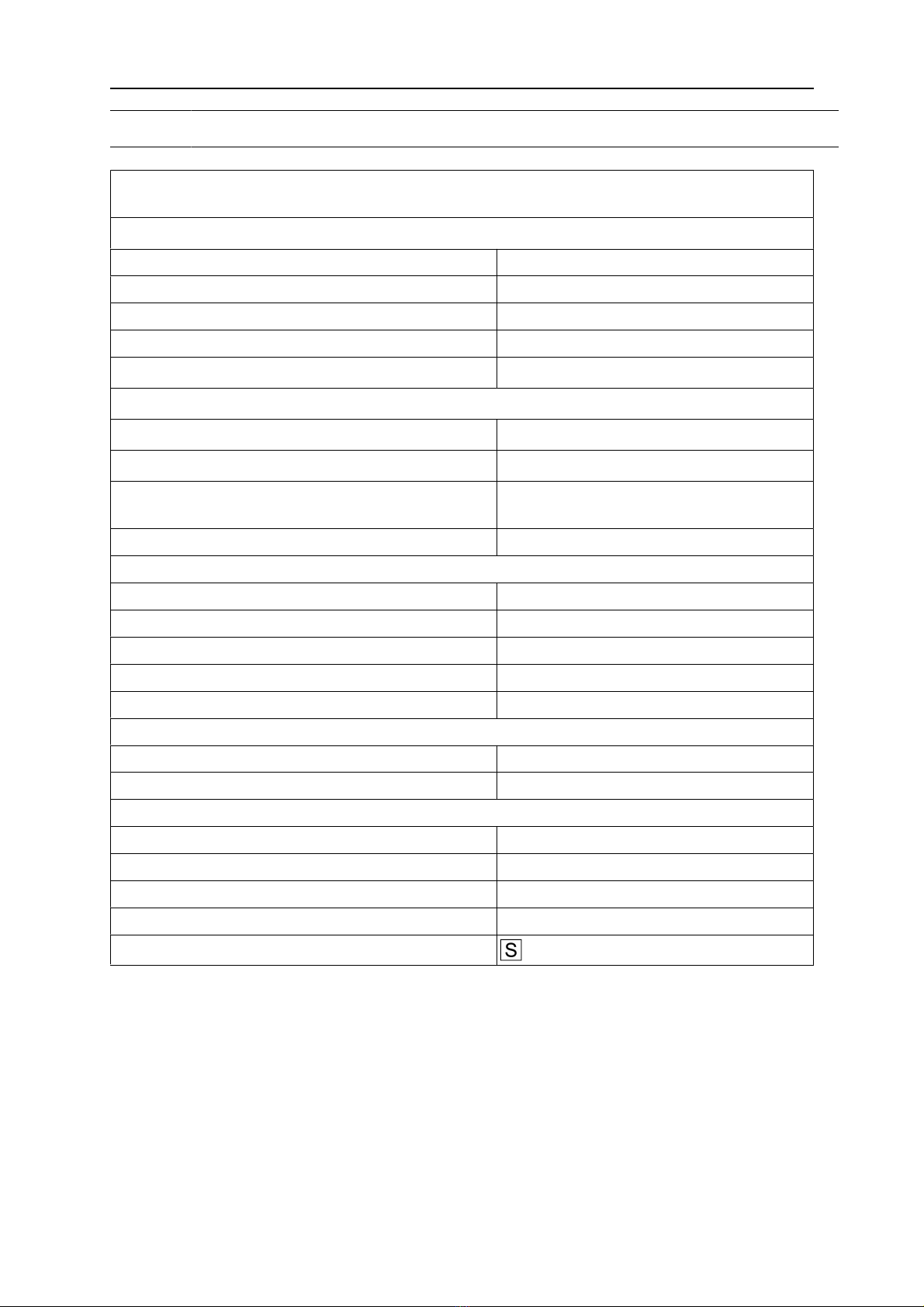

TABLE OF CONTENTS

0463 601 001 © ESAB AB 2022

1SAFETY ....................................................................................................... 4

1.1 Meaning of symbols ............................................................................... 4

1.2 Safety precautions ................................................................................. 4

2INTRODUCTION.......................................................................................... 7

2.1 Equipment ............................................................................................... 7

2.2 Before setup of your WeldCloud™ Universal Connector................... 7

2.2.1 Charging the lithium-ion battery ........................................................... 7

3TECHNICAL DATA ...................................................................................... 8

4INSTALLATION............................................................................................ 9

4.1 Main components ................................................................................... 9

4.2 Inserting the lithium-ion battery into the electronics box .................. 10

4.3 Installing WeldCloud™UniversalConnector ...................................... 10

4.3.1 Replacing connector............................................................................. 11

4.4 Setup of WeldCloud™UniversalConnector........................................ 13

4.4.1 Setting up a site in WeldCloud ............................................................. 13

4.4.2 Downloading and installing the WeldCloudLink application ................ 15

4.4.3 Powering up the WeldCloud™ Universal Connector............................ 15

4.4.4 Pairing the Android device to the WeldCloud™ Universal Connector.. 15

4.4.5 Connecting the WeldCloud™ Universal Connector to a local Wi-Fi

network and to WeldCloudCloudPlatform...........................................

16

4.4.6 Setup additional weld parameters ........................................................ 17

4.4.7 Factory reset ........................................................................................ 18

5OPERATION ................................................................................................ 19

5.1 Power supply .......................................................................................... 19

5.2 Operation modes .................................................................................... 19

5.3 Status indication LEDs .......................................................................... 19

5.4 Measuring and storing data................................................................... 21

5.5 Welding system compatibility ............................................................... 21

5.5.1 Test voltage .......................................................................................... 21

6MAINTENANCE........................................................................................... 23

6.1 Inspection and cleaning......................................................................... 23

6.2 Validation ................................................................................................ 23

6.3 Charging the lithium-ion battery ........................................................... 23

6.3.1 Storing the Universal Connector .......................................................... 23

7TROUBLESHOOTING ................................................................................. 24

8ORDERING SPARE PARTS ........................................................................ 25

DIAGRAM ............................................................................................................ 26

ORDERING NUMBERS....................................................................................... 27

WEAR PARTS...................................................................................................... 28

ACCESSORIES ................................................................................................... 29

Rights reserved to alter specifications without notice.