Procentec VPGate User manual

VPGate Manual

PROFIBUS to serial

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 2/82

Important information

Purpose of the Manual

This user manual provides information how to work with the VPGate PROFIBUS to serial.

Document Updates

You can obtain constantly updated information on PROCENTEC products on the Internet at

www.procentec.com

You can also contact PROCENTEC Customer Support:

•by phone at +31-(0)174-671800

•by fax at +31-(0)174-671801

•by email at support@procentec.com

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 3/82

Content

Important information........................................................................................... 2

1. Technical Specifications................................................................................. 5

1.1 General characteristics ......................................................................................................................5

1.2 Electrical characteristics ....................................................................................................................7

1.3 Mechanical characteristics ................................................................................................................7

2. Hardware Setup............................................................................................. 8

2.1 Connectors pin out ............................................................................................................................8

2.1.1 Power connector ...............................................................................................................................8

2.1.2 SERIAL Connector ..............................................................................................................................8

2.1.3 Digital input .......................................................................................................................................9

2.1.4 Digital output.....................................................................................................................................9

2.2 Front panel indicators......................................................................................................................10

2.3 DIP switches.....................................................................................................................................10

2.3.1 Selecting the RS-232/RS-485 modes ...............................................................................................10

2.3.2 Termination resistance....................................................................................................................11

2.4 Selection of the PROFIBUS address .................................................................................................12

3. Software Setup for PROFIBUS DPV0............................................................ 13

3.1 Configuration tool for PROFIBUS DP Master DPV0 .........................................................................13

3.2 Include VPGate into a project..........................................................................................................13

3.2.1 Import the VPGate GSD file into the third party configuration tool................................................13

3.2.2 Insert VPGate into the network configuration ................................................................................14

3.3 VPGate parameters .........................................................................................................................14

3.3.1 General parameters.........................................................................................................................14

3.3.2 Setup VPGate in TRANSPARENT mode............................................................................................16

3.3.3 Setup VPGate as MODBUS Master ..................................................................................................18

3.3.4 Generic master mode: PASS-FRAME function.................................................................................23

3.3.5 Setup VPGate as MODBUS slave .....................................................................................................24

3.4 Insertion of Input / output modules................................................................................................25

3.4.1 When VPGate is in TRANSPARENT mode ........................................................................................25

3.4.2 When VPGate is in Master MODBUS mode.....................................................................................28

3.4.3 When VPGate is in MODBUS Slave mode........................................................................................29

4. Fail safe mode.............................................................................................. 31

5. DPV1 PROFIBUS acyclic functionalities........................................................32

5.1 Configuration tools of the PROFIBUS DPV1 master.........................................................................32

5.2 Identification Informations..............................................................................................................32

5.3 Acyclic communication in «MODBUS master» mode......................................................................33

5.3.1 Description of the index 0 «COMMAND»........................................................................................34

5.3.2 Description of the index 1 «STATUS» ..............................................................................................34

5.3.3 Description of the index 2 «ADDRESS»............................................................................................35

5.3.4 Description of the index 3 «FUNCTION» .........................................................................................35

5.3.5 Description of the index 4 «OFFSET» ..............................................................................................36

5.3.6 Description of the index 5 «LENGTH» .............................................................................................36

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 4/82

5.3.7 Description of the index 6 «DATA» .................................................................................................36

5.4 Example ...........................................................................................................................................36

6. Digital I/O’s .................................................................................................. 38

6.1 Digital output...................................................................................................................................38

6.2 Digital input .....................................................................................................................................38

7. Diagnostic ....................................................................................................40

7.1 PROFIBUS extended diagnostic .......................................................................................................40

7.2 Digital output for diagnostic............................................................................................................42

8. Firmware Update......................................................................................... 43

9. Appendices ..................................................................................................44

Appendix A: List of errors sent by VPGate..................................................................................................44

Appendix B: Format of MODBUS messages................................................................................................49

10. ‘Other PROCENTEC products’......................................................................71

11. Sales offices and distributors.......................................................................73

12. About PROCENTEC....................................................................................... 78

13. Notes ........................................................................................................... 79

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 5/82

1. Technical Specifications

1.1 General characteristics

PROFIBUS DPV0 and DPV1

Baud Rate

9.6kbps –12 Mbps (Auto Baud)

