ProArc PT-103 User manual

OWNER’S MANUAL

Important

:

Read these instructions before installing, operating or servicing this product.

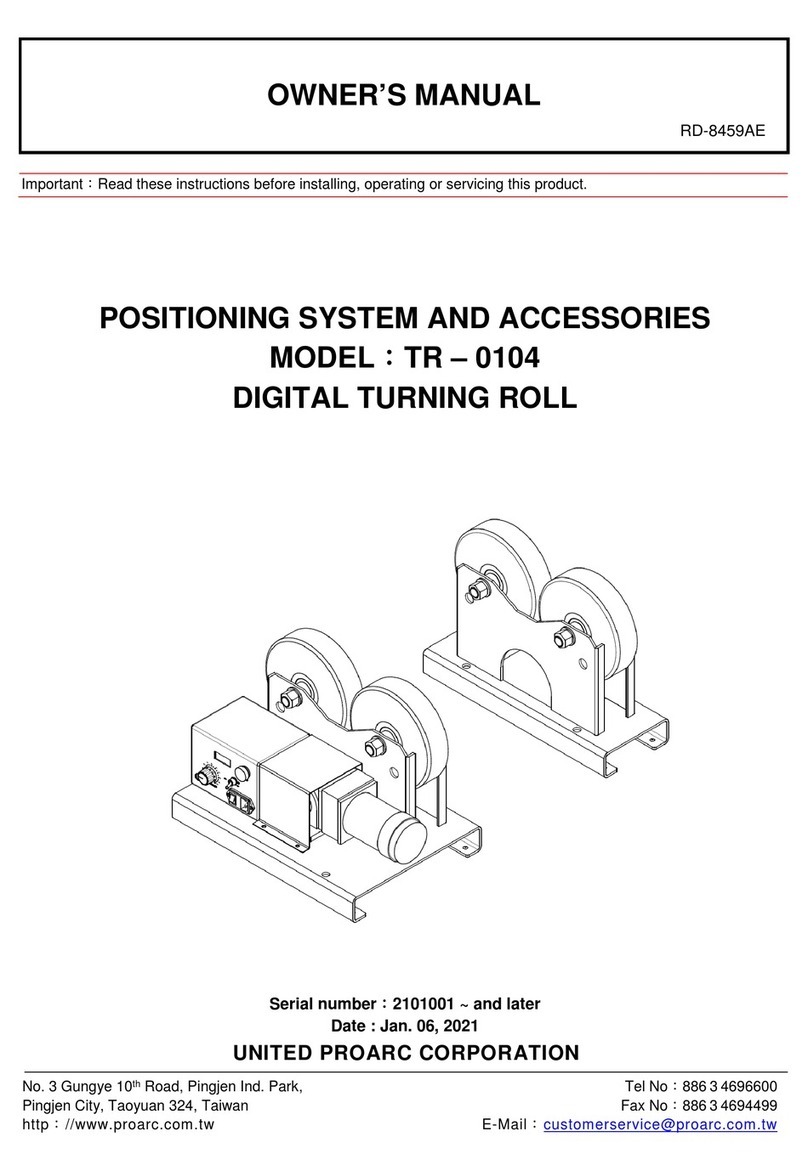

POSITIONING SYSTEM AND ACCESSORIES

MODEL

:

PT‒103 / PT‒203

WELDING POSITIONERS

(With CB-101/CB-102)

Serial number

:

1808001 ~ and later

Date : Aug. 21, 2018

UNITED PROARC CORPORATION

No. 3 Gungye 10th Road, Pingjen Industrial Park, Tel No:88634696600

Pingjen City, Taoyuan 324, Taiwan Fax No:88634694499

http://www.proarc.com.tw E-Mail:customerservice@proarc.com.tw

RD-8457E

TABLE OF CONTENTS

Introduction

Features

Specification

Operation

Troubleshooting

Part list

Circuit diagram

Introduction...............................................................................................................i

Safety precautions ....................................................................................................ii

Limited warranty.......................................................................................................iii

1.1. General information........................................................................................... 1

1.2. Specification...................................................................................................... 2

2.1 Control panel...................................................................................................... 3

2.2 Operation........................................................................................................... 4

2.3 Installation.......................................................................................................... 5

2.4 Timing diagram .................................................................................................. 6

3.1 Troubleshooting ................................................................................................. 7

4.1 Part List ‒Mechanism (PT-103)......................................................................... 9

4.2 Part List ‒Mechanism (PT-203)........................................................................11

4.3 Part List ‒Control box (CB-101) ......................................................................13

4.4 Part List ‒Control box (CB-102) ......................................................................14

5.1 Circuit Diagram .................................................................................................15

i

INTRODUCTION

A procedure, which if not properly followed, may cause injury to the operator

or others in the operating area.

Read and understand this entire manual regarding the rules for users’ safety

before installing, operating, or servicing the equipment.

