PRODEM PHC 050 User manual

Operation and Maintenance Manual

Plate Compactor

PHC 050

PHC 100

PHC 150

PHC 200

PHC 300

Parts No.: AA099-0053

Revision Date: 2011-12-15

©ProDem.

- 2 -

Foreword

WARNING!

It is very important for you to read and understand this manual before operating and to keep

the instructions provided herewith. Never fail to follow the instruction related to safety.

This manual contains instructions and information on safe and correct use of PRODEM Compactors.

Please read and understand this manual before operation, inspections and maintenance of the compactor.

Keep this manual with your equipment all the time for your quick and easy reference, and read it regularly.

Do not operate the compactor until you have been trained in the use of all operating controls and

understand the hydraulic compactor operation.

Get a replacement manual from PRODEM dealer if you lost it.

If you transfer the compactor to the other, do transfer this manual as well.

The figures in this manual is for better understanding and may not correspond exactly to the compactor.

For exact shape, refer to the parts list or ask PRODEM.

For the purpose of constant product improvement, some parts of this manual may be changed. If you

found the parts unclear or not corresponding to the compactor, call and consult PRODEM dealer or

service center

Important information on safety is described in the safety information chapter of this book. Be familiarized

with the instructions on the safe operation and observe the instructions before and during operation

Injury, death or damage caused by unauthorized product modifications and operation under unallowed

application will not be responsible by PRODEM. Consult PRODEM for such modifications and

applications.

Use PRODEM genuine parts. PRODEM takes no responsibility for damages caused by use of non-

PRODEM spare parts.

For warranty, we refer you to the warranty conditions provided separately.

We always exert all our efforts for your satisfaction, and promise you quick and constant service.

We thank you for using PRODEM compactor and wish you a good luck in every your job,

Dec. 2011

PRODEM Corp.

Copyright © 2011 PRODEM Corp. All rights reserved.

This manual is copyrighted by PRODEM Corp. with all rights reserved in accordance with prevailing law. It is

positively prohibited to use or reproduce its contents in whole or in part without prior written permission.

- 3 -

TABLE OF CONTENTS

Foreword..................................................................................................................................................................2

TABLE OF CONTENTS...........................................................................................................................................3

1. Safety Information................................................................................................................................................4

1.1. BASIC SAFETY INSTRUCTIONS...............................................................................................................5

1.2. PREPARATIONS FOR SAFE OPERATION................................................................................................6

1.3. Safety information for operation ..................................................................................................................7

1.4. Safety instructions for maintenance ............................................................................................................8

2. Product information..............................................................................................................................................9

2.1. Product configuration ..................................................................................................................................9

2.2. Product features........................................................................................................................................10

2.3. Specifications ............................................................................................................................................ 11

3. Installation..........................................................................................................................................................13

3.1. Installation of the piping.............................................................................................................................13

3.2. Installation of the compactor......................................................................................................................15

4. Operation...........................................................................................................................................................17

4.1. How to use compactor...............................................................................................................................17

4.2. Correct working mothod............................................................................................................................18

5. Service and maintenance...................................................................................................................................20

5.1. General guidelines ....................................................................................................................................20

5.2. Daily inspection.........................................................................................................................................20

5.3. Gear oil inspection and oiling ....................................................................................................................21

5.4. Maintenance instructions...........................................................................................................................21

5.5. Tightening torques.....................................................................................................................................23

5.6. Troubleshooting.........................................................................................................................................24

5.7. Dismounting and storing............................................................................................................................25

- 4 -

1. Safety Information

This manual describes correct use of the product and safety messages. Important or certain instructions in

this manual are marked with symbol. When you see this symbol provided in the manual or on the

product, be alert to the possibility of personal injury or death. Be sure to observe the instruction in the safety

message.

The safety messages in this manual do not describe all the possibilities of personal injury or death or of

damages to the product. This safety manual and the marks with symbols are intended to provide some of

basic instructions for safe operation, inspection and maintenance. It is operator’s responsibility to observe

the safety instructions and regulations though this manual does not include all the possible situations.

Remember! Safety is up to you

Safety Alert Symbol

The Safety Alert Symbol represents that

ATTENTION

is involved.

If you see the mark in this manual or on the products, never fail to read and

observe the instructions for safe operation.

Signal Words

The words “DANGER”, “WARNING”, “CAUTION” and “IMPORTANT” appeared with the above Safety Alert

Symbol indicate degree of risk of hazards or unsafe practices. All four degrees of risk indicate that safety is

involved. Observe precautions indicated whenever you see the Safety Alert Symbol, no matter which signal

word appears next to the “Exclamation Point” symbol.

DANGER! Indicates imminent hazard of a situation that, if not avoided, is very likely to cause

death or extremely serious injury. It may also be used to alert against product that

may exploded or detonate if handled or treated carelessly.

WARNING!

Indicates potential of a hazardous situation that, if not avoided, could result in serious

injury or death. It may also be used to alert against a highly unsafe practice.

CAUTION! Indicates potential of a hazardous situation that, if not avoided, could result in minor

or moderate injury. It may also be used to alert against a general unsafe practice.

IMPORTANT!

Indicates potential of damages that, if not avoided, could caused to the product or

shorten the product life.

- 5 -

1.1. Basi safety instru tions

WARNING!

The following instructions are those that should never be fail to observe in operation of

construction equipment.

