Safety F rst

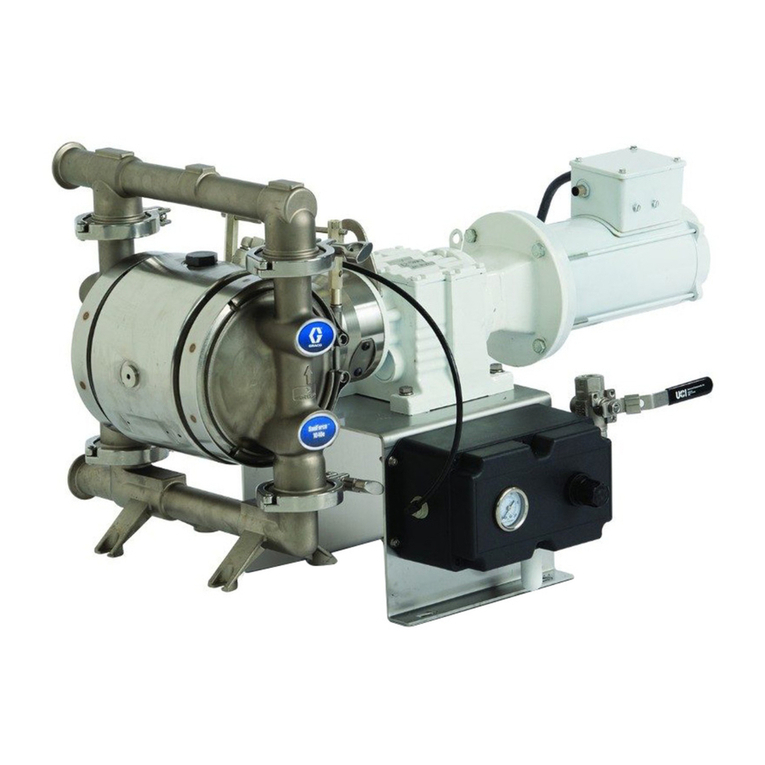

Carefully plan your system by select ng components des gned to perform the ntended operat on and

wh ch w ll adequately perform w th ex st ng equ pment. Always check the product l m tat ons regard ng

pressure ranges, capac t es and set-up requ rements. The system operat ng pressure must not

exceed the pressure rat ng of the lowest rated component n the system. Real all CAUTIONS,

WARNINGS, and INSTRUCTIONS ncluded w th, or attached to each product. Follow all safety

precaut ons to avo d personal njury or property damage dur ng the system operat on.

THE MANUFACTURER CANNOT BE RESPOSIBLE FOR DAMAGE OR INJURY RESULTING

FROM UNSAFE PRODUCT USE, LACK OF MAINTENANCE OR INCORRECT PRODUCT AND

SYSTEM APPLICATION.

Caut on

Make sure that the h ghest level of system pressure does not exceed the lowest pressure rat ng of any

component w th the system.

The follow ng general nstruct ons and gu des w ll be helpful to determ ne f your system components

are properly connected:

1.Be sure all hydraul c connect ons, hoses, f tt ngs are rated for the h ghest pressure your system s

capable of generat ng. Always use hoses and tub ng recommended by the hydraul c component

manufacturer.

2.Be sure all connect ons are fully t ghtened. Seal all p pe connect ons w th a h gh -grade p pe thread

sealer.

3.DO NOT over t ghten any connect ons. All connect ons should be snug and leak free. Excess ve

t ghten ng w ll cause stra n on the threads and cast ngs, wh ch could cause f tt ng fa lure at pressures

below rated capac ty.