Equipment identification

Receipt of equipment

The identification number, model, and serial number of this unit usually appear

on a nameplate attached to the control panel; record these numbers for future

reference.

When you receive the equipment, check it against the shipping documents.

Make sure it is complete and inspect the equipment for possible damage

during shipping. If there is any damage, notify the carrier immediately to file a

claim.

Furnish complete information concerning damage claims or mistake(s) in

shipment to United ProArc Corporation: No. 3 Gungye10th Road, Pingjen

Industrial Park, Pingjen City, Taoyuan 324, Taiwan. Include the equipment

identification number along with a description of the parts in question.

Move the equipment to the installation site before uncrating the unit. Use care

to avoid damaging the equipment when using bars, hammers, etc. to uncrate

the unit.

WARNING

WARNING

ii

SAFETY PRECAUTIONS

Operation and maintenance involves potential hazards. All operators and

personnel should be alerted to possible hazards and precautions should be

taken to prevent possible injury.

Electrical safety

Maintenance

Individual safety

Machine:

﹡The counter, safety device against excess current and electrical installation, are

compatible with its maximum power and its main voltage.

﹡The connection, single-phase or three-phase, is possible on a stand compatible

with the plug of its cable link.

﹡If the cable is connected with the electrical network, the earth must never be cut

by the protection device against electrical shocks.

Work Place:

﹡Be very careful to avoid contact between metal part and phase conductor and the

neutral of electric network.

﹡Electrical messes of different electrical machine and apparatus are connected

between themselves and with the terminal of earth neutral wire.

Interventions:

﹡Before control and repair, see the apparatus is switched off and insulated.

﹡Connection with fixed installation cable is impossible.

﹡It’s on “Stop” and connection is impossible.

﹡Some apparatus are provided with starting circuit HT HF (with a plate). Never

enter into the corresponding switch cupboard.

﹡Only qualified persons are authorized for intervention concerning electrical

installation.

﹡Often check the insulation and connection good state of apparatus and electrical

accessories: taps, appliance cords, coatings, switch, extension cords, etc.

﹡Maintenance and repair of insulating coatings operations are very important.

﹡Do repair with a specialist or better replace defective accessories.

﹡Check regularly the right adjustment and the non-heating of electrical

connections.

﹡The operator must be dressed and protected in relation with his work.

﹡Avoid contacting metal parts connected or accidentally connected.

﹡Wear leather gloves with gauntlet.

﹡Safety clothes:gloves, apron, safety shoes protect the operator and his

assistants against burns of hot parts, projections and slag.

WARNING

ii

SAFETY PRECAUTIONS

Gases and fumes

Fire

Noise

Protection goggle

﹡Gases and fumes produced during the plasma cutting or welding process can

be dangerous and hazardous to your health.

﹡Ventilation must be adequate to remove gases and fumes during operation.

﹡Keep all fumes and gases from the breathing area.

﹡Use an air supplied respirator if ventilation is not adequate to remove all fumes

and gases.

﹡Oil or grease in the presence of oxygen may ignite and burn violently. Keep

cylinders, valves, couplings, regulators, hoses, and other apparatus clean and

free from oil and grease. Oxygen cylinders and apparatus should not be

handled with oily hands or gloves. Do not allow an oxygen stream to contact oily

or greasy surfaces.

﹡Do not use oxygen as a substitute for compressed air.

﹡Fire can be caused by hot slag and sparks.

﹡Remove combustibles from working area or provide a fire watch.

﹡Do not cut containers that have held combustibles. Remove all flammable and

combustible materials in the operating area that may be ignited by sparks.

﹡Noise can cause permanent hearing loss.

﹡Wear proper protective ear muffs or plugs.

﹡Make sure others in the operating are protected from noise.

﹡Welding radiation may cause permanent sight damage

Eyes protection goggle recommended

iii

LIMITED WARRANTY

UNITED PROARC CORPORATION warrants all new equipment to be free from defects in material and

workmanship, provided that the equipment is installed and operated according to instructions stated in this

manual.

UNITED PROARC’s obligation under this warranty policy is expressly limited to the replace or repair, at its

option, of the defected part only. ProArc’s option to repair or replacement of a defected part under this

warranty shall be based on FOB Taiwan basis.

UNITED PROARC CORPORATION shall not be liable for any loss or consequential damage or express

accruing directly or indirectly from the use of equipment covered by this warranty.

This warranty supersedes all previous ProArc warranties and is exclusive with no other guarantees or

warranties expressed or implied.

This warranty excludes the consumable parts that are used in normal operation.

1

1.1 GENERAL INFORMATION

Features - Multiple selection of gear reducer for TIG, MAG/MIG welding application.

- High frequency interference tested.

- Tilting angle ranges from 0o ~120o

-Faceplate through-hole Ø22mm for gas purge application.

-Faceplate with 3 straight slots for 3-jaws fixture (PG-150,450L,500) mounting.

-Control box selection:

CB-101 standard controller:Speed adjuster / Welding timer.