Know yourself

All the operators and service men must wear safety equipment

required, hearing protection, respirator, hard hat, safety shoes, eye

protection glass, heavy gloves and other necessary equipment.

Wearing loose clothing or any accessories such as flopping cuffs,

dangling neckties and scarves, untied shoe-laces, rings, wrist

watches and long hair could be the cause of personal injury or

death.

Use the proper tools for inspection or maintenance work, which

must be carried out after ensuring the equipment stops completely

and is placed stably in the safe place

Figure 1

Know your equipments

Never fail to read and understand the safety messages, operation

manual and maintenance manual before installation and operation

of the compactor. The operator who has been trained and licensed

should only operate the carrier and the compactor. Familiarize

yourself with the operating especially safety related devices such

as safety lock, emergency stop and the others.

Figure 2

Know the work site

Before beginning operation, check in and around the work site for

any unusual conditions that could be dangerous and prepare the

appropriate warnings for safe work.

Be careful, especially when work in the vicinity of electric power

line, buried gas lines or oil tank. And pay your careful attention to

the people and the cars reside and passing near to the work site.

Prepare for every possible injury and damages.

Figure 3

Know the rules

Every people who operate or maintain the equipment should know

the meaning, rules and laws in terms of equipment handling. They

should know also the traffic rules, fire service act, emergency

measures and where the relief equipment is.

Keep the fire extinguisher and the first aid case in the operator’s

cabin for emergency use.

Figure 4

- 6 -

1.2. Preparations for safe operation

WARNING!

The following section describes the matters that must be prepared and checked in advance

for safe use of the compactor. Make yourself familiar with and keep the following instructions.

Install to a suitable arrier.

The excavator to which compactor is to be mounted should be selected based on the compactor capacity,

the mounting dimensions and the hydraulic device specification. If equipment that does not comply with the

prescribed specification is used for the compactor, either the compactor or the equipment may be damaged

or its life may be shortened. So, be sure to mount the compactor to the specified excavator. For matters

concerning the equipment selection, contact us or our sales representative.

Safety Guidelines for Installation

Install the compactor to the arm and link of the excavator, using mounting pins. The excavator operator and

the mounting worker should pay special attention, and agree on details and sequence of the work and

determine hand signals in advance. The operator should run the excavator as slowly as possible and the

worker should keep a safe distance and should keep his hands off from the excavator arm or link while the

excavator works. After assembling the mounting pin, tighten the bolts firmly, so that the pin may not get loose

during work.

When installing a pipe for mounting the compactor, follow our pipe installation specification. When

connecting a hydraulic hose, connect it with the specified connection torque and check if the hose is

completely connected before starting the excavator. If a sudden pressure is applied when the connection is

incomplete, the hose may sway to cause personal injury.

For more information about piping and pipe installation, see “3. Installation” in this Manual.

Inspe t the equipment before work.

Carefully inspect each checkpoint of the compactor and the

excavator before starting work. Check everything related to

safety such as equipment damage (breakage, crack, wear and

tear, deformation, etc.), part connection state and oil leakage

according to the check items specified in the operation manual

and that of the excavator. In particular, focus on checking if

there is any crack in the welded parts on the compactor body,

if bolts/nuts in each joint are loose, pin fixing state and

leakage from cylinder and hose.

If there is any problem in the compactor or in the excavator,

do not operate the excavator until proper maintenance work is

done. In this case, attach a warning tag to the equipment

driver seat so as to inform other people clearly of the

equipment status. It is desirable that the same person who

attached the warning tag removes it in person.

Figure 5

- 7 -

1.3. Safety information for operation

WARNING!

The following is the safety guidelines especially focused on using the compactor. Follow

these guidelines and refer to “4. Operation” for detailed information.

Never operate in unallowed appli ations

Do not carry out dangerous works that are not allowed in this manual. Improper operation of the compactor

could result in serious injury or death. For a correct method for using the compactor, see “4.2 Correct

Working Methods”.

Do NOT use for on rete or bedro k

Operating the compactor on the hard object such like concrete or bedrock will cause damage to the

compactor. Use the compactor only for soft objects.

Do NOT use for breaking or transport

Hammering or ramming with the compactor body to break a object or transporting a heavy object using the

compactor may damage the product and shorten its life, so it is absolutely prohibited.

Do NOT use under water

Never use the compactor in or under water. Operating the compactor under water will cause serious damage

to the cushion rubber.

Do NOT support arrier with ompa tor

Do not support the carrier using the compactor body, or do not apply excessive force to it.

For piling work, always use pile- lamp

When operating in piling work - driving-in or pull-up, always use the optional pile-clamp for safety. Piling

without the pile-clamp can bring out the risk of falling down of piles.

Do NOT use for rane work

This product is not equipped with safety devices for crane work. So, never perform crane work with this

product.

Stop working if any problem is found

If the compactor shakes unusually or there is abnormal vibration and/or noise during work, stop operating

immediately. In addition, if oil leakage from hose connections or any loose pin or joint is detected during the

operation, stop the compactor and check the problem.

- 8 -

1.4. Safety instru tions for maintenan e

Follow the manual

Follow the instructions in the manual for inspection and maintenance. In

particular, pay special attention to safety alerts and do not rush. Accidents

during maintenance are mostly attributed to negligence of the guidelines.

Figure 6

Completely stop the arrier

Inspection and maintenance should be done, after completely stopping the excavator on an even and safe

surface, with all control levers and switches on safe position.