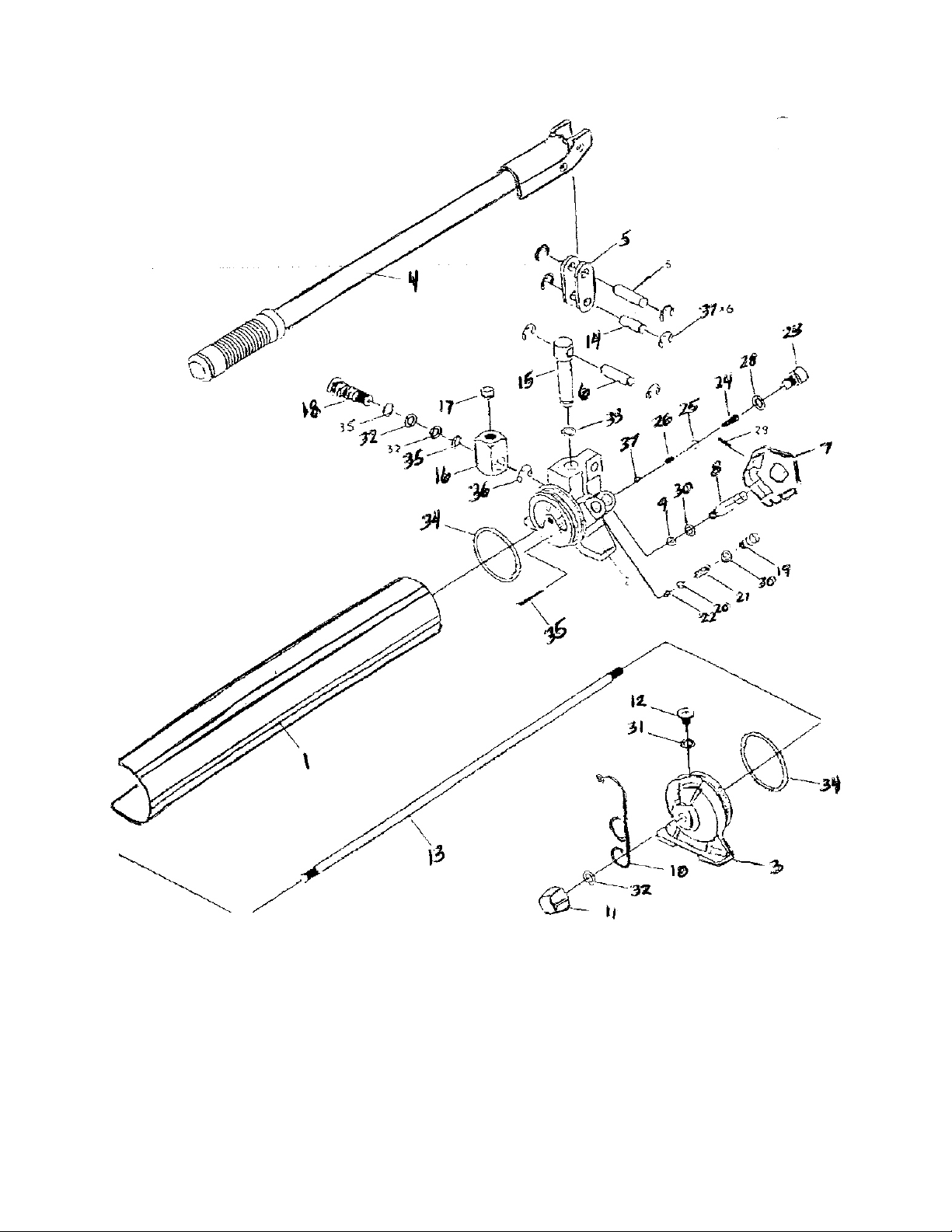

Inspect on

1.V sual nspect on shall be made before each use of th s equ pment check ng for leak ng hydraul c

flu d, worn or damaged hose and f tt ngs, damaged or bent extens on tubes or attachments.

2.Each p ece of equ pment shall be nspected by an author zed serv ce center mmed ately, f

subjected to an abnormal load or shock.

3.Owners and/or users should be aware that repa r of th s equ pment may requ re spec al zed

knowledge and fac l t es. It s recommended that an annual nspect on of th s equ pment be made by a

serv ce center and that any defect ve parts, decals, or warn ng labels be replaced w th genu ne parts.

A l st of author zed serv ce centers s ncluded.

Damaged Equ pment

Any equ pment wh ch appears to be damaged n any way s found to be badly worn, or operates

abnormally SHALL BE REMOVED FROM SERVICE unt l necessary repa rs are made by an

author zed serv ce center.