Quickstart

Power supply: Class 2

UL Environmental Rating: Enclosure Type 1

8025127:

Q U I C K S T A R T

en

These instructions are only valid in combination with the 8025143 Operating

Instructions. The operating instructions are available at www.sick.com.

Mounting, connection, and configuration should only be performed by trained

specialists.

This device is not a safety component in accordance with the EU Machinery

Directive.

Do not install at locations that are exposed to direct sunlight or other weather

influences, unless this is expressly permitted in the operating instructions.

de

Diese Anleitung ist ausschließlich in Verbindung mit der Betriebsanleitung

8025085 gültig. Die Betriebsanleitung finden Sie unter www.sick.com.

Anschluss, Montage und Einstellung nur durch Fachpersonal.

Kein Sicherheitsbauteil gemäß EU-Maschinenrichtlinie.

Installieren Sie das Gerät nicht an Orten, die direkter Sonneneinstrahlung oder

sonstigen Wettereinflüssen ausgesetzt sind, ausser dies ist in der Betriebsanlei‐

tung ausdrücklich erlaubt.

it

Le presenti istruzioni sono valide solo in abbinamento alle istruzioni per l'uso

8025143. Le istruzioni per l'uso sono reperibili su www.sick.com.

Collegamento, montaggio e regolazione solo a cura di personale tecnico specializ‐

zato.

Nessun componente di sicurezza ai sensi della direttiva macchine UE.

Non installare il dispositivo in luoghi esposti all’irraggiamento solare diretto o ad

altri influssi meteorologici, se non espressamente consentito nelle istruzioni per

l’uso.

fr

Cette notice n'est valable qu'avec la notice d'instruction 8025143. La notice

d'instruction est disponible sur le site Internet www.sick.com.

Confier le raccordement, le montage et le réglage uniquement au personnel

qualifié.

Il ne s'agit pas d'un composant de sécurité au sens de la directive machines CE.

N’installez pas l’appareil à des endroits directement exposés aux rayons du soleil

ou à d’autres conditions météorologiques, sauf si cela est explicitement autorisé

dans la notice d'instruction.

es

Estas instrucciones solo son válidas junto con las instrucciones de uso 8025143.

Puede encontrar las instrucciones de uso en www.mysick.com.

La conexión, el montaje y el ajuste deben efectuarlos exclusivamente técnicos

especialistas.

No se trata de un componente de seguridad según la Directiva de máquinas de la

UE.

No instale el dispositivo en lugares directamente expuestos a la radiación solar

o a otras influencias climatológicas, salvo si las instrucciones de uso lo permiten

expresamente.

