EN

1. PREFACE

1.1 General

Congratulations on choosing the SuperSnake equipment. Used correctly, Kemppi products

can signicantly increase the productivity of your welding, and provide years of economical

service.

This operating manual contains important information on the use, maintenance and safety of

your Kemppi product. The technical specications of the device can be found at the end of the

manual.

Please read the manual carefully before using the equipment for the rst time. For your

own safety and that of your working environment, pay particular attention to the safety

instructions in the manual.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

Important notes

Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with the ’NOTE!’ notation. Read these sections carefully and follow

their instructions.

Disclaimer

While every eort has been made to ensure that the information contained in this guide

is accurate and complete, no liability can be accepted for any errors or omissions. Kemppi

reserves the right to change the specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit the contents of this guide without

prior permission from Kemppi.

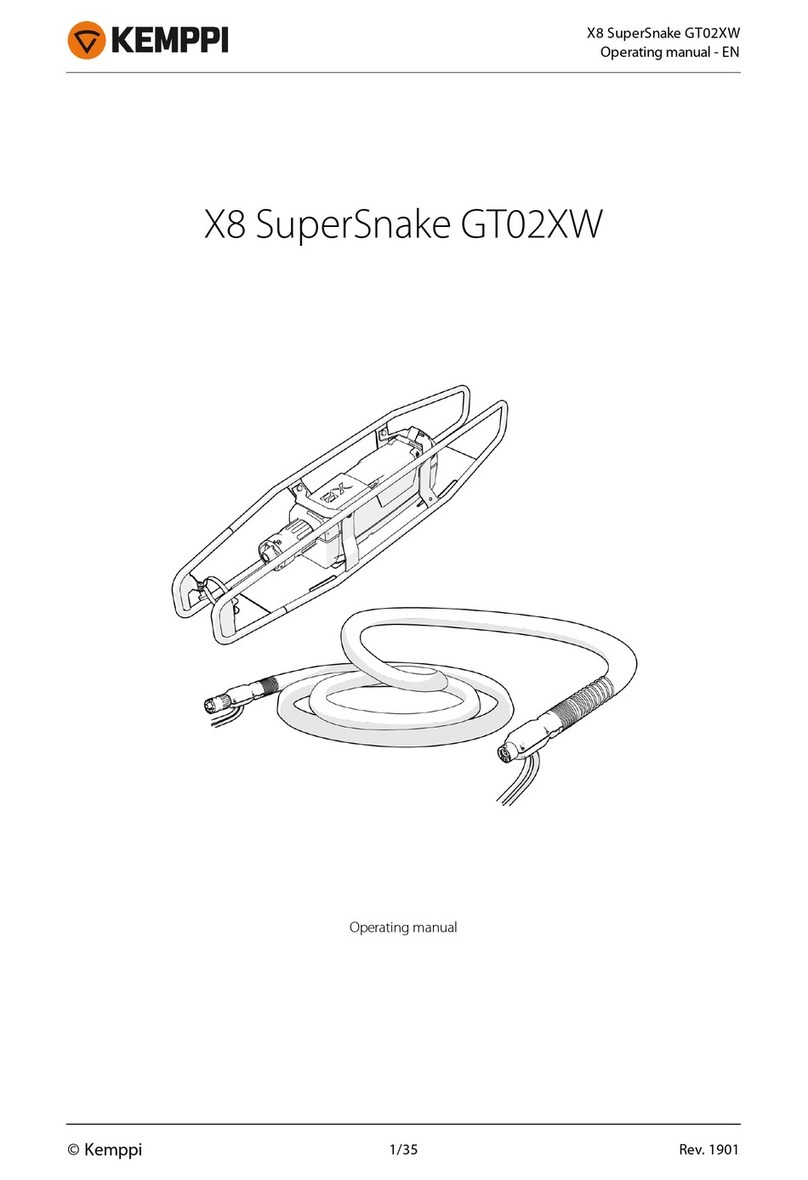

1.2 About SuperSnake products

SuperSnake is a combined solution for distance wire feeding and restricted access welding. It

extends the reach of standard euro MIG/MAG welding guns up to 30 metres, providing simple

distance wire feeding for a variety of ller wires, taking quality welding to locations other

welding equipment can’t reach.

SuperSnake models connect easily to FastMig MXF/MXP wire feed units with a special MXF

synchronisation kit, and to ProMig 501, 501L and 530 wire feed units with a ProMig 50

synchronisation kit.

3

© Kemppi Oy / 1336