Use proper tools

Use proper tools for inspection and maintenance. If you carry out any inspection or maintenance work using

improper tools, it may result in personal injury or damage to product.

Pay attention to hydrauli system

Draw special attention to maintain hydraulic system. Even though it is stopped,

the inside of a hydraulic system that has been operated can be hot. So, do not

disassemble it rashly. Be sure to remove the pressure left inside the hydraulic

device, close the lock and prevent any external forces from being applied to the

device according to a maintenance guide, before maintain it. For the compactor

cylinder in particular, there may be pressure left in the system even after the

compactor stops, and it may be exploded when it is disassembled. Therefore, be

sure to follow the disassembly order.

If there is a tiny hole or crack in the hydraulic device, pressurized fluid may

spout from it, to injure people near it. Fluid that spouts lightly may not be seen

by the naked eye. In this case, check the leakage using a sheet of paper or a

wooden board, wearing eye protection.

Right after operation, fluid is very hot. So, you have to be careful not to get

burned. In addition, as air inside the oil tank of the excavator is compressed, a

large amount of hydraulic oil may gush out if the hydraulic line connected to the

oil tank is disassembled. So, open the filler-cap slowly to remove the

compressed air from the oil tank before disassemble the hydraulic device.

Figure 7

Remove oil from the floor

When there is oil on the floor, it may result in an accident. So, when you spill or drop oil on the floor, wipe it

out immediately

.

Do not alter or modify

Unauthorized product modification or attachment of any unauthorized accessories can cause very dangerous

accidents. In addition, use of non-genuine parts can result in accidents or product damages. Therefore, use

our genuine parts only.

- 9 -

2. Produ t information

2.1. Produ t onfiguration

Mounting Plate

Upper Frame

Base Frame

Drive Casing Compacting Plate

Motor Control Valve

Motor

'P' Port

(IN) 'T' Port

(OUT)

Cushion Plate

Figure 8

The product configuration may vary depending product model.

Functions of the major parts

are as follows

Upper frame and base frame are the structures that form upper and lower parts of the Compactor

body.

In Drive casing, drive axis with eccentric weight which generates compacting force and bearings

that support the axis are assembled.

Motor (hydraulic motor) rotates at high speed by pressurized hydraulic oil from the carrier, to drive

the eccentric axis, and the vibration and centrifugal force induced by the rotation of the eccentric

weight generates compacting force.

Motor control valve is a built-in integrated valve to protect the hydraulic motor. There are two type

of the motor control valve; ‘N’ type valve has the reverse-flow-bypass and anti-cavitation functions

and ‘P’ type valve includes flow and pressure control function in addition to the standard features of

the ‘N” type valve.

Compacting plate contacting the ground compacts soil and make surface flat.

Cushion rubbers (cushion plates) is parts that help get effective compacting force from the

centrifugal force generated from eccentric weight and protect the carrier and operator by dampening

the vibration during compaction work.

Mounting plate is used to mount the compactor to the carrier using a mounting adapter.

’P’ port (IN) and ’T’ port (OUT) are connection ports to connect with piping of the carrier.

Components supplied

at the time of delivery are:

Compactor Assembly

Standard tool kits

User’s Manual, Parts List,

Hose and Fitting Set (Optional)

Mounting Adapter and fasteners set

(Optional, for Adapter Mount Type only)

Piping Kit (Optional)

(Components of the piping kit vary with

the carrier model.)

- 10 -

Compactor verson code

Version Code NA PA ND PD

Motor

Control

Valve

‘N’ Type Valve:

Reverse-flow-bypass and anti-cavitation

‘P’ Type Valve:

Flow and Pressure control

Reverse-flow-bypass and anti-cavitation

Bracket Adapter mount type

Direct mount type

2.2. Produ t features

High compacting productivity

PRODEM’s hydraulic plate compactor guarantees high compacting productivity by means of powerful impulse force.

Easy and versatile mounting

Adapter Mount: Flat top frame allows for installation on any carriers using a standard or custom made mounting

adapter.

Direct Mount: The frame is designed to accept a variety of slip-fit bushings and pins, resulting in versatile

installation on any carrier.

Firm and safe hose array

All Hoses are routed within the frame and connected to a mono hose block located on the frame. It protects the hoses

from damage and make it easy to connect the hoses.

High quality cushion rubber

Specially designed high quality cushion rubbers dampens vibration effectively and thus protect carrier and operator

from the vibrations.

Heavy duty gear motor and bearings

Heavy duty and high efficiency gear motor with splined shaft and self-aligning double row spherical roller bearings

provides a long service life of the rotating components and prevent possible damage caused by pressure shock

during start-up and shut-down.

Easy maintenance

Every part of the compactor is very easy to access for the maintenance.

Motor with built-in cross-check valve

Built-in cross-check valve within the hydraulic motor eliminates the need of a additional drain line, thus provides great

versatility for using general 2-line plumbing. And it also protects the motor shaft seal from damage caused by internal

oil leak of the motor.

Standard motor control valve (Reverse-flow-bypass and anti-cavitation check)

Built-in high flow check valve within standard motor control valve (‘N’ type valve) protects the motor from damage

caused by unintentional reverse connection of plumbing and cavitation induced by abrupt shutdown of hydraulic flow.