CB-102 advanced controller:Speed adjuster / start delay / overlap timer, and home

sensor.

CB-107 Multi-function controller:PLC with HMI process control to support various E.Z.Arc

system assembly.

2

1.2 SPACIFICATION

Model Unit PT-103 PT-203

Power input ~ 1 Phase 100 ~ 240V 50/60Hz

Capacity(Horizontal/Vertical) kg 100 / 60 200 / 130

Rated eccentricity mm A:180, B:90, C:60, D:45 A:84, B:42, C:28, D:10

Table dimension (E) mm ψ320

Rotation speed rpm A:0.3 ~ 4 B:0.6 ~ 8 C:0.8 ~ 12 D:1 ~ 16

Spindle thru hole mm ψ22

Earthing Amp 200 @ 100% ( 300 @ 40% )

Tilt range deg. 0 ~ 120

Welding timer sec. 0 ~ 60

Overall length (A) mm 460

Overall width (B) mm 315

Overall height (C) mm 340

Center to floor (D) mm 250

Net weight kg 38 42

3

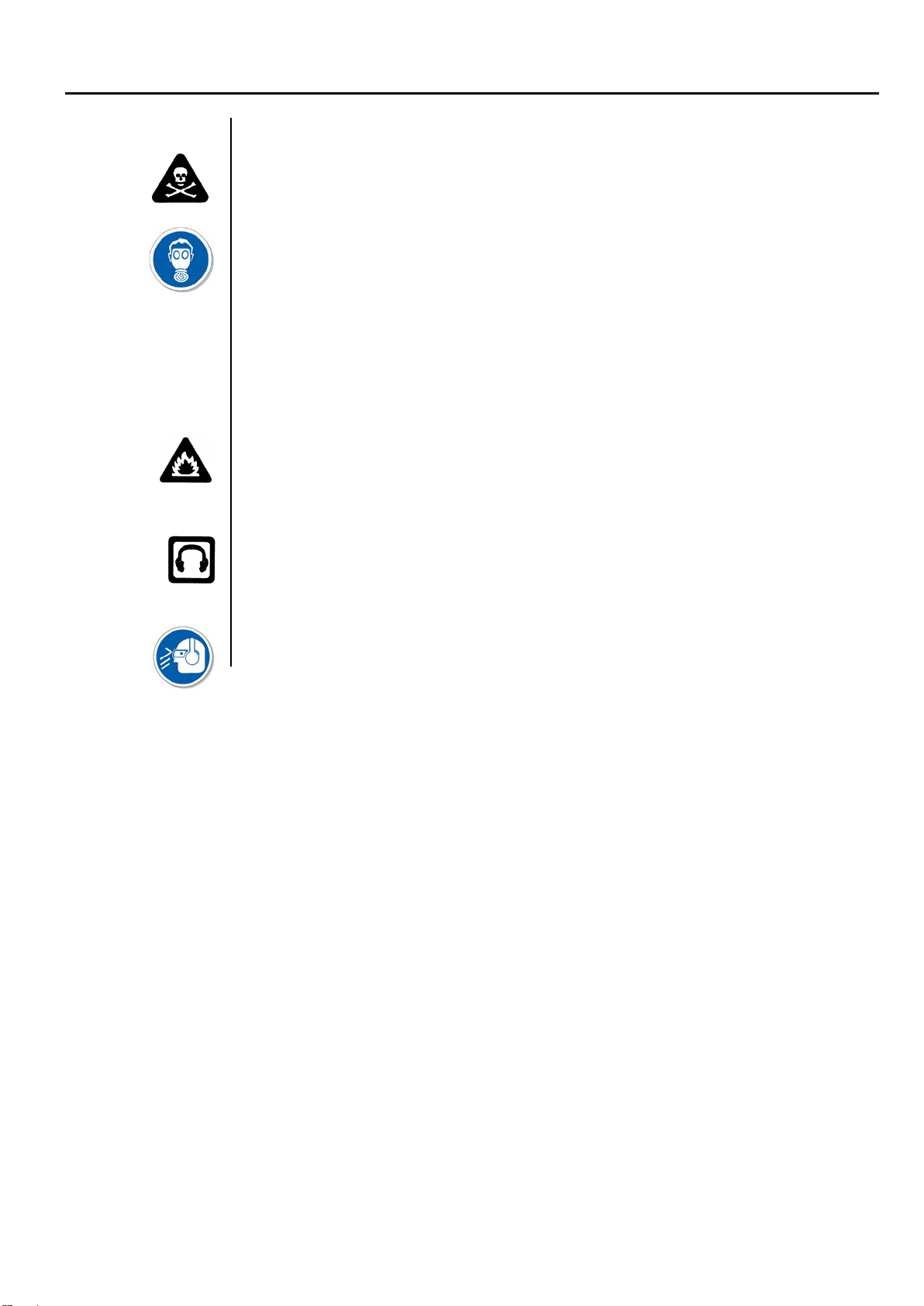

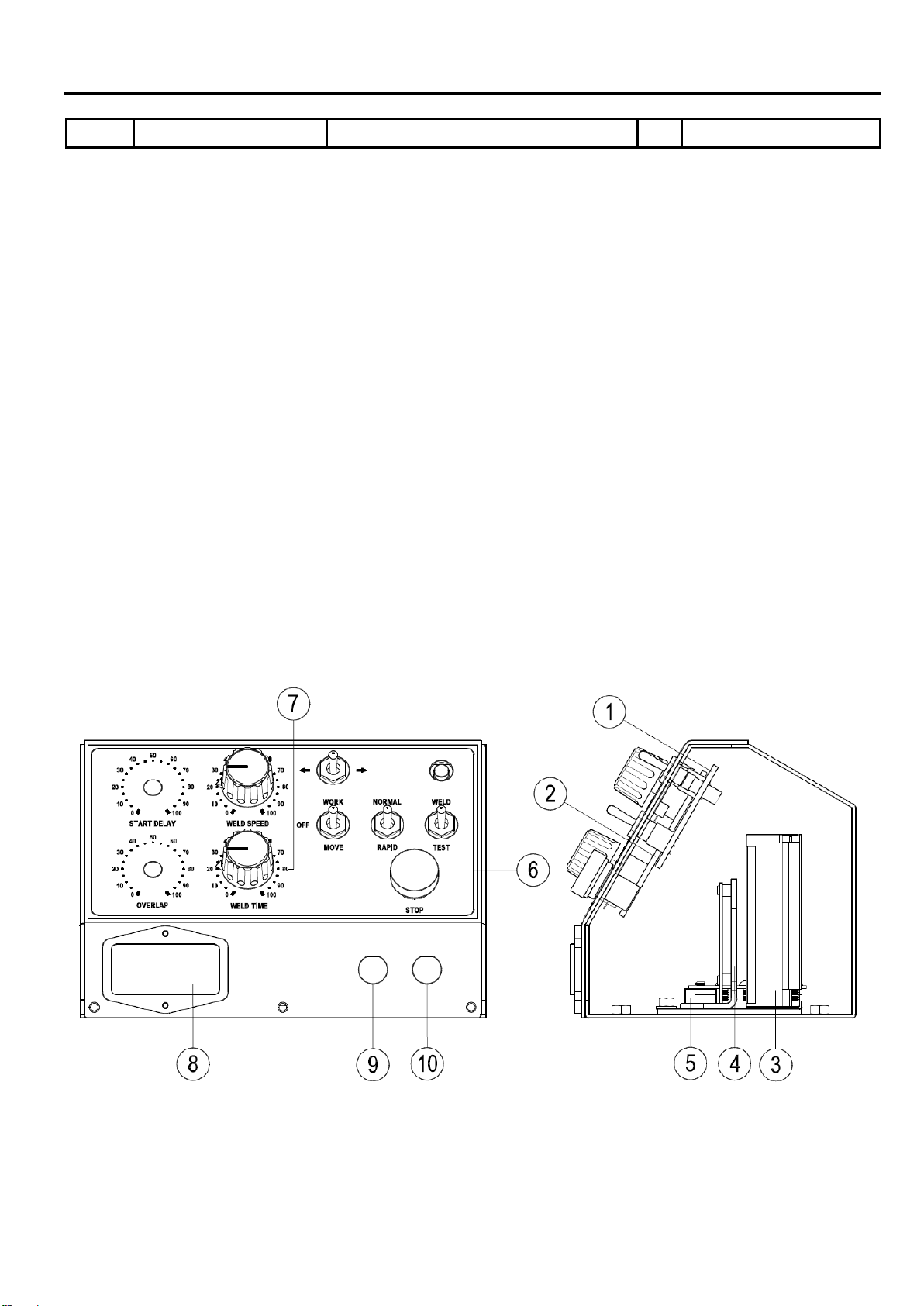

2.1 CONTROL PANEL

1. Power On signal (LED)

2. CW/CCW selection switch. (SW1)

3. Weld / Test mode selection switch. (SW4)

4. Normal / Rapid speed selection switch. (SW3)

5. Work / Move mode selection switch. (SW2)

6. Stop button (STOP)

7. Welding speed adjustment. (VR1)

8. Welding timer adjustment. (VR2)

9. Welding start delay timer adjustmen.t (VR3) (For CB-102)

10. Welding overlap timer adjustment. (VR4) (For CB-102)

11. Power switch. (PSW)

12. Foot switch connector. (P1)

13. Power source connector. (P2)

4

2.2 INSTALLATION

Power cord. Connect the power cord to 1 phase 100V~240VAC

Note:The standard power connector is NEMA-5-15P, different region may select different power

connector.

NEMA-5-15P(Standard) European Adapter(Option) Australian Adapter(Option)

Grounding Stud

To avoid potential electrical damage, please connect the grounding stud to actual ground.

