6540T-00 Nov 9712

Pro-Bel

ltd

Technical manual

•

2.9

Exchanges

Exchanges

are

normally

issued

if a

module

has

gone

faulty

within

the

first two

months

of delivery.

When

returning

your

faulty

module,

which

has

been

ex

changed

,

please

supply

the

following

information

:

•

the

exchange

reference

number

• a

contact

name

and

telephone

numb

er

• a

description

of

the

fault

symptoms

• a list of

module

s

supplied

with

their

serial

numbers

For

correct

address

to

send

your

exchange

returns

to,

see

'Address

Information'

•

2.10

Address information

The

following

addresses

should

be

used

when

sending

repairs,

loan

returns

and

exchange

returns

to Pro-Bel.

UK customers

Customer

Support

Telephone

: 44 (0)

118986-6123

Pro-Bel Limited

Danehill

Lower Earley

Berkshire RG6 4

PB

England

6540T-00

Nov 97 13

Freeway

Range

Pro-Bel

Ltd

US customers

Customer

Support

Telephone:

5168452132

Pro-Bel America

5

IIub

Drive

Melville

NY 11747

Other customers

All

other

customers

should

contact

their

local

agent

, or

UK

Customer

Support

for

their

correct

return

addr

ess.

6540T-00 Nov

97

14

Pro-Bel

ltd

Technical manual

6540T-00 Nov 97 15

FreewayRange Pro-Bel

ltd

3 Installation

During

the

installation

process

it is

important

to

observe

the

following

points

:

• do

not

obstruct

the

vents

on

the

unit

to allow cooling to

take

place

•

remove

shipping

brackets

• 3.1 Door removal

The

frame

has

a

horizontally

hinged

front

panel

door

that

can

be

opened

by

turning

the

knob

anti-clockwise.

The

door

can

be

removed

from

the

frame by

opening

it

approximately

45

(,

and

lifting

upwards.

It will

not

disconnect

from

the

hinge at a

greater

angle.

For

correct

re-fitting

of

the door,

ensure

that

it is

centrally

located

on

the

hinge.

•

3.2

Power supply removal

There

are

two

power

suppl

y

modules

used

for

main

and

backup

. For

EMC

and

safety

reasons

the

mains,

chassis

and

signal

earths

are

permanently

connected

together

with

the

module

.

A

green

LED

on

each

PSU

indicates

the

status

of

the

power

supply.

PSU

relay

alarms

are

also fitted.

The

power

supply

modules

are

push

fit

into

the

frame

and

each

secured

by two

screws

on

the

rear

of the frame.

When replacing

the

power

supply

the

following

recommendations

must

be

observed:

• always

disconnect

the

mains

from the

unit

before

removal

or

during

repair

•

the

securing

screws

should

always

be fitted

before

connecting

the

mains

to

provide

essential

chassis

earthing

Note: The

Freeway

PSU

automatically

adapts

to the voltage

range

supplied. There

is no

need

to set a

mains

voltage selector position.

A WARNING:

The

screws

form

an

essential

chassis

connection

for

ili

EMC

compliance

and

must

not

be

omitted

6540T-00 Nov 97

16

Pro-Bel

ltd

Technical manual

o

o

0

0

©

Power

OK

Power

OK

Green

LED

Green

LED

/\ ©

6 o

"

~

::::

" 0

::::::::::::::::: ::::::::::::::::: ::::::::::::::::: ::::::::::::::::: I

JL~

bf-ln

JL ::::::::::::::::: I::::::::::::::::: II::::::::::::::::: I I::::::::::::::::: I I JL

~

~

I 0

,....,

,...,

.....