Optional motor control valve (Flow & pressure control)

Flow control valve (Pressure compensated priority flow divider) regulates hydraulic in-flow to the motor not to

excess the permissible maximum flow of the motor to prevent it from over-speeding. Thus, the compactor can be

installed on a carrier not equipped with a flow control valve on its auxiliary plumbing. And, it also control the motor

speed regardless of load pressure to generate the maximum compacting force continuously.

Pressure relief valve is also incorporated in the optional valve pack and it prevents system from over-pressure to

protect the motor. An attachment, such as breaker, which works at a relatively higher pressure than compactor can be

easily switched to the compactor on the same auxiliary plumbing without re-setting of the carrier’s relief valve

pressure.

All the valves; flow control, pressure relief, and reverse-flow-bypass & anti-cavitation check valves are packed within

the single mono valve block (‘P’ type valve).

- 11 -

2.3. Spe ifi ations

Adapter Mount Type Direct Mount Type

L

H

W

'P' Port

(IN) 'T' Port

(OUT)

LW

H

'T' Port

(OUT)

'P' Port

(IN)

Figure 10 Figure 11

Model PHC 050 PHC 100 PHC 150

Impulse Force

t

onne

(

klbs)

2.1

(4.6)

4.0

(8.8)

6.4

(14.1)

Weight

1)

A

dapter mount type(N*)

kg

(lbs)

260

(573)

A

dapter mount type(G*)

kg

(lbs)

280

(617)

430

(948)

689

(1,519)

D

irect mount type (N*)

kg

(lbs)

264

(582)

D

irect mount type (G*)

kg

(lbs)

344

(759)

Height (H)

1)

A

dapter mount type(N*)

mm

(

in.)

650

(25.6)

A

dapter mount type(G*)

mm

(

in.)

675

(26.6)

640

(25.2)

750

(29.5)

Direct mount type

(N*)

mm

(in.)

695

(27.4)

Direct mount type

(G*)

mm

(in.)

720

(28.3)

Width (W) (N*) mm

(

in.)

320

(12.6)

Width (W) (G*) mm

(

in.)

500

(19.7)

610

(24.0)

740

(29.1)

Base Plate

Dimensions (W x L) (N*) mm

(

in.)

320

x

745

(12.6 x 29.3)

Dimensions (W x L) (G*) mm

(

in.)

500

x

800

(19.7 x 31.5)

6

1

0

x

90

0

(24.0 x 35.4)

740

x

1,05

0

(29.1 x 41.3)

Compaction Area (N*)

m

2

(

ft

2

)

0.24

(2.6)

Compaction Area (G*)

m

3

(

ft

3

)

0.40

(4.3)

0.55

(5.9)

0.78

(8.4)

Oil Flow

w

ith 'N' type valve

l

pm

(gpm)

5

0 ~

72

(13.2 ~ 19.0)

80

~

116

(21.1 ~ 30.6)

w

ith 'P' type valve

2)

l

pm

(gpm)

45

~

65

(11.9 ~ 17.2)

5

0 ~

120

(13.2 ~ 31.7)

80

~

170

(21.1 ~ 44.9)

Max. Cycles Per Minute

r

pm

2,100

2,000

2,000

Operating Pressure

F

ree load

bar

(psi)

3

0 ~ 50

(440 ~ 730)

3

0 ~ 50

(440 ~ 730)

3

0 ~ 50

(440 ~ 730)

With load bar (psi) 100 ~ 220 (1,450 ~ 3,190) 100 ~ 138 (1,450 ~ 2,000) 100 ~ 138 (1,450 ~ 2,000)

Recommended Carrier

t

onne

(ton)

4 ~ 6

(4 ~ 7)

6 ~ 10

(7 ~ 11)

1

1

~

16

(12 ~ 18)

Weight

Recommended Hydraulic mm

(

in.)

12.7

(1/2)

19

(3/4)

19

(3/4)

Line Size (In / Out)

Max. Acceptable Back bar (psi) 15 (220) 15 (220) 15 (220)

Pressure

Max. Pressure Relief bar (psi) 220 (3,190) 138 (2,000) 138 (2,000)

Type of Hose Connection Ports

BSP

1/2

O-Ring Boss Female

BSP

3/4

O-Ring Boss Female

BSP

3/4

O-Ring Boss Female

(JIS B2351 Type 'O')

(JIS B2351 Type 'O')

(JIS B2351 Type 'O')

Available Fitting Set

O

RFS -8

3)

O

RFS -12

3)

O

RFS -12

3)

B

SP 1/2 (60º Cone)

4)

B

SP 3/4 (60º Cone)

4)

B

SP 3/4 (60º Cone)

4)

J

IC -8

5)

J

IC -12

5)

J

IC -12

5)

- 12 -

Model PHC 200 PHC 300

Impulse Force

t

onne

(

klbs)

11.2

(24.7)

17.3

(38.1)

Weight

1)

Adapter mount type(N*) kg (lbs)

Adapter mount type(G*) kg (lbs) 1,094 (2,412) 1,502 (3,312)

D

irect mount type (N*)

kg

(lbs)

Direct mount type (G*) kg (lbs)

Height (H)

1)

A

dapter mount type(N*)

mm

(

in.)

Adapter mount type(G*) mm (in.) 840 (33.1) 943 (37.1)

Direct mount type (N*) mm (in.)

Direct mount type (G*) mm (in.)

Width (W) (N*) mm

(

in.)