Tilt Lock / Release Handle

Clockwise rotation to lock, counter clockwise rotation to release

Danger! Do not release the tilt handle when part is loaded on the faceplate.

(PSW) Power Switch

I = On,O = Off

LED Indicator Color Identification.

Green:Standby.

Red:Stop button activated.

White:Auto-procedure in progress.

Flashing Green:Homing sequence in progress. (CB-102 only)

Flash Red:Overload.

Forward / Reverse Switch (SW1)

Faceplate rotation direction.

CW ( ) / CCW ( )

Forward

Reverse

5

2.3 OPERATION

WORK / OFF/MOVE Toggle Switch (SW2)

WORK:Enable the system in “WORK procedure” standby. Press/release the footswitch to start “WORK

procedure”. Faceplate rotates according to timer VR1-VR4.

OFF:Reset error and stop work procedure.

MOVE:Enable the system in “MOVE” procedure standby. Press the footswitch to start the rotation, and

release footswitch to stop the rotation. Rotation speed varies according to VR1 or SW3 setting.

NORMAL / RAPID Toggle Switch (SW3)

NORMAL:Faceplate rotation speed varies according to WELD SPEED Knob (VR1).

RAPID:Faceplate rotates with maximum speed.

WELD / TEST Toggle Switch (SW4)

WELD:Welder output(P2) will be enabled when faceplate start rotating in either WORK or MOVE (SW2)

procedure.

TEST:Welder output (P2) is disable in WORK/MOVE procedure.

Note:Welder output (P2) type : Relay dry contact.

Speed Adjustment Knob (VR1)

Adjust rotation speed. CW to increase rotation speed. CCW to decrease rotation speed.

Weld Timer Knob (VR2)

Active in WORK procedure. Weld Timer is the duration of rotation after footswitch is triggered. Adjustable

between 1~60 second.

Start Delay Knob (VR3) (CB-102 only)

Active in WORK procedure. Start delay is the time delay before faceplate rotation. Adjustable between

0-9.9 second.

Overlap Knob (VR4) (CB-102 only)

Active in WORK procedure. Overlap is the time delay after faceplate has hit the home sensor before

faceplate stops rotation. Adjustable between 0-9.9 second

STOP Button

Press to stop the all control. Rotate CW/Pull to reset.