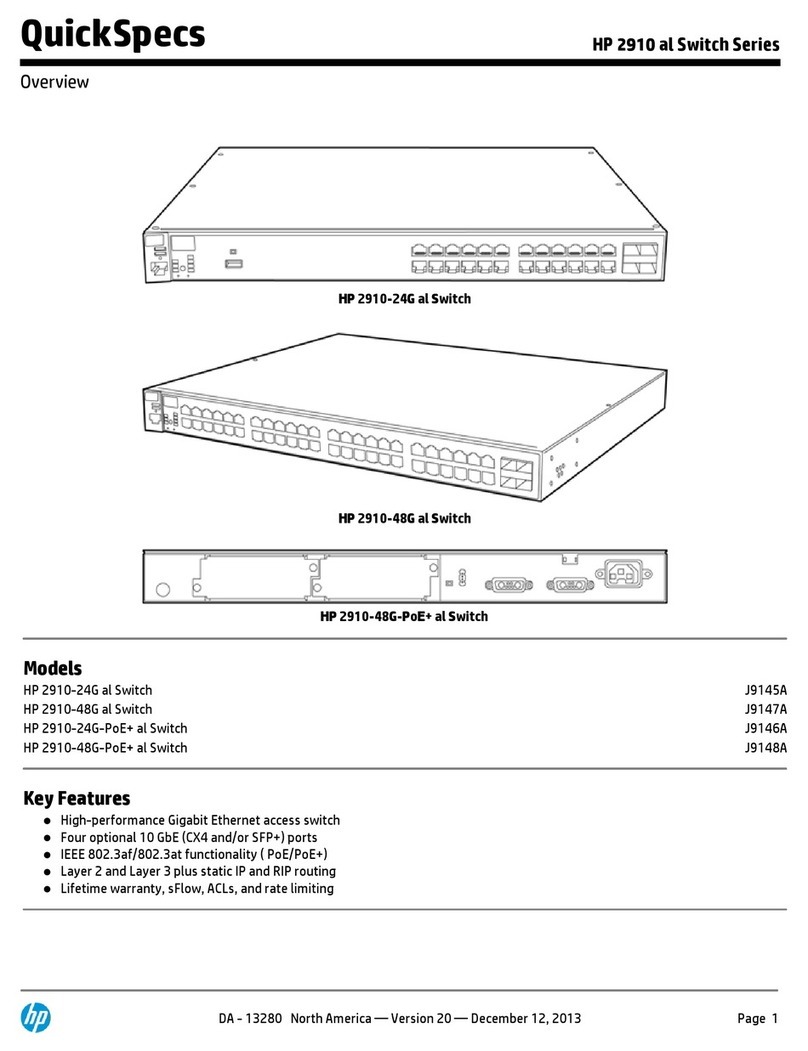

...........

. ....... ..........

.................

................. ::::::::::::::::: ::::::::::::::::: JL

~

I

!:!

Control

panel

Po

sitionof

screws

onrearof panel

6540T

-00 Nov 97 17

FreewayRange

Pro-Bel

Ltd

•

3.3

Signal rear panel removal

Connections

to

the

outside

world

are

made

through

panels

on

the

rear

of

the

frame.

The

control

panel

is

common

throughout

the

Freeway

range

and

is fixed.

The

signal

rear

panels

are

easily

removed

in

the

following

manner:

•

disconnect

power

from

the

frame

•

remove

the

screws

•

gently

pull

panel

out

• replace

panel

and

screws

ensuring

a

good

fit is

made

for

EMC

compliance

The

connection

details

for the

rear

panels

supplied

are

described

in

the

second

part

of

the

Freeway

User Guide.

•

3.4

Removal and replacement

of

modules

The

modules

can

be

removed

and

replaced

from

the

frame,

powered

or

un-

powered,

using

the

following

procedure.

For

removal

purposes

it is

advisable

to

remove

the

ribbon

cables

first

and

then

the

cards.

• release

the

ribbon

cables

by

pushing

the

catches

up on

either

end

of

the

connector

as

shown

• lift up

the

card

ejector

on

the

module

and

gently

pull

the

card

out

Replacement

is

the

reverse

of above:

• slide

the

card

along

the

guide

rail of

the

required

slot,

gently

pushing

it fully

home

until

it

marries

up with

the

connector

on the

motherboard

• if a

card

has

a

board

reset

pin (eg

4740

card), it is wise to exercise

this

when

plugging a

board

in

with

the

power

on

6540T-00 Nov 9718

Pro-Bel

Ltd Technical

manual

Signal

rear

panels

®®

o

®®®

o

®®®®®®

®®®®®®

®®®®®®

®®

®®®®®®

o®®

®®®®®®

@®®®®

o

®®®®®®

0

~o

~~

®®®®®®

U

~

®®®®®®

M

®®®®®®

°

Catches

Top

view

Front

view

6540T-00 Nov 97 19

FreewayRange

Pro-Bel

Ltd

•

3.5

Cable connections

The

standard

cable

connections

diagram

for a

Freeway

router

is

shown

below.

Note: The

Freeway

router

can be

controlled

from

multidropped

panels

(i.e. a

chain

of

panels

on a

common

pin-to-pin cable

bus,

each

set to a

different

address)

on

ports

RS485-1

and

RS485-2 or

from

control

systems

on point to

point

links.

General

Genera

l

PC

editorport remoteport

remote

port

or

general

2/panel l /panel

remote

port3 port port

11 11

625 PALori 1

525

NTSC

i

TTL

pulse

I I

RS232

RS485 RS485

Inputs

...

r

utputs

~

...

.. ... ... ..-... ........\ 9way

/...\

9 way/...\ 9 way!..o...................°-...°--- .. -..........-....

°

Video

ref1

Video

ref2

(looping)

(looping)

I

Freeway Freeway

router router

modules modules

Master

Master

2440 2440

control control

Inter

processo

r

subrnodule

submodu

l

II

(Serial

cornrns)

II

:

-Input

Outpu

...-

s

Rp

RP

ea ea

an an

e e

r

I I

s s

ts

- .

~

.. -. -. . .. . . -

.. ..

-_. ---....-.--.... -------... .....j .

...

.. .... ..

....

........

....

..

----.-

. -- .

...

---- .. -..

\.

37 way

Contro

l

1

o

6540T-00 Nov 97

Parallel

xpt

bus

(to

slave

routers)

20

Table of contents

Other pro bel Switch manuals

Popular Switch manuals by other brands

Ruijie

Ruijie RG-S6250-48XS8CQ Series Hardware installation

NETGEAR

NETGEAR GS108T - ProSafe - Gigabit Smart Switch Hardware installation guide

hager

hager HIC4 T Series quick start guide

VeEX

VeEX OX-MPO-12 Technical notes

VADDIO

VADDIO OneLINK HDMI Integrator's complete guide

D-Link

D-Link DKVM-8 user manual

Alpha Technologies

Alpha Technologies Cordex CXRF 48-3.6kW Installation and operation manual

Bticino

Bticino F67SR64 manual

Lantech

Lantech IPES-5416T Series user manual

SMC Networks

SMC Networks SMC8606SX Specification sheet

Enterasys

Enterasys SecureStack A2 A2H123-24 Hardware installation guide

Raritan

Raritan PARAGON II Series user guide