Width (W) (G*) mm (in.) 860 (33.9) 1,000 (39.4)

Base Plate

Dimensions (W x L) (N*) mm

(

in.)

Dimensions (W x L) (G*) mm (in.) 860 x 1,200 (33.9 x 47.2) 1,000 x 1,300 (39.4 x 51.2)

Compaction Area (N*) m

2

(ft

2

)

Compaction Area (G*) m

3

(ft

3

) 1.03 (11.1) 1.30 (14.0)

Oil Flow

with 'N' type valve lpm (gpm) 110 ~ 162 (29.1 ~ 42.8) 160 ~ 220 (42.3 ~ 58.1)

with 'P' type valve

2)

lpm (gpm) 110 ~ 200 (29.1 ~ 52.8) 160 ~ 250 (42.3 ~ 66.0)

Max. Cycles Per Minute rpm 2,000 2,000

Operating Pressure

F

ree load

bar

(psi)

3

0 ~ 50

(440 ~ 730)

3

0 ~ 50

(440 ~ 730)

With load bar (psi) 100 ~ 138 (1,450 ~ 2,000) 100 ~ 138 (1,450 ~ 2,000)

Recommended Carrier tonne (ton) 17 ~ 25 (19 ~ 28) 26 ~ 40 (29 ~ 44)

Weight

Recommended Hydraulic mm (in.) 25 (1) 32 (1-1/4)

Line Size (In / Out)

Max. Acceptable Back bar (psi) 15 (220) 15 (220)

Pressure

Max. Pressure Relief bar (psi) 138 (2,000) 138 (2,000)

Type of Hose Connection Ports

BSP

1

O-Ring Boss Female

BSP

1-1/4

O-Ring Boss Female

(JIS B2351 Type 'O')

(JIS B2351 Type 'O')

Available Fitting Set ORFS -16

3)

ORFS -20

3)

B

SP

1

(

60

º Cone

)

4)

B

SP

1

-

1

/

4

(

60

º Cone

)

4)

JIC -16

5)

JIC -20

5)

Notes: 1) Excluding mounting adapter, hydraulic hoses, fittings and mounting pins.

2) Standard settings at the factory. Other extra flow ranges are also available on request.

3) The O-Ring Face Seal (ORFS) type hose coupling according to SAE J1453

4) The 60º cone type hose coupling according to JIS B8363 (hoses with 60º male sealing face)

5) The 37º flare type hose coulping according to SAE J514

6) PHC 050: (N*)-Narrow type, (G*)-General type

- 13 -

3. Installation

3.1. Installation of the piping

CAUTION!

Inappropriate piping may result in damaging the compactor or carrier and shortening of its life.

Be sure to follow our regulations on pipe installation.