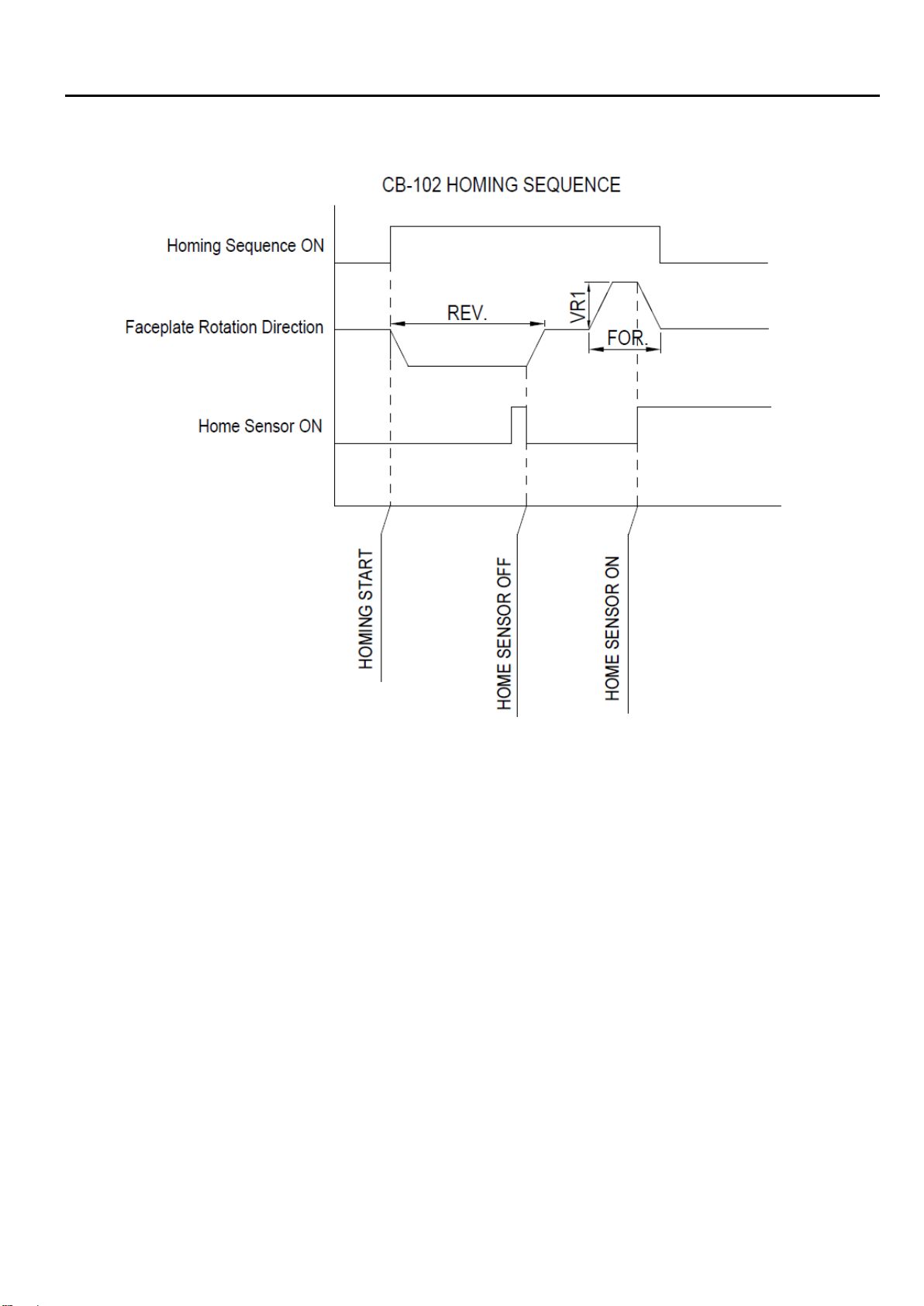

Homing Sequence (CB-102 only)

Homing sequence activates automatically when below condition are met.

A. Right after placing WORK / MOVE toggle switch (SW2) in WORK position.

B. 2 seconds after end of “WORK procedure”.

C. Flipping Forward/Reverse (SW1) switch in “WORK procedure” standby.

D. Reset the STOP button in “WORK procedure” standby.

Note:Homing sequence is divided into 2 stages. Faceplate first rotates in half of maximum speed until

home sensor is triggered and stops. Then faceplate rotates according to VR1 setting to trigger

the home sensor again. Problem may rise in second stage when VR1 is adjusted too small.

Warning:Homing sequence is a semi-automatic process that activates when above conditions

are met. Operator caution is advised.

Variable Speed Foot Switch (Option)

Variable foot switch change welding speed as a percentage of VR1. Example1, Set weld speed

knob 100% and external variable foot switch 50%, the resulting rotation speed is 100% x 50% =

50%. Example2, Set weld speed knob 50% and external variable foot switch 50%, the resulting

rotation speed is 50% x 50% = 25%.

6

2.4 TIMING DIAGRAM (CB-102)

7

3.1 TROUBLESHOOTING GUIDE

SYMPTOMSPOSSIBLE CAUSES / REMEDIES

Power indicator LED does not

illuminate.

A. Blown fuse: Check the fuse, replace fuse when necessary.

B. Input power switch malfunction:Check and replace the power

switch.

C. Check for any loose cable connection between Control Board and

Switch Board.

D. LED malfunction, replace Switch Board.

E. Power supply malfunction, use a voltmeter and check power

supply’s 24VDC output.

Motor has no motion.

A. Damaged motor:

Use ohmmeter to measure CM1 female plug pin

1

& Pin2 and It should read around 2ohm. Replace motor when

reading is either 0 (short circuit between wires) or infinite (broken

wires)

B. Check motor power cable for loose or disconnect cable.

C. Damaged foot switch:

Step on the footswitch and use an ohmmeter

to measure footswitch connector pin4 and pin5

. The reading should

be 0 (short circuit). Replace the footswitch when necessary.

D. Inspect Control Board JP2 for loose connection

E. Inspect Control Board fuse F1

Welder start output no response. A. Damaged Weld / Test toggle switch (SW4), replace Switch Board.

B. Inspect Control Board JP3 for loose connector.

Forward / Reverse rotation

function no response.

A. Switch Board:Step on the footswitch and flip the CW/CCW toggle

switch(SW1). Observe the TR and TL LED on the Control Board

. If

both LEDs have no response, replace the Switch Board.

Speed adjustment no response

A. Take the VR Board JP1 connector off. Rotate the weld speed knob

and measure JP1 Pin1 & Pin2’s resistance. The value should

varies from 0-10kΩ. If there is no variation, check for any

disconnection or replace VR1.

B. Check for any loose cable connection between VR Board and

Switch Board.

C. Normal / Rapid toggle switch (SW3) is set to Rapid position

causing the faceplate to rotate at max speed. Flip to “Normal”

position.

8

3.2 TROUBLESHOOTING GUIDE (CB-102)

SYMPTOMS POSSIBLE CAUSES / REMEDIES

Weld timer function no

response.

A. Take VR Board JP2 connector off. Rotate the Start Delay knob and

measure JP2 Pin 1 & 2’s resistance. The value should vary from

0-10kΩ. If there is no variation, check for any disconnection or

replace VR2.

B. Check for any loose cable connection between VR Board and Switch

Board.

Overload (Blinking Red LED) Inspect the work and make sure it isn’t over-spec (weight /

eccentricity ...etc). Place the Work/Move switch (SW2) in “OFF” position

to reset the system.