zh

本说明书仅在结合使用 8025143 操作指南情况下有效。查看操作指南可访问

www.sick.com 网页。

仅允许由专业人员进行接线、安装和设置。

本设备非欧盟机械指令中定义的安全部件。

请勿将设备安装在阳光直射或受其它气候影响的位置,除非操作指南中明确允

许这一行为。

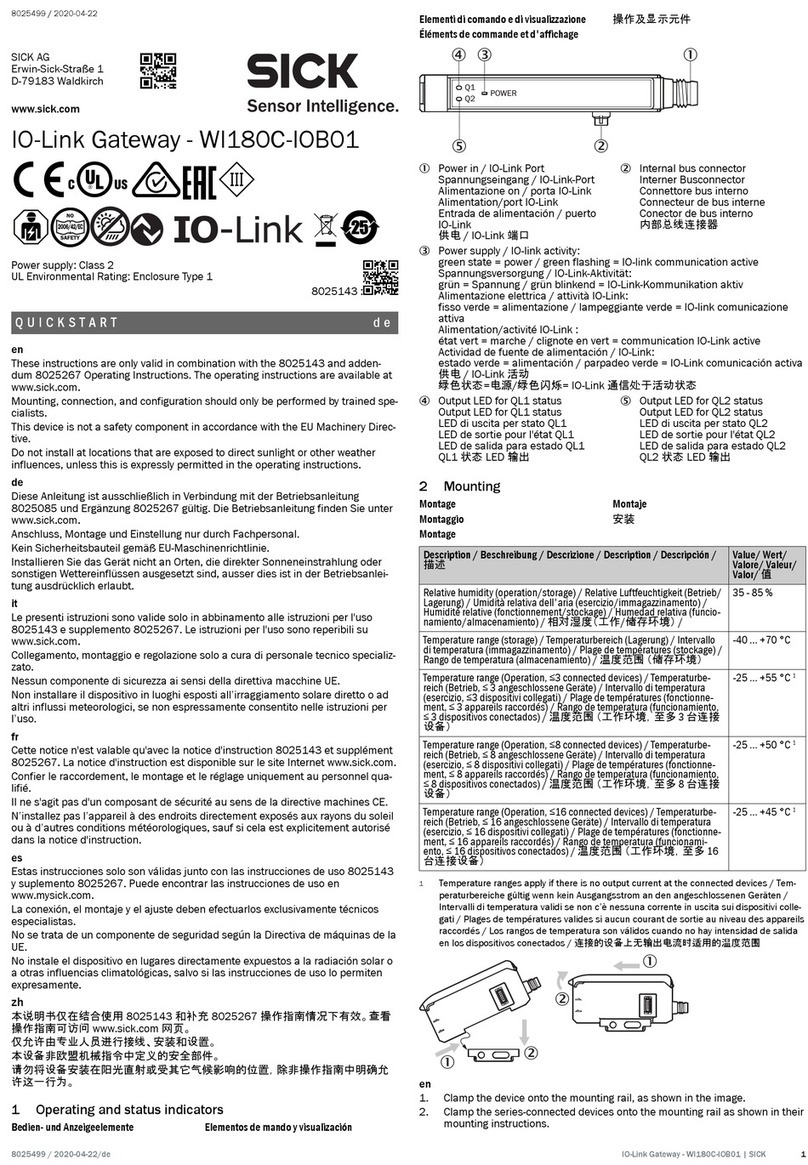

1 Operating and status indicators

Bedien- und Anzeigeelemente Elementos de mando y visualización

Elementi di comando e di visualizzazione 操作及显示元件

Éléments de commande et d'affichage

1Power in / IO-Link Port

Spannungseingang / IO-Link-Port

Alimentazione on / porta IO-Link

Alimentation/port IO-Link

Entrada de alimentación / puerto

IO-Link

供电 / IO-Link 端口

2Internal bus connector

Interner Busconnector

Connettore bus interno

Connecteur de bus interne

Conector de bus interno

内部总线连接器

3Power supply / IO-link activity:

green state = power / green flashing = IO-link communication active

Spannungsversorgung / IO-Link-Aktivität:

grün = Spannung / grün blinkend = IO-Link-Kommunikation aktiv

Alimentazione elettrica / attività IO-Link:

fisso verde = alimentazione / lampeggiante verde = IO-link comunicazione

attiva

Alimentation/activité IO-Link:

état vert = marche / clignote en vert = communication IO-Link active

Actividad de fuente de alimentación / IO-Link:

estado verde = alimentación / parpadeo verde = IO-Link comunicación activa

供电 / IO-Link 活动

绿色状态=电源/绿色闪烁= IO-Link 通信处于活动状态

4Output LED for QL1 status

Output LED for QL1 status

LED di uscita per stato QL1

LED de sortie pour l'état QL1

LED de salida para estado QL1

QL1 状态 LED 输出

5Output LED for QL2 status

Output LED for QL2 status

LED di uscita per stato QL2

LED de sortie pour l'état QL2

LED de salida para estado QL2

QL2 状态 LED 输出

2 Mounting

Montage

Montaggio

Montage

Montaje

安装

Description / Beschreibung / Descrizione / Descrip‐

tion / Descripción / 描述 Value/ Wert/ Valore/Valeur/

Valor/ 值

Relative humidity (operation/storage) / Relative Luft‐

feuchtigkeit (Betrieb/Lagerung) / Umidità relativa

dell'aria (esercizio/immagazzinamento) / Humidité

relative (fonctionnement/stockage) / Humedad rela‐

tiva (funcionamiento/almacenamiento) / 相对湿度

(工作/储存环境) /

35 - 85 %

Temperature range (storage) / Temperaturbereich

(Lagerung) / Intervallo di temperatura (immagazzina‐

mento) / Plage de températures (stockage) / Rango de

temperatura (almacenamiento) / 温度范围(储存环

境)

-40...+70°C

Temperature range (Operation, ≤3 connected devi‐

ces) / Temperaturbereich (Betrieb, ≤3angeschlossene

Geräte) / Intervallo di temperatura (esercizio, ≤3 dis‐

positivi collegati) / Plage de températures (fonctionne‐

ment, ≤3appareils raccordés) / Rango de tempera‐

tura (funcionamiento, ≤3dispositivos conectados) /

温度范围(工作环境,至多 3 台连接设备)

-25...+55°C 1

Temperature range (Operation, ≤8 connected devi‐

ces) / Temperaturbereich (Betrieb, ≤8angeschlossene

Geräte) / Intervallo di temperatura (esercizio, ≤ 8 dis‐

positivi collegati) / Plage de températures (fonctionne‐

ment, ≤8appareils raccordés) / Rango de tempera‐

tura (funcionamiento, ≤8dispositivos conectados) /

温度范围(工作环境,至多 8 台连接设备)

-25...+50°C 1

Temperature range (Operation, ≤16 connected devi‐

ces) / Temperaturbereich (Betrieb, ≤16angeschlos‐

sene Geräte) / Intervallo di temperatura (esercizio, ≤

16 dispositivi collegati) / Plage de températures (fonc‐

tionnement, ≤16appareils raccordés) / Rango de

temperatura (funcionamiento, ≤16dispositivos conec‐

tados) / 温度范围(工作环境,至多 16 台连接设

备)

-25...+45°C 1

1Temperature ranges apply if there is no output current at the connected devices / Tem‐

peraturbereiche gültig wenn kein Ausgangsstrom an den angeschlossenen Geräten /

Intervalli di temperatura validi se non c’è nessuna corrente in uscita sui dispositivi

collegati / Plages de températures valides si aucun courant de sortie au niveau des

appareils raccordés / Los rangos de temperatura son válidos cuando no hay intensidad

de salida en los dispositivos conectados / 连接的设备上无输出电流时适用的温度范围

8024908.187N/2023-01-31/de IO-Link Gateway - WI180C-IOA00 | SICK 1

8024908.187N/2023-01-31

www.sick.com

IO-Link Gateway - WI180C-IOA00