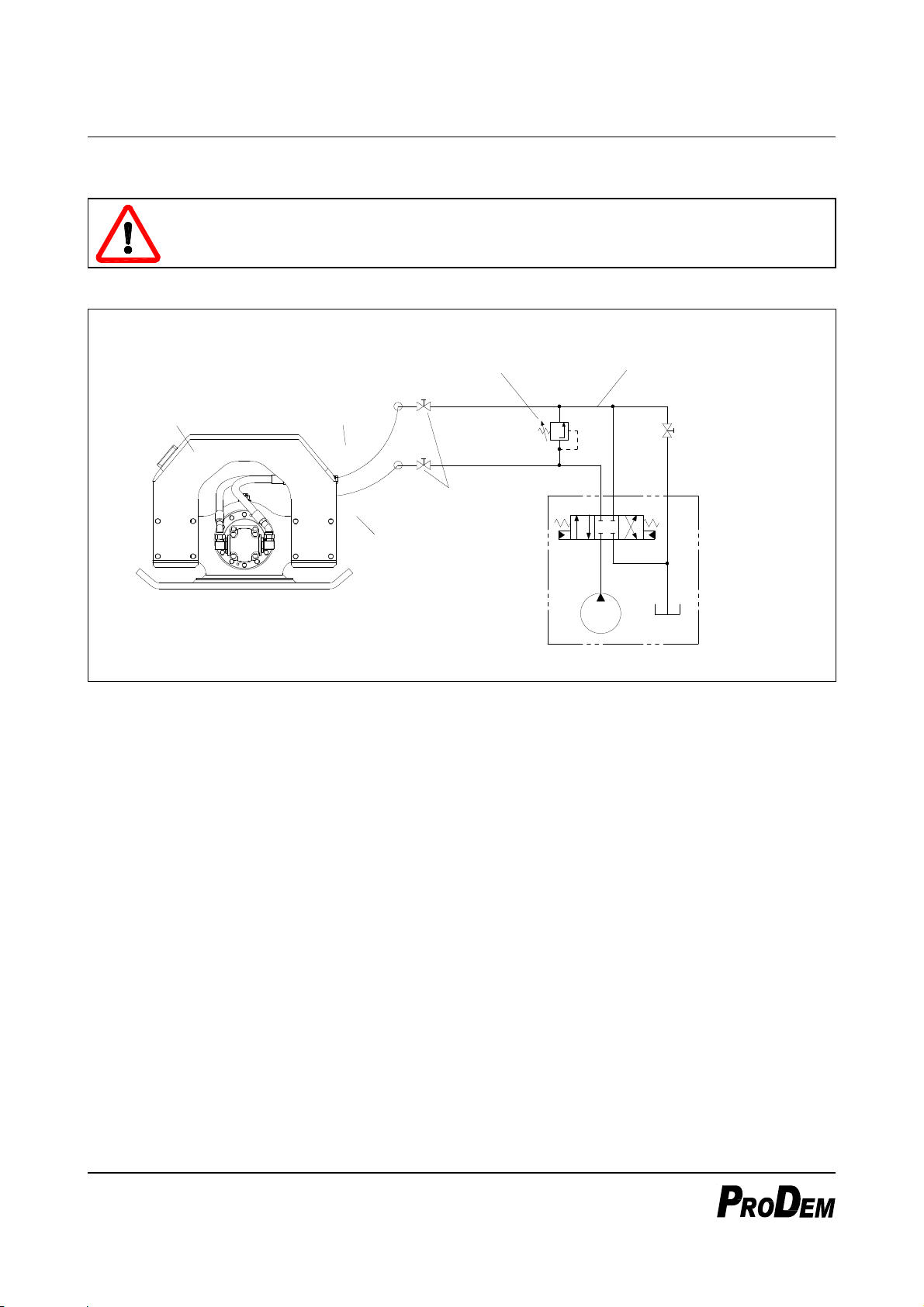

Hydraulic Circuit Diagram (recommended)

Compactor

'P' Port

(IN)

'T' Port

(OUT)

Stop Valve

Relief Valve

(See ※)

Drain line

(necessarily required)

Stop Valve for

by-directional

operation

(option)

★ Carrier's hydraulic systemmay vary depending

on the model and maker.

P

T

PT

AB

Figure 12 The above circuit diagram is for reference only.

The specifications of carrier’s hydraulic system required to operate the compactor is as follows.

Pump Flow: Higher than the minimum working flow of the compactor

System Pressure: 180 bar or higher

Allowable Back-Pressure: 15 bar or less

Compactor piping is basically the same as breaker piping, and thus it is possible to use the breaker piping

as it is without any modification.

★But, the drain(low-pressure) line must be connected directly to oil cooler or oil tank.

If the drain line is connected to the control valve of the carrier, the compactor’s motor can be

damaged.

If the drain line of carrier has a stop valve for by-directional operation, be sure to operate the compactor

with opening the stop valve.

The drain line should has sufficiently large inner diameter to meet the specified maximum acceptable

back-pressure of the compactor. If the back pressure – measured at the ‘T’ port during operation – is

higher than the specified value, check the inner diameters of pipes, hoses or fittings of the drain line.

- 14 -

Setting and Adjusting Relief Valve (※

※※

※)

For the compactor with ’N’ type valve, a relief valve must be installed to compactor piping, and must be

adjusted to the specified maximum operating pressure ot the compactor.

For the compactor with ‘P’ type valve, you do not need to install a relief valve to compactor piping. If a

relief valve has already been installed for other attachment, such as breaker, you do not also need to re-

adjust the setting pressure according to the compactor’s operating pressure.

Please consult PRODEM or our dealer for more detail about the compactor piping.

Piping should be placed as follows when the compactor is viewed from the operator in carrier’s cab:

P Line (IN) : Left

T Line (OUT) : Right

When ‘P’ and ‘T’ lines are reversed with each other, the compactor does not work or rotate very slowly by

means of the reverse-flow-bypass check valve of the motor control valve to protect the hydraulic motor.

So, make it sure that piping is installed in right direction.

When you newly install piping, make it sure that there is no foreign substance inside piping sub-parts

such as hoses, pipes, valves and fittings. After finishing installation of piping, connect ‘P’ and ‘T’ line

directly to each other without connecting the compactor and do flushing process during minimum 5

minute to make hydraulic oil clean before connecting the hoses to the compactor.

Be sure to use piping parts that conform to the hydraulic specification of the compactor and carrier. When

using the compactor with the piping modified for other purpose or modified with parts whose configuration

has not been confirmed, be sure to consult our service or dealer. Remember that problems resulting from

wrong piping or wrong installation are not covered by our warranty.

- 15 -

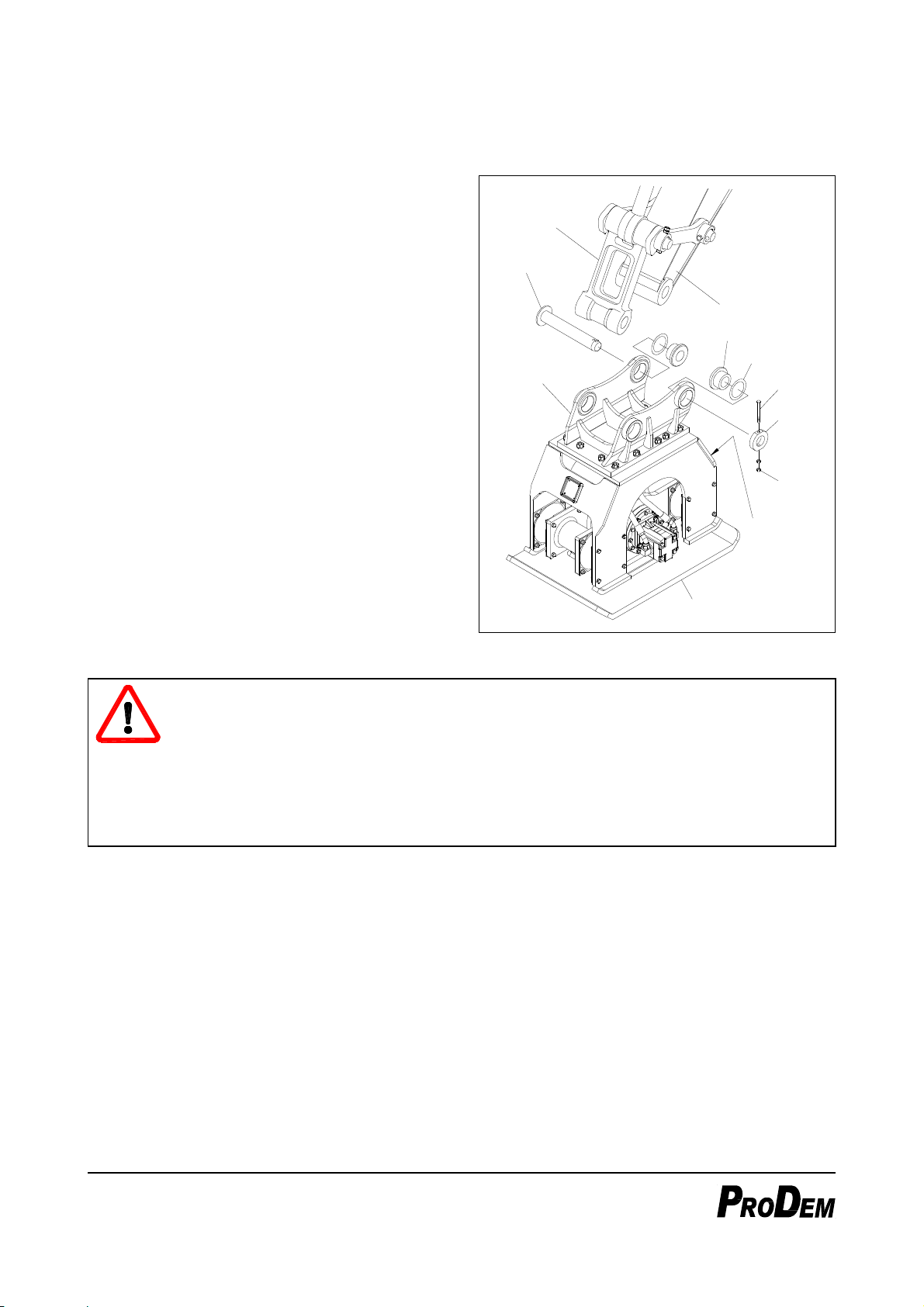

3.2. Installation of the ompa tor

Mount the compactor to the carrier as following;

1. In case of adapter mounting type (‘NA’ or ‘PA’

version), assemble a mounting adapter to the

compactor as shown in Figure13.

2. Place the carrier and compactor on flat and firm

ground in the direction as shown in Figure 13.

3. Assemble the spacers and shims to the bores

of the mounting adapter.

The dimensions of the spacers and the number

of shims may vary depending on carrier’s

mounting dimensions, such as the pin diameter

or the width of the arm or link.

4. Move carrier’s arm slowly until its pin-bore is

flush with the pin bore of the mounting adapter,

and insert the mounting pins.

5. Assemble the stop-rings, and tighten bolts and

nuts to fix the mounting pins.

6. Then, assemble the mounting pin for carrier’s

link in the same way as for carrier’s arm.

Arm

Link

Spacer

Shim

Mounting

Pin

Mounting

Adaptor Bolt

Stop

Ring

Nuts

Compactor

Hose

Connector

(P/T)

Figure 13

DANGER!

When moving the carrier, do not touch any part of the carrier. Keep hands away from linkage

area and pin-bores of the carrier.

When aligning pin-bores, never put a finger into the pin-bore, align only by sight or with using

drift pin.

Agree with the assistant on clear hand signals. The operator in the carrier’s cab should run the

carrier as slowly as possible. When the carrier is moving, workers should keep safe distance

from the carrier.

- 16 -

Connect the hoses to the carrier as follows;

1. After assembling of the mounting pins is completed, turn off the excavator completely.

2. Close the stop valves on the arm end, and remove caps.

3. Connect hydraulic hoses as shown in Figure 14. Make it sure that ‘P’ and ‘T’ lines are not reversed each

other.

4. When connecting the hoses, make it sure that no foreign substances get into the hoses. Dirt, sand or it

may cause a serious trouble to the compactor and carrier.

5. Arrange the connecting hoses not to be twisted or excessively bent.

Bucket Cylinder

Compactor Stop Valve

Cap

★

Pay attention to piping direction!

P Line (IN) : Left

T Line (OUT): Right

(in view from the driver's seat)

Figure 14

When all installation works are completed, check the followings before operating the compactor.

While moving the carrier’s bucket cylinder slowly in and out – in the direction of ‘crowd’ and ‘dump’,

check;

Any interference or obstruction between the compactor and carrier,

Whether the length of the connecting hoses are too short or too long,

Twisting, excessive bending or squeezing of the connecting hoses,

Fixing status of the mounting pins.

While operating the compactor with lifting up the compactor not to touch the ground (no-loading condition),

check;

Whether the compactor runs normally without delay when the operating switch is pressed ON, and it

stops when OFF.

Any oil leak from hoses, fitting, hydraulic motor or motor control valve,

Loosening of bolts or nuts,

Crack or tear out of the cushion rubbers,

Abnormal vibration or noise while the compactor running.

- 17 -

4. Operation

DANGER!

The following section describes a correct use and precautions for compactor operation. These

are the fundamentals for safe operation. So, make yourself familiar with them before initial

use.

IMPORTANT!

If you operate compactor, having it touched a solid ground such as concrete floor or a

bedrock, it would apply very high impact to the compactor, which might result in a serious

damage to the compactor.

4.1. How to use ompa tor

Place the compactor on the ground you want to compact to be in touch with it uniformly.

Lower the carrier’s boom slowly to press the compactor vertically to the ground. At this time, make it

sure that cushion plate is pressed less than 4 cm. If the cushion plate is pressed more than the

specified limit, it might be damaged or its life might be shortened.

If you operate the compactor, having it touched a very hard object such as concrete floor or bedrock,

it would apply very high impact to the compactor, which might result in a serious damage to the

compactor.

When the ground starts to be lowered by compacting work, lower the carrier’s boom gradually and

keep a constant applying pressure. At this time also, make it sure that the cushion plate is not pressed

too much.

When compacting a wide area, advance working positions sequentially in a uniform direction with

some overlapped area.

Mostly for normal soil condition, proper working time is 5 ~ 10 seconds at once.

Continuous operating for a long time have no more effect on compacting and, on the contrary, may

result in trouble to the compactor.

To obtain optimal compaction of the soil, repeat the compacting work in two or three passes. The

duration of compacting for the later pass can be shorten than initial pass.

★Do not use for the following objects:

Concrete floor

Bedrock or surface covered with stones

Steel plate

Press down in a

direction vertical

to the ground.

Continous

operating time

should be

limited to 10

seconds or less.

Cushion rubber

(Cushion plate)

Less than

4 cm

Figure 15

- 18 -

4.2. Corre t working method

IMPORTANT!

Figure 16

Keep vertical to the ground.

Operating the compactor with a tilt

to the ground surface –without

uniform contact to the ground–,

the compactor might be damaged.

Always keep the compacting plate

in parallel to the ground and press

it vertically to the ground.

IMPORTANT!

Figure 17

Do not transport using the

compactor.

Do not move or break a heavy

object using the compactor, which

may result in the compactor

damage or shorten its life.

IMPORTANT!

Figure 18

Do not support carrier with the

compactor.

Do not support the carrier using

the compactor body, and do not

apply excessive force to the

compactor.

- 19 -

IMPORTANT!

Figure 19

Do not use for unallowed

purpose

If the compactor is used for

unallowed purpose or harsh work

which apply exce

ssive force to the

compactor, both the compactor and

the carrier would be damaged and

their lives rapidly shortened.

DANGER!

Figure 20

Do not use for crane work.

The compactor is not equipped

with safety devices for crane work,

so it is very dangerous to use the

compactor for crane work. And

also, lifting a heavy object up with

the compactor will result in severe

damage and shortening of its life.

IMPORTANT!

Figure 21

Do not work under water.

The compactor should not be used

for underwater work. Operating the

compactor under water will cause

serious damage to the cushion

rubbers.

- 20 -

5. Servi e and maintenan e

IMPORTANT!

To use the product in its best condition without any troubles for a long time, observe the

following inspection and maintenance instructions.

In addition, be sure to follow the safety instructions in performing inspection and maintenance.

5.1. General guidelines

Be sure to do the following sequence prior to inspection or maintenance work:

1. Stop the carrier completely.

2. Shut off the stop valves.

3. When disconnecting the hoses, seal them with plugs or caps to prevent entry of impurities.

Whenever maintenance work is carried out, always follow the basic instructions of maintenance for your

safety and product life.

Use proper tools only. Using improper tools may cause personal injury or part damage.

Even after the carrier completely stopped, quite high hydraulic pressure may remain within the compactor.

Disassemble slowly with care.

All of the rotating parts assembled in the drive casing of the compactor are precise parts. Be sure to

handle them carefully, and keep them free of foreign substances or humidity.

Use only genuine parts. Use of unapproved parts may cause damage to the compactor or personal injury.

The troubles in this case voids the warranty.

Do not make any modification to the compactor. We do not take responsibility for accidents and product

damages resulting from unauthorized product modification.

Please contact PRODEM or our dealer for details regarding service and maintenance.

5.2. Daily inspe tion

To use the compactor for a long time in its best condition, do the following daily inspection and maintenance

job regularly.

CHECK POINTS RELATED PARTS ACTION

Tightening of Bolts and Nuts

All the bolts and nuts of

Cushion Plates, Motor, Covers, Valve,

etc.

Mounting adapter bolts

Retighten the loose one,

Replace the broken or worn parts.

Oil Leak

Hoses, Fitting or Plugs

Hydraulic Motor

Motor Control Valve

Retighten the loose one.

Replace damaged O-ring or seal.

Abnormal Noise or Vibration

during Operation

Hydraulic Motor

Bearings (in Drive Casing)

Cushion Plates (Cushion Rubbers)

Check oil level and inspecting after

refilling oil.

Contact PRODEM service if the

problem persists.

Breakage, Deformation, Crack,

or Wear and Tear

Base Frame and Mounting Frame

Cushion Plates (Cushion Rubbers)

Mounting Pins

Contact PRODEM service, if any

problem is detected.

Other manuals for PHC 050

1

This manual suits for next models

4

Table of contents

Other PRODEM Industrial Equipment manuals