Home sequence problem

A. Work / Move switch (SW2) malfunction, replace Switch Board.

B. If the green LED is flashing and there is no rotation, place the

Work/Move switch (SW2) in “Move” position and adjust the welding

speed knob (VR1) to desired speed. Restart the homing sequence.

C. Proximity switch too far:Adjust the proximity switch so it can sense

the homing block correctly.

D. Proximity switch malfunction: use a screwdriver to test trigger the

proximity switch. Replace when necessary.

Overlap delay function

inaccurate or no response

A. Take VR Board JP4 connector off. Rotate the OVERLAP knob and

measure JP4 Pin 1 & 2’s resistance. The value should vary from

0-10kΩ. If there is no variation, check for any disconnection or

replace VR4.

B. Check for any loose cable connection between VR Board and

Switch Board.

Welding start delay function no

response

A. Take VR Board JP3 connector off. Rotate the START DELAY knob

and measure JP3 Pin 1 & 2’s resistance. The value should vary

from 0-10kΩ. If there is no variation, check for any disconnection or

replace VR3.

B. Check for any loose cable connection between VR Board and

Switch Board

9

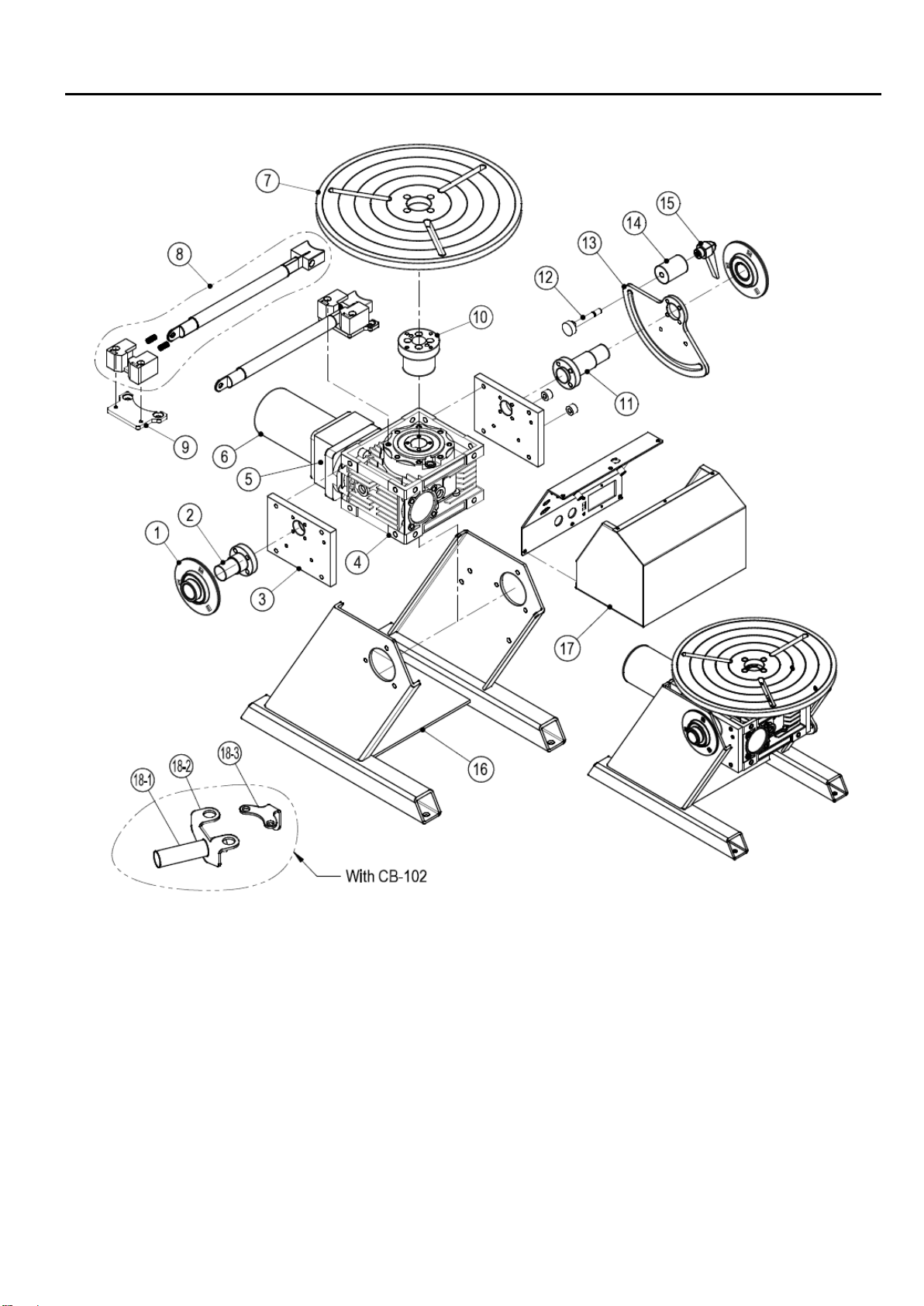

4.1 PART LIST ―MECHANISM (PT-103)

Item.