Connector

DB9 female

Bus Address

7 DIP switches

PROFIBUS Versions

DP V0, DP V1 (1 connection MS-C1 and 1 connection MS-C2)

Diagnostic

27 bytes of extended diagnostic, 6 status indicators

Input Bytes

0 –244

Output Bytes

0 –244

Max number of

Inputs/Outputs

488

Isolation

1 kV

Others

Sync, Freeze, Fail-Safe

SERIAL LINK

Baud Rate

1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200 baud

Data bits

7 or 8 bits

Interface

RS-232 or RS-485

Distance

Maximum 1200m copper cable without repeater (depending on speed and

cable quality)

Cable

Shielded twisted pair

Connector

Female open style connector 3 contacts

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 6/82

Bus termination resistor

120 Ω configurable by switches

TRANSPARANT MODE

End of frame delimiter

EOF character, known length, on timeout

MODBUS MODE

Bus Access

Master or Slave

Protocol

MODBUS RTU or ASCII

Max number of devices

on the network

32

Supported Functions

1, 2, 3, 4, 5, 6, 7, 15, 16; 23

Number of slave

accessible by the master.

20 MODBUS Slaves in PROFIBUS DPV0

247 slaves in PROFIBUS DPV1

Range of slave addresses

1 –247

Number of accessible

MODBUS registers

1 - 122 read registers with PROFIBUS DPV0

1 - 122 write registers with PROFIBUS DPV0

1 –120 read/write registers with PROFIBUS DPV1

Max total number of

accessible MODBUS

registers

244 with PROFIBUS DPV0

Unlimited with PROFIBUS DPV1

Number of messages

1 - 20 different MODBUS messages with PROFIBUS DPV0

Unlimited with PROFIBUS DPV1

Message trigger

Cyclic, On change, Once with PROFIBUS DPV0

On demand with PROFIBUS DPV1

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 7/82

INPUT / OUTPUT

1 digital isolated input

0 –24 V

1 relay output

Switch contact (rated current 1.2A, switching current 0.5A)

1.2 Electrical characteristics

POWER SUPPLY

Input Voltage

24V DC +/- 10%

Current consumption

40 mA -1 W at 24V DC

75 mA - 0.9 W at 12V DC

Connector

Open style 3 contacts, female

Polarity protection

Yes

Short circuit protection

Yes

1.3 Mechanical characteristics

MECHANICAL

Housing

Plastic box

IP20 –DIN rail mountable

Dimensions

120 x 100 x 23 mm (L x W x H)

Weight

About 100g

Storage Temperature

-25°C…+70°C

Operating Temperature

0°C…+55°C

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 8/82

2. Hardware Setup

2.1 Connectors pin out

2.1.1 Power connector

Pin

Name

Description

1

24 V DC

Power supply 24 V ± 10%

2

0 V DC

Power supply 0 V

3

Earth

Earth

2.1.2 SERIAL Connector

Pin

Name

Description

1

Rx

Rx RS-232 (VPGate < device)

2

Tx

Tx RS-232 (VPgate > device)

3

GND

RS-232 grounding

4

Shield

Earth

5

Data -

Signal Data - RS-485

6

Data +

Signal Data + RS-485

Important: The shield of the SERIAL RS-485 cable must be connected to the earth at each end in

order to protect against EMC. Pin 4 of the connector may be used. In this case the earth pin of the

power connector must be connected.

However, it is better to use a shield clamp, fixed at each end of the serial cable on a grounding rod

or a bottom plate of a cabinet.

Fig. 1 Connector on top of the enclosure

1

2

3

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 9/82

Fig. 2 Connectors on bottom of the enclosure

2.1.3 Digital input

IEC61131-2 compliant, type 1:

2.1.4 Digital output

IEC61131-2 compliant:

Interrupting capacity 0.5 A

Maximum accepted current: 1.2 A

Pin

Name

Description

1

IN +

Insulated digital input (15-24 V)

2

IN -

Insulated digital input, ground return

Pin

Name

Description

1

OUT

Relay contact

2

OUT

Relay contact

OUT

2

1

IN

2

1

+

-

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 10/82

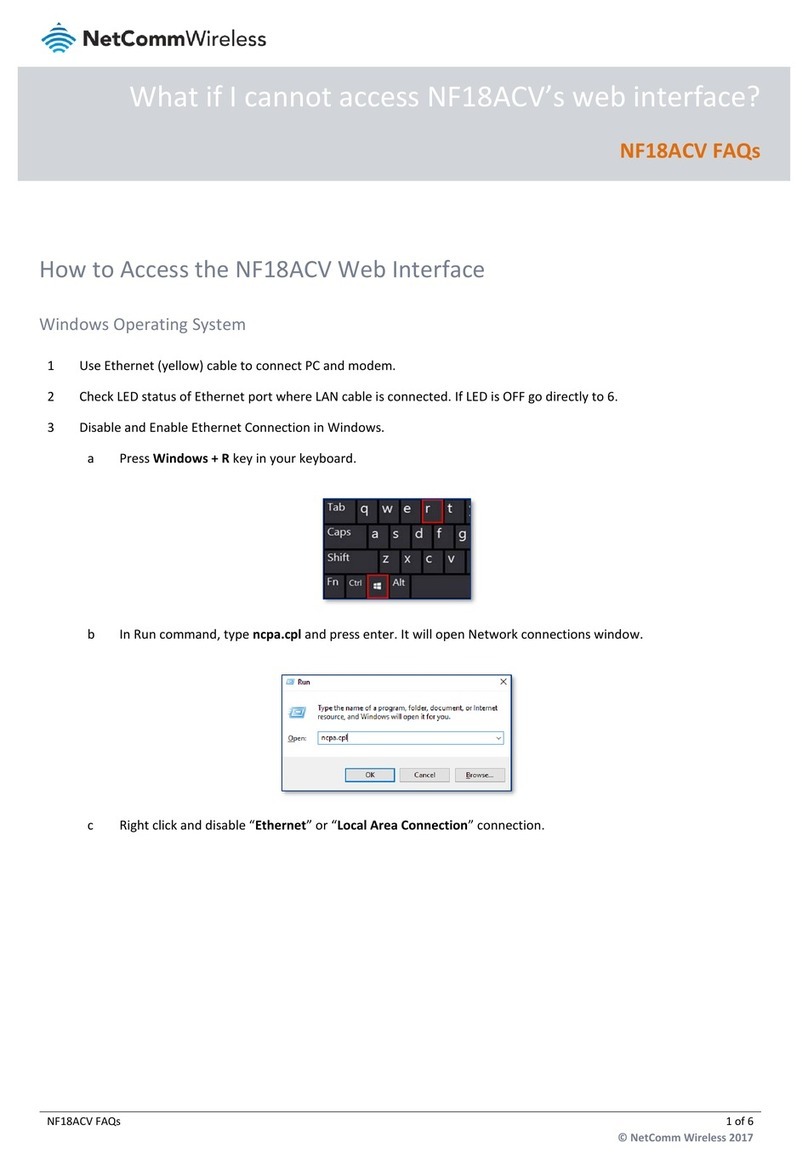

2.2 Front panel indicators

2.3 DIP switches

DIP switches enable:

•selection of the PROFIBUS address of the device (1 to 126),

•selection of the physical support of the serial link: RS-232 or RS-485,

•activation of a termination and line polarisation in RS-485 mode.

Fig. 3 DIP switches

2.3.1 Selecting the RS-232/RS-485 modes

A switch enables specifying the operating mode of the serial link in RS-232 or RS-485 (when delivered, VPGate

is preset to RS-485):

Name

Lit

Description

Blink

Description

ON

Gateway is powered

PFB

No established communication on

PROFIBUS (BF)

diagnostic related to PROFIBUS

Serial

No reply from a MODBUS slave

diagnostic related to the serial line

RUN

Firmware is running

Tx

Sending on serial line

Rx

Receiving on serial line

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 11/82

RS-232 mode:

This mode can only be used in case of communication between 2 individual devices (point-to-point

connection). The maximum distance in RS-232 is 15 m at 19200 baud.

RS-485 mode:

This mode is used more often as it allows connection of several slaves on the bus. It also has other advantages

such as immunity to EMC disturbances and a greater inter-device distance than in RS-232. The maximum

distance in RS-485 is 1200 m.

2.3.2 Termination resistance

If the communication mode used is RS-485, there must be a termination resistance of 120Ω at both ends of the

network. A termination resistance can be added directly in VPGate if it is positioned at the end of a segment. It

is connected using 2 DIP switches (when delivered, VPGate is preset without a termination resistance).

Fig. 6 Termination of the RS-485 bus

Fig. 4 Serial network in RS-232

Fig. 5 Serial network RS-485 mode

Note 1: To ensure proper operation of the termination, the 2 switches must be in the

same position.

Note 2: In RS-232 mode, these 2 DIP switches must be on TERM OFF.

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 12/82

2.4 Selection of the PROFIBUS address

Use the switches 1,2,4,8,16,32,64 to select the PROFIBUS address of the VPGate. (VPGate default factory setting

is address 3). The label next to each switch corresponds to its weight.

PROFIBUS address must be set to a value between 0 and 126.

Ex: To set address 3, set the switches 1 and 2 to ON.

Fig. 7 PROFIBUS address set to 3

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 13/82

3. Software Setup for PROFIBUS DPV0

3.1 Configuration tool for PROFIBUS DP Master DPV0

The setup of VPGate PROFIBUS to serial is done using the configuration tool of the PROFIBUS network. The

configuration is automatically sent to the PROFIBUS slaves (VPGate PROFIBUS) during the network initialisation

phase.

The detailed configurations hereafter was created as examples using the PROFIBUS configuration tools from

third party vendors, "Console" of Woodhead and "HW Config" of SIEMENS. However the principle is the same

with other PROFIBUS master configuration tools of the market place.

3.2 Include VPGate into a project

Before to continue, it is mandatory to create a project into the third party configuration tool. The project must

include a PROFIBUS network and a master port.

3.2.1 Import the VPGate GSD file into the third party configuration tool.

This GSD file allows you to use the VPGate as a PROFIBUS slave device. It is named PROC6980.GSD and it is

located on our website under PROCENTEC https://procentec.com/service-support/gsd-files. It is necessary to

import this GSD file into the third party configuration PROFIBUS to have the VPGate device appearing in the list

of slave devices to be included on the network.

HW config. TIA portal

Console, Woodhead

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 14/82

Console, Woodhead

Console, Woodhead

3.2.2 Insert VPGate into the network configuration

The different stages are as follows:

•From the list of PROFIBUS devices, insert VPGate on the network.

•Setup the appropriate PROFIBUS address of the VPGate (this value must match with the one configured on

the VPGate hardware (DIP switches)

3.3 VPGate parameters

3.3.1 General parameters

Once VPGate is inserted into the PROFIBUS network configuration, it is necessary to configure the serial line.

HW config. TIA portal

Note: The communication baudrate of VPGate is automatically defined according to the

configuration of the PROFIBUS DP master.

HW config. TIA portal

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 15/82

Name

Description

Possible values

Baudrate

Baudrate of the serial link (in bits/s)

1200

2400

4800

9600

19200

38400

57800

115200

Data bits (*)

Number of data bits

7

8

Stop bits and parity

bit (**)

Number of stop bits and parity bit specification

No parity / 1 stop

No parity / 2 stops

Even parity / 1 stop

Odd parity / 1 stop

Timeout

Timeout on serial link in reception

10 ms

100 ms

500 ms

1000 ms

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 16/82

Console, Woodhead

Name

Description

Possible values

Protocol selection

Mode selection

MODBUS RTU

MODBUS ASCII

transparant

Extended diagnosis

Enable or disable PROFIBUS extended diagnosis

Enabled

Disabled

Interframe silence

Specifies a time that must be respected between

received and transmitted frames in ms.

20 –65535 ms

(*) In MODBUS RTU, data are coded on 8 bits. In MODBUS ASCII, data are coded on 7 bits. In those modes,

parameter "data bits" is ignored.

(**) In MODBUS ASCII, if there is not parity bit ("No parity"), others MODBUS equipments on the network must

be configured with 2 stop bits.

3.3.2 Setup VPGate in TRANSPARENT mode

In this mode, data exchange is full duplex on the serial link, without any master / slave relation. Frames detected

over the serial link are immediately transferred to the PROFIBUS inputs, starting at the offset 0. Also, if a serial

frame format is detected in the PROFIBUS outputs, it is immediately transferred to the serial link. In order to do

so, it is necessary to define how frames are delimited.

To setup VPGate in transparent mode:

•Set the parameter "Protocol selection" on "TRANSPARENT":

HW config. TIA portal

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 17/82

Console, Woodhead

•Then setup parameters dedicated to transparent mode:

Name

Description

Possible values

EOF delimiter (1)

Defines how an end of frame will be detected

NULL (0x00)

SPACE (0x20)

LF (0x0A)

CR (0x0D)

CR LF

LF CR

User defined

Length in 1st byte

On timeout (2)

Fill-in unused bytes

(3)

Defines if unused bytes in PROFIBUS inputs frame must

be modified in end of frame character

Enabled

Disabled

Add frames

counter (4)

Defines if a frame counter is added at the beginning of

PROFIBUS inputs and outputs frames

Enabled

Disabled

Add and control

CRC 16

Defines if a CRC16 must be checked in the data received

from the serial equipment, and must be added to the

data sent to the serial equipment.

Enabled

Disabled

HW config. TIA portal

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 18/82

(1): If this parameter is set on User defined, the end of frame character taken into account is the one specified

by parameter "User defined EOF". If it is set as on timeout, the reception timeout taken is the one defined in

the serial link configuration.

(2): When "EOF delimiter" is set to on timeout, only detection of frames received from serial line is on timeout.

On PROFIBUS side, 1st byte must be used to specify the length of received/sent frame (cf. §3.4.1).

(3): When "EOF delimiter" is set on length in 1st byte or on timeout, the filled value is 0x00.

(4): This counter is used as a trigger:

•If this parameter is enabled, 1st byte of PROFIBUS outputs must be a counter incremented each time data

are available and must be sent. Relevant data begin at 2nd byte. Otherwise, the frame is copied from the

1st byte as soon as a change on PROFIBUS outputs is detected.

•If this parameter is enabled, 1st byte of PROFIBUS inputs is incremented each time a new frame was

received on serial link. Useful data are copied following this counter. Otherwise, received frame is copied

from the 1st byte.

The inter frame silence parameter leads to the following behaviour:

If there is no recently detected frame, VPGate sends frames through the serial line without waiting for an inter

frame time. But, when there is a detected frame through the RX line, VPGate will wait for the inter frame time

before sending the following frame through TX.

3.3.3 Setup VPGate as MODBUS Master

To use VPGATE as MODBUS master, proceed as follows:

•Adjust first of all parameter "Protocol selection" on "MODBUS RTU" or "MODBUS ASCII" depending on the

protocol used.

Note: Each principle in TRANSPARENT mode is detailed in §3.4.1.

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 19/82

•Select then the parameter "VPGate Master/Slave" on "Master".

•Then setup general parameters dedicated to MODBUS master mode: "CRC/LRC" and "Retries"

Name

Description

Possible values

CRC / LRC

Defines if CRC (MODBUS RTU) or LRC (MODBUS ASCII)

must be controlled

Enabled

Disabled

Retries

Number of iterations before signalling a timeout

0

1

2

3

Set the parameter “inter frame silence” to specify the minimum time VPGate can take to send a new MODBUS

request to a slave after receiving the last reply (see the figure below).

HW Config, TIA portal

Console, Woodhead

HW Config, TIA portal

Console, Woodhead

VPGate PROFIBUS to serial manual | 09 juli 2018 | ©PROCENTEC 20/82

•Then setup the different scenarios in order to define the different MODBUS commands to be sent as well as

how VPGate is going to send them:

HW Config, TIA portal

Console, Woodhead

Other manuals for VPGate

3

Table of contents

Other Procentec Gateway manuals

Popular Gateway manuals by other brands

Mennekes

Mennekes eMobility-Gateway Professional+ OPERATING AND INSTALLATION Manual

Elecsys

Elecsys RediGate 400 Series Hardware manual

CommScope

CommScope Touchstone TG6452 user guide

RTA

RTA 460TCP-N2E Product user guide

Micro control systems

Micro control systems MCS-BMS-GATEWAY Startup guide

Anyfi Networks

Anyfi Networks Carrier Wi-Fi System reference guide