Part No.

Description

Q’ty

Remark

1 0312-0501 Shaft 2

2

5012-1150200-11

Reducer shaft

1

3 5112-1130000-10 Reducer fixing plate 2

4 0353-0332 Worm reducer 1

5 0351-0109 Gear reducer (15K) 1 A:0.3~4 rpm

0351-0115 Gear reducer (7.5K) 1 B:0.6~8 rpm

0351-0122 Gear reducer (5K) 1 C:0.8~12 rpm

0351-0129 Gear reducer (3.6K) 1 D:1.0~16 rpm

6

*

0361-1002-9

PMDC Motor w/ cable & terminals

1

7 5010-1010100-10 Faceplate 1

8 5010-2040010-20 Grounding brush w/ conducting seat 1

9

5114-12305105000-10

Grounding brush mounting plate

1

10 5114-12305104000-10 Reducer flange 1

11 5012-1150100-20 Reducer Shaft 1

12 5012-2320000-20 Tilt fixing axle 1

13 5012-2300000-20 Tilt angle plate 1

14 5012-2310000-20 Tilt fixing module 1

15 0130-0125 Tilt fixing handle 1

16

5012-1120000-20

Base column plate

1

17 6511-0110 Control box 1 CB-101 (Option)

6511-0120 Control box 1 CB-102 (Option)

18-1

*

3231-2007-9

Proximity sensor w/ connector

1

With CB-102

18-2 5010-4041000-30 Proximity sensor bracket 1 With CB-102

18-3 5010-4040000-30 Fixed sensing plate 1 With CB-102

*Recommended spare parts

10

4.1 PART LIST ―MECHANISM (PT-103)

11

4.2 PART LIST ―MECHANISM (PT-203)

Item.

Part No.

Description

Q’ty

Remark

1

0312-0501

Bearing

2

2 5012-1150200-11 Reducer shaft 1

3 5112-1130000-10 Reducer fixing plate 2

4 0353-0332 Worm reducer 1

5

0351-0109

Gear reducer (15K)

1

A:0.3~4 rpm

0351-0115 Gear reducer (7.5K) 1 B:0.6~8 rpm

0351-0122

Gear reducer (5K)

1

C:0.8~12 rpm

0351-0129

Gear reducer (3.6K)

1

D:1.0~16 rpm

6 *

0361-1002-9 PMDC Motor w/ cable & terminals 1

7 5010-1010100-10 Faceplate 1

8

5010-2040010-20

Grounding brush w/ conducting seat

1

9 5114-12305105000-10 Grounding brush mounting plate 1

10

5114-12305104000-10

Reducer flange

1

11 5012-1150100-20 Shaft 1

12 5012-2360000-22 Tilting worm reducer 1

13

3053-1002

Tilting hand wheel

1

14 5012-2350000-20 Tilting worm shaft 1

15 0331-2003 Self-lubricating bushing 2

16

5012-2340000-20

Mounting bracket

2

17 5012-1120000-20 Base column plate 1

18 6511-0110 Control box 1 CB-101 (Option)

6511-0120

Control box

1

CB-102 (Option)

19-1 *

3231-2007-9 Proximity sensor w/ connector 1 With CB-102

19-2 5010-4041000-30 Proximity sensor bracket 1 With CB-102

19-3

5010-4040000-30

Fixed sensing plate

1

With CB-102

*Recommended spare parts

12

4.2 PART LIST ―MECHANISM (PT-203)

13

4.3 PART LIST ―CONTROL BOX (CB-101)

Item.

Part No.

Description

Qty

Remark

1

*

6622-1010

Printed circuit board

1

Switch board

2

*

3922-1210

Printed circuit board

1

VR Board

3

3326-0008

Power supply

1

4

*

6651-1110

Printed circuit board

1

Motor speed control board

5

3545-5001

Grounding copper bar

1

6

3214-2009

Push button

1

7

3216-0006

Knob

2

VR1~VR2

3747-1001-8

Potentiometer w/Connector

2

8

3331-2001

IEC Inlet filter

1

PSW

9

3242-1116

Foot switch

1

3124-2006

Socket male 5Pin

1

P1

10

3123-2005

Plug female 4Pin

1

3124-2005

Socket male 4Pin

1

P2

*Recommended spare parts.

This manual suits for next models

1

Table of contents

Other ProArc Welding Accessories manuals

Popular Welding Accessories manuals by other brands

AOSafety

AOSafety AOTuffmaster Heat Reflective Aluminum-Infused... brochure

3M

3M Speedglas Utility User instructions

Lincoln Electric

Lincoln Electric W000315558 Safety instruction for use and maintenance

Kemppi

Kemppi SuperSnake GT02SW operating manual

Miller Electric

Miller Electric RGCR-1A owner's manual

GYS

GYS TF